A metal reshaping assembly line

A reshaping and assembly line technology, applied in the direction of furnace type, charge processing type, furnace, etc., can solve the problems of high worker ability requirements, polluted air, and workers' difficulty in handling, so as to reduce air pollution, increase yield rate, and improve qualification rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

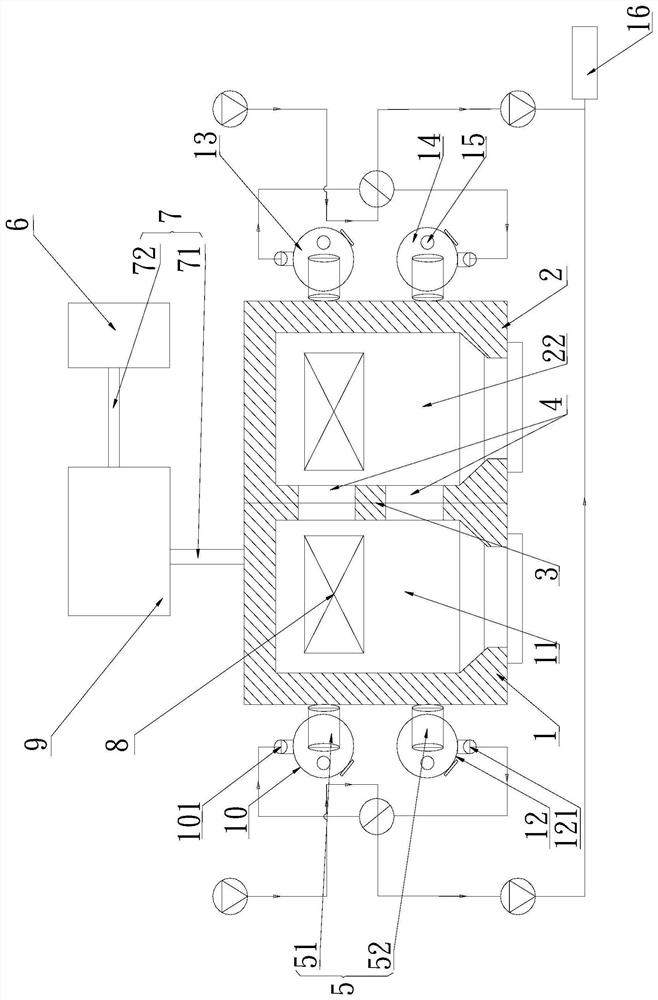

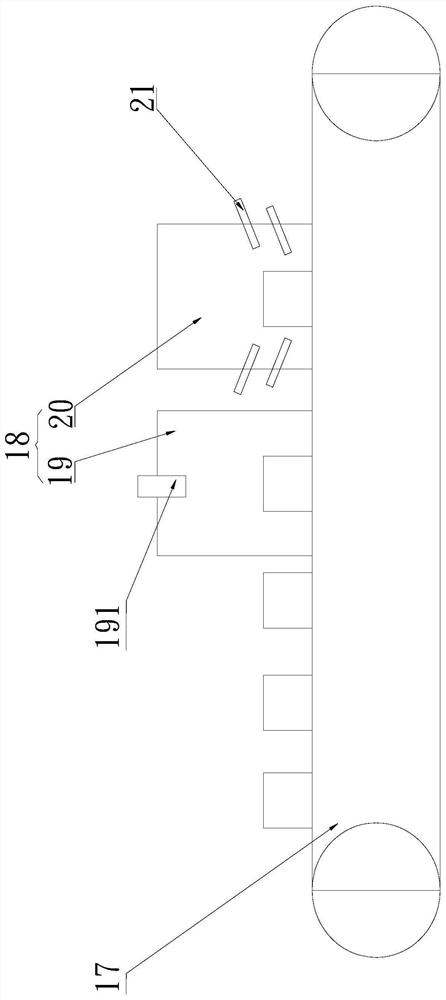

[0025] Such as Figure 1~2 The shown metal reshaping line includes two smelting furnaces arranged side by side, that is, A smelting furnace 1 and B smelting furnace 2; the smelting furnace is equipped with a smelting chamber for smelting metal, that is, A smelting furnace A smelting chamber 11 is provided in 1, and a B smelting chamber 22 is provided in B smelting furnace 2; one side of the adjacent smelting chamber is bonded to each other and a bonding wall 3 is formed; the bonding wall 3 is provided with a through-hole 4 that runs through the bonding wall 3 for the passage of air; the adjacent smelting chambers communicate with each other through the through-hole 4; each of the smelting furnaces is provided with a set of A combustion device 5 for heating and melting metal scrap; also includes a casting chamber 6 for casting products and processing recycled metal products and a drainage groove 7 for draining molten metal into the casting chamber 6; A smelting chamber 11 A dr...

Embodiment 2

[0038] Such as Figure 1~2 The shown metal reshaping line includes two smelting furnaces arranged side by side, that is, A smelting furnace 1 and B smelting furnace 2; the smelting furnace is equipped with a smelting chamber for smelting metal, that is, A smelting furnace A smelting chamber 11 is provided in 1, and a B smelting chamber 22 is provided in B smelting furnace 2; one side of the adjacent smelting chamber is bonded to each other and a bonding wall 3 is formed; the bonding wall 3 is provided with a through-hole 4 that runs through the bonding wall 3 for the passage of air; the adjacent smelting chambers communicate with each other through the through-hole 4; each of the smelting furnaces is provided with a set of A combustion device 5 for heating and melting metal scrap; also includes a casting chamber 6 for casting products and a drainage groove 7 for draining molten metal into the casting chamber 6; A smelting chamber 11 and B smelting chamber 22 share a drainage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com