Granularity multi-stage treatment mechanism for coal samples

A coal sample and particle size technology, applied in grain processing and other directions, can solve the problems of low coal particle size multi-level processing efficiency and blockage of processing mechanisms, and achieve the effect of improving efficiency and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

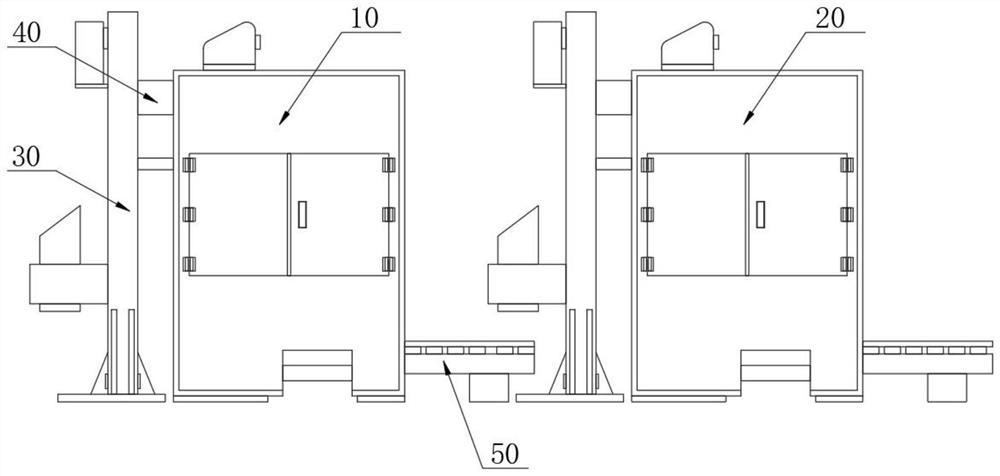

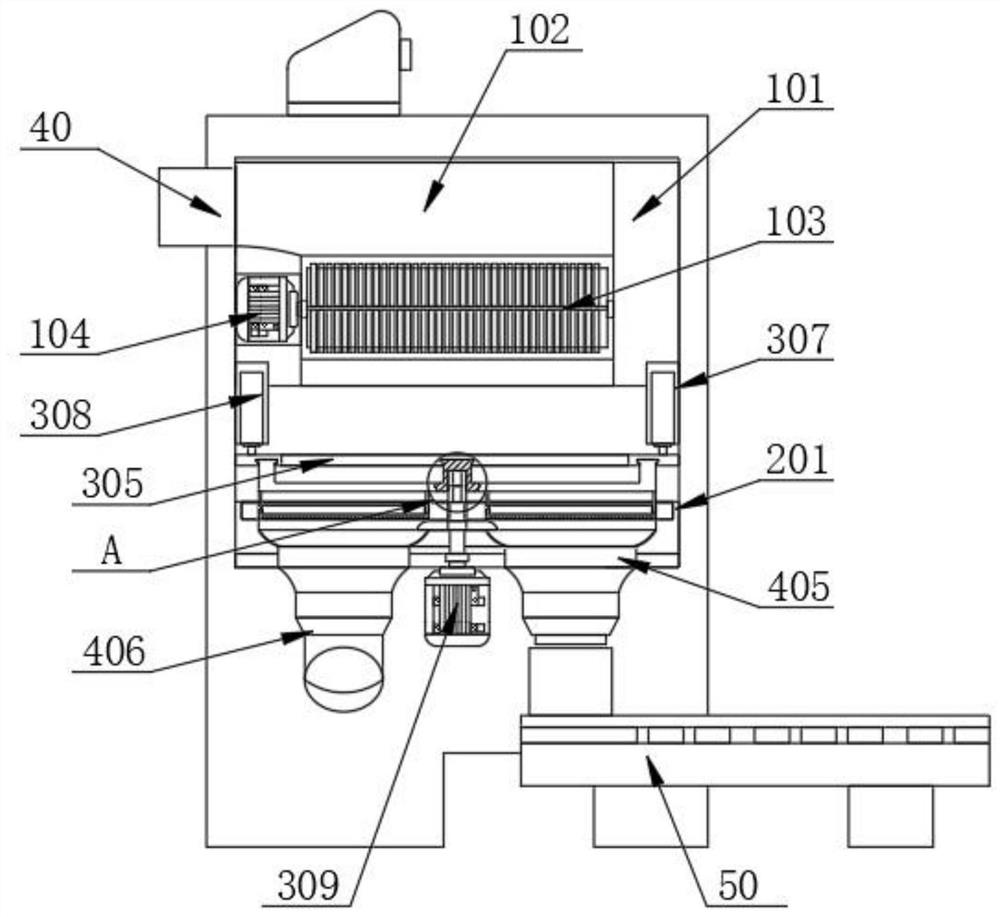

[0039] see Figure 1-2As shown, a particle size multi-level processing mechanism for coal samples includes a primary treatment box 10 and a secondary treatment box 20, the primary treatment box 10 and the secondary treatment box 20 are arranged side by side, and the primary treatment box 10 and the secondary treatment box 10 are arranged side by side. The left side of box 20 is all provided with material-lifting pipeline 30, and one side of two material-lifting pipelines 30 is all provided with material guide pipe 40, and one end of two material guide pipes 40 extends to primary treatment box 10 and secondary treatment box 10 respectively. Inside the processing box 20, the material-lifting pipeline 30 adopts a pneumatic pipeline, and the coal sample to be processed is sent from the storage box into the interior of the multi-stage processing mechanism by using the material-lifting pipeline 30. Compared with the traditional screw feeding method, adopting The pneumatic pipeline c...

Embodiment 2

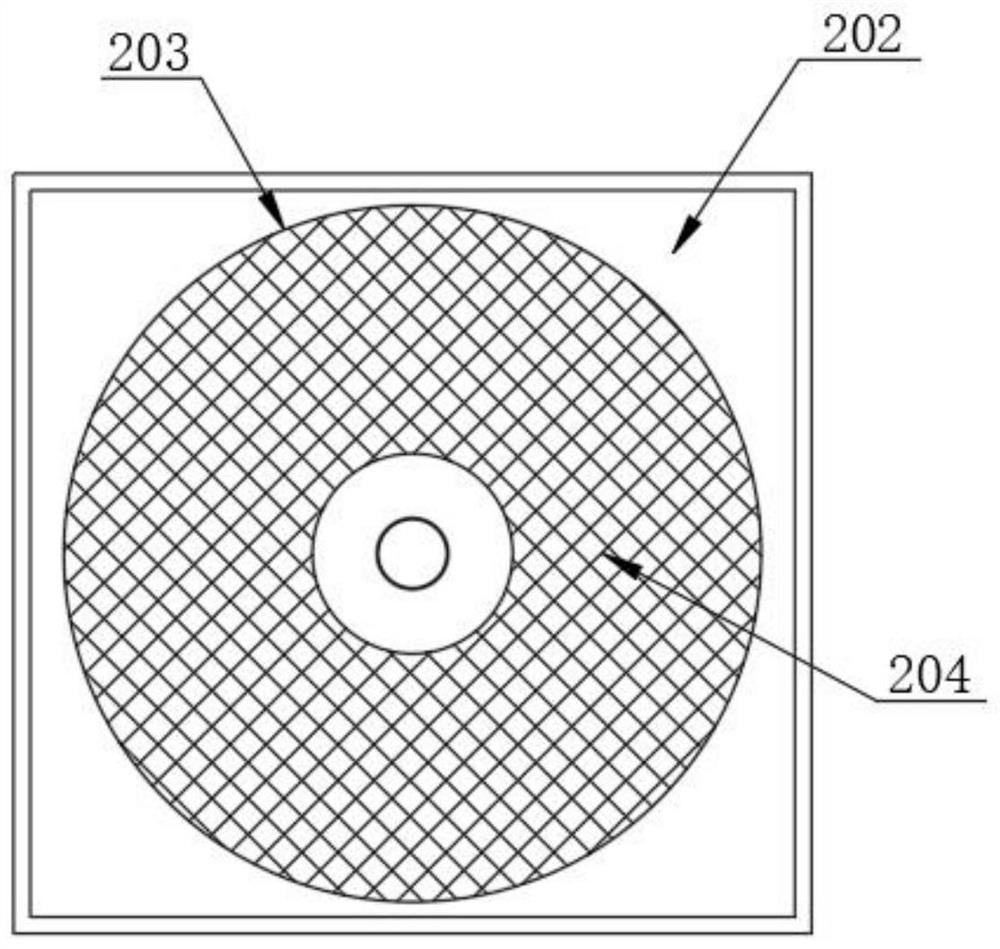

[0042] see Figure 2-3 As shown, in the present invention, the inside of the first-level treatment box 10 and the second-level treatment box 20 is provided with a sieve assembly, and the sieve assembly includes a sieve rack 201, and the bottom of the sieve rack 201 and the inner wall of the first-level treatment box 10 The bottom is fixedly connected, and an installation frame 202 is provided above the inside of the sieve frame 201, and a blanking trough 203 is provided inside the installation frame 202, and a screen 204 is provided inside the blanking chute 203. The coal sample processed by the roller 103 passes through the discharge hole and enters the inside of the discharge trough 203. The coal sample inside the discharge trough 203 has a particle size that meets the mesh diameter of the sieve 204 and directly passes through the sieve 204, and the particle size is larger than the sieve. The mesh diameter of the net 204 is left on the top of the screen 204, and the mesh dia...

Embodiment 3

[0044] see Figure 4-5 As shown, the inside of the primary treatment box 10 and the secondary treatment box 20 in the present invention are all provided with a pressing assembly, and the pressing assembly is located above the sieve assembly, the pressing assembly includes a pressing frame 301, and the pressing frame Both sides of the 301 bottom are provided with connecting frames 302, and the insides of the two connecting frames 302 are all rotated to be provided with nip rollers 303, and the two nip rollers 303 arranged below the nip frame 301 can be used to clean the inside of the blanking trough 203. The coal sample is subjected to secondary crushing treatment, so that the coal sample left on the top of the screen 204 can quickly pass through the screen 204 and fall into the bottom of the screen 204, so as to realize the unified control of the particle size of the coal sample. The primary treatment box 10 and The inside of secondary treatment box 20 is all slidably provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com