Method for preparing porous metal by high temperature oxidation and reduction

A porous metal, high-temperature oxidation technology, applied in the field of porous metal preparation, can solve problems such as complicated methods, high production equipment requirements, and dependence on templates, and achieve the effect of simple process, low equipment requirements, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

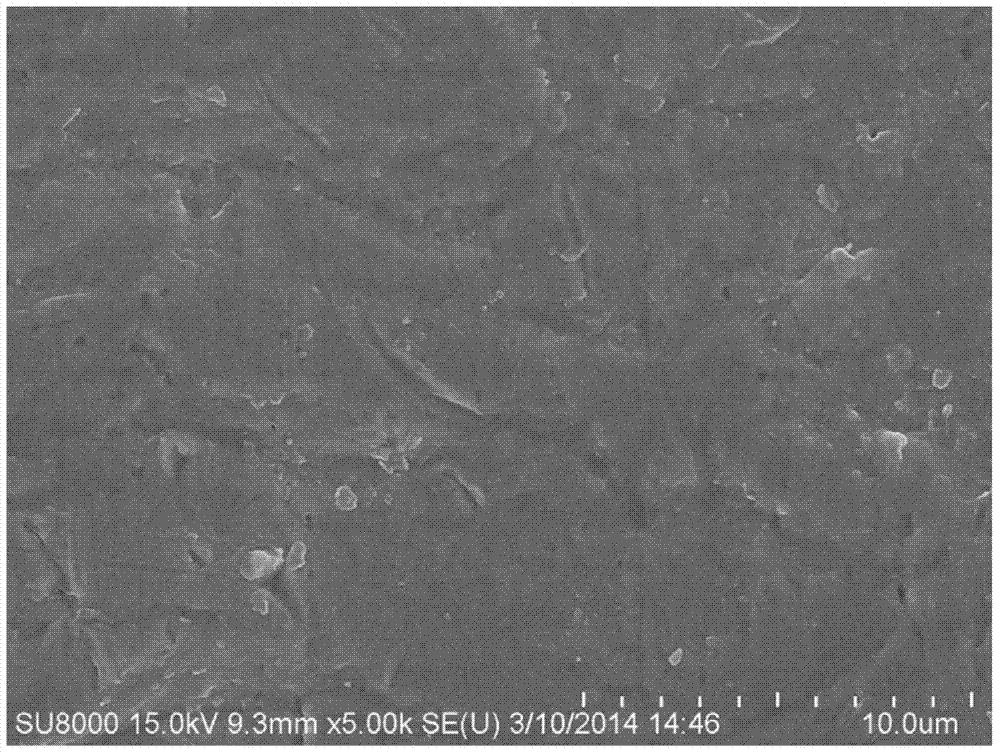

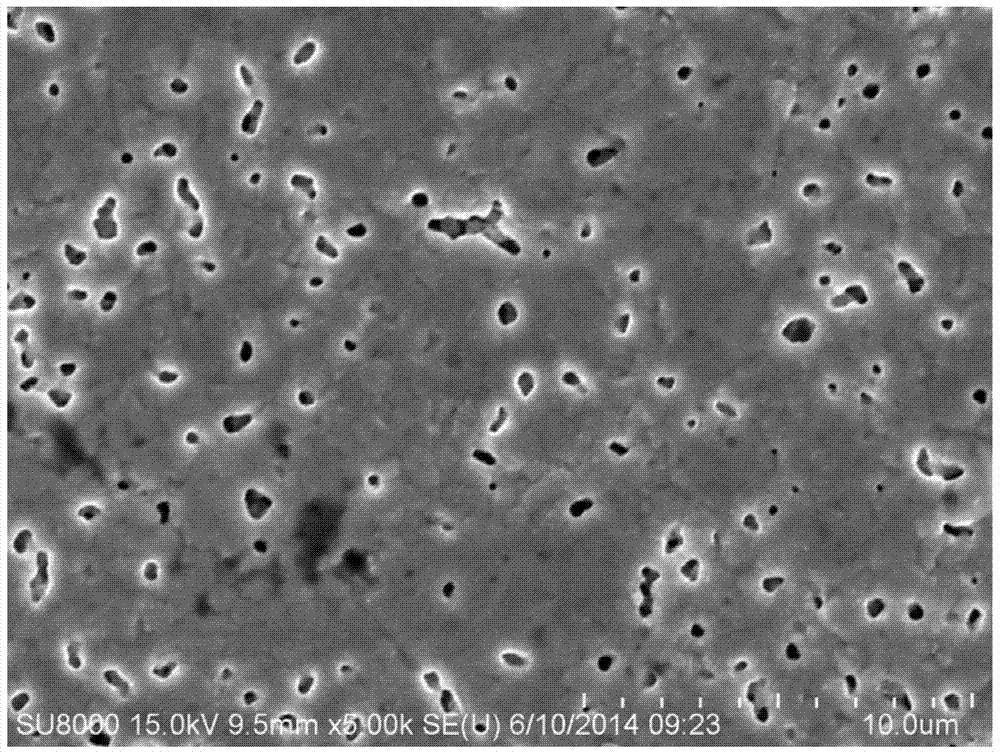

[0022] Embodiment 1: The method for preparing porous metal by high-temperature oxidation and reduction in this embodiment is implemented according to the following steps:

[0023] 1. The metal material or (corresponding) foam metal material is ultrasonically cleaned with acetone, then cleaned with absolute ethanol and deionized water in turn, and the cleaned metal is obtained after drying;

[0024] 2. Place the cleaned metal obtained in step 1 in a high-temperature-resistant carrier, raise the temperature to 100-850°C under the protection of an inert gas, and then pass the oxidizing gas into the carrier where the metal is placed, so that the metal is exposed to oxidation. Oxidation treatment in gas to form metal oxides;

[0025] 3. Use an inert gas to purge and exhaust the oxidizing gas in the high-temperature-resistant carrier body, and then pass the reducing gas into the high-temperature-resistant carrier body at a temperature of 300-850 ° C, so that the metal oxide is expos...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the metal material described in step 1 is aluminum, gallium, indium, thallium, germanium, tin, lead, antimony, bismuth, polonium, manganese, iron, cobalt, Nickel, copper, gold, silver, ruthenium, rhodium, palladium, osmium, iridium, platinum, iron, copper, mercury or titanium alloys. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

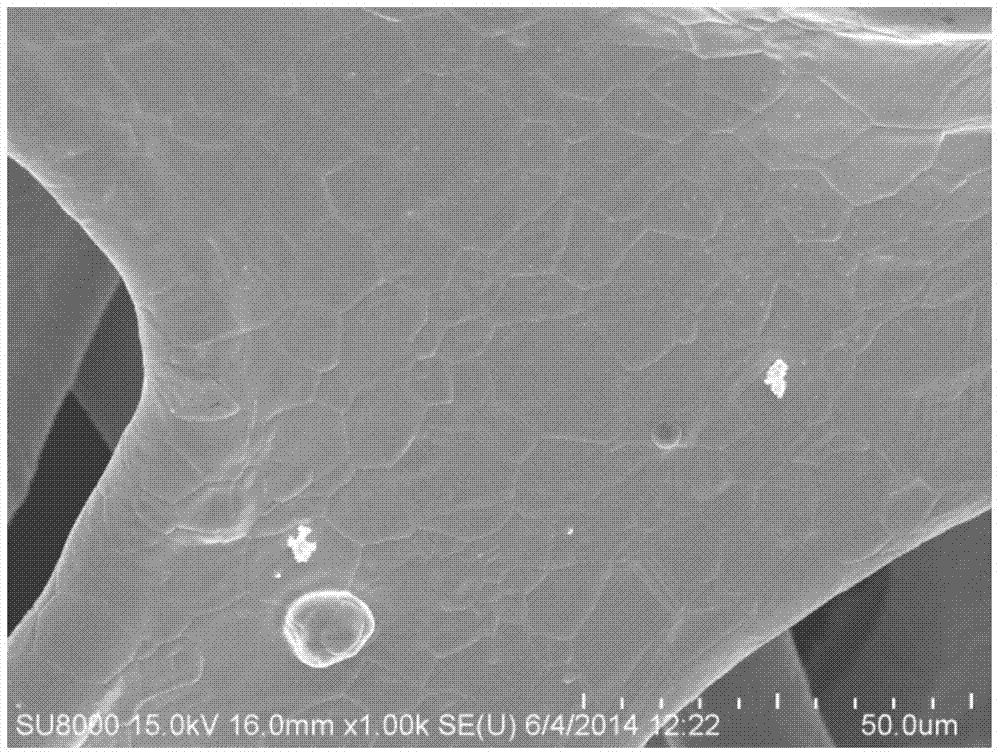

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the form of the metal material in Step 1 is powder, metal wire, metal sheet or metal film. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0032] In this embodiment, the metal material can also be a prepared metal device, and the oxidation-reduction process is used to realize in-situ porous preparation on the surface of the complex device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com