Method for recovering and extracting hydrogen based on discharged torch waste gas

A torch waste gas and waste gas technology, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve problems that restrict the high-quality and sustainable development of enterprises, waste of effective components, and adverse impacts on the atmospheric environment, so as to reduce C emission content And the comprehensive energy consumption of the production line, the reduction of operating costs, and the remarkable effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, a method for recovering and extracting hydrogen based on exhaust torch exhaust gas, is characterized in that: the specific steps are as follows:

[0015] 1) Conversion: According to the components of recovered exhaust gas (CO, H 2 , CO 2 、CH 4 , N 2 , O 2 ), use a special sulfur-resistant cobalt-steel shift catalyst for shift treatment, the CO content in the recovered waste gas is calculated as 30%, and the ratio of steam and waste gas is controlled at 0.30-0.40, and the steam and waste gas are mixed in the mixing tank and then enter the shift bed Perform a shift reaction (CO+H 2 O=CO 2 +H 2 ), the inlet temperature of the shift bed is controlled at about 200°C, and the bed reaction temperature is controlled at 200-450°C. CO is converted into hydrogen through the shift reaction, and the CO conversion efficiency reaches over 99.0%.

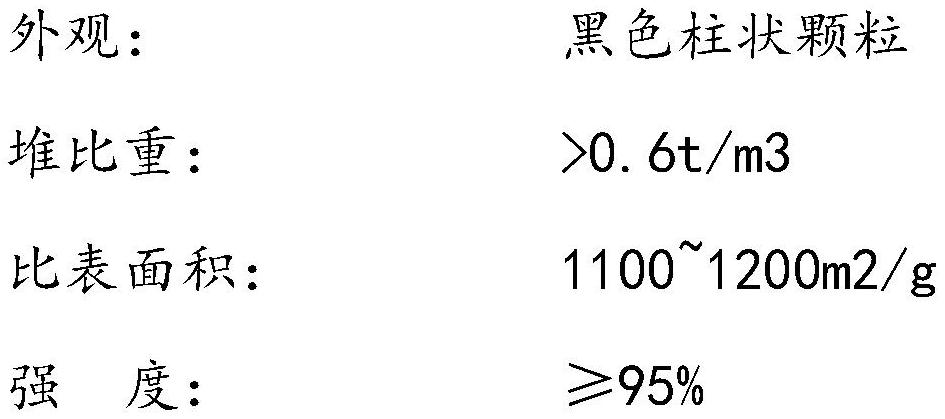

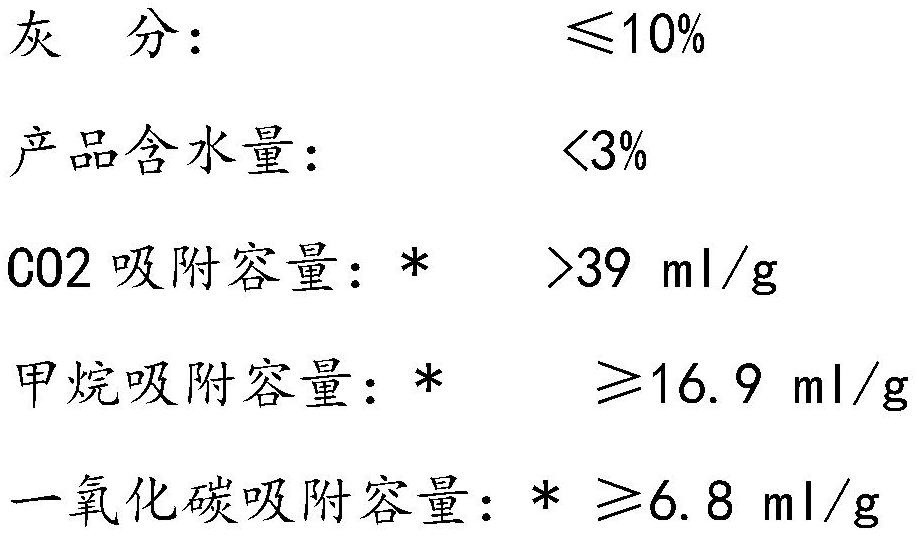

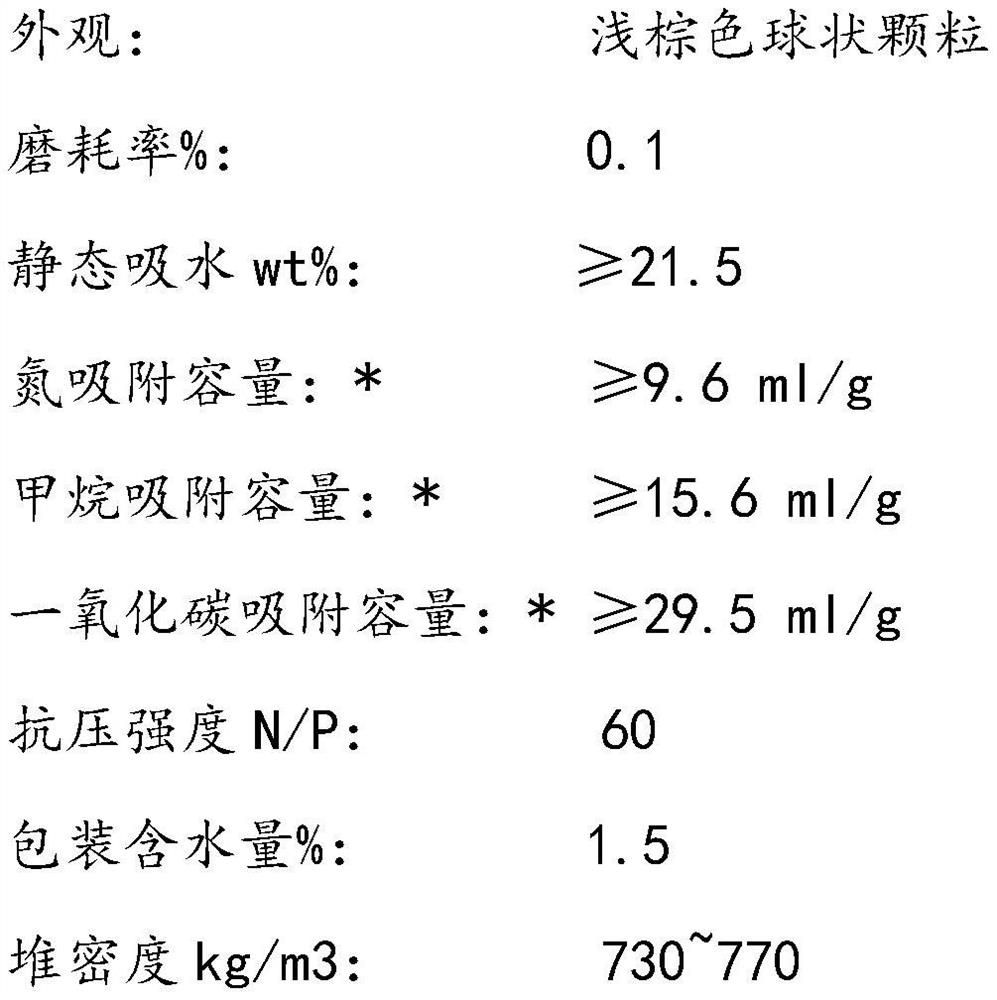

[0016] 2) Decarburization: decarbonize the exhaust gas after conversion, select activated alumina and silica gel as ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com