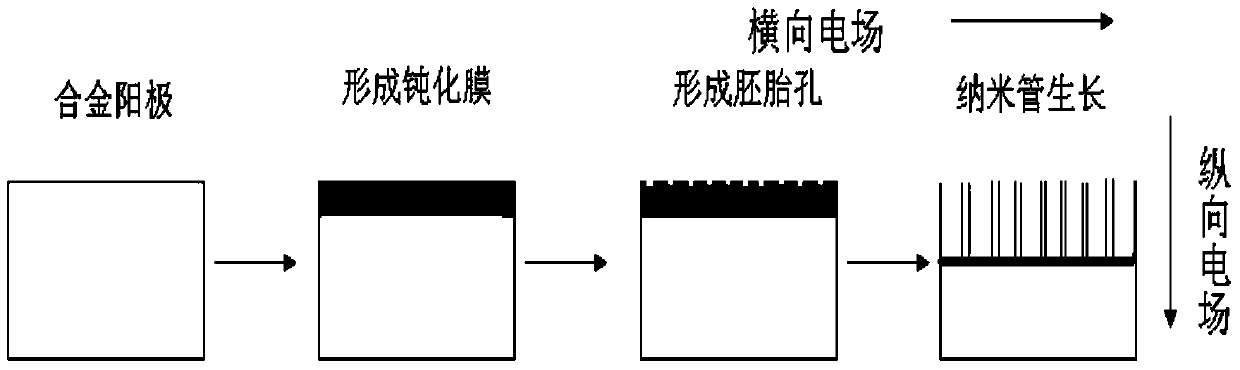

Preparation method and application of Co and Al2O3 compound nanotube array membrane catalyst

A nanotube array, catalyst technology, applied in the preparation of organic compounds, nanotechnology for materials and surface science, preparation of amino compounds, etc., can solve the problems of long anodizing time, low strength of nanotubes, slow growth, etc. To achieve the effect of controllable pipe diameter and pipe length, smooth pipe wall and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 100g of cobalt and 400g of aluminum, put these metals into the cavity of an intermediate frequency induction furnace (purchased from Suzhou Hengfu Vacuum Technology Co., Ltd.), heat and melt at 1600°C, pour them into 8cm×10cm molds in batches, and melt to make a thickness of about 2mm Co-Al alloy sheet.

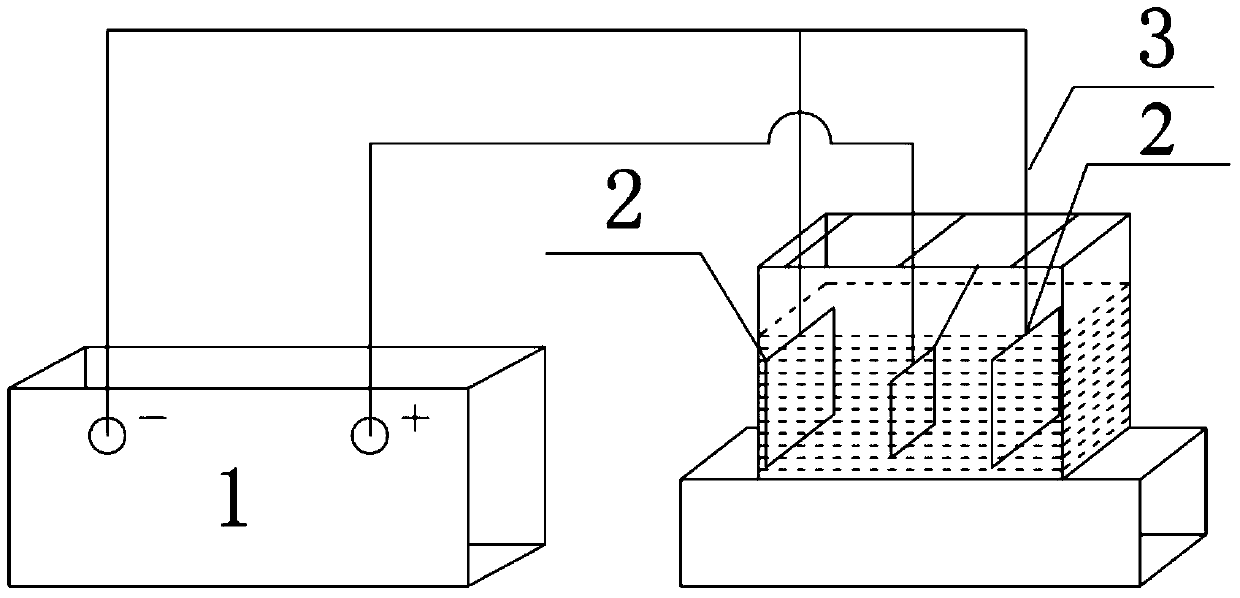

[0039] Prepared with 1wt%NH 4 F, 3200g ethylene glycol solution of 2.8v% distilled water is used as electrolyte, such as figure 2 The device shown: add urea to the electrolyte in batches, the molar ratio of the total amount of urea to the distilled water in the electrolyte is 2:3, after anodizing for 10 minutes, add the first batch of urea, accounting for 10% of the total, anodizing 2.5 After hr, about 8.2% of the total amount was added every 30 minutes; a Co-Al alloy sheet with a thickness of 2mm and a size of 8cm×10cm was used as the anode, high-purity graphite was used as the cathode, and the area ratio of the anode to the cathode was 1:1.3. The distance be...

Embodiment 2

[0042] Weigh 125g of cobalt, 370g of aluminum, 2g of nickel, and 2g of chromium, add these metals into the cavity of an intermediate frequency induction furnace (purchased from Suzhou Hengfu Vacuum Technology Co., Ltd.), heat and melt at 1600°C, and pour them into 8cm×10cm molds in batches , smelted into a Co-Al alloy sheet with a thickness of about 2 mm.

[0043] Prepared with 1.45wt%NH 4 F, 3240g of ethylene glycol solution of 2.8v% distilled water is used as electrolyte, such as figure 2 The device shown: add urea into the electrolyte in batches, the molar ratio of the total amount of urea to the distilled water in the electrolyte is 1:2, after anodizing for 5 minutes, add the first batch of urea, accounting for 12% of the total amount, and anodize for 2hr After that, 8% of the total amount was added every 30 minutes; a Co-Al alloy sheet with a thickness of 2mm and a size of 8cm×10cm was used as the anode, platinum was used as the cathode, and the area ratio of the anode ...

Embodiment 3

[0046] Weigh 100g of cobalt, 394g of aluminum, 3g of molybdenum, and 3g of iron, add these metals into the cavity of an intermediate frequency induction furnace (purchased from Suzhou Hengfu Vacuum Technology Co., Ltd.), heat and melt at 1600°C, and pour them into 8cm×10cm molds in batches , smelted into a Co-Al alloy sheet with a thickness of about 2 mm.

[0047] Preparation contains 0.5wt%NaF, 3600g of diethylene glycol solution of 1.5v% distilled water is used as electrolyte, such as figure 2 The device shown: add urea into the electrolyte in batches, the molar ratio of the total amount of urea to the distilled water in the electrolyte is 3:4, after anodizing for 8 minutes, add the first batch of urea, accounting for 20% of the total amount, and anodize for 2hr After that, add about 8.9% of the total amount every 30 minutes; take the Co-Al alloy sheet with a thickness of 2mm and a size of 8cm×10cm as the anode, ruthenium as the cathode, and the area ratio of the anode to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com