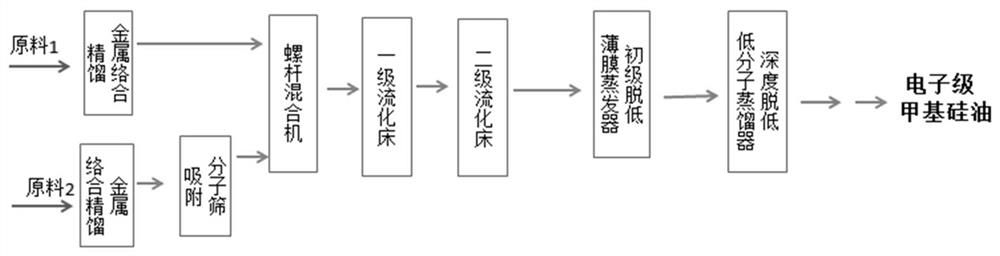

Continuous preparation method of electronic-grade methyl silicone oil

A technology of methyl silicone oil and electronic grade, which is applied in the field of continuous preparation of electronic grade methyl silicone oil, can solve the problems of design improvement and poor effect, and achieve the effect of stable polymerization and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 10kg octamethylcyclotetrasiloxane (D 4 ) mixed with 2kg crown ether mixture A (100 parts of crown ether mixture A contains 35 parts of 12-crown 4-ether, 35 parts of 15-crown ether-5, 30 parts of 18-crown ether-6), and the temperature and pressure of the rectification tower is 20kpa Under the condition, the fraction D at 130℃ was collected 4 -21; Mix 1kg of hexamethyldisiloxane (MM) and 200g of crown ether mixture A evenly, and collect the fraction MM-11 at 70°C under the condition of temperature and pressure of the rectification tower at 20kpa, and M-11 is treated by two-stage 4A molecular sieve adsorption The device removes water, and stays in the primary and secondary 4A molecular sieve adsorption treatment devices for 24h and 24h respectively, and the pretreated product is recorded as MM-21 (water content is 8ppm); raw material D 4 -21 and MM-21 are input into the screw mixer at a mass flow rate of 100:1.5, and mixed at 65±3°C to obtain premix D 4 MM-21; Premix D a...

Embodiment 2

[0022] In addition to octamethylcyclotetrasiloxane (D 4 ) and crown ether mixture A are 10kg and 1kg respectively, hexamethyldisiloxane (MM) and crown ether mixture A (20 parts of 4-nitrobenzo-15-crown 5-ether, dibenzo-18 - 60 parts of -crown-6-ether, 20 parts of 1-aza-12-crown 4-ether) were 1 kg and 100 g respectively, the other processes and steps were the same as in Example 1 to obtain the finished product PDMS-312. The polymerization conversion rate is 89.1%, and the finished product PDMS-312 test index: viscosity 315mm 2 / s, molecular weight distribution coefficient 1.52, low boiler 0.11%, silanol content 6ppm, Na ion content 9ppb, K ion content 6ppb, Cu ion content 6ppb, Pb ion content 8ppb, As ion content 9ppb, Fe ion content 12ppb. ,

Embodiment 3

[0024] In addition to octamethylcyclotetrasiloxane (D 4 ) and crown ether mixture A are 10kg and 400g respectively, hexamethyldisiloxane (MM) and crown ether mixture A (35 parts of 24-crown 8-ether, 22 parts of benzo-12-crown ether-4, Except that 36 parts of 4-aminobenzo-15-crown-5-ether and 7 parts of aza-18-crown ether) were 1kg and 40g respectively, other processes and steps were the same as in Example 1 to obtain the finished product PDMS-313. The polymerization conversion rate is 89.0%, and the finished product PDMS-313 test index: viscosity 311mm 2 / s, molecular weight distribution coefficient 1.63, low boiler 0.11%, silanol content 6ppm, Na ion content 25ppb, K ion content 36ppb, Cu ion content 21ppb, Pb ion content 18ppb, As ion content 20ppb, Fe ion content 45ppb.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com