Pyrolysis-gasification integrated treatment device and method

A processing device and pyrolysis technology, which is applied in the gasification process, the manufacture of combustible gas, and the gasification of granular/powdered fuels, etc., and can solve the problems of complex tar components, slag blocking, and difficulty in refining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

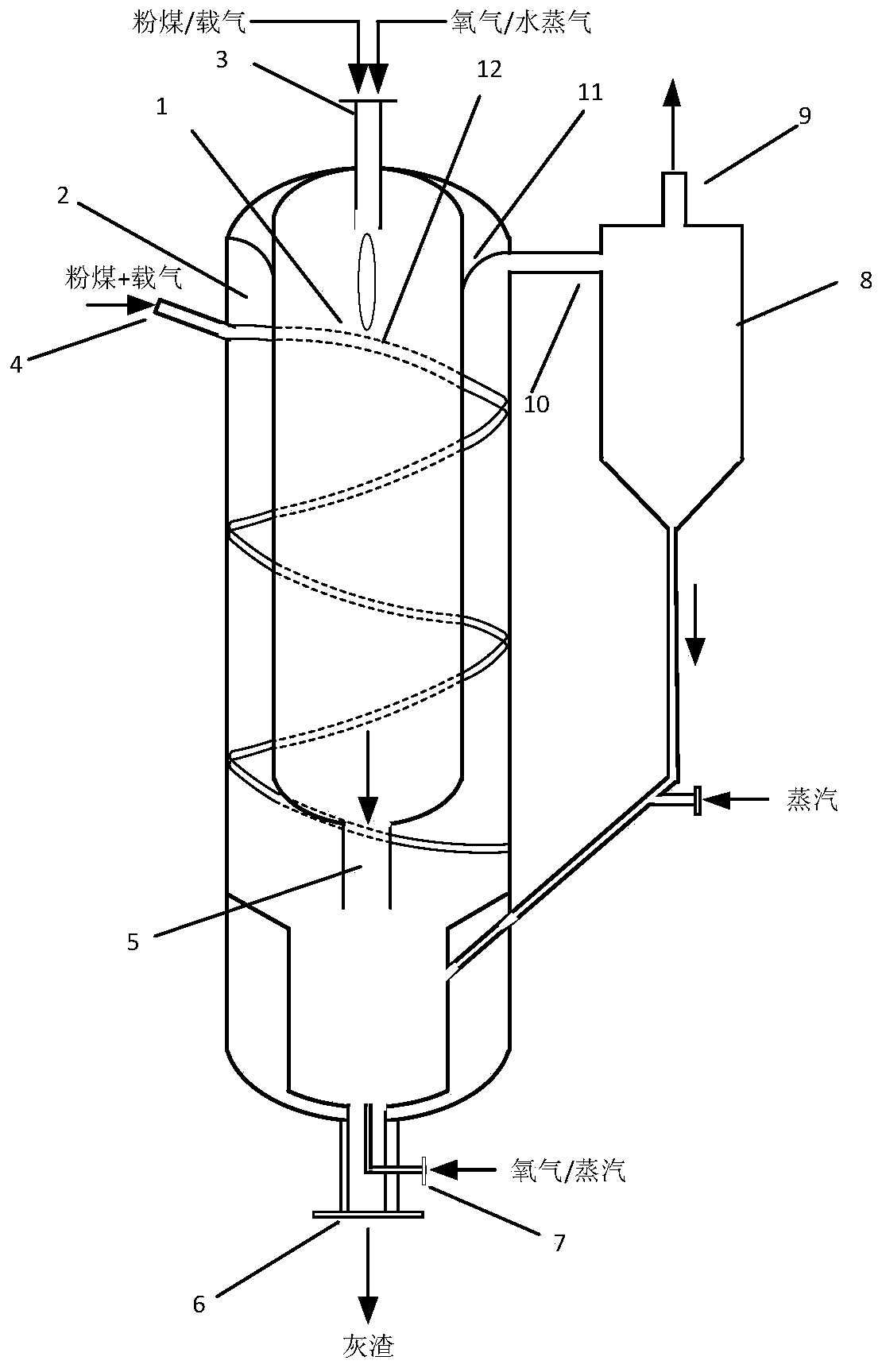

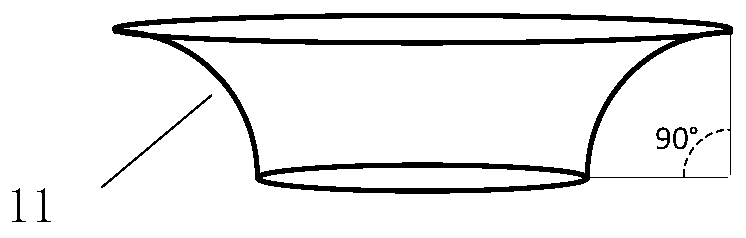

[0063] A pyrolysis-gasification integrated treatment device, such as figure 1 As shown, the device includes a gasification furnace 1 and a pyrolysis furnace 2, the gasification furnace 1 is arranged in the upper area of the pyrolysis furnace 2 furnace cavity, and the two furnace bodies are coaxially distributed; the top of the gasification furnace 1 is provided with Pulverized coal feed port 3, with gasification discharge port 5 at the bottom;

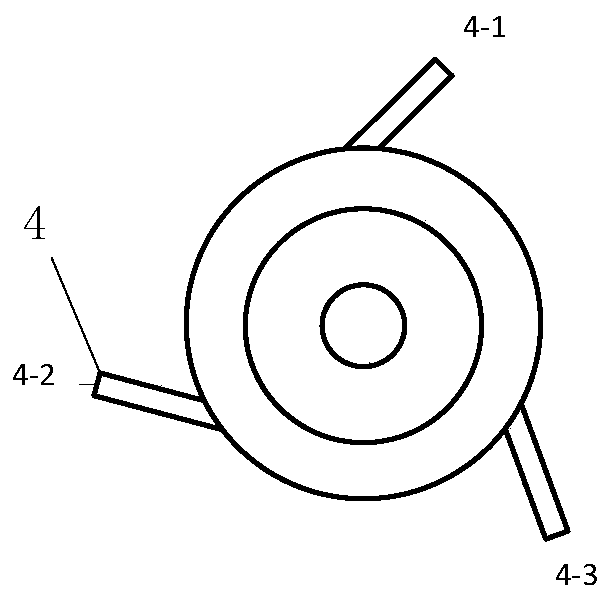

[0064] The upper part of the pyrolysis furnace 2 is provided with three pyrolysis raw material inlets 4 and a synthesis gas outlet 10, and the bottom is provided with a gasification agent inlet 7 and a slagging outlet 6; the three pyrolysis raw material inlets 4 are on the same plane along the pyrolysis The outer wall of the furnace is evenly distributed (such as figure 2 shown).

[0065] The inlet of the cyclone separator 8 is connected with the synthesis gas outlet 10, and the bottom of the cyclone separator 8 is connected with ...

Embodiment 2

[0071] A pyrolysis-gasification integrated treatment method using the device of embodiment 1, the steps comprising:

[0072] 1) It includes two stages of gasification and one stage of pyrolysis, wherein: the gasification furnace cavity of gasification furnace 1 is a gasification zone; The gap is the pyrolysis area; the lower part of the furnace chamber of the pyrolysis furnace 2, which is located below the furnace body of the gasification furnace 1, is the second-stage gasification area;

[0073] 2) First-stage gasification area: pulverized coal (Shenhua coal) and gasification gas enter the furnace cavity of gasifier 1 from the pulverized coal feed port 3 at the top of gasifier 1 through the nozzle, and gasification reaction occurs at 1250-1300°C to generate A section of hydrogen-rich gas and a section of ash are discharged from the first section of gasification area through the gasification outlet 5, a section of hydrogen-rich gas deflects upwards and enters the pyrolysis are...

Embodiment 3

[0112] Only in following difference with embodiment 2:

[0113] In step 2), the ratio of oxygen to pulverized coal (volume / mass) is adjusted to 0.7:1; the mass ratio of water vapor to pulverized coal is 0.18:1; pulverized coal is changed to CO 2 delivery;

[0114] Step 3) The pyrolysis raw material is mixed with Shenhua coal powder and chlorine-free TDI tar solid waste at a ratio of 1:1. The ash melting point of the mixture is about 1200°C. Adjust the carrier gas N 2 / CO 2 The carrier gas ratio is 1:1.

[0115] The volume percentage composition of the hydrogen-rich gas in the first section includes H 2 24% or so, CO 62% or so, CO 2 Around 5%, CH 4 About 0.4%, and other sulfur- and nitrogen-containing gases; the first stage of ash residue carbon is about 9-13wt%, and the temperature of hydrogen-rich gas is about 1100°C.

[0116] After passing through the pyrolysis zone, the hydrogen content increased by about 3%, CH 4 Content increased by about 2%, C 2 ~C 4 Hydrocarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com