Parabolic grading concentration tank

A kind of technology of concentration pool and pool body, which is applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of increasing difficulty in coal slime water treatment, and achieve the goal of increasing system processing capacity, intensifying dispersion, and increasing contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

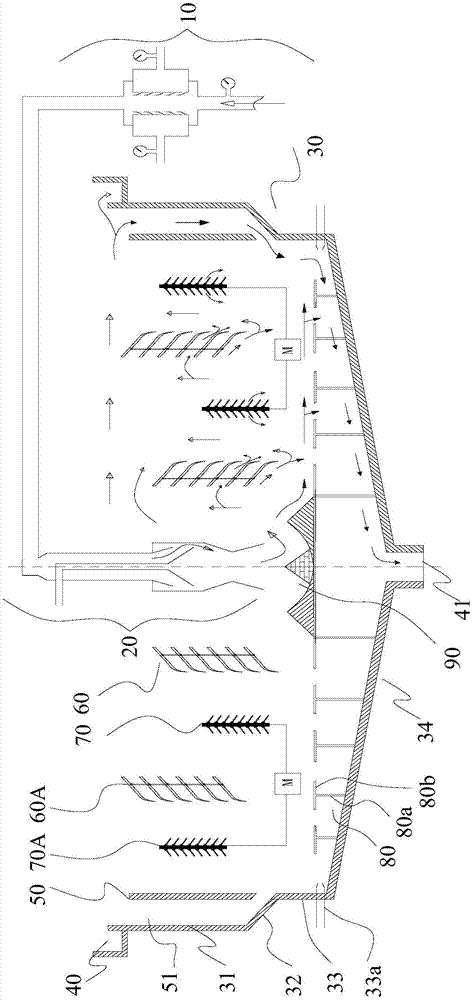

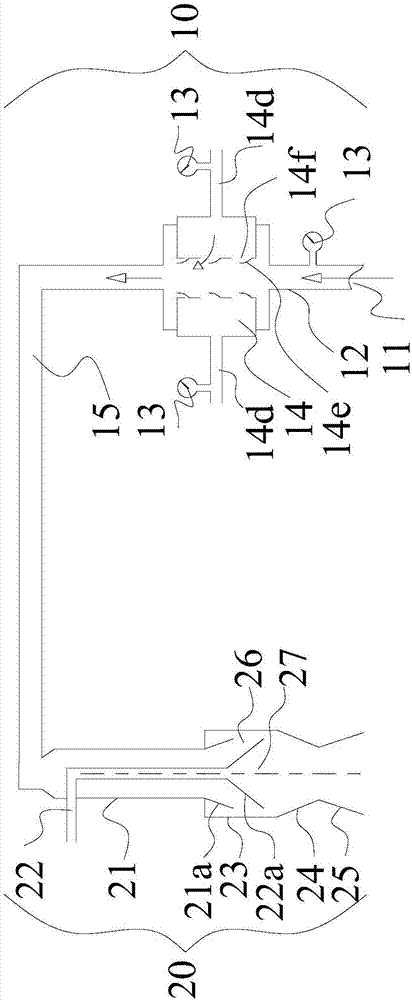

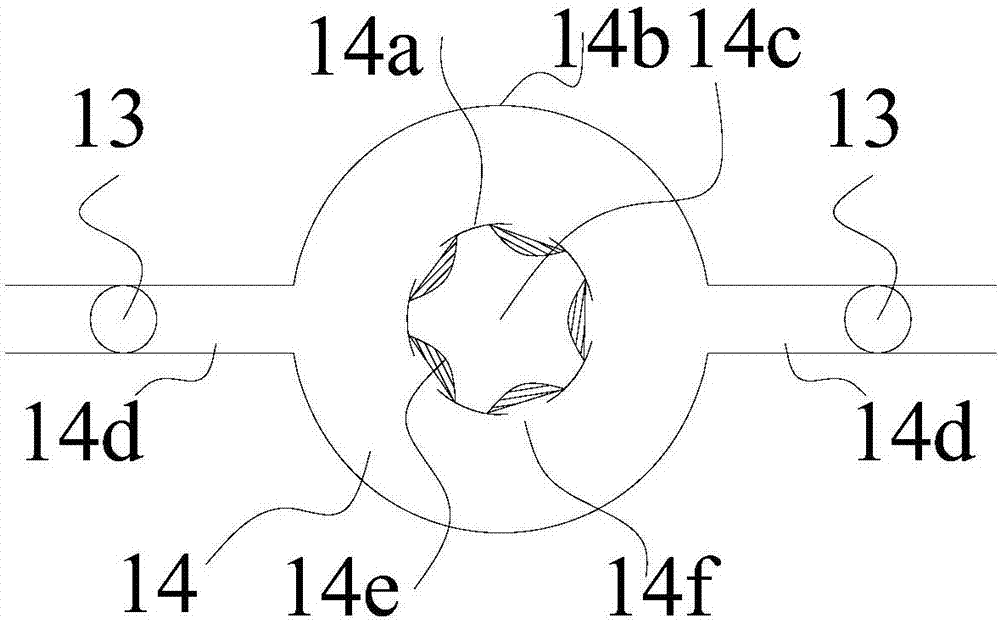

[0058] For ease of understanding, combined here Figure 1-7 , the specific embodiments of the present invention are further described below, and the arrows in the figure are schematic representations of ore slurry and coal slime settlement flow:

[0059] The specific components of the present invention are divided into several modules, including: medicament addition system 10, feeding system 20, thickening tank body 30, first drainage stagnation plate unit 60, second drainage stagnation plate unit 60A , the first adjustable vibrating plate device 70, the second adjustable vibrating plate device 70A, the discontinuous false bottom 80, and the conical disperser 90 are described in detail one by one below:

[0060] 1. Drug adding system

[0061] its institutions such as figure 1 , 2 , 3, the agent addition system 10 is the focus of the present invention; the agent addition system 10 of this example can realize the quantitative addition of agents according to the size of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com