A device and production method for producing food-grade CO2 using nh3/co2 cascade refrigeration

A food-grade, cascading technology, applied in refrigeration and liquefaction, chemical instruments and methods, cold treatment separation, etc., can solve the problems of large footprint, complex process, high energy consumption, etc., and achieve the reduction of refrigeration equipment investment and energy consumption The effect of reducing and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

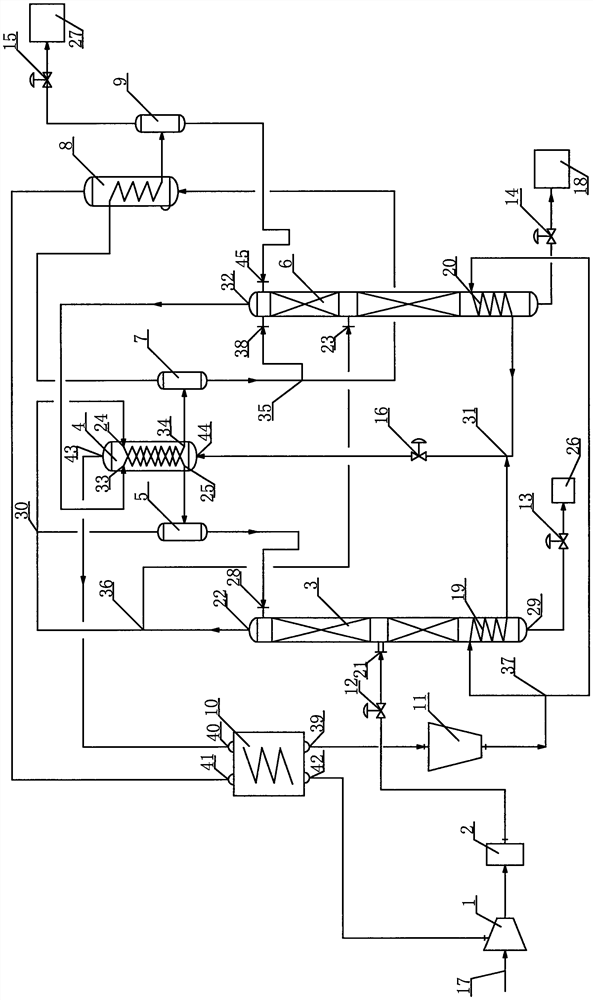

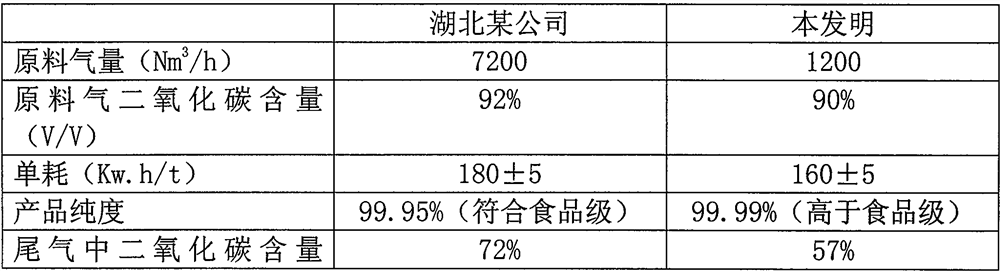

[0043] One using NH 3 / CO 2 Cascade refrigeration produces food grade CO 2 The device comprises the compressor 1 that is connected with the feed gas pipeline 17, the outlet of the compressor 1 is connected with the first feed gas inlet 21 of the first flash tower 3 through the drier 2, and the top gas phase outlet of the first flash tower 3 is 22 is connected with the first feed gas inlet 23 of the second flash tower 6 through the first tee 36, and the liquid phase outlet at the bottom of the second flash tower 6 is connected to the food-grade CO 2 The storage tank 18 is connected; the gas phase outlet 32 at the top of the second flash tower 6 enters the first gas-liquid separation through the second feed gas inlet 33 of the first heat exchanger 4 and the second feed gas outlet 34 of the first heat exchanger 4 In the device 7, the top gas phase outlet of the first gas-liquid separator 7 is connected to the second gas-liquid separator 9 through the tube side of the second h...

Embodiment 2

[0055] One using NH 3 / CO 2 Cascade refrigeration produces food grade CO 2 The device comprises the compressor 1 that is connected with the feed gas pipeline 17, the outlet of the compressor 1 is connected with the first feed gas inlet 21 of the first flash tower 3 through the drier 2, and the top gas phase outlet of the first flash tower 3 is 22 is connected with the first feed gas inlet 23 of the second flash tower 6 through the first tee 36, and the liquid phase outlet at the bottom of the second flash tower 6 is connected to the food-grade CO 2 The storage tank 18 is connected; the gas phase outlet 32 at the top of the second flash tower 6 enters the first gas-liquid separation through the second feed gas inlet 33 of the first heat exchanger 4 and the second feed gas outlet 34 of the first heat exchanger 4 In the device 7, the top gas phase outlet of the first gas-liquid separator 7 is connected to the second gas-liquid separator 9 through the tube side of the second h...

Embodiment 3

[0067] One using NH 3 / CO 2 Cascade refrigeration produces food grade CO 2 The device comprises the compressor 1 that is connected with the feed gas pipeline 17, the outlet of the compressor 1 is connected with the first feed gas inlet 21 of the first flash tower 3 through the drier 2, and the top gas phase outlet of the first flash tower 3 is 22 is connected with the first feed gas inlet 23 of the second flash tower 6 through the first tee 36, and the liquid phase outlet at the bottom of the second flash tower 6 is connected to the food-grade CO 2 The storage tank 18 is connected; the gas phase outlet 32 at the top of the second flash tower 6 enters the first gas-liquid separation through the second feed gas inlet 33 of the first heat exchanger 4 and the second feed gas outlet 34 of the first heat exchanger 4 In the device 7, the top gas phase outlet of the first gas-liquid separator 7 is connected to the second gas-liquid separator 9 through the tube side of the second h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com