Continuous organic waste gas catalytic purification device and running method thereof

A technology for organic waste gas and catalytic purification, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of low concentration of organic pollutants, incombustibility, unsuitable for organic waste gas, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

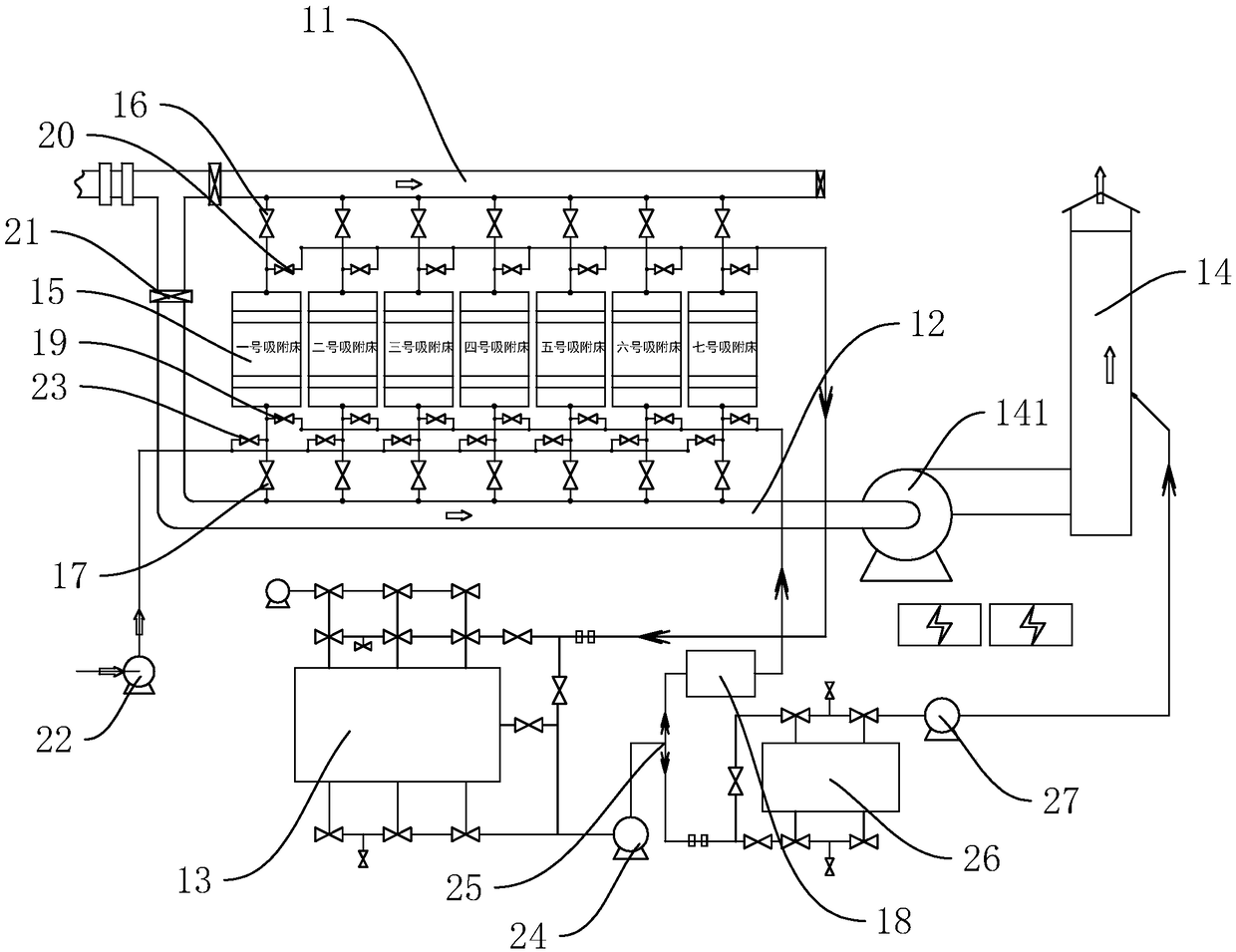

[0026] Embodiment 1: Continuous organic waste gas catalytic purification device, such as figure 1As shown, it includes an intake pipe 11, an exhaust pipe 12, a primary catalytic combustion device 13 and a smoke exhaust pipe 14 connected to the outlet of the exhaust pipe 12, and also includes at least five adsorption beds 15. The specific number of adsorption beds 15 in this embodiment It is seven, wherein, exhaust pipe 14 is provided with power and is the general blower fan 141 of 160kw, and adsorption bed 15 entrances are communicated with inlet pipe 11, and are provided with air intake valve 16, and adsorption bed 15 outlets are communicated with exhaust pipe 12, And be provided with outlet valve 17; Also comprise heater 18, heater 18 is communicated with the outlet end of adsorption bed 15, and between each adsorption bed 15, be respectively provided with heating valve 19, the intake air of primary catalytic combustion device 13 The end communicates with the inlet end of th...

Embodiment 2

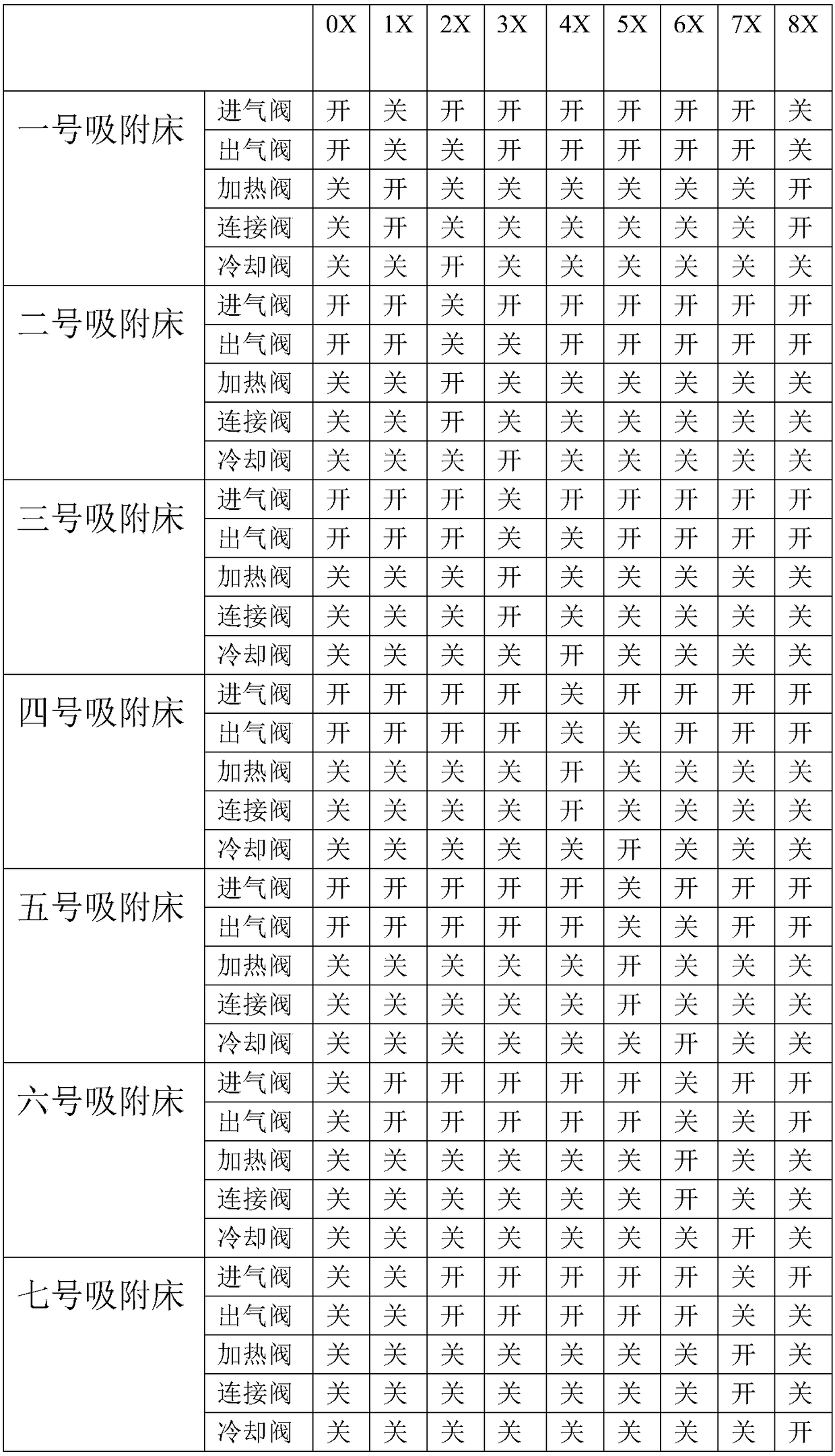

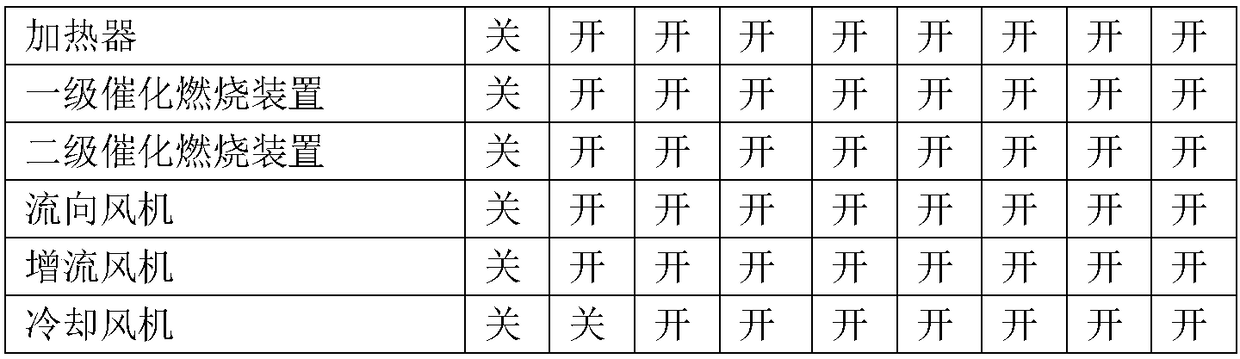

[0032] Embodiment 2: The operation method of the continuous organic waste gas catalytic purification device, such as figure 1 As shown, the specific number of adsorption beds 15 is limited to seven, which are respectively No. 1 adsorption bed, No. 2 adsorption bed, No. 3 adsorption bed, No. 4 adsorption bed, No. 5 adsorption bed, No. 6 adsorption bed, and No. 7 adsorption bed No. adsorption bed, set three operation modes respectively for seven adsorption beds 15, three operation modes are adsorption mode, desorption mode and cooling mode respectively; In the open state, the heating valve 19, the connecting valve 20 and the cooling valve 23 are in the closed state; in the desorption mode, the inlet valve 16, the outlet valve 17 and the cooling valve 23 of the adsorption bed 15 are in the closed state, and the heating valve 19, the connecting valve 20 is in the open state; the cooling mode is that the cooling valve 23 and the inlet valve 16 of the adsorption bed 15 are in the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com