Manufacturing and processing method of flexible plate material

A processing method and flexible technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of inability to reprocess, increase the production and processing of the lower fabric process, and insufficient strength of thermoplastic processing, etc. , to achieve the effect of shortening the processing time and reducing the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

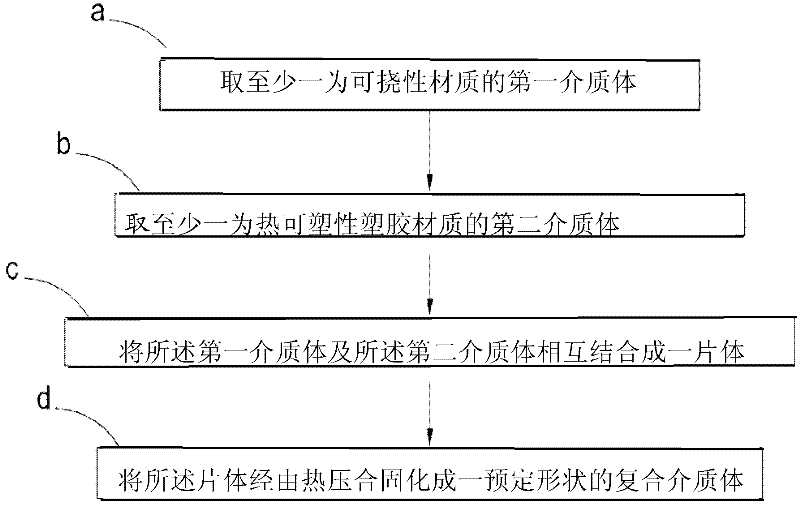

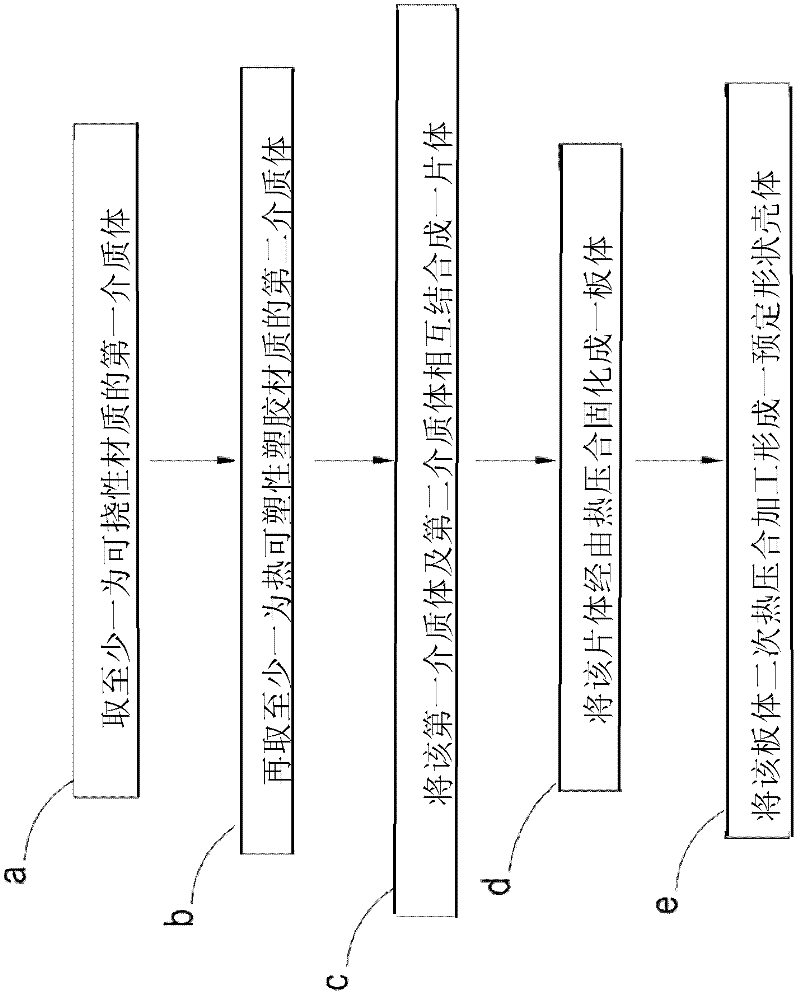

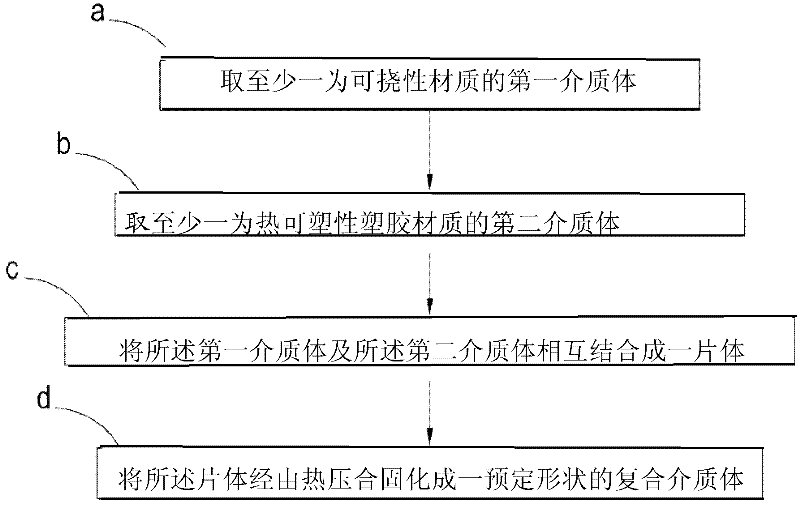

[0018] see first figure 1 As shown, it is a flow chart of a preferred embodiment of the manufacturing and processing method of the present invention. From the figure, it can be clearly seen that the manufacturing and processing method of the flexible plate of the present invention has the following steps:

[0019] (a) taking at least one first medium body made of flexible material;

[0020] Wherein, the flexible material can be selected from carbon fiber, non-woven fabric or metal wire;

[0021] (b) at least one second medium body made of thermoplastic plastic material;

[0022] Among them, the thermoplastic plastic material can be selected polyethylene terephthalate (polyethylene terephthalate, PET), high density polyethylene (High Density polyethylene, HDPE, PE), polyvinyl chloride (polyvinylchlride, PVC), low density polyethylene (Low Density polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com