Hydrocarbon-resistant outdoor ultra-thin steel structure fireproof coating

A kind of fireproof coating, ultra-thin technology, applied in the direction of fireproof coating, epoxy resin coating, coating, etc., can solve the problem of not being able to prevent hydrocarbon fire, weather resistance, water resistance can not meet the requirements of fireproof coating, anti-corrosion, Anti-rust, acid and alkali resistance and other poor performance, to achieve the effect of good electrical insulation and mechanical strength, excellent chemical corrosion resistance, low emission content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Hydrocarbon-resistant outdoor ultra-thin steel structure fireproof coating, the formula includes A component and B component, wherein A component includes liquid epoxy resin OER-95, propylene glycol methyl ether, B component includes water-based amine curing agent 751, deionized Water, propylene glycol methyl ether, ammonium polyphosphate, melamine, pentaerythritol, chlorinated paraffin, nano-TiO 2 Slurry, expanded graphite, composite iron-titanium powder, dispersant, wetting agent and defoamer; A and B are mixed at a mass ratio of 1:5.5;

[0038] The content of each component by mass percentage in component A is as follows:

[0039] Liquid epoxy resin OER-95 96.5%

[0040] Propylene Glycol Methyl Ether 3.5%

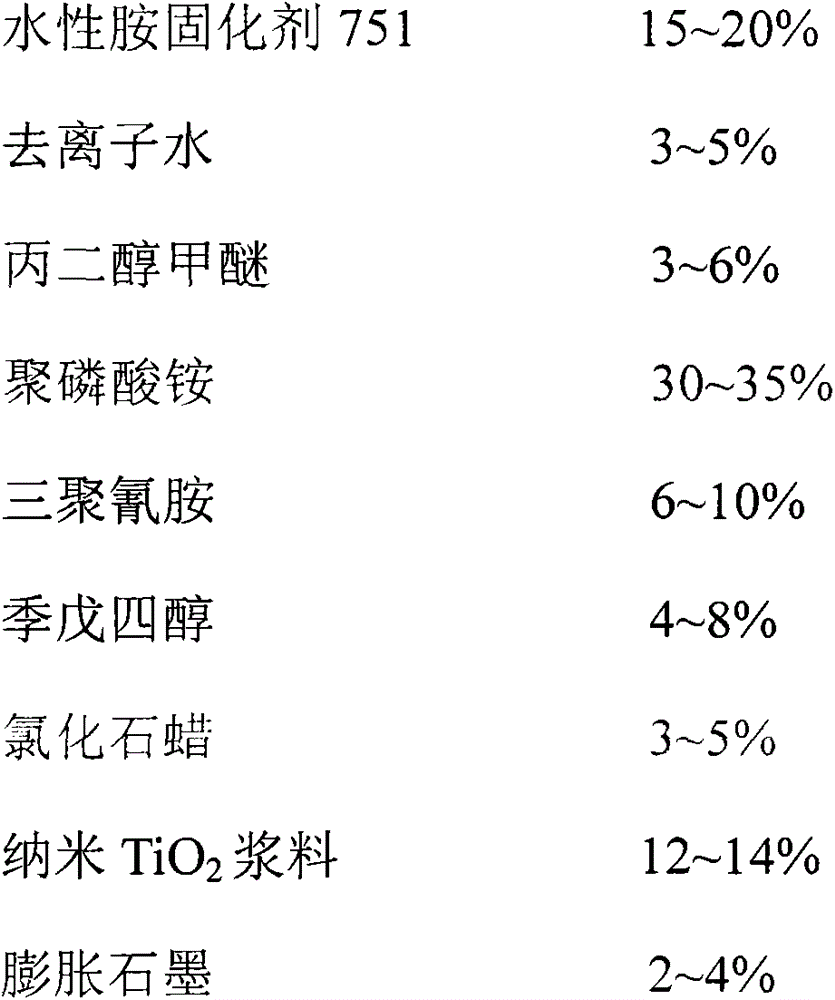

[0041] The content of each component in component B is composed as follows by mass percentage:

[0042]

[0043]

Embodiment 2

[0045] Hydrocarbon-resistant outdoor ultra-thin steel structure fireproof coating, the formula includes A component and B component, wherein A component includes liquid epoxy resin OER-95, propylene glycol methyl ether, B component includes water-based amine curing agent 751, deionized Water, propylene glycol methyl ether, ammonium polyphosphate, melamine, pentaerythritol, chlorinated paraffin, nano-TiO 2 Slurry, expanded graphite, composite iron-titanium powder, dispersant, wetting agent and defoamer; A and B are mixed at a mass ratio of 1:5.7;

[0046] The content of each component by mass percentage in component A is as follows:

[0047] Liquid epoxy resin OER-9596%

[0048] Propylene Glycol Methyl Ether 4%

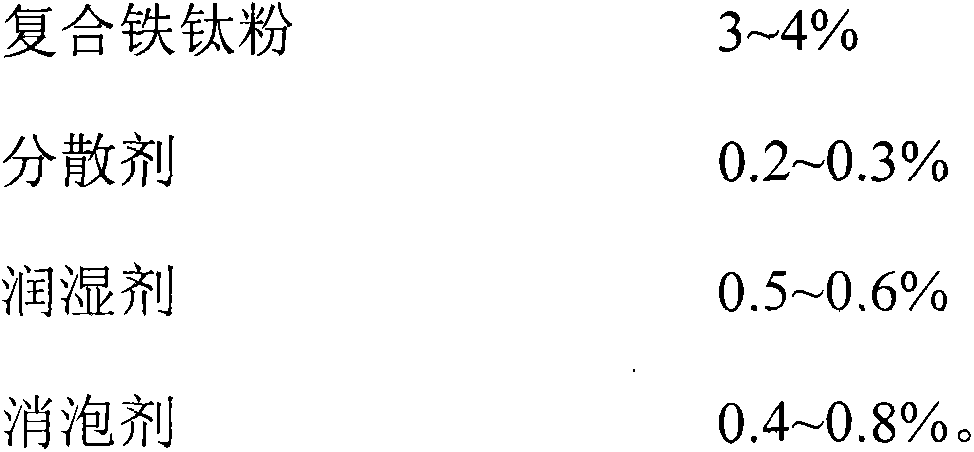

[0049] The content of each component in component B is composed as follows by mass percentage:

[0050]

[0051]

Embodiment 3

[0053] Hydrocarbon-resistant outdoor ultra-thin steel structure fireproof coating, the formula includes A component and B component, wherein A component includes liquid epoxy resin OER-95, propylene glycol methyl ether, B component includes water-based amine curing agent 751, deionized Water, propylene glycol methyl ether, ammonium polyphosphate, melamine, pentaerythritol, chlorinated paraffin, nano-TiO 2 Slurry, expanded graphite, composite iron-titanium powder, dispersant, wetting agent and defoamer; A and B are mixed at a mass ratio of 1:5.6;

[0054] The content of each component by mass percentage in component A is as follows:

[0055] Liquid epoxy resin OER-9595.8%

[0056] Propylene Glycol Methyl Ether 4.2%

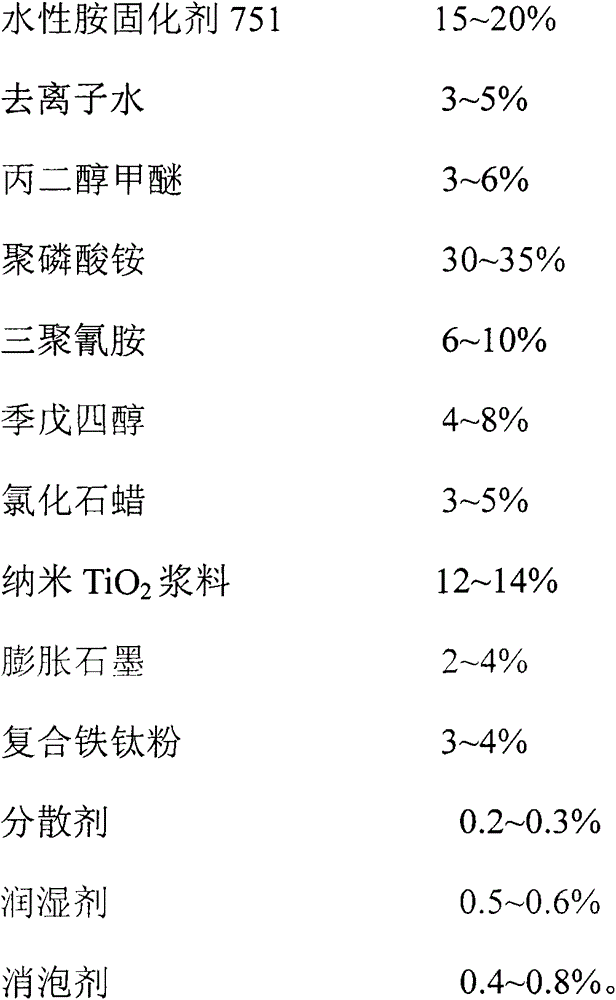

[0057] The content of each component in component B is composed as follows by mass percentage:

[0058]

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com