Welding electrode for welding -50 DEG C low-temperature pressure container steel

A pressure vessel and welding rod technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of not meeting the design requirements of -50°C low-temperature pressure vessel, poor welding processability, and low low-temperature toughness, etc. Achieve stable arc, beautiful weld shape and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is an electric welding rod used for welding steel of pressure vessel at -50°C low temperature. The electric welding rod includes a welding core, a coating and a binder, and is manufactured according to conventional techniques. The ratio of the coating and the The welding core is shown in the technical scheme, and the binder is used for routinely preparing welding electrodes.

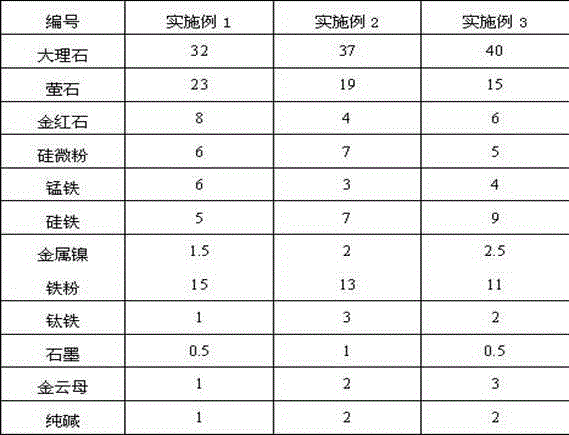

[0031] The following table is three embodiment formulas of said drug skin by weight.

[0032]

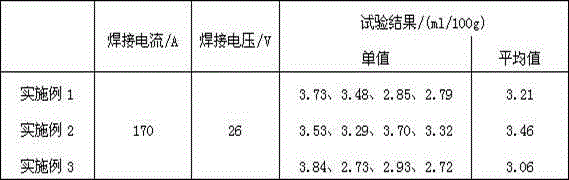

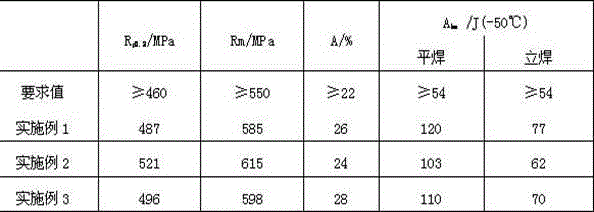

[0033] Mix and stir the components according to the formulas of the above three embodiments, and then add 24% by weight of 3.2M pure sodium water glass according to the total weight of the above proportions for mixing and stirring, if the total number of parts of the above proportions is 100 parts , then add 24 parts of 3.2M pure sodium water glass, and the density of 3.2M pure sodium water glass is required to be controlled at 1.40~1.45g / mm 3 , so that the drug skin has the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com