A kind of treatment method of diketene production waste water

A technology for diketene and waste water production, which is applied in the treatment of biological organic parts, fertilizers made from biological waste, radiation treatment, etc., can solve the problems of waste of residual resources, environmental pollution, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

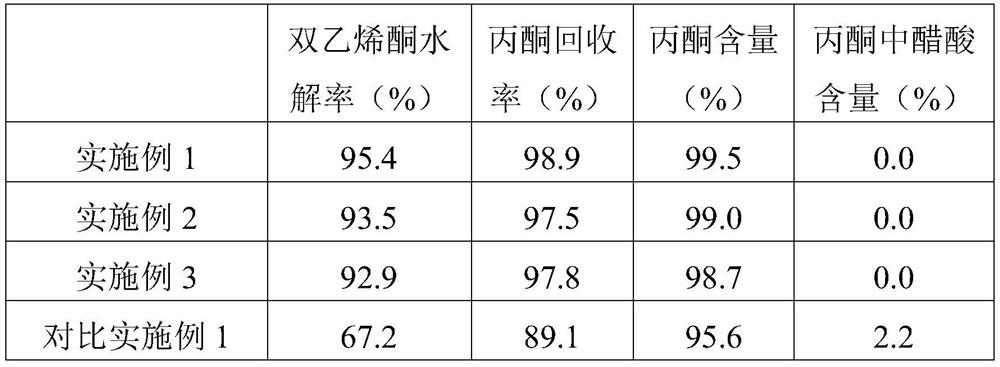

Examples

Embodiment 1

[0044] Embodiment 1: a kind of treatment method of diketene production waste water, comprises the following steps:

[0045] (1) Hydrolysis

[0046] Mix the rectification residue and waste liquid produced by the acetic acid cracking method to prepare diketene as wastewater to be treated; add water, disodium EDTA, low molecular weight sodium polyacrylate and sodium dodecylsulfonate to the wastewater to be treated, and stir at room temperature reaction, collect the CO produced by the reaction 2 , until the reaction is free of CO 2 produce;

[0047] On a mass basis, the ratio of waste water to be treated, water, disodium EDTA, low molecular weight sodium polyacrylate and sodium dodecylsulfonate is 1:2.0:0.02:0.25:0.05;

[0048] (2) Separation of acetone

[0049] Distill the slurry obtained in step (1) at a distillation temperature of 45° C., and collect the distilled gas into an acetone receiving tank after condensation;

[0050] (3) Dehydration

[0051] Concentrate the slur...

Embodiment 2

[0058] Embodiment 2: a kind of treatment method of diketene production waste water, comprises the following steps:

[0059] (1) Hydrolysis

[0060] Mix the rectification residue and waste liquid produced by the acetic acid cracking method to prepare diketene as wastewater to be treated; add water, disodium EDTA, low molecular weight sodium polyacrylate and sodium dodecylsulfonate to the wastewater to be treated, and stir at room temperature reaction, collect the CO produced by the reaction 2 , until the reaction is free of CO 2 produce;

[0061] On a mass basis, the ratio of waste water to be treated, water, disodium EDTA, low molecular weight sodium polyacrylate and sodium dodecylsulfonate is 1:1.5:0.01:0.24:0.04;

[0062] (2) Separation of acetone

[0063] Distill the slurry obtained in step (1) at a distillation temperature of 42° C., and collect the distilled gas into an acetone receiving tank after condensation;

[0064] (3) Dehydration

[0065] Concentrate the slur...

Embodiment 3

[0072] Embodiment 3: a kind of treatment method of diketene production waste water, comprises the following steps:

[0073] (1) Hydrolysis

[0074] Mix the rectification residue and waste liquid produced by the acetic acid cracking method to prepare diketene as wastewater to be treated; add water, disodium EDTA, low molecular weight sodium polyacrylate and sodium dodecylsulfonate to the wastewater to be treated, and stir at room temperature reaction, collect the CO produced by the reaction 2 , until the reaction is free of CO 2 produce;

[0075] On a mass basis, the ratio of waste water to be treated, water, disodium EDTA, low molecular weight sodium polyacrylate and sodium dodecylsulfonate is 1:2.5:0.02:0.28:0.06;

[0076] (2) Separation of acetone

[0077] Distill the slurry obtained in step (1) at a distillation temperature of 48° C., and collect the distilled gas into an acetone receiving tank after condensation;

[0078] (3) Dehydration

[0079] Concentrate the slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com