Internal bracing clamp with tightened side face and adjustable inner diameter and machining method of internal bracing clamp

A technology of internal support fixtures and processing methods, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of poor precision of blanks, unreachable precision, large size span, etc., and achieve large size span and convenient operation , strong operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

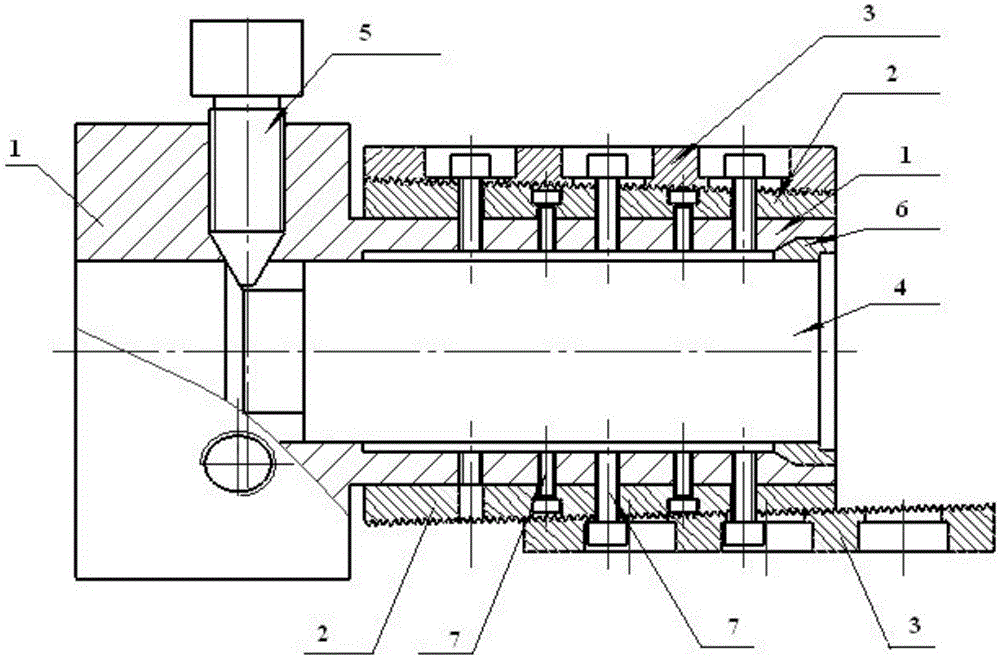

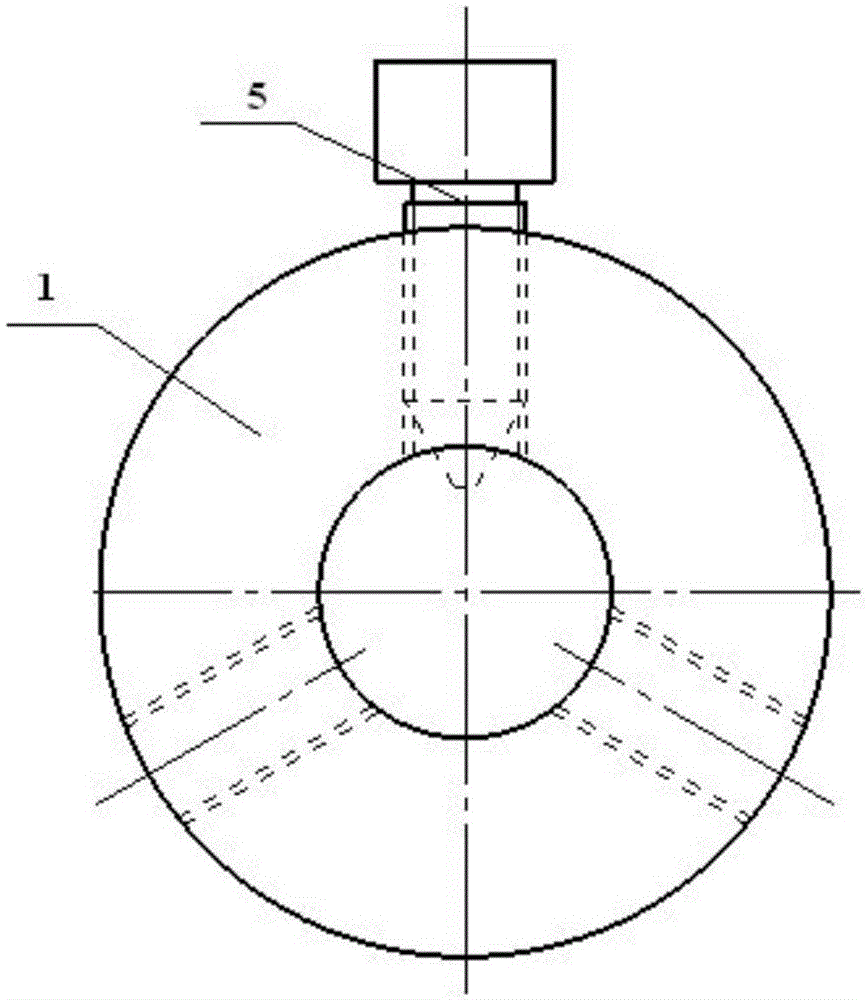

[0030] Such as figure 1 and figure 2 Shown, a kind of side tightening and internal diameter adjustable internal support fixture, it comprises: open sleeve (1), the fixed block (2) that is fixed on the outer circle surface of open sleeve (1), is fixed on the fixed block ( 2) The adjustment block (3) on the top, the tensioning mandrel (4) installed in the split sleeve (1), and the side of the big end of the split sleeve (1) are provided with 3 tightening screw holes, and the tightening screw holes A tightening screw (5) is installed inside, and the tightening screw (5) tightens and locks one end of the tensioning mandrel (4) in the open sleeve (1);

[0031] The contact surfaces of the fixed block (2) and the adjusting block (3) are connected in tooth form; the contact surfaces of the fixed block (2) and the adjusting block (3) are taper at an angle of 2 degrees;

[0032] An inner support ring (6) is installed between the open end of the open sleeve (1) and the tension mandrel...

Embodiment 2

[0039] A method for processing an inner support fixture with side tightening and inner diameter adjustable, characterized in that it includes the following steps:

[0040] 1) Turning a cylinder with an outer diameter of 60mm, an inner hole diameter of 35mm, and a length of 60mm; wire cutting: vertically cut the cylinder into six equal parts, and the gap between each equal part is 2mm, and the cutting results in 6 6 fixed blocks (2) and 6 adjustable blocks (3), then clamped with a vise, cut 60° teeth on the contact surface of the fixed block (2) and the adjusted block (3), and cut at the same time to obtain 2° taper; miller: process the waist-shaped groove on the fixed block (2) and the adjustment block (3); fitter: then process the threaded holes and Via;

[0041] 2) Turning of the tensioning mandrel (4) and inner support ring (6);

[0042] 3) Tighten the screw (5) and turn it with the screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com