Evaporating system capable of conducting online descaling and working continuously and evaporating process

An evaporation system and process technology, applied in the direction of evaporation, steam pressurized evaporation, evaporator adjustment/control, etc., can solve the problems of heat loss, high operating cost, low utilization rate of system equipment, etc., and achieve the effect of reducing times and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

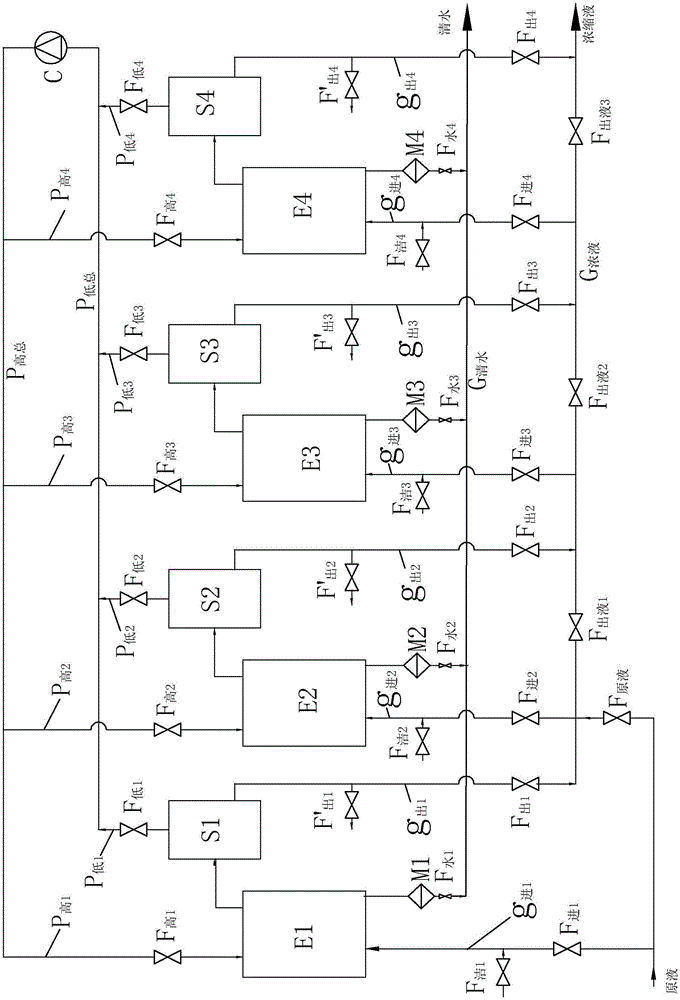

[0080] Such as figure 1 The shown online descaling and continuous working evaporation system is an embodiment of the present invention, which includes a control device (not shown in the figure), an evaporator E, a steam compressor C, a supplementary heat system (not shown in the figure) shown), the steam-water separation tank S, each piping system and the on-off valves on it, wherein each piping system includes a liquid inlet pipe g 进 , Concentrate out of pipe g 出 , condensate outlet pipe, low temperature steam outlet pipe P 低 , high temperature steam into pipe P 高 And evaporator E, as well as washing liquid inlet pipe and washing liquid outlet pipe, are equipped with on-off valves on the piping system. In the inlet pipe g 进 , Concentrate out of pipe g 出 , Condensed water outlet pipe, washing liquid inlet pipe, washing liquid outlet pipe, low temperature steam outlet pipe P 低 and high temperature steam into the pipe P 高 The on-off valves are respectively called: inlet ...

Embodiment 2

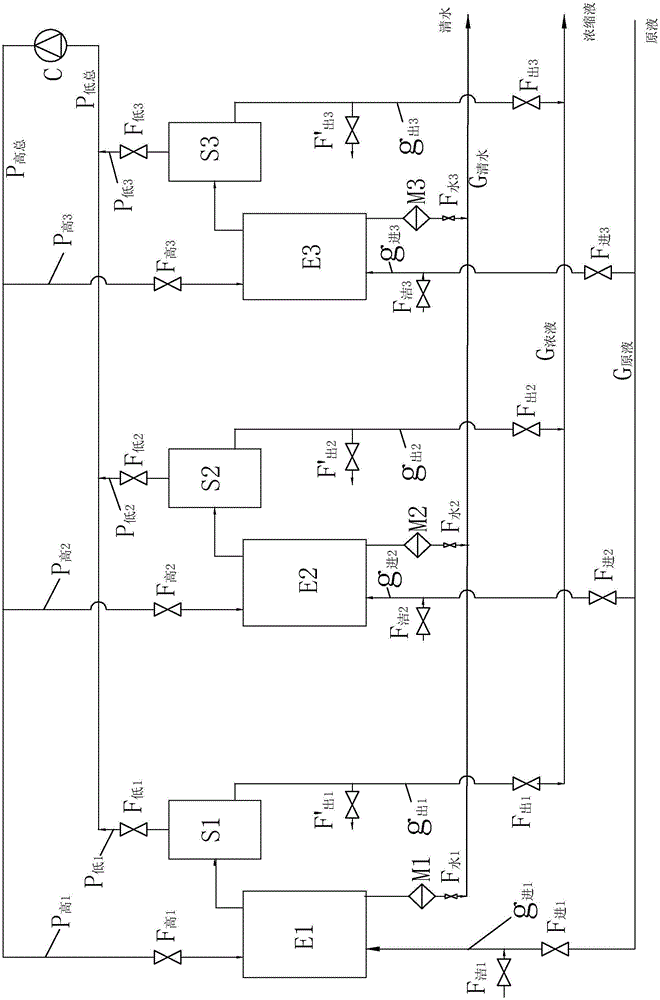

[0092] figure 2 The shown online descaling and continuous working evaporation system is an embodiment of the present invention. The difference from Embodiment 1 is that

[0093] The evaporation system has 3 sets of evaporation units, and the 3 sets of evaporation units are connected in the way of liquid inlet parallel evaporation to form a complete evaporation system. The way of liquid inlet parallel evaporation refers to the 3 inlet pipes on the 3 sets of evaporation units 进 Both are respectively connected with a main liquid pipe G 原液 connected to form parallel mode, such as figure 2 Shown, the first liquid inlet pipe g 进1 , the second liquid inlet pipe g 进2 and the third liquid inlet pipe g 进3 G 原液 Connect so that the liquid inlet pipes of each evaporation unit g 进 Both are connected to the raw liquid and evaporated at the same time, and there is no relationship between the upper and lower stages of concentration between each set of evaporation units.

[0094] When ...

Embodiment 3

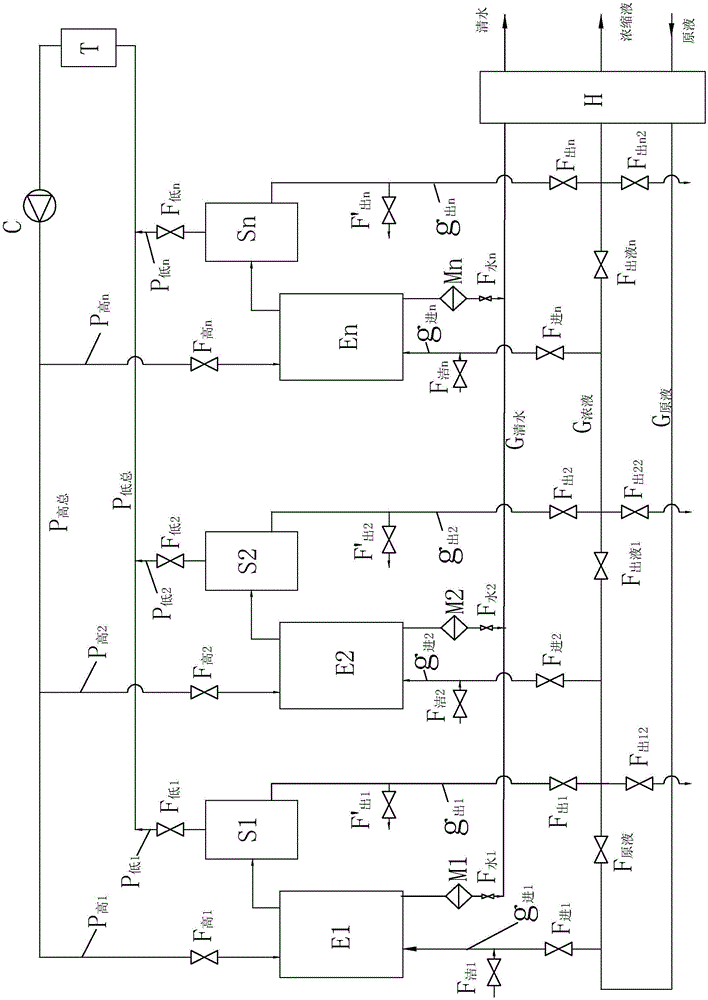

[0096] image 3 The shown online descaling and continuous working evaporation system is an embodiment of the present invention. The difference from Example 1 is that this evaporation system has n sets of evaporation units, and n is a natural number greater than 1. As a preferred implementation Mode n is 2-5.

[0097] Liquid inlet pipe g of the first set of evaporation units in n sets of evaporation units 进 with stock solution manifold G 原液 connection, another set of a concentrate pipe G 浓液 , the concentrated solution of the first set of evaporation unit comes out of the pipe g 出1 with concentrate manifold G 浓液 Connection, the liquid inlet pipes of other sets of evaporation units g 进 and concentrate out of tube g 出 Also connected to the concentrate manifold G 浓液 connection, and the inlet pipe g of each evaporation unit 进 and concentrate out of tube g 出 A concentrated liquid valve F is set on the concentrated liquid main pipe section between 出液 , adopting different ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com