Composite polyether, composition including composite polyether and polyurethane block foam and preparing method and application of composite polyether

A technology for combining polyether and polyether polyol, applied in the field of combining polyether, can solve the problems of uneven density, low dimensional stability and low production efficiency of rigid polyurethane blocks, and achieve high dimensional stability and uniform density. , to avoid the effect of foam heartburn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Preparation of fast release combined polyether for rigid polyurethane block foam

[0061] Polyether polyol SA4606, SA3803, MN5001, surfactant B85450.15, LK6650.15, catalyst PC80.05, PC410.05, TMR-20.1, blowing agent HFC-365mfc / 2272 Parts, 0.2 parts of water and 1 part of flame retardant TCPP, 0.5 parts of TEP.

[0062] According to the above formula, add each component into a stainless steel mixing kettle, stir at a speed of 500 rpm at room temperature for 1 hour, and discharge the materials to obtain a combined polyether for rapid release of rigid polyurethane block foam.

[0063] (2) Preparation of rigid polyurethane block foam:

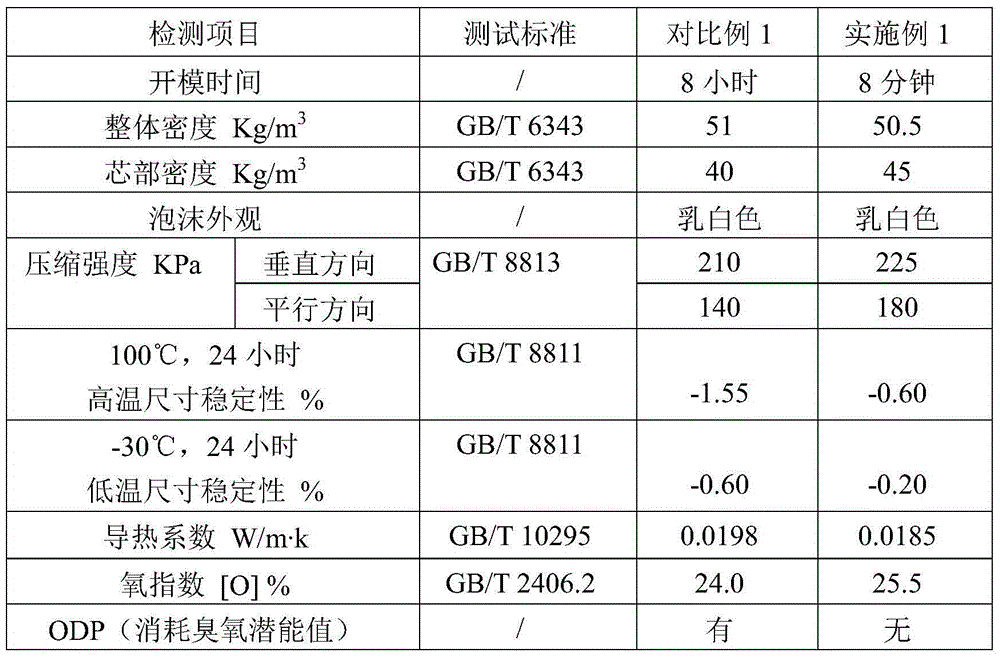

[0064] The rigid polyurethane block foam is reacted with polyether and isocyanate PM200 according to the mass ratio of 1:1.2 at 20°C with rapid release, and injected into the open mold. After the foam stops growing, the foam is taken out, and the overall density is about 50Kg. / m 3 The rigid polyurethane block foam, the physical prope...

Embodiment 2

[0076] (1) Preparation of fast release combined polyether for rigid polyurethane block foam

[0077] Polyether polyol SA4604 parts, SA3804 parts, MN5002 parts, surfactant B85450.15 parts, LK6650.15 parts, catalyst PC80.05 parts, PC410.05 parts, TMR-20.15 parts, blowing agent HFC-365mfc / 2272 Parts, 0.2 parts of water and 2 parts of flame retardant TCPP, 1 part of TEP.

[0078] According to the above formula, add each component into a stainless steel mixing kettle, stir at a speed of 500 rpm at room temperature for 1 hour, and discharge the materials to obtain a combined polyether for rapid release of rigid polyurethane block foam.

[0079] (2) Preparation of rigid polyurethane block foam:

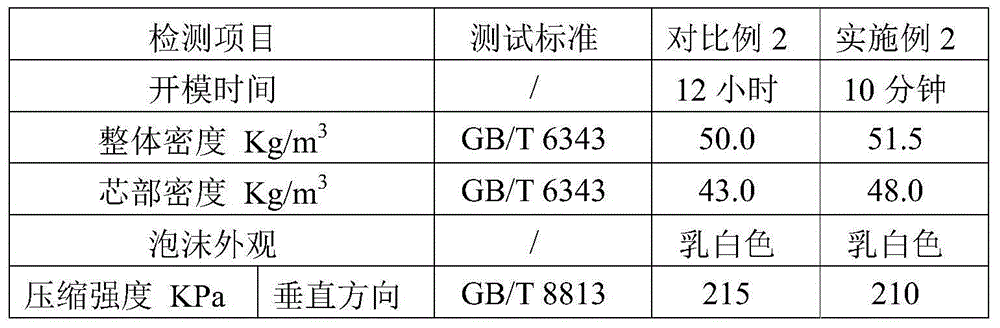

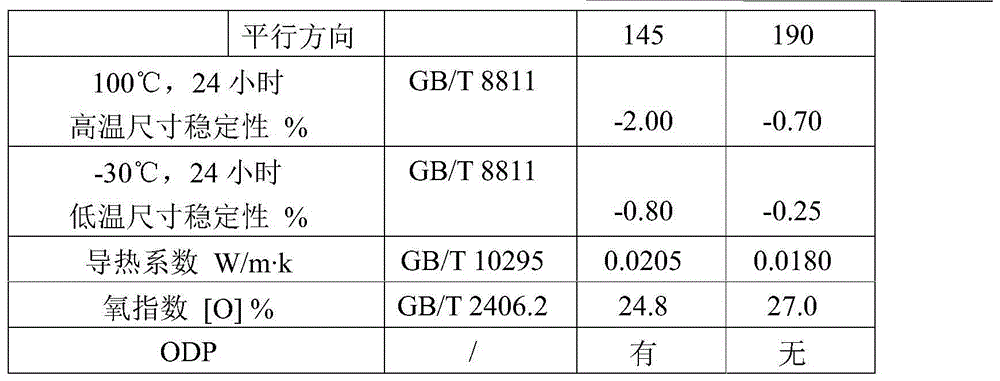

[0080] The rigid polyurethane block foam is reacted with polyether and isocyanate PM200 according to the mass ratio of 1:1.2 at 20°C with rapid release, and injected into the open mold. After the foam stops growing, the foam is taken out, and the overall density is about 50Kg. / m 3 The ri...

Embodiment 3

[0093] (1) Preparation of fast release combined polyether for rigid polyurethane block foam

[0094] Polyether polyol SA4605 parts, SA3803.5 parts, MN5001.5 parts, surfactant B85450.15 parts, LK6650.15 parts, catalyst PC80.05 parts, PC410.05 parts, TMR-20.15 parts, blowing agent HFC -365mfc / 2272 parts, 0.2 parts of water and 1.5 parts of flame retardant TCPP, 0.8 parts of TEP.

[0095] According to the above formula, add each component into a stainless steel mixing kettle, stir at a speed of 500 rpm at room temperature for 1 hour, and discharge the material to obtain a combined polyether for rapid release of rigid polyurethane block foam.

[0096] (2) Preparation of rigid polyurethane block foam:

[0097]The rigid polyurethane block foam is reacted with polyether and isocyanate PM200 according to the mass ratio of 1:1.2 at 20°C with rapid release, and injected into the open mold. After the foam stops growing, the foam is taken out, and the overall density is about 50Kg. / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com