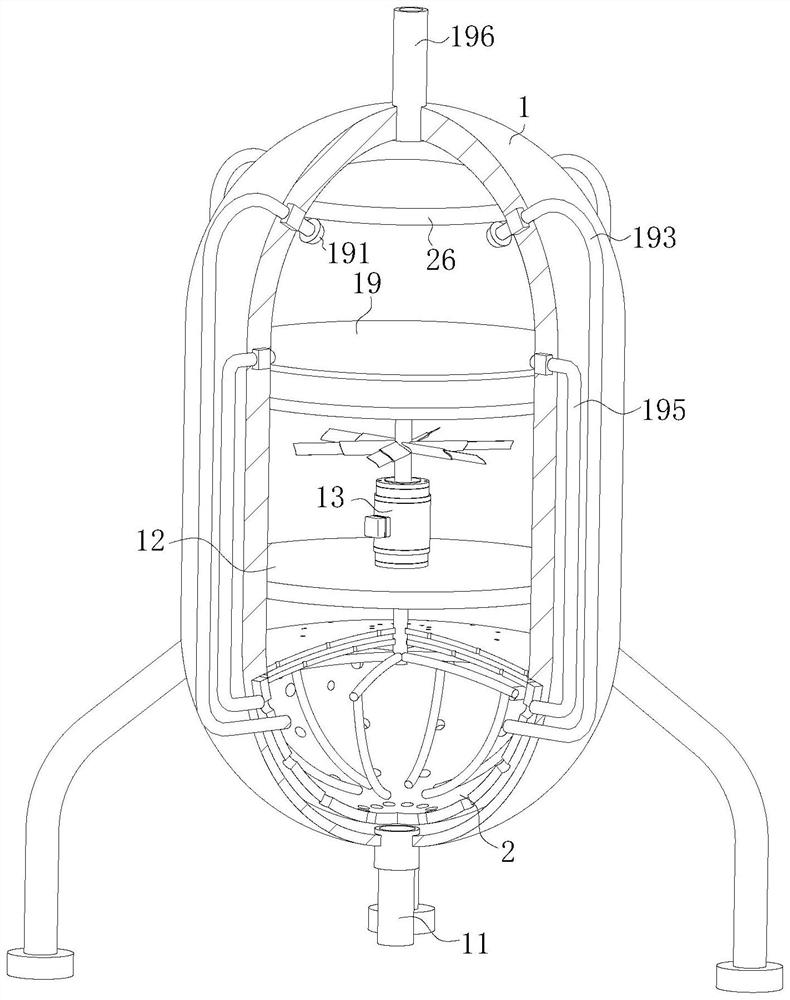

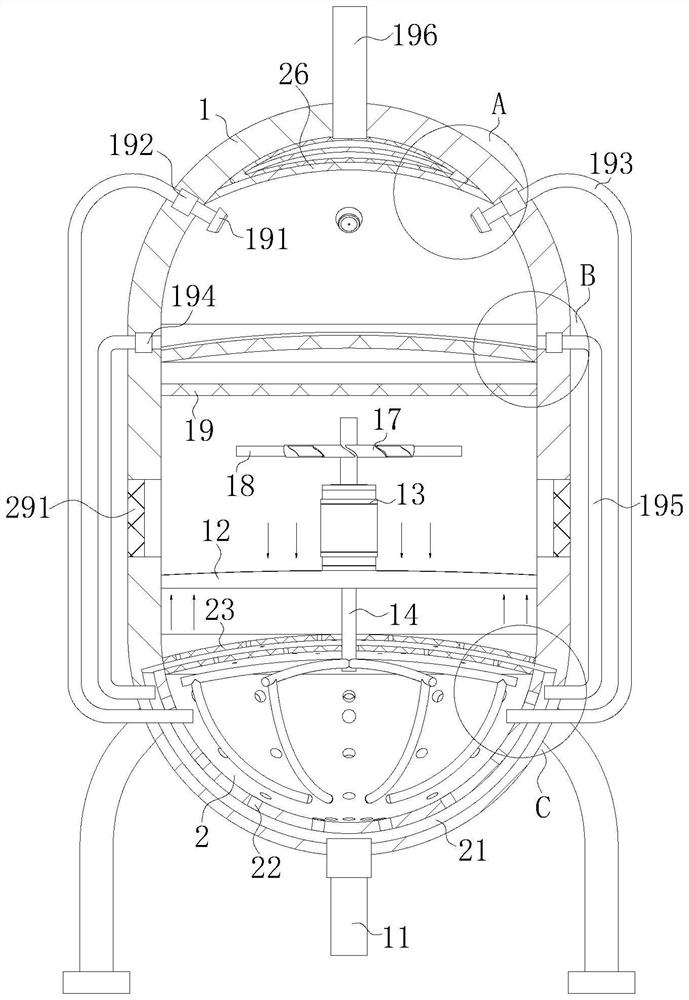

Three-stage tail gas purification tower for high-concentration nitric oxide

A nitrogen oxide, high-concentration technology, which is applied in the direction of chemical instruments and methods, combined devices, and dispersed particle separation, can solve the problems of increasing nitrogen oxide purification process steps, increasing nitrogen oxide process steps, and easily generating waste water and residue. , to achieve the effects of small footprint, large operating flexibility, and no power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

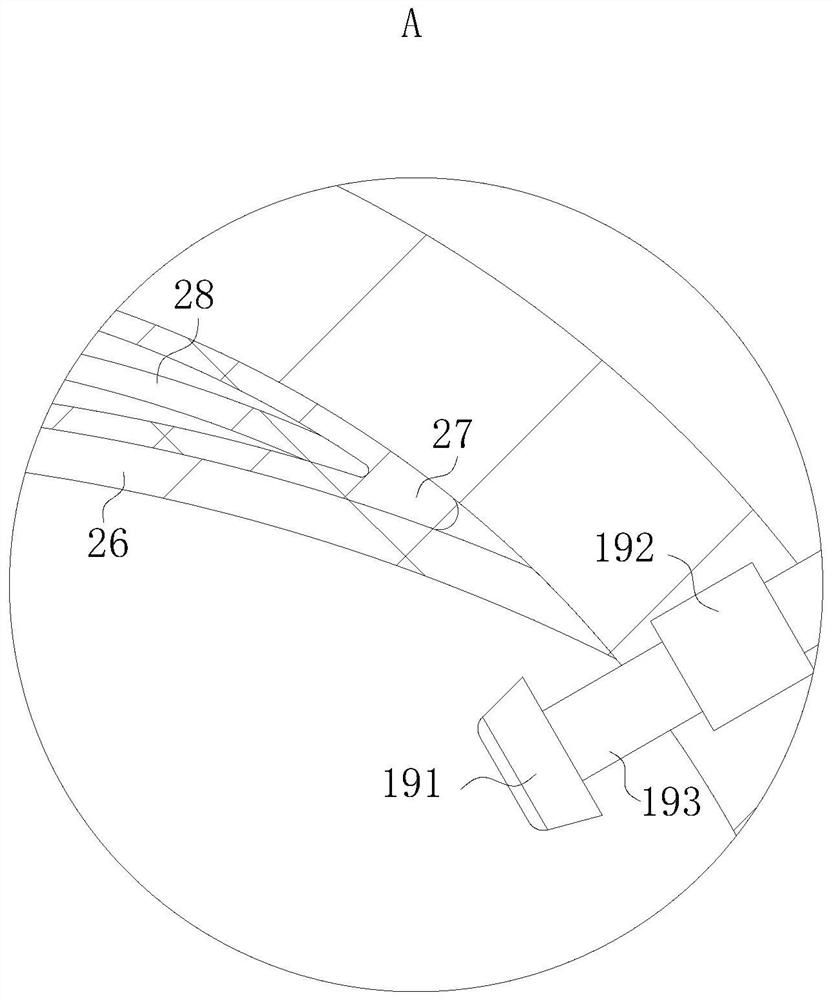

[0034] As an embodiment of the present invention, a filter membrane 23 is fixedly connected to the inner wall of the purification chamber 2 above the first annular groove 21, and the filter membrane 23 is of elastic design; the elastic membrane is placed on the first arc rod 15 Above; the inner wall of the filter membrane 23 is provided with a second annular groove 24, and the second annular groove 24 communicates with the first annular groove 21; the inner walls of the upper and lower sides of the second annular groove 24 are provided with evenly arranged through holes 25, and the through holes 25 on the upper and lower sides are arranged in a staggered manner;

[0035] When working, since the filter membrane 23 is fixedly connected to the inner wall of the purification chamber 2, the gas can be filtered when the gas passes through the filter membrane 23, thereby reducing the impurity content in the gas. When the gas flows through the through hole 25 into the second ring When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com