Patents

Literature

35results about How to "Does not affect throughput" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose acetate forward osmotic membrane and preparation method thereof

The invention relates to a cellulose acetate forward osmotic membrane and a preparation method of the cellulose acetate forward osmotic membrane. The preparation method comprises the following steps: preparing raw materials according to a ratio of adding 20ml-40ml of acetone, 50ml-70ml of 1,4-dioxane and 7ml-10ml of methanol into 3g-5g of cellulose acetate; adding a pore former, namely 5ml-10ml of lactic acid or 0.8g-28g of zinc chloride; uniformly mixing the raw materials and completely dissolving the cellulose acetate under room-temperature agitation; standing a membrane casting solution for more than 12 hours; immersing and treating by a sodium hydroxide solution; immersing a mixture into the membrane casting solution for 30-60 seconds; and pulling for one time and immersing into de-ionized water for carrying out phase inversion for 2-6 hours so as to obtain the cellulose acetate forward osmotic membrane, wherein a middle base membrane is a polysulfone membrane and attached cellulose acetate membranes are formed on the two sides of the base membrane. The preparation method is simple in process and the prepared forward osmotic membrane can effectively prevent solutes from entering a porous supporting layer; the cellulose acetate forward osmotic membrane has good chemical stability and high salt rejection rate and membrane flux.

Owner:SOUTH CHINA UNIV OF TECH

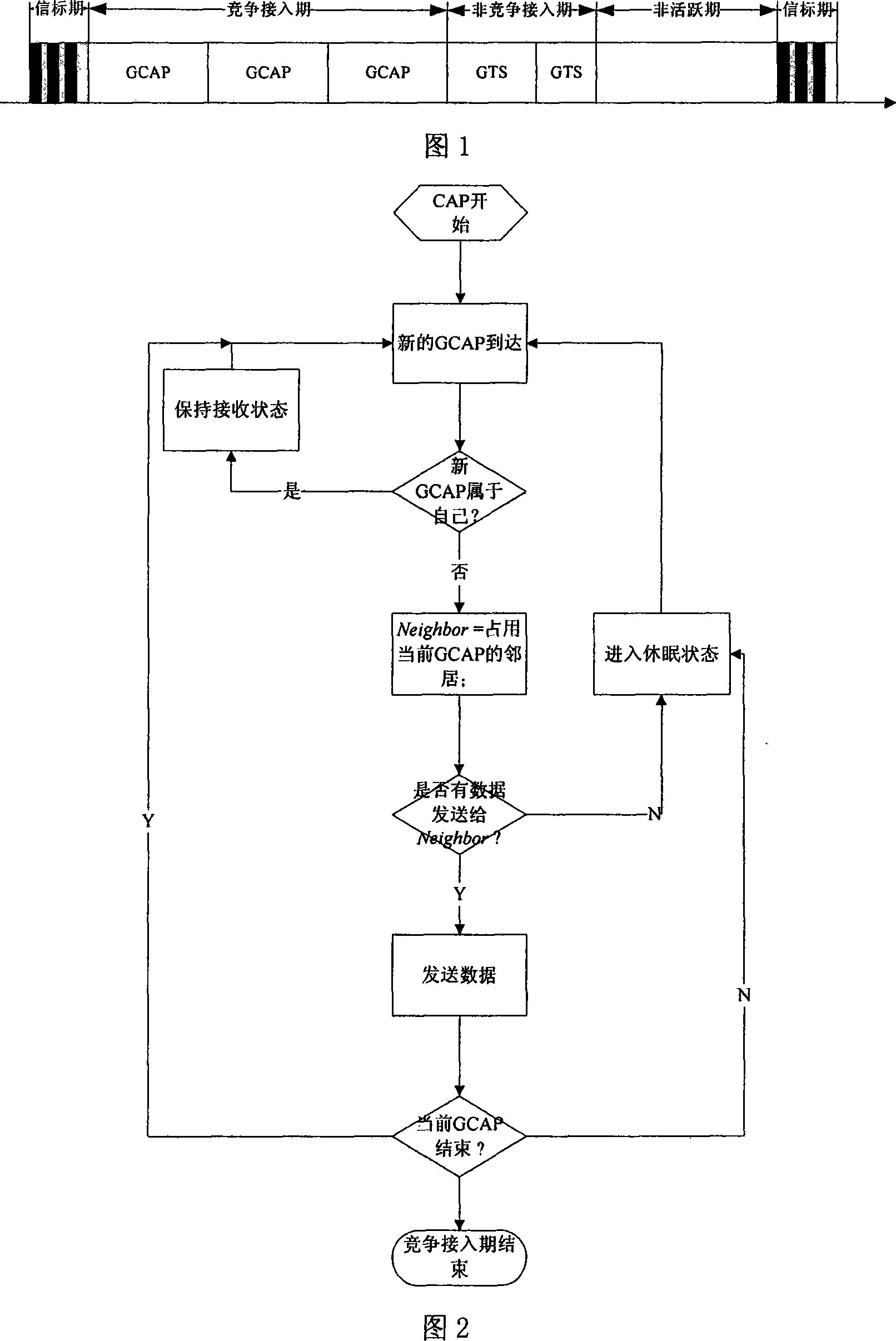

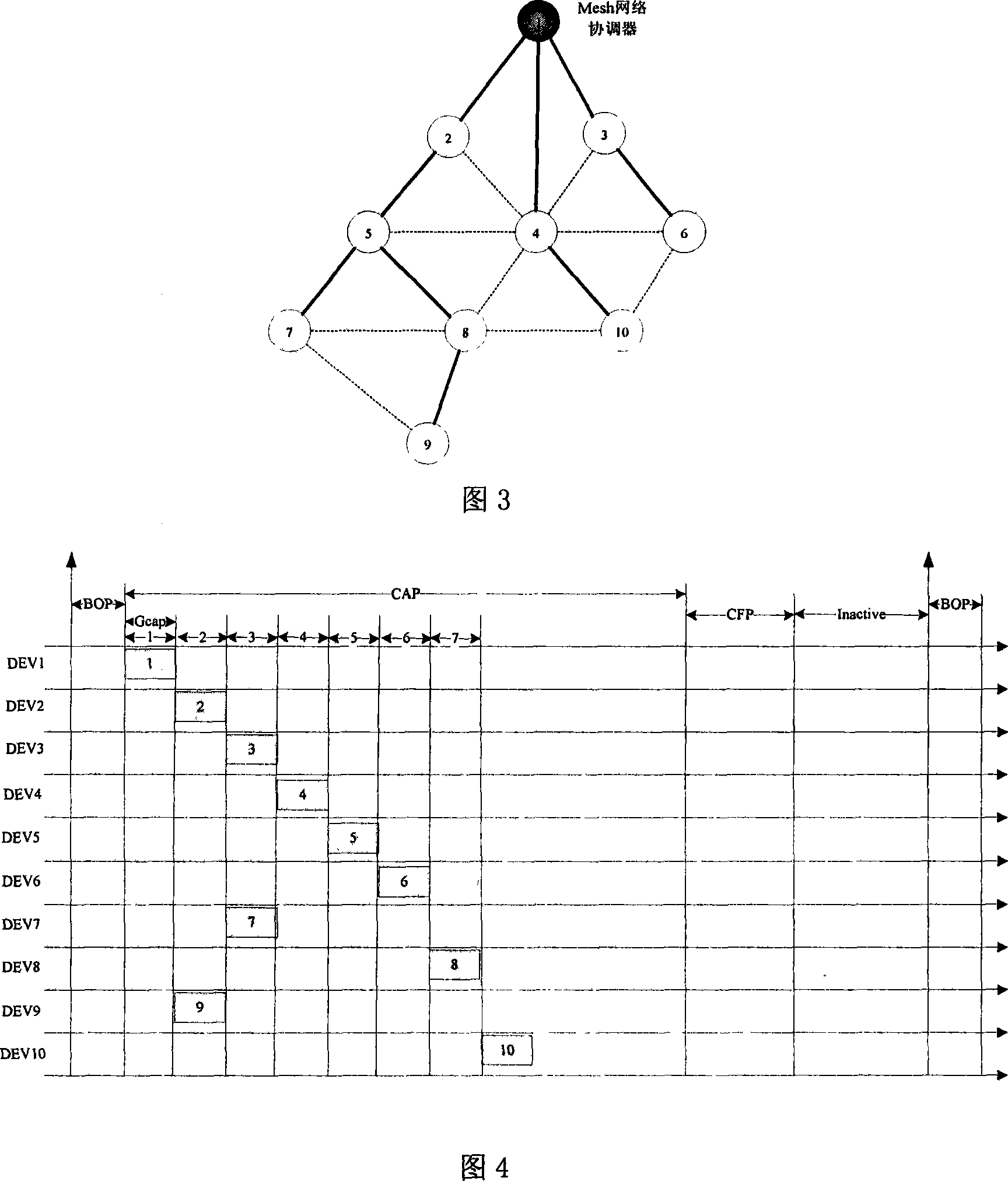

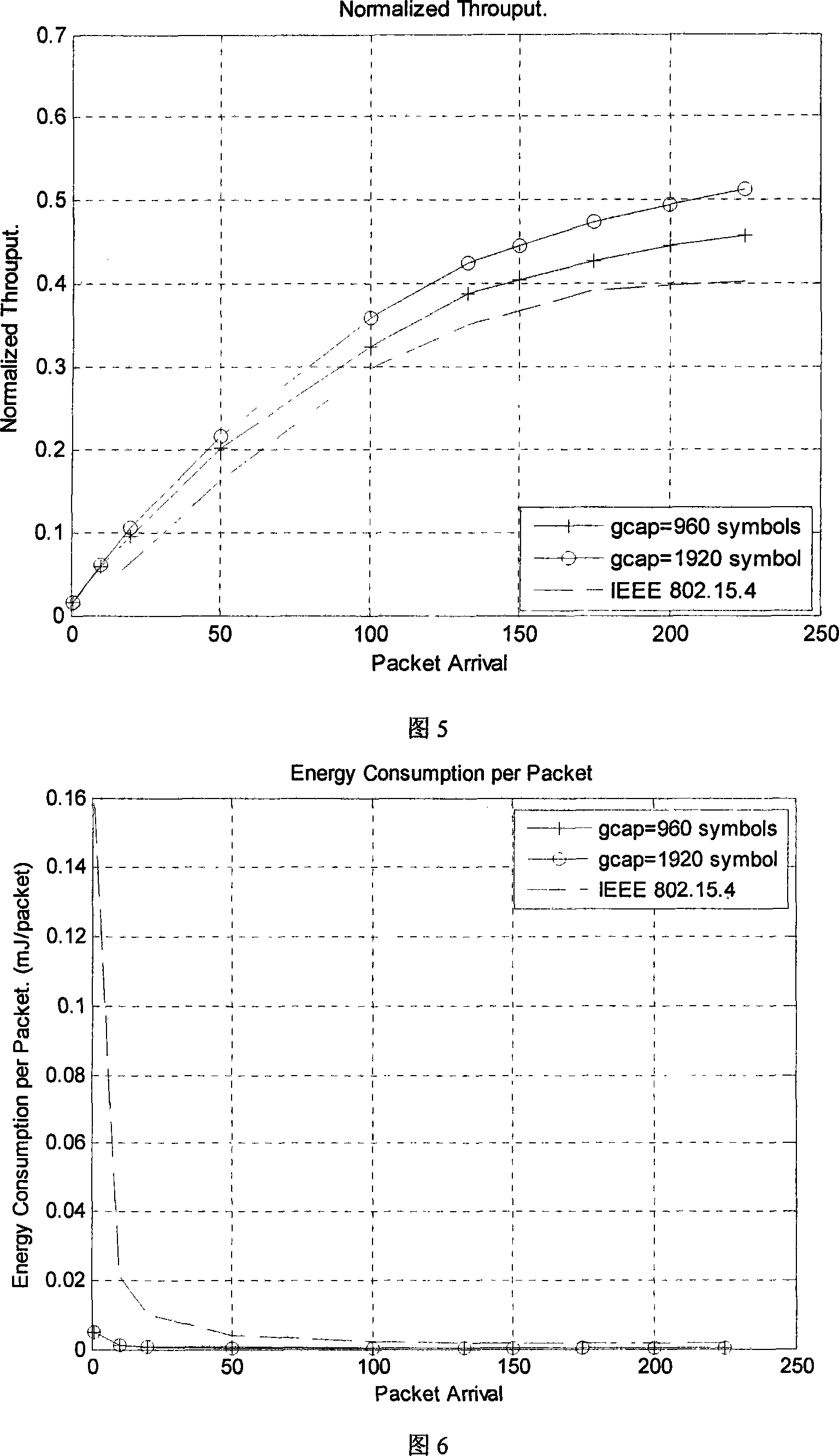

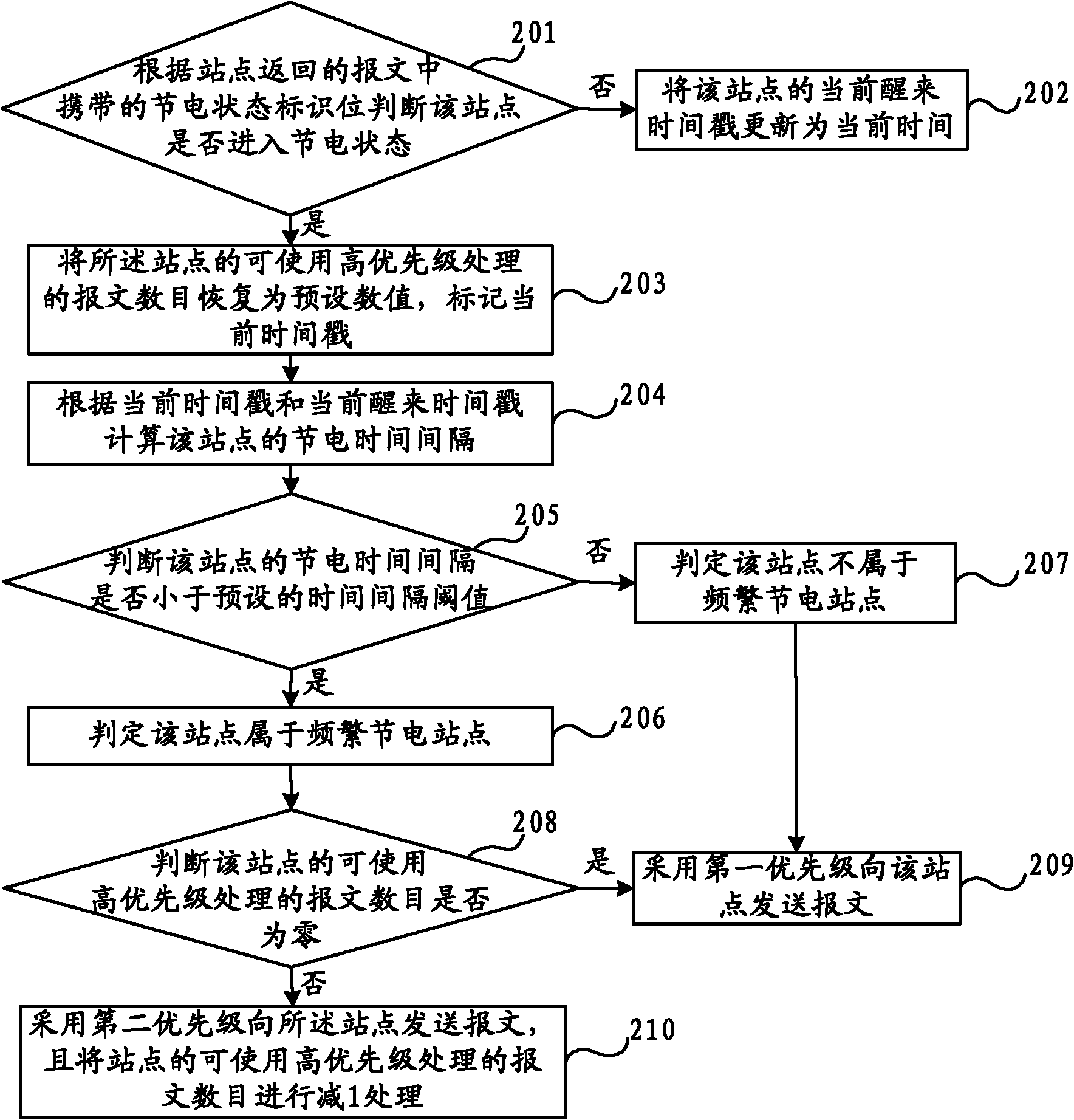

Method for competing access period multilevel collocation of distributed wireless sensor network

InactiveCN101227367AImprove energy efficiencyDoes not affect throughputData switching by path configurationCollocationWireless sensor networking

The invention relates to a process for accessing a distributed-type wireless transducer in a cycle multi-stage configuration, which is suitable for a series of novel distributed-type wireless transducer network such as environmental monitoring, military, national defence, industrial and agricultural production, city administration and the like. The method comprises dividing competitive access period in superframe to be several little second-grade competitive access period time slot, namely guaranteed competitive access periodic time (GCAP, Guaranteed CAP), and allocating a GCAP for each equipment for sending beacon. Every apparatus does not try a competitive access channel in self GCAP period, but opens self receiver as a coordinator in a star-shaped network, and the equipment waits data or data request which is sent from other equipment. During the period, data which reaches on the upper layer is put into the relative cache queue according to destination address. The invention can greatly improve energy-consumption efficiency of a system in the application occasion with small network load and low real-time request, which has very important operation significance.

Owner:SOUTHEAST UNIV

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143260AGood dissolution and removal effectImprove solubilitySemi-permeable membranesReverse osmosisCleaning methods

The invention relates to a cleaning agent composition, comprising an A agent and a B agent. The A agent and the B agent are stored independently. The A agent comprises citric acid, hydrochloric acid and trisodium nitrilotriacetate; and the B agent contains an anionic surfactant and a dispersing agent, wherein the anionic surfactant is C8-C16 alkylbenzene sulfonate; and the dispersing agent is a (methyl)acrylic homopolymer and / or a (methyl)acrylic acid copolymer. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. A cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

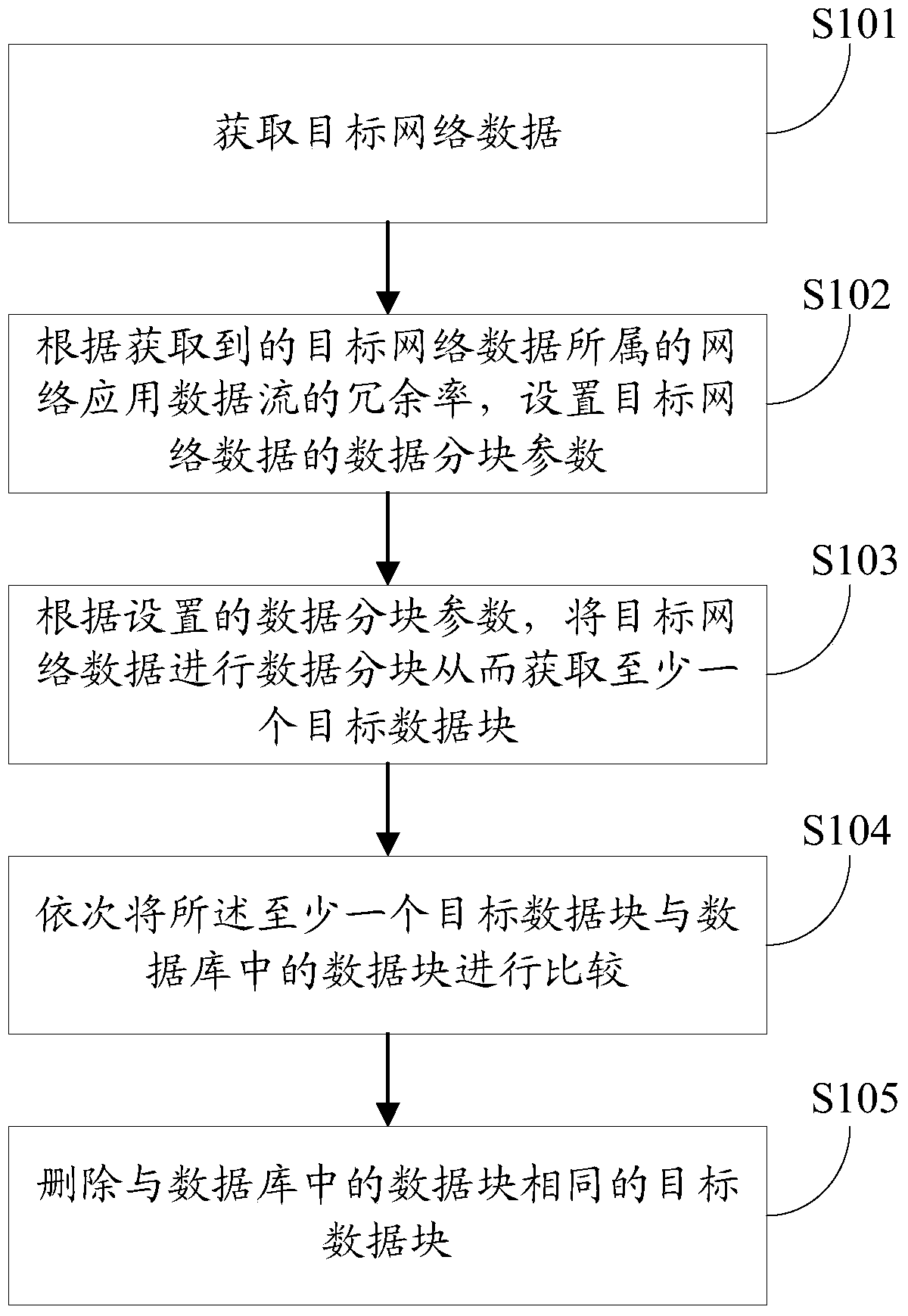

Data compression method, equipment and system

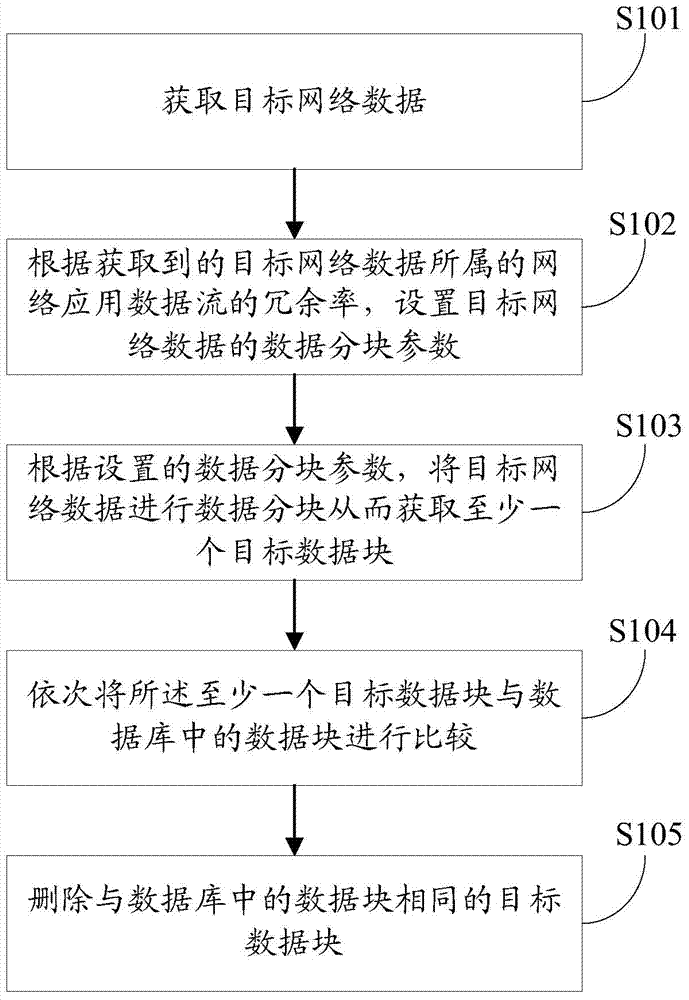

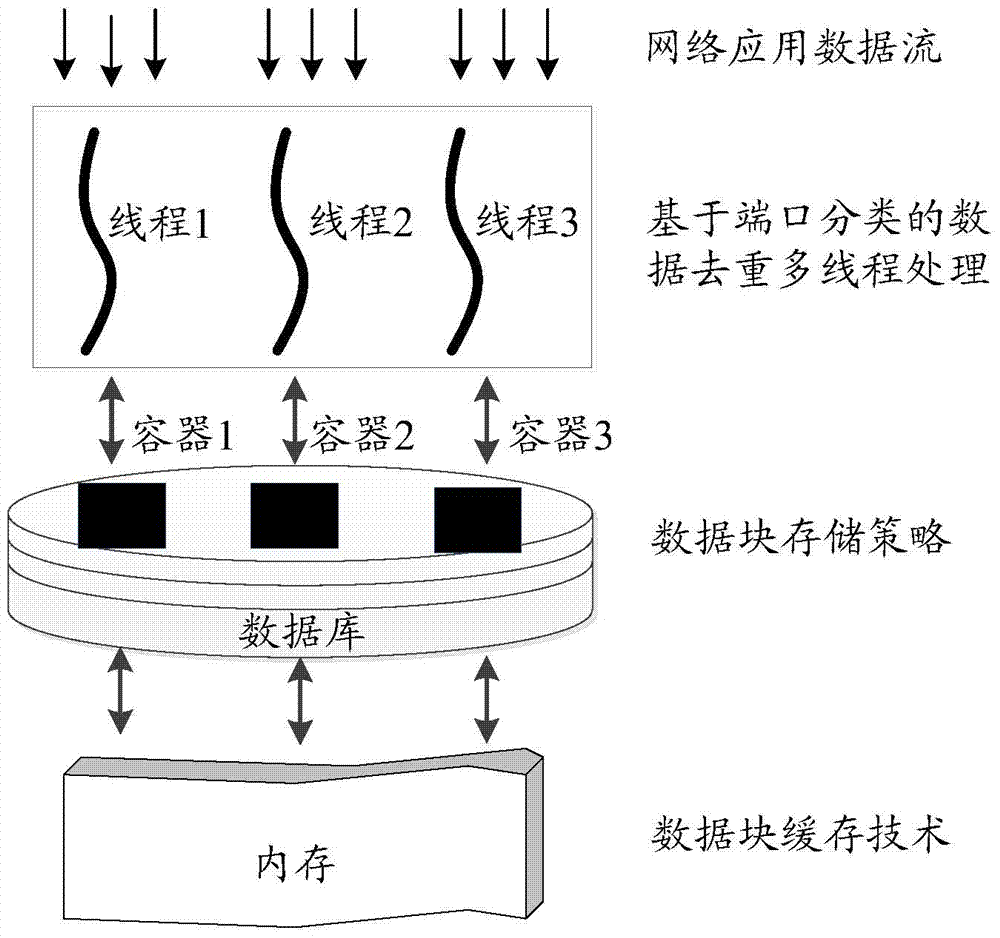

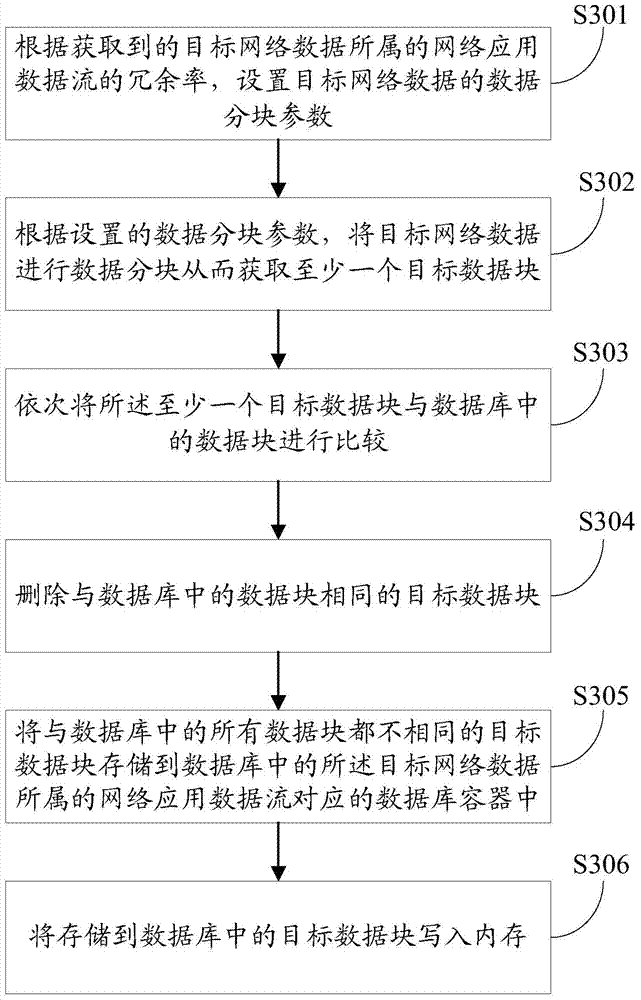

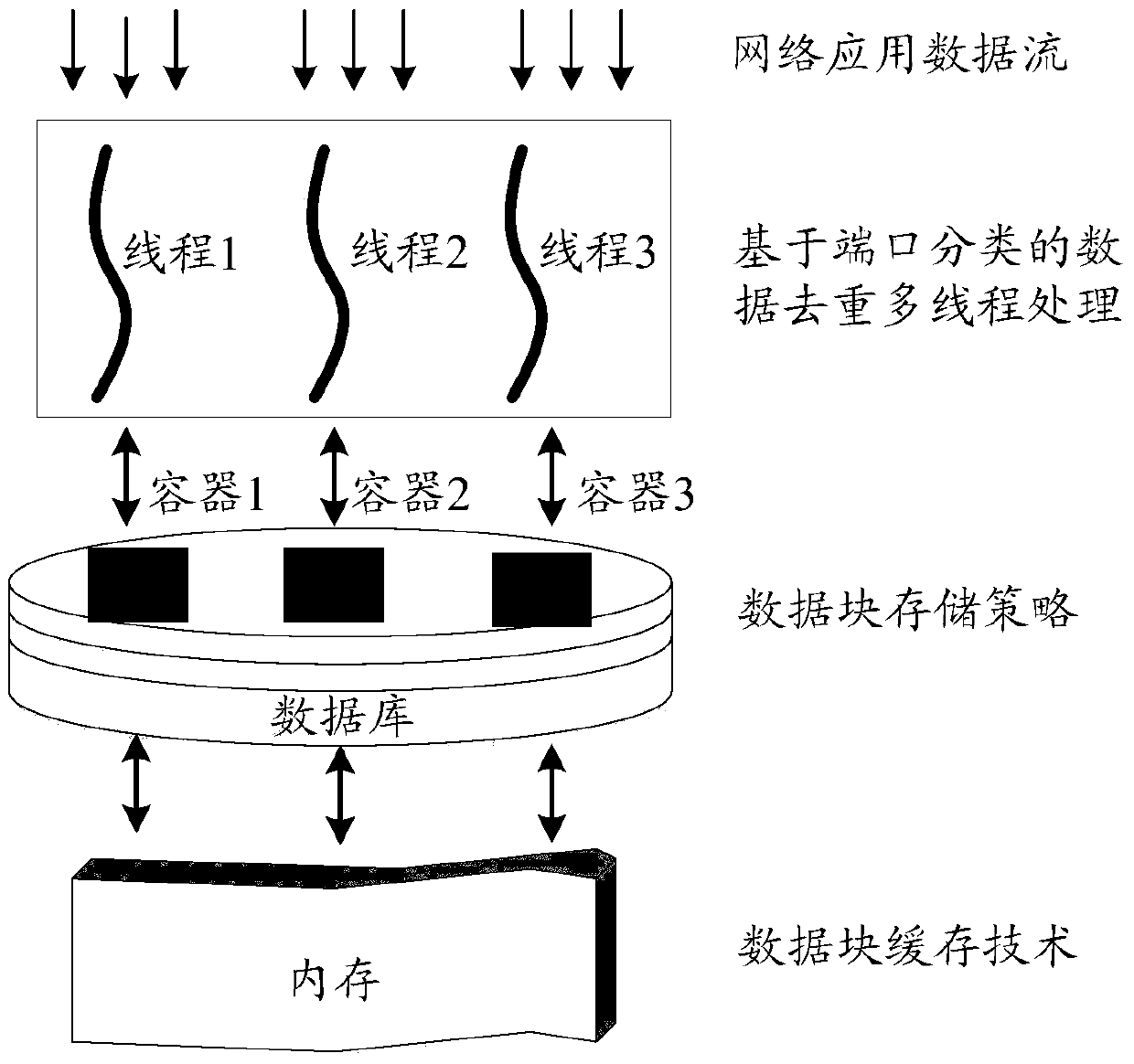

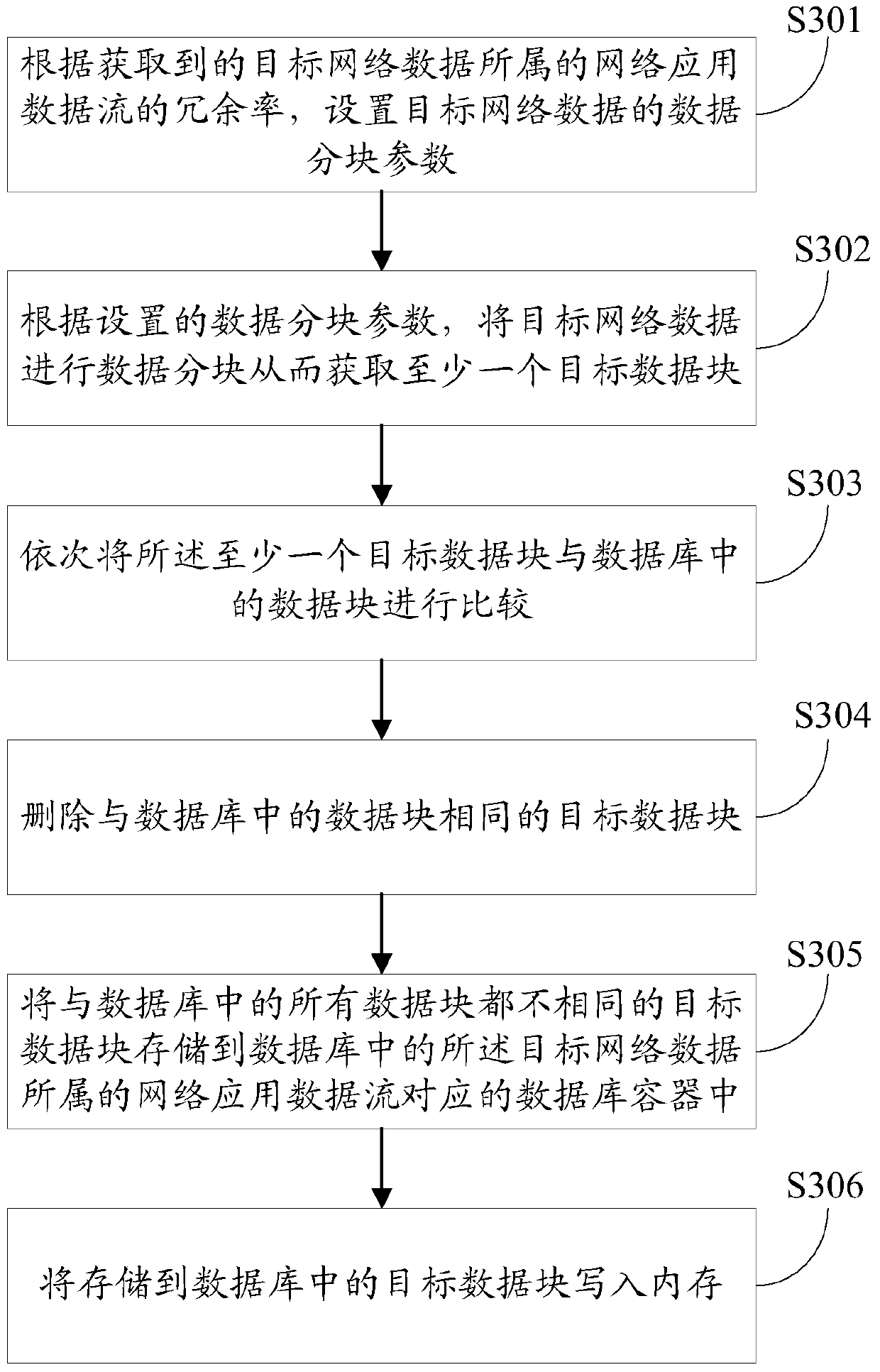

ActiveCN104753626AImprove weight removal rateDoes not affect throughputError preventionSpecial data processing applicationsData compressionData stream

The embodiment of the invention discloses a data compression method. The method comprises the following steps: acquiring target network data; setting a data segmentation parameter of the target network data according to the redundancy rate of a network application data stream to which the target network data belongs; performing data segmentation on the target network data according to the set data segmentation parameter to obtain at least one target data block; comparing the at least one target data block with data blocks in a database in sequence; and deleting the target data blocks which are the same as the data blocks in the database. The embodiment of the invention also discloses equipment and a system. The embodiment of the invention further discloses equipment and a system. Through adoption of the method, the equipment and the system, the data block partitioning granularity can be set according to the redundancy rate corresponding to the network application data stream, so that the data deduplication rate is increased under the situation of not influencing the throughput rate.

Owner:HUAWEI TECH CO LTD

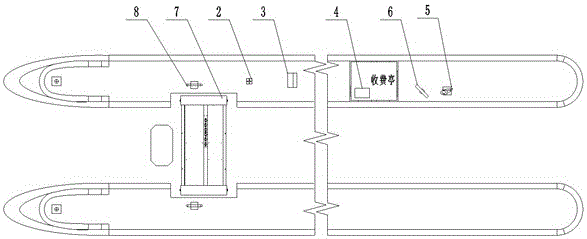

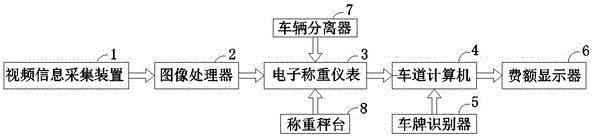

Vehicle type recognition and cheating diagnosis system based on video image technology

InactiveCN106441529APrevent weight evasionReduce the impactCharacter and pattern recognitionSpecial purpose weighing apparatusPattern recognitionVideo image

The invention belongs to the technical field of vehicle type recognition and weighing, and specifically relates to a vehicle type recognition and cheating diagnosis system based on a video image technology. The solved technical problem of the vehicle type recognition and cheating diagnosis system based on a video image technology is that provided is a vehicle type recognition and cheating diagnosis system which can utilize the video image technology to recognize the axle type and the tire type of a vehicle and can diagnose cheating behaviors, such as pound reducing, pound dragging and pound twisting of the vehicle. The vehicle type recognition and cheating diagnosis system based on a video image technology includes a video information acquisition apparatus, an image processor, a weighing platform, an electronic weighing meter and a lane computer, and is suitable for the technical field of traffic.

Owner:SHANXI WANLI TECH

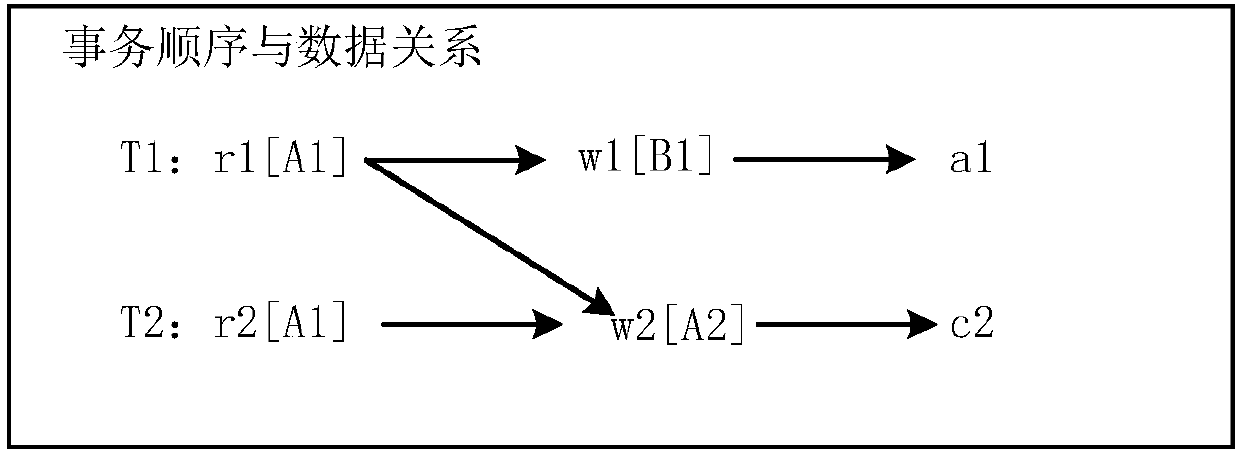

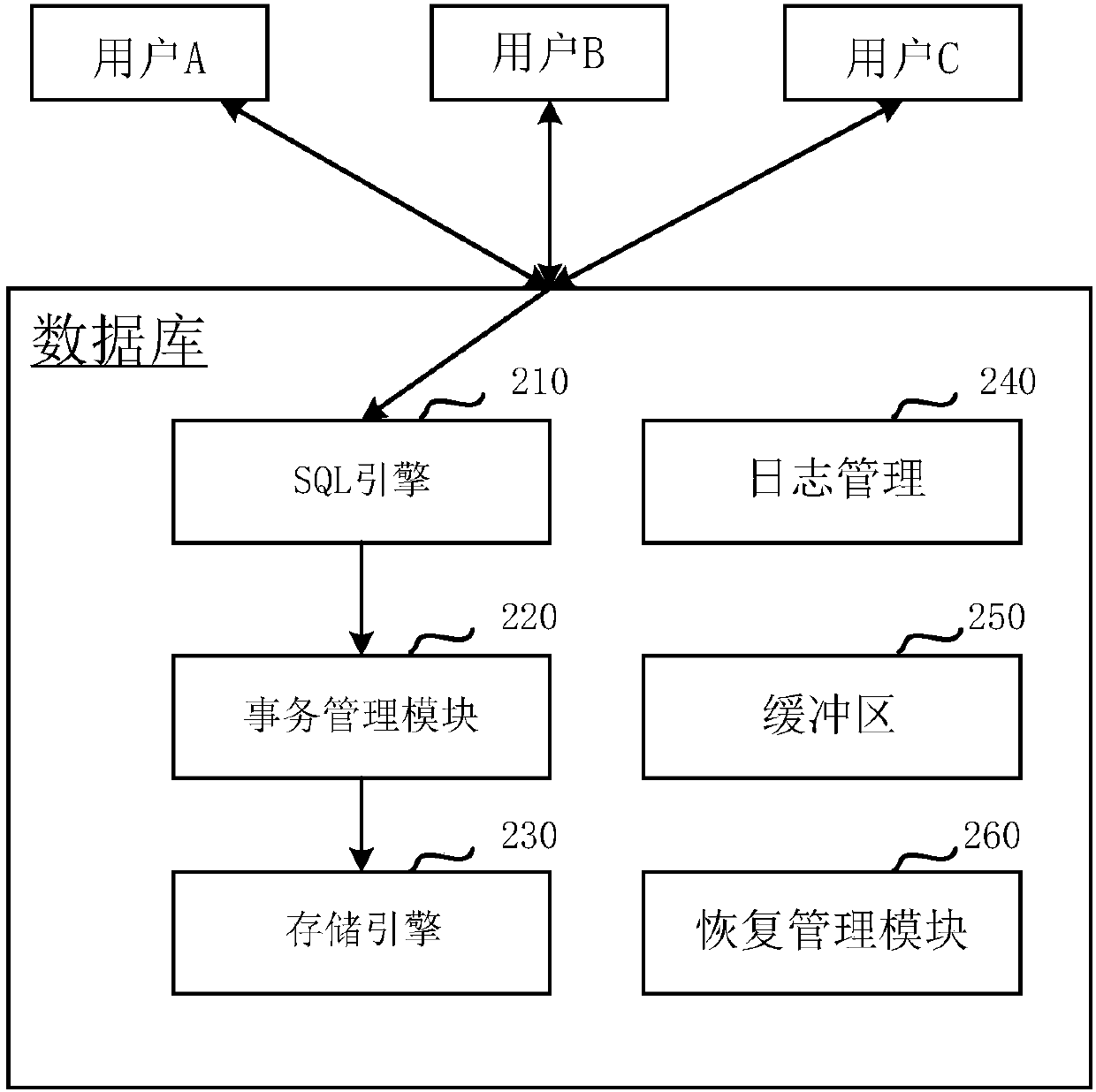

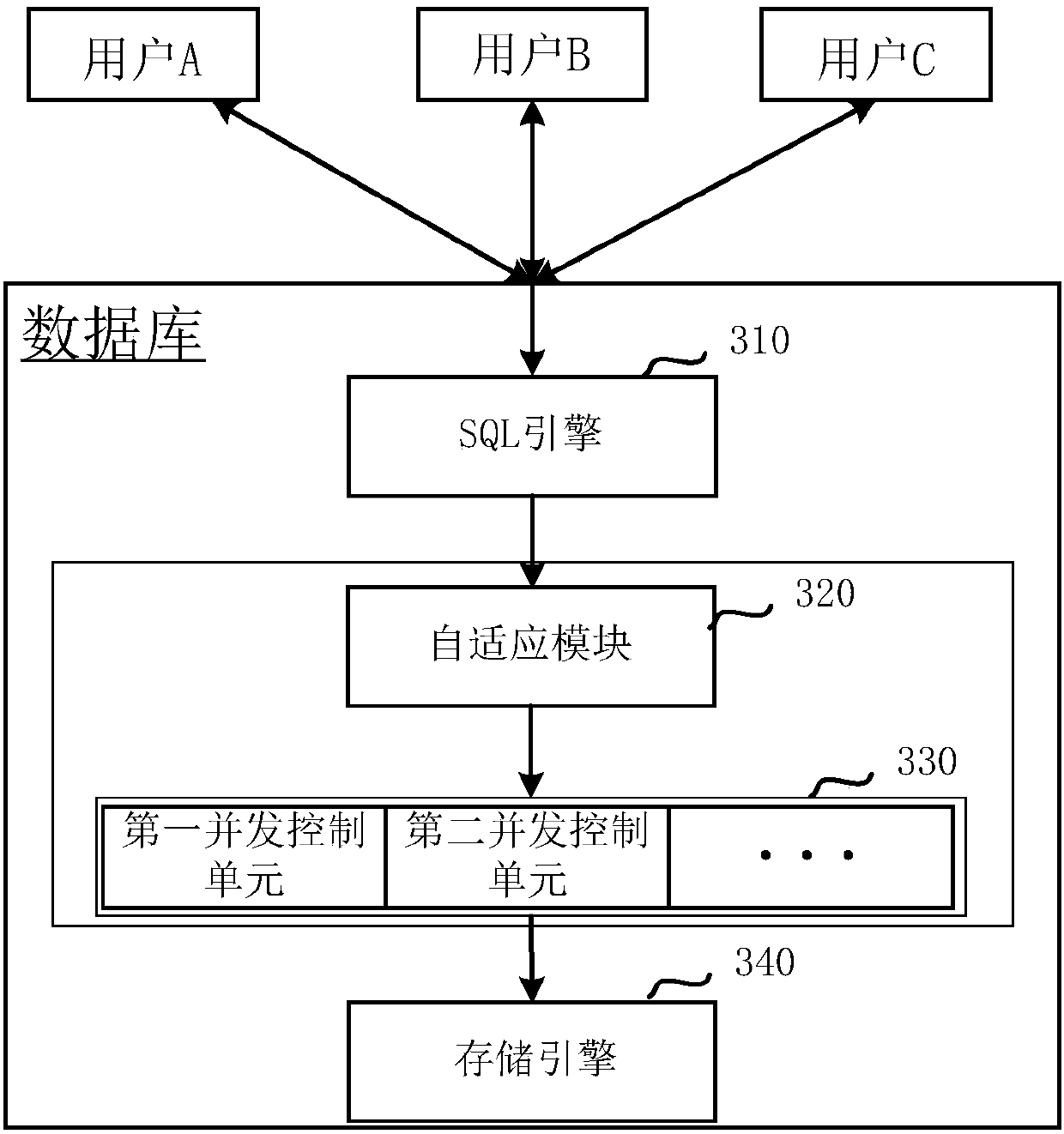

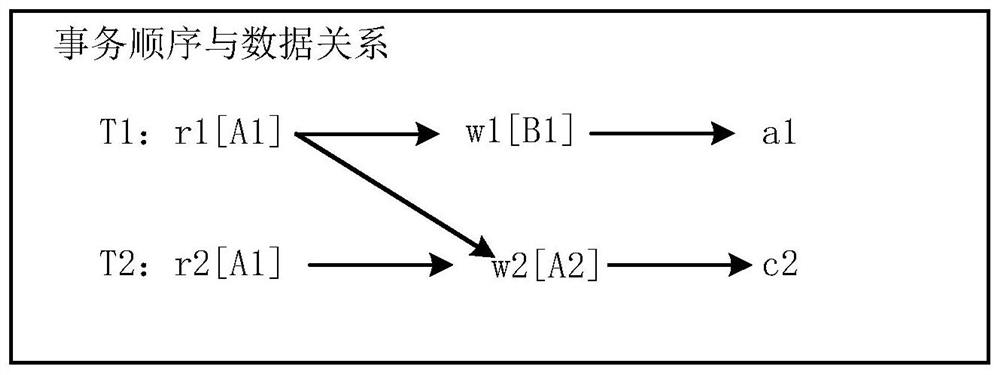

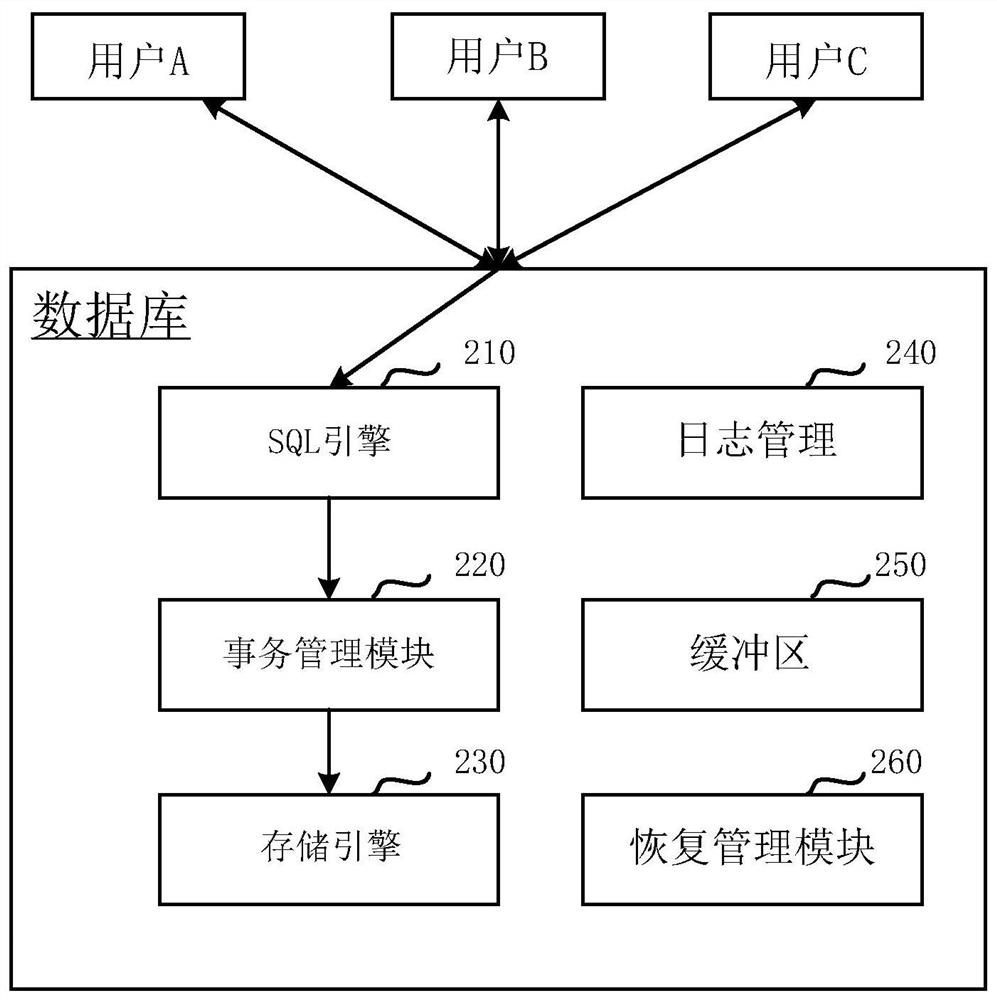

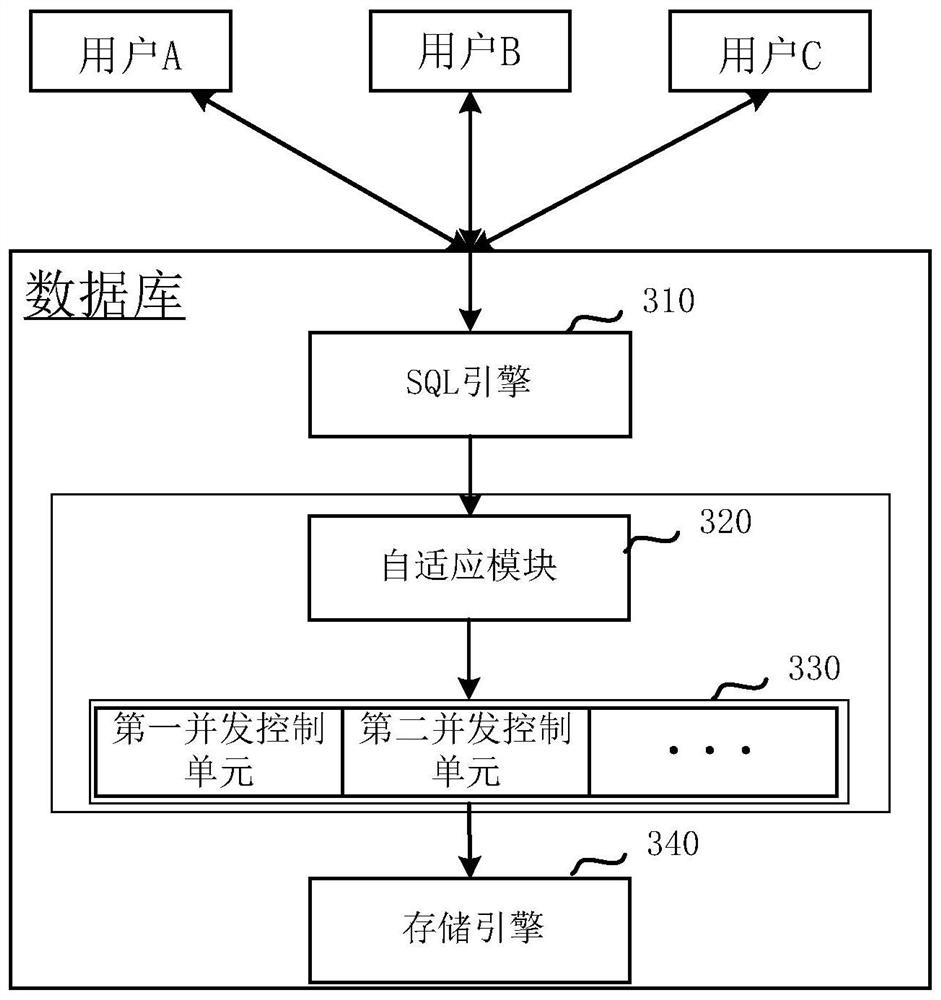

Database system and database access method

ActiveCN110019468ASolve the problem of tps dropDoes not affect throughputDatabase management systemsSpecial data processing applicationsData segmentConcurrency control

The embodiment of the invention discloses a database system and a database access method. The database system comprises: an SQL engine used for receiving a first transaction, wherein the first transaction comprises corresponding first data; a switching unit which is used for determining the heat degree of the first data segment, wherein the first data segment is a database data segment in which first data falls when the first transaction is executed, and the heat degree of the first data segment is the transaction number of all operations occupied by the transaction number cancelled in unit time on the history of the first data segment; a concurrency control selection unit which is used for selecting the first concurrency control unit when the heat degree of the first data segment is greater than a first threshold value; a first concurrency control unit which is used for determining whether a second transaction exists or not, and executing the first transaction when the second transaction does not exist, wherein the data read by the first transaction is the data written by the second transaction, and the data writing time of the second transaction is later than the data reading time of the first transaction.

Owner:HUAWEI TECH CO LTD

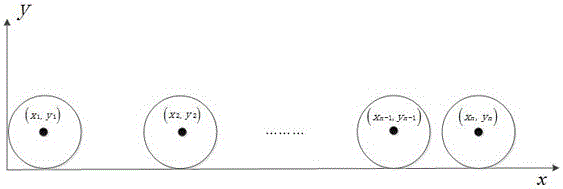

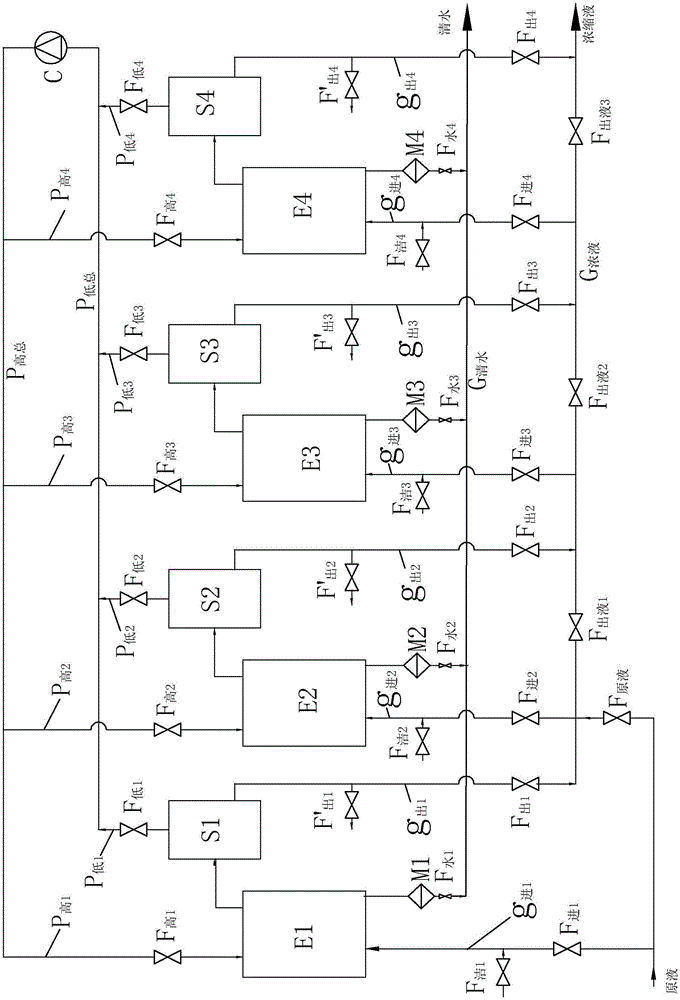

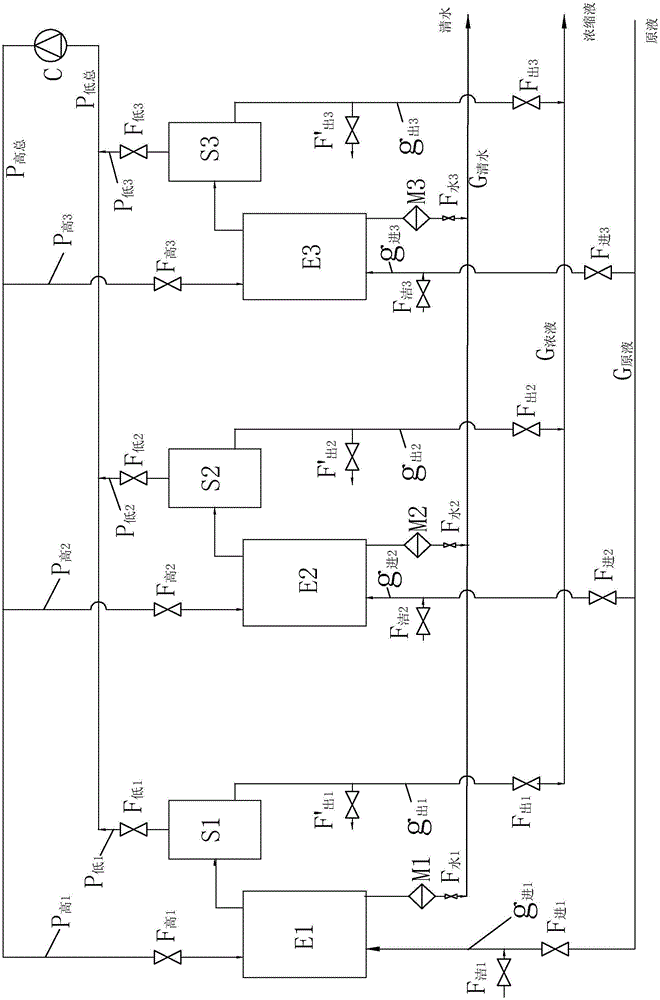

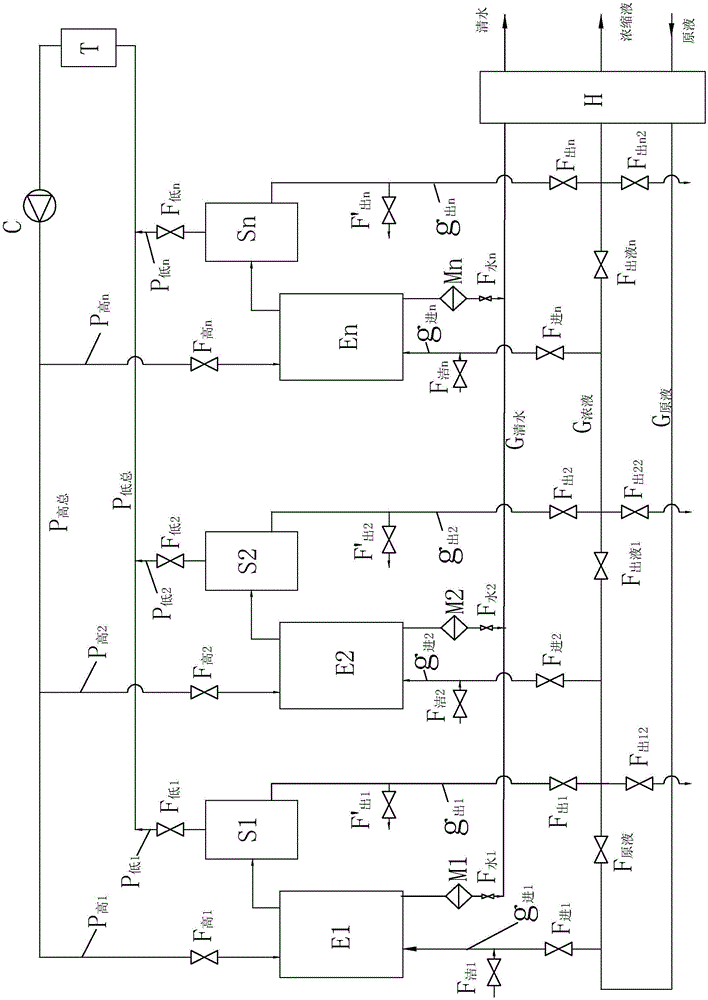

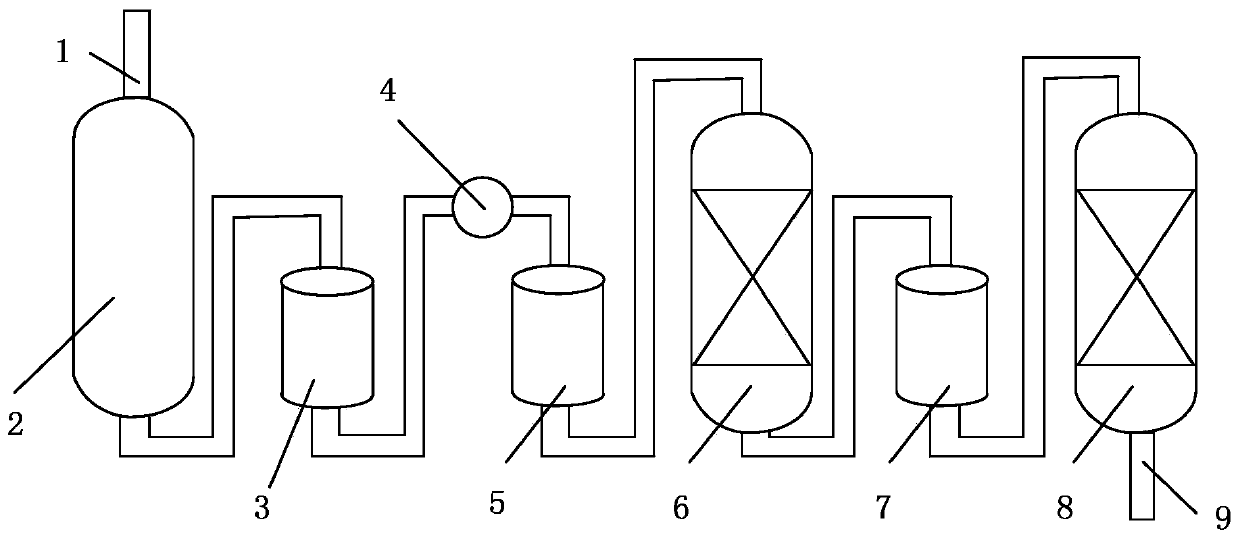

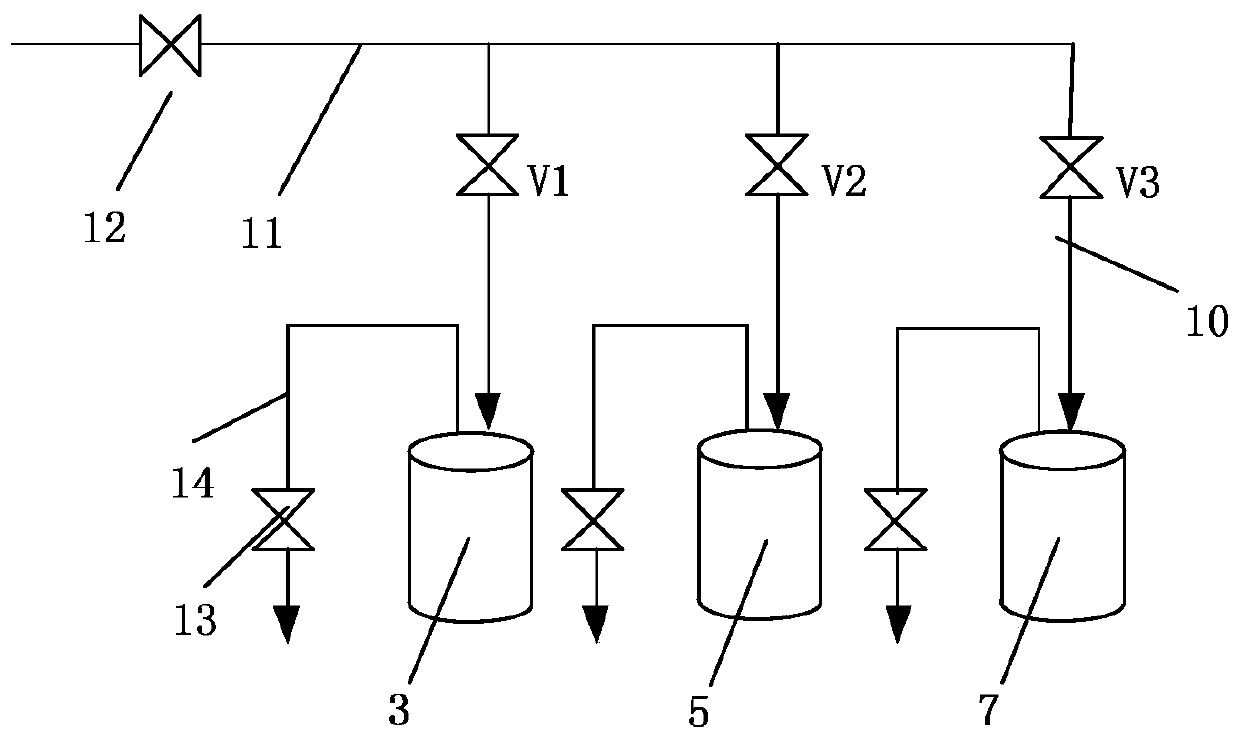

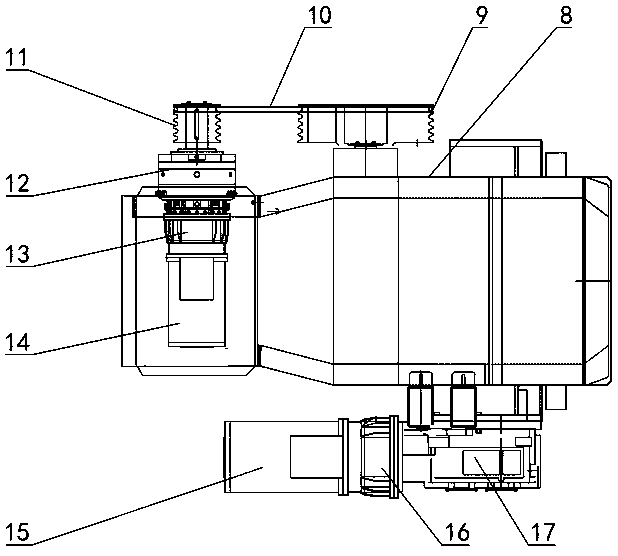

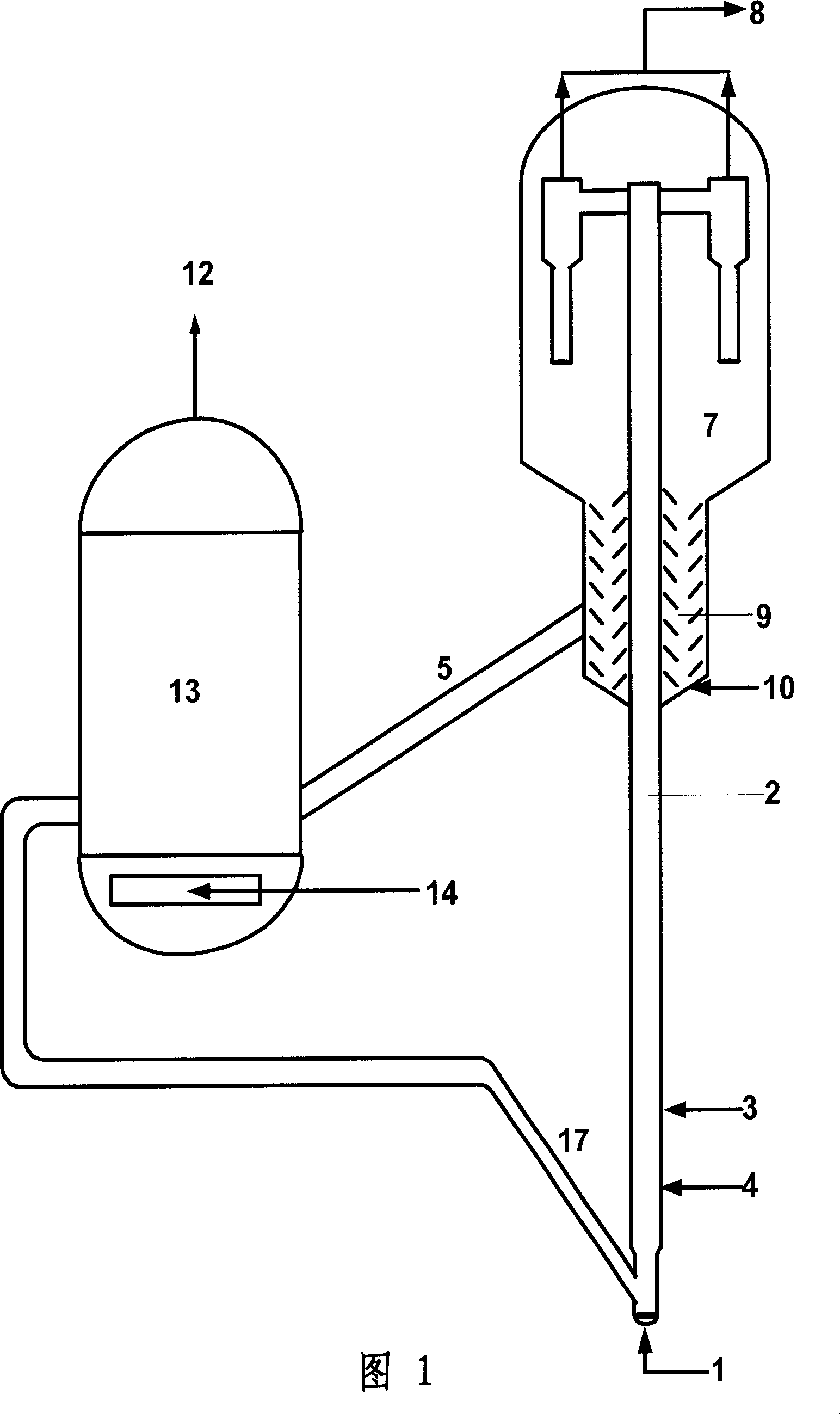

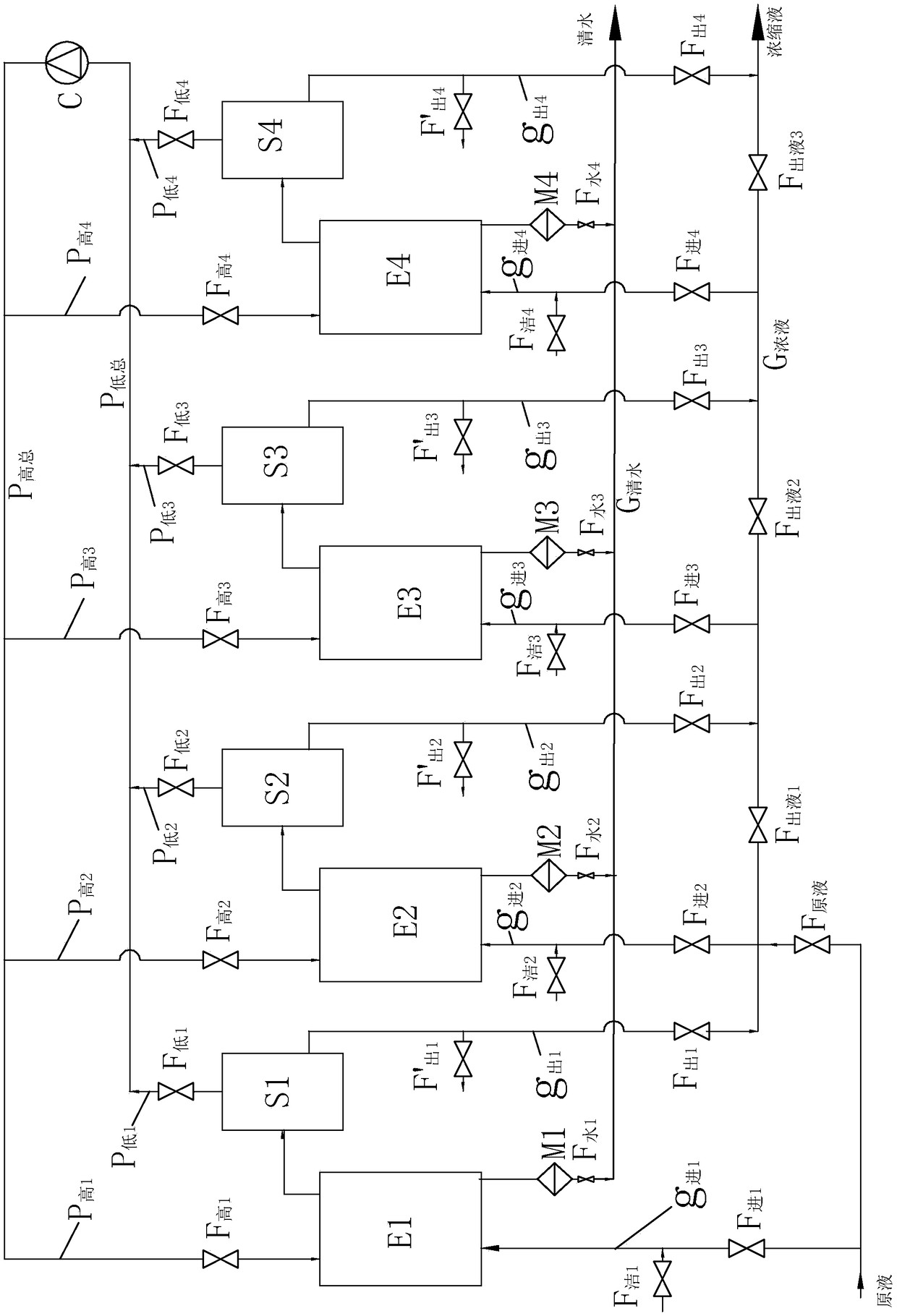

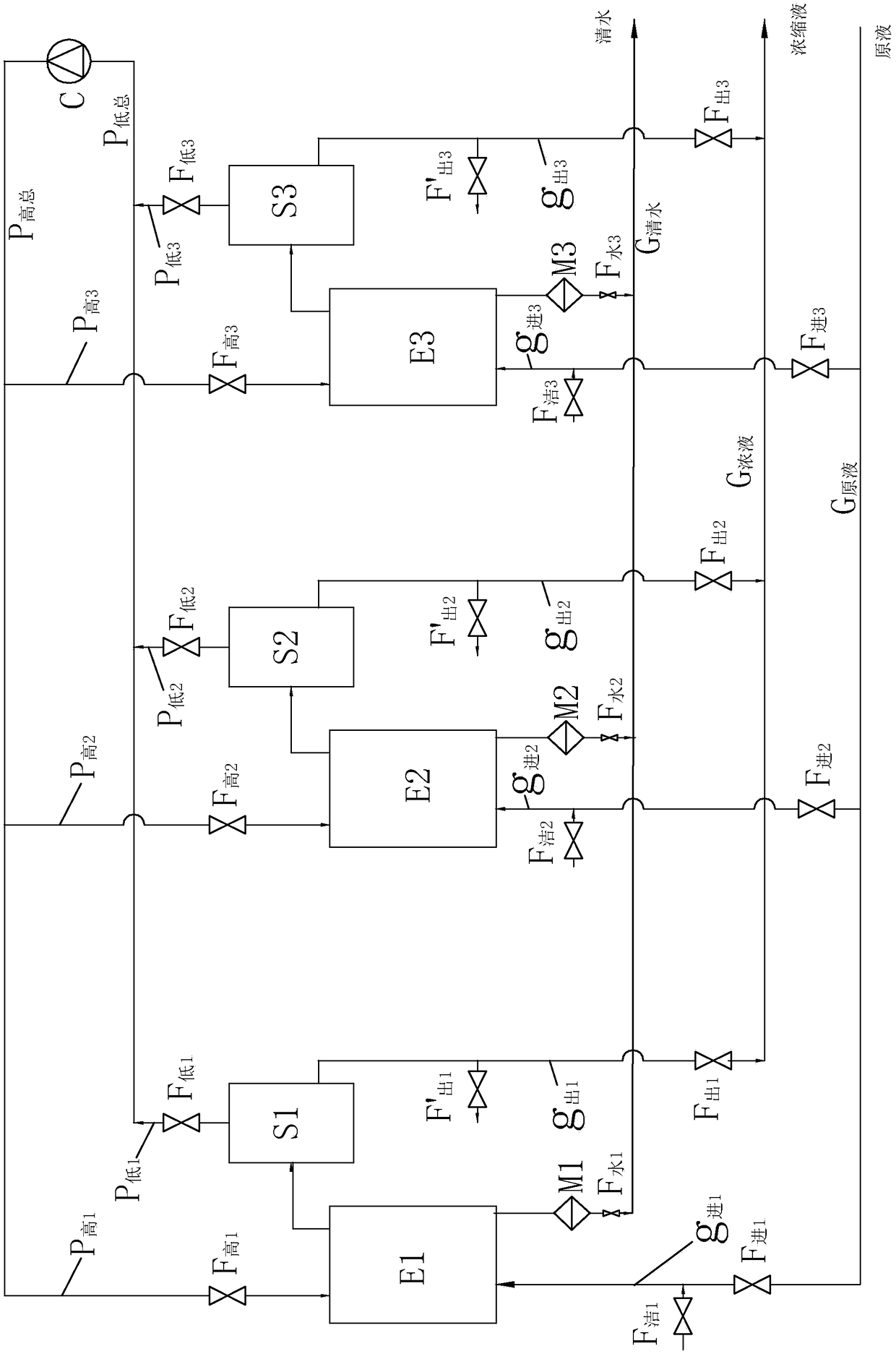

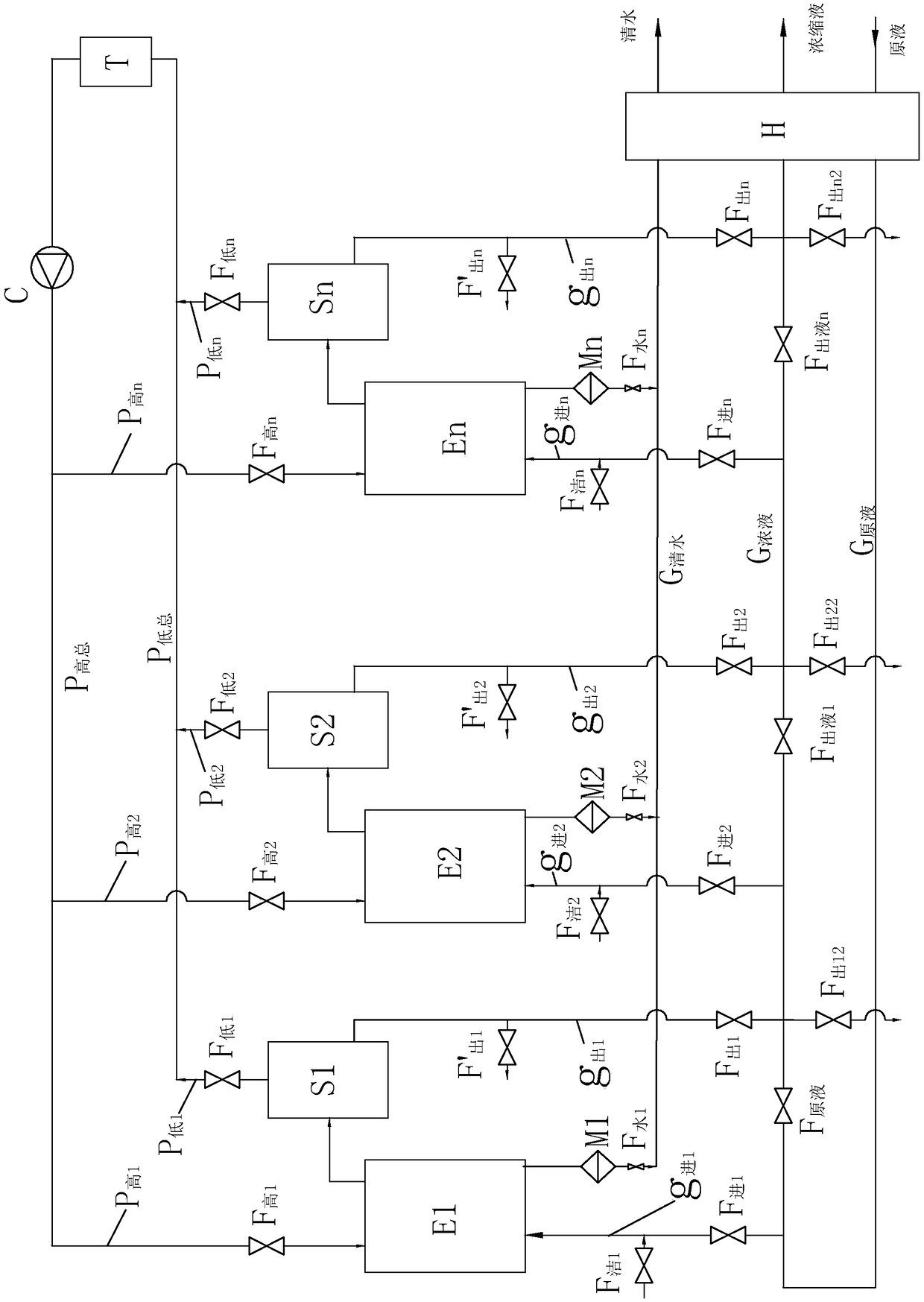

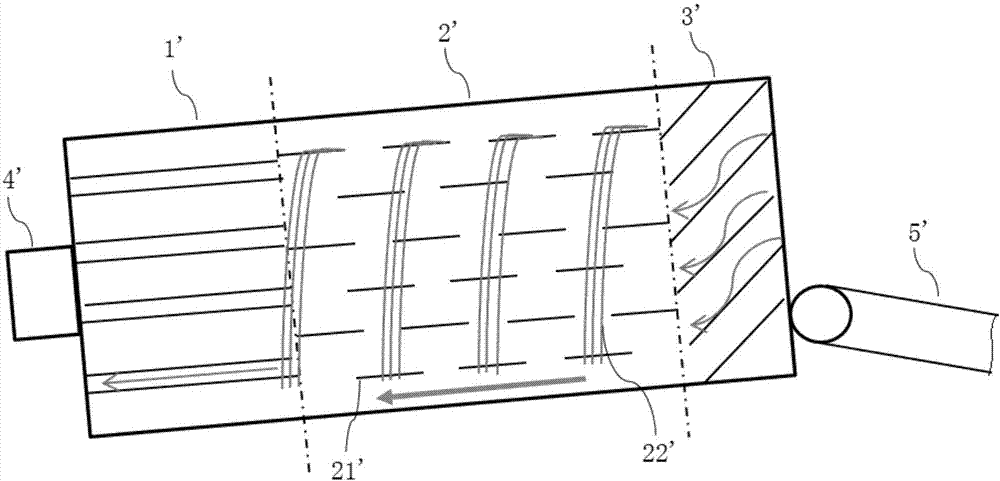

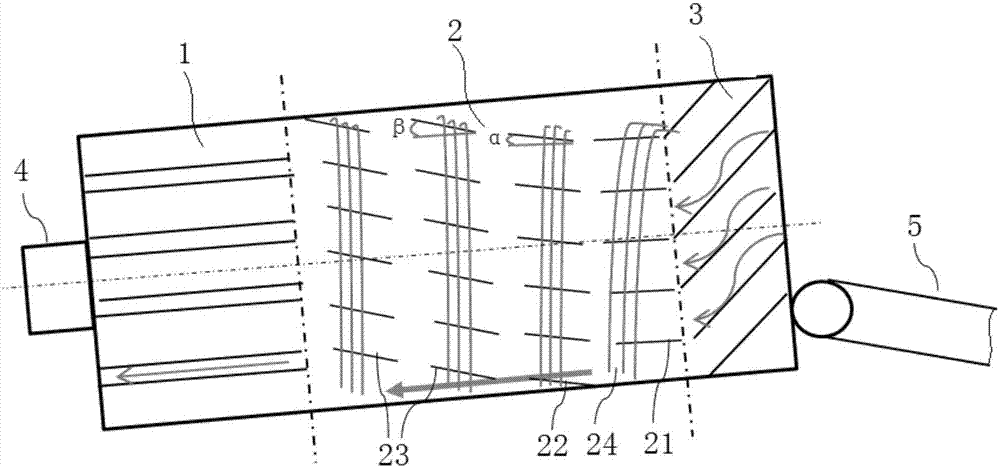

Evaporating system capable of conducting online descaling and working continuously and evaporating process

ActiveCN105999750AGuaranteed uptimeReduce the number of timesEvaporation with vapour compressionEvaporator regulation/controlEvaporationEngineering

The invention discloses an evaporating system capable of conducting online descaling and working continuously and an evaporating process. The evaporating system comprises n evaporating units, each evaporating unit is composed of an evaporator E and a steam-water separation mechanism S, the n evaporating units are connected in a feed liquor series-connection or parallel-connection evaporation mode to form the complete evaporating system, secondary steam generated by the n evaporating units shares one steam compression machine for pressurization and temperature raising, and a high-temperature steam main pipe is connected out of the steam compression machine and connected to high-temperature steam inlet pipes on the evaporating units in parallel; a liquid inlet pipe of the second-level / set evaporating unit is simultaneously connected with the first-level / set concentrate outlet pipe and a stoste inlet pipe; a concentrate main pipe is arranged, all the evaporating units except the first level / set evaporating unit are connected with the concentrate main pipe, the concentrate main pipe segment between the liquid inlet pipe and the concentrate output pipe of each evaporating unit is provided with a concentrate valve, valves on related inlet pipes and outlet pipes are controlled to isolate the evaporating units to be cleaned, and evaporating work of the system is not affected.

Owner:广州中科鑫洲科技有限公司 +1

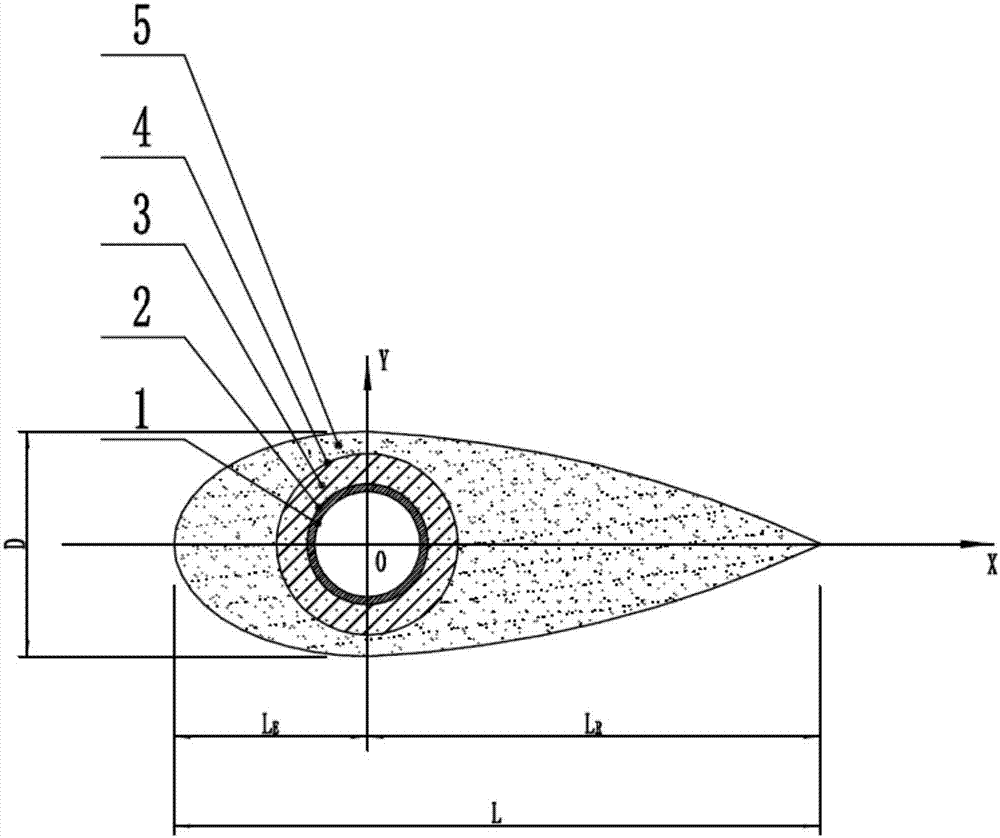

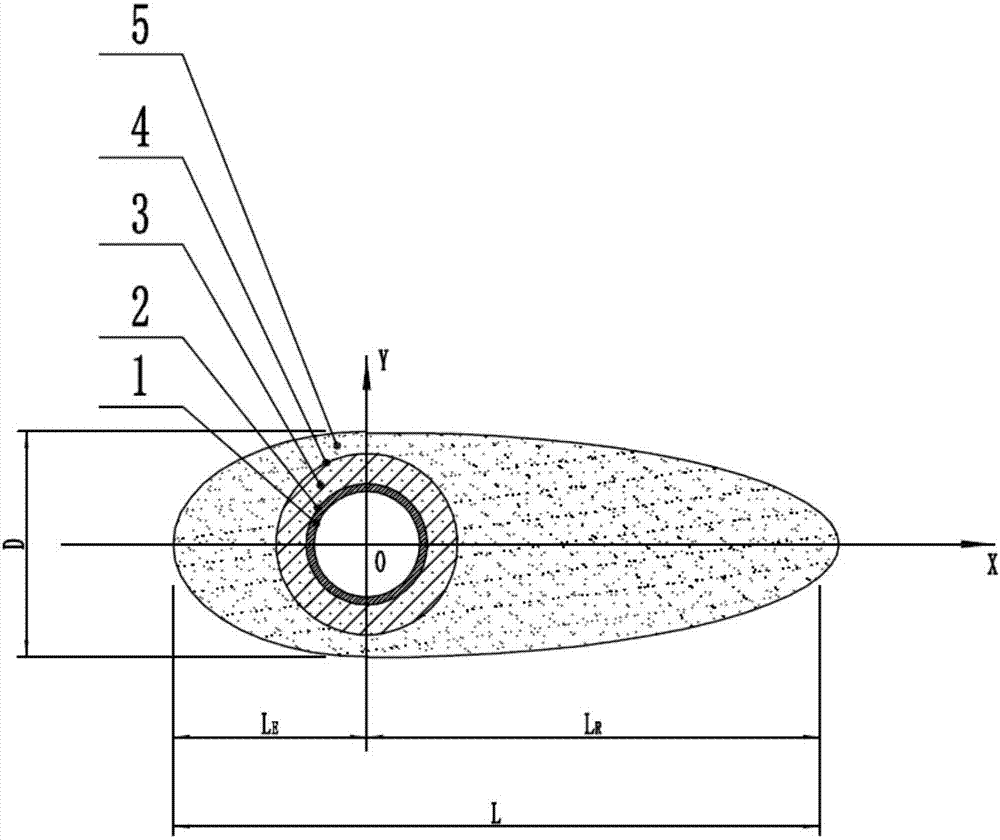

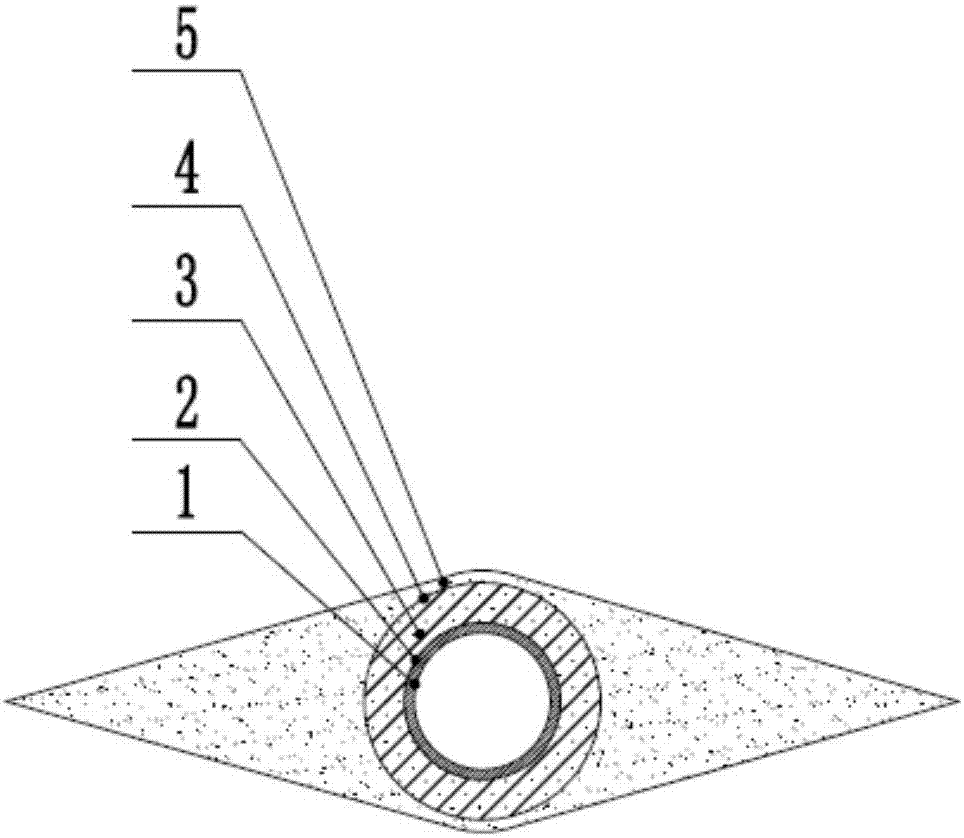

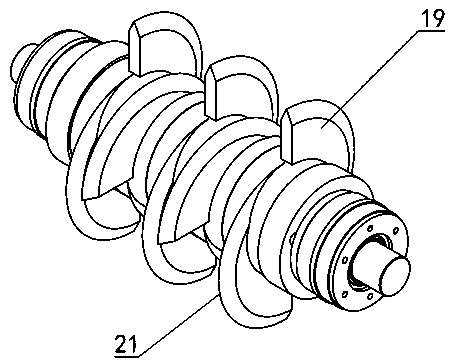

Streamlined energy pipeline capable of relieving submarine landslide impact

PendingCN107091379AAvoiding the Risk of ResonanceImprove the protective effectSynthetic resin layered productsCoatingsOcean bottomResonance

The invention belongs to the technical field of production of submarine energy pipelines, and relates to a streamlined energy pipeline capable of relieving submarine landslide impact. A streamlined type is applied to a concrete weight coating on the outermost part of the traditional submarine pipeline structure, the interior structure of the traditional energy pipeline is retained, the cross section of the energy pipeline is streamlined, and except a concrete layer, other layers are consistent to a current engineering standard. The drag force and the lift force on the pipeline can be obviously smaller than the drag force and the lift force on the traditional pipeline with a circular cross section, the impact effect of submarine landslide is reduced effectively, meanwhile, a continuous oscillating lift force is transformed into a stabilizing effect, the risk of resonance of the pipeline is prevented effectively, and the disaster reduction effect is remarkable; and by the design, the disaster reduction effect on accidental load such as submarine landslide is good, and the protection effect on environmental load of flowing bodies such as bottom flow and sand wave is also good. In addition, the streamlined energy pipeline capable of relieving submarine landslide impact does not affect delivery amounts of oil, gas and water in current engineering, a production process of the pipeline does not need to be changed on a large scale either, and therefore, popularization and actual application are facilitated.

Owner:DALIAN UNIV OF TECH

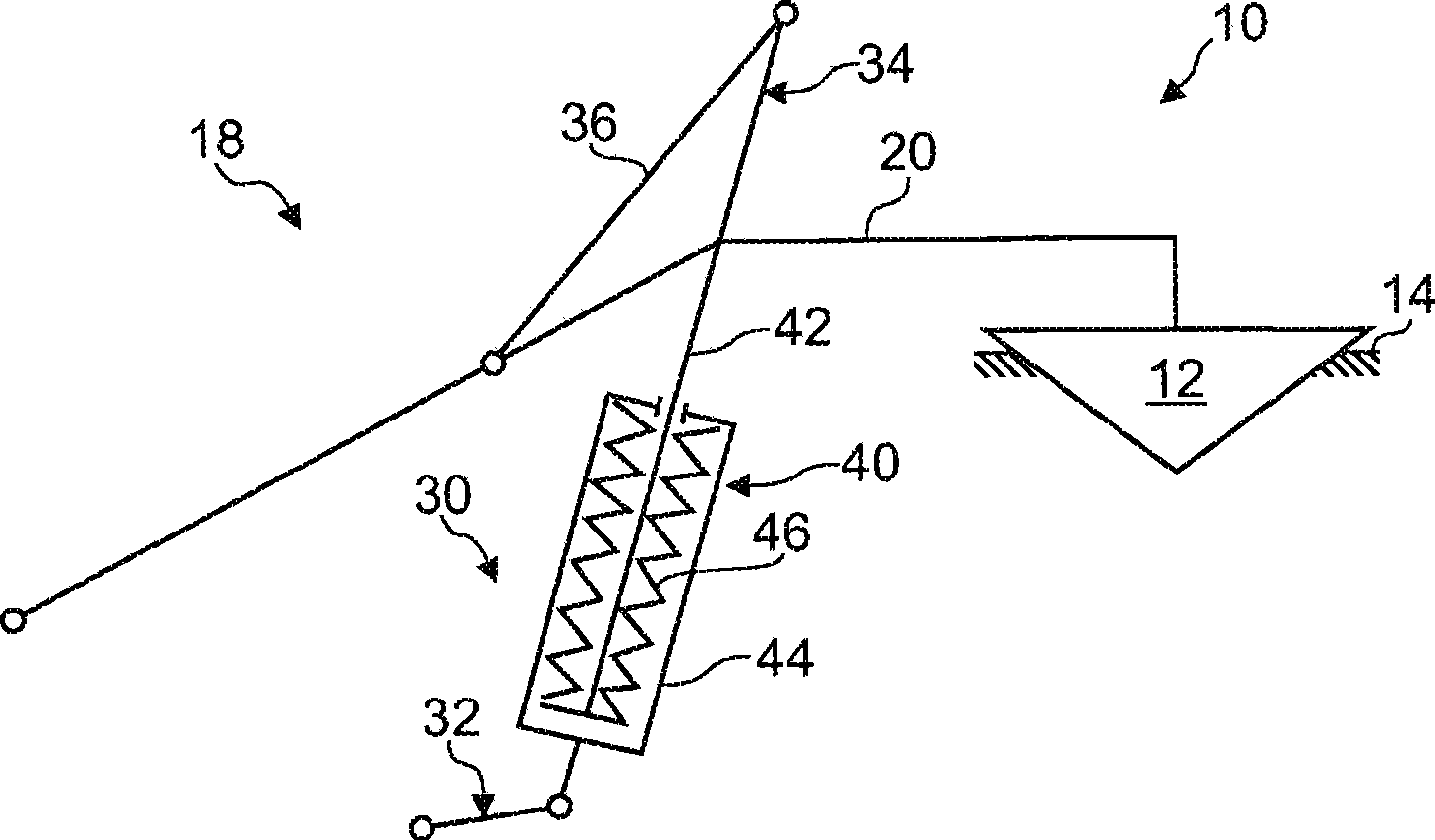

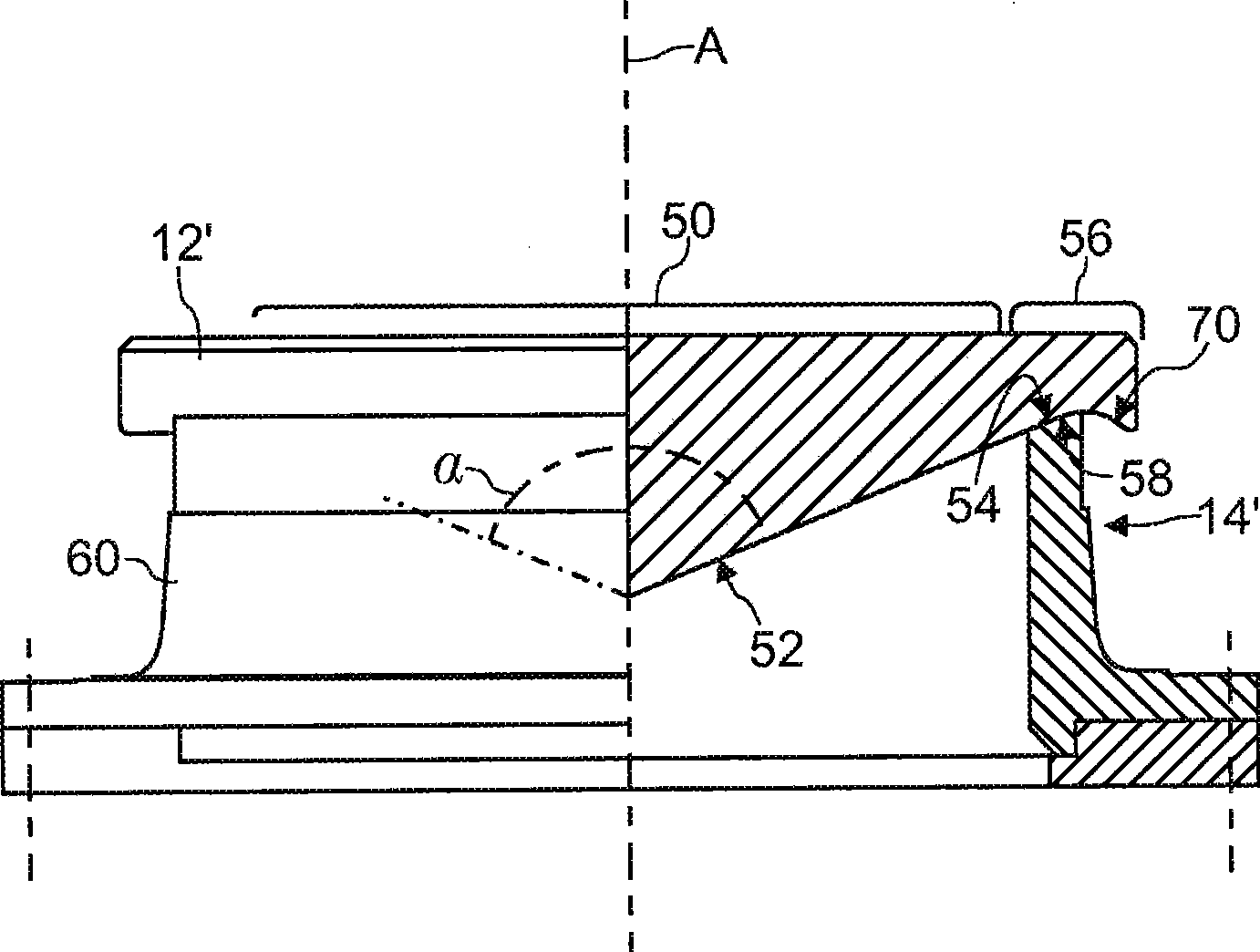

Bleeder valve for pressurised furnace

ActiveCN101379199ADoes not affect throughputImprove throughputOperating means/releasing devices for valvesEqualizing valvesElevation angleShaft furnace

A bleeder valve for controlling a gas outflow from the interior of a pressurized furnace to the ambient atmosphere through an exhaust conduit is proposed. The bleeder valve comprises a valve seat associated with the exhaust conduit, a movable closure member having a generally convex central closure surface and a peripheral sealing surface cooperating with the valve seat, and an actuating mechanism which is connected to the closure member for moving the closure member between a closed position on the valve seat and an open position distant from the valve seat. According to an important aspect, the closure member comprises a recurved deflection surface with an elevation angle between 30 to 70 degrees at the periphery of the peripheral sealing surface, the recurved deflection surface being shaped so as to impart to a gas outflow passing between the valve seat and the closure member a velocity component which is opposite to the initial opening movement of the closure member.

Owner:PAUL WURTH SA

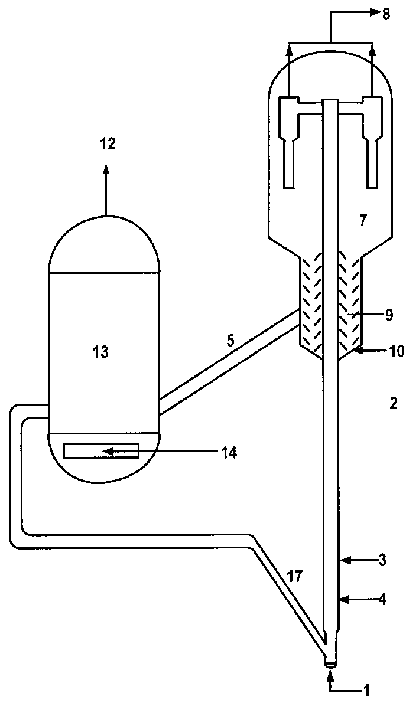

Process for online increase of chill pipeline to refined-desulfurization pre-hydrogenation catalyst

InactiveCN110684570ADoes not affect throughputAvoid parking vulcanization problemsGaseous fuelsPtru catalystPhysical chemistry

The invention discloses a process for online increase of a chill pipeline to a refined-desulfurization pre-hydrogenation catalyst. The process comprises a heater, a hydrogenation pre-convertor, a primary hydrogenation convertor, a primary zinc oxide desulfurizer, a secondary hydrogenation convertor, a secondary zinc oxide desulfurizer and a chill header pipe, wherein the heater, the hydrogenationpre-convertor, the primary hydrogenation convertor, the primary zinc oxide desulfurizer, the secondary hydrogenation convertor and the secondary zinc oxide desulfurizer are arranged sequentially, andthe chill header pipe is used for conveying chill coal gas; and a plurality of branch pipes are arranged on the chill header pipe, and the other end of each branch pipe is separately introduced to a trough inlet of the hydrogenation pre-convertor, a trough inlet of the primary hydrogenation convertor and a trough inlet of the secondary hydrogenation convertor so as to control a temperature of a bed layer. According to the process, through increasing a coal gas chill header pipe at the trough inlets of the hydrogenation convertors, the catalyst bed layer is liable to overtemperature during curing or new trough pouring of a replaced raw catalyst, added chill coal gas is used for cooling the catalyst bed layer when the temperature of the bed layer rises too fast, so that the problem of shutdown curing is avoided, online curing is achieved, the production output of LNG (Liquefied Natural Gas) is not affected, and production loss is reduced.

Owner:INNER MONGOLIA HENGKUN CHEM CO LTD

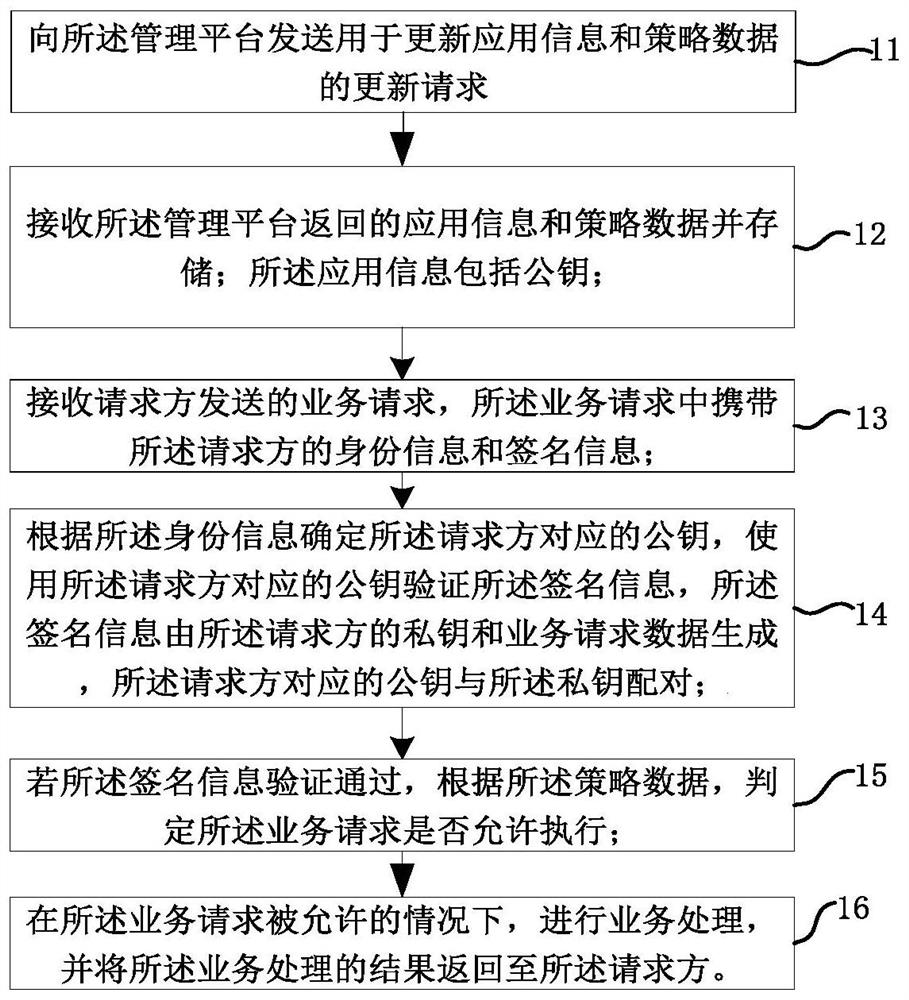

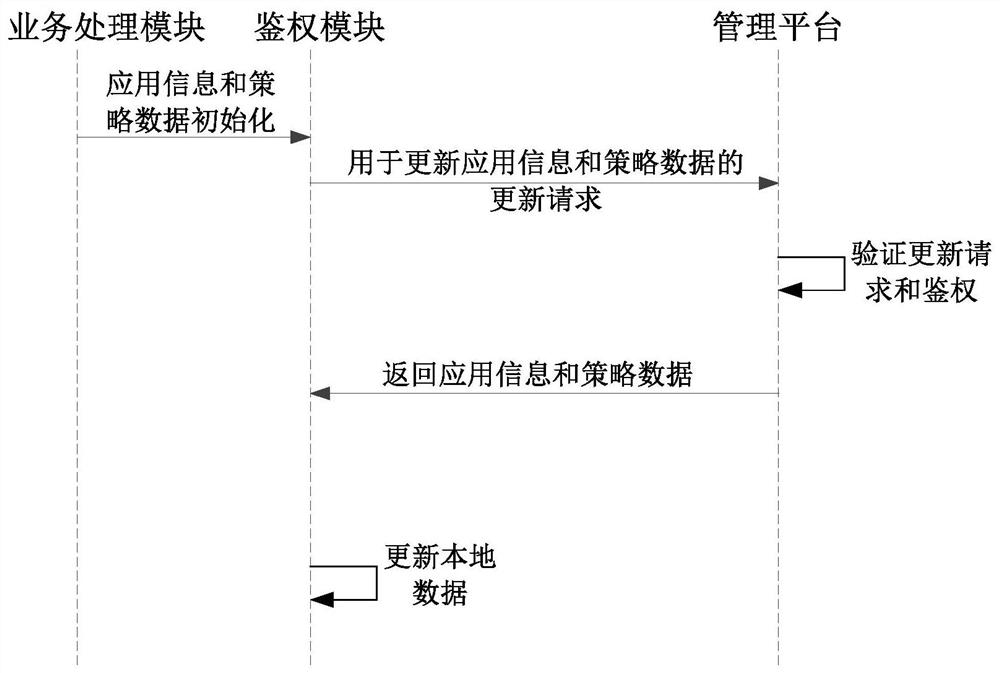

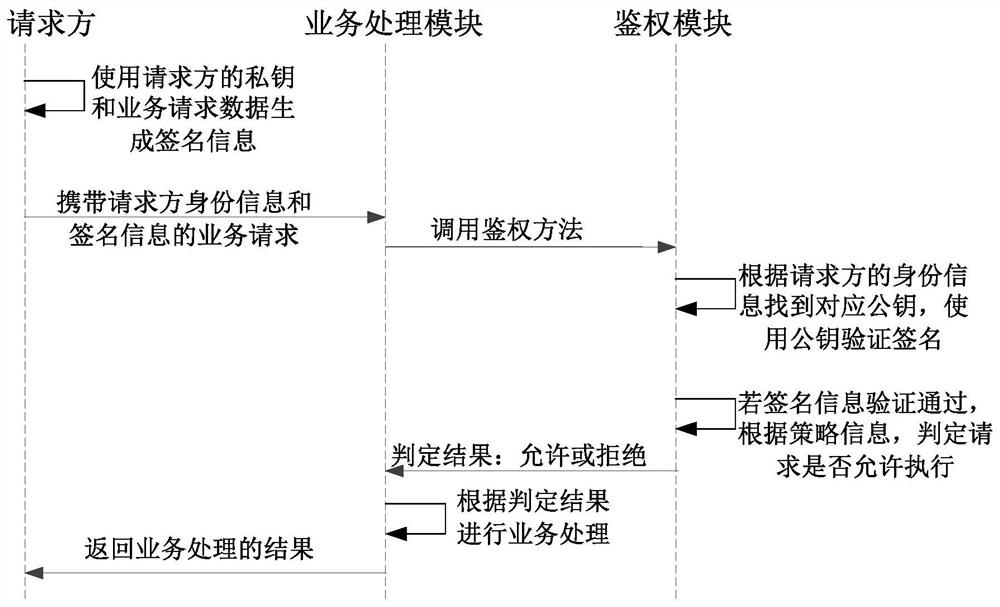

Authentication method and device, electronic equipment and readable storage medium

InactiveCN111901321AAvoid Performance Bottleneck SituationsReduce operation and maintenance costsUser identity/authority verificationEngineeringAuthentication

The invention provides an authentication method and device, electronic equipment and a readable storage medium. The method comprises the steps of sending an update request for updating application information and policy data to a management platform; receiving and storing application information and strategy data returned by the management platform; wherein the application information comprises apublic key; receiving a service request sent by a requester, wherein the service request carries identity information and signature information of the requester; determining a public key correspondingto the requester according to the identity information, verifying the signature information by using the public key corresponding to the requester, the signature information being generated by a private key of the requester and the service request data, and the public key corresponding to the requester being paired with the private key; if the signature information passes the verification, judging whether the service request is allowed to be executed or not according to the strategy data; and under the condition that the service request is allowed, performing service processing, and returninga service processing result to the requester. The problem that centralized authentication has a performance bottleneck under the condition of high flow is solved.

Owner:云账户技术(天津)有限公司

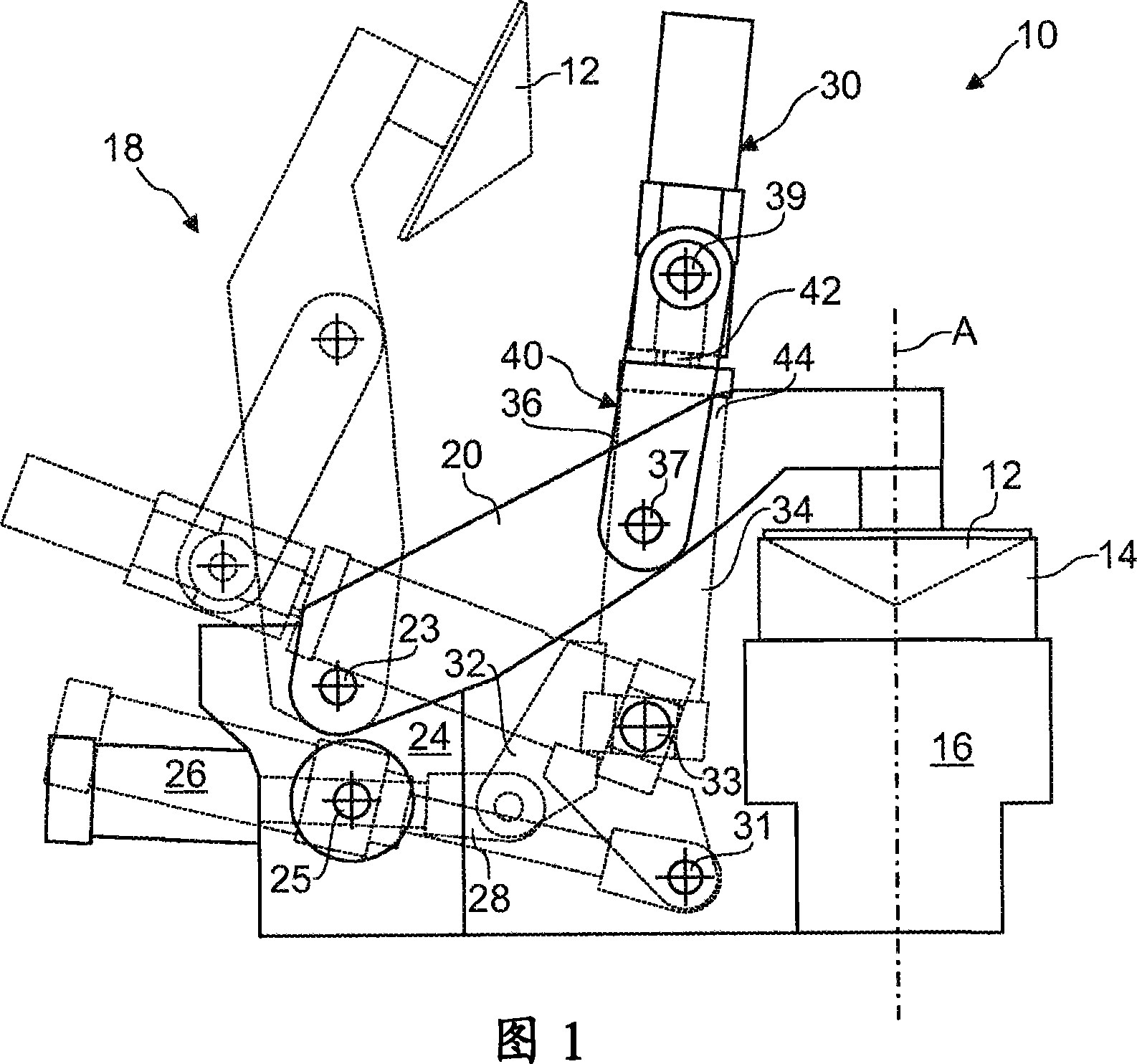

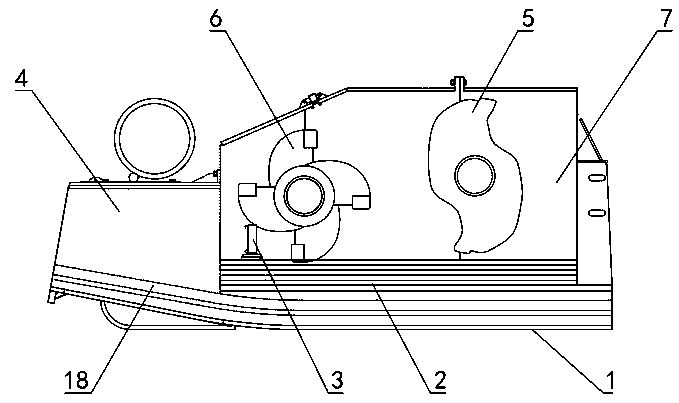

Continuous two-stage crushing type crusher

PendingCN110694745AImprove crushing effectCompact structureGrain treatmentsThermodynamicsStructural engineering

The invention discloses a continuous two-stage crushing type crusher, and belongs to the field of crushing devices. The continuous two-stage crushing type crusher comprises a crusher main box body (8), a first-stage crushing hammer group (5) and a second-stage crushing hammer group (6). The first-stage crushing hammer group (5) and the second-stage crushing hammer group (6) are rotationally arranged in the crusher main box body (8). The first-stage crushing hammer group (5) is arranged on the side close to a crusher feeding groove (7), and the second-stage crushing hammer group (6) is arrangedon the side close to a crusher discharging groove (4). The first-stage crushing hammer group (5) and the second-stage crushing hammer group (6) are connected with a power device for driving the first-stage crushing hammer group (5) and the second-stage crushing hammer group (6) to work. The coal and gangue obtained through second-stage crushing has the particle size of 300 mm or below; coal blocks can be blocked to a certain extent by the second-stage crushing hammer group, large coal blocks passing through the first-stage crushing hammer group can be crushed under the impact of the first-stage crushing hammer group, and therefore the crushing effect can be effectively improved. The crusher is good in crushing effect, compact in structure and high in coal throughput.

Owner:淄博科漫机电设备有限公司

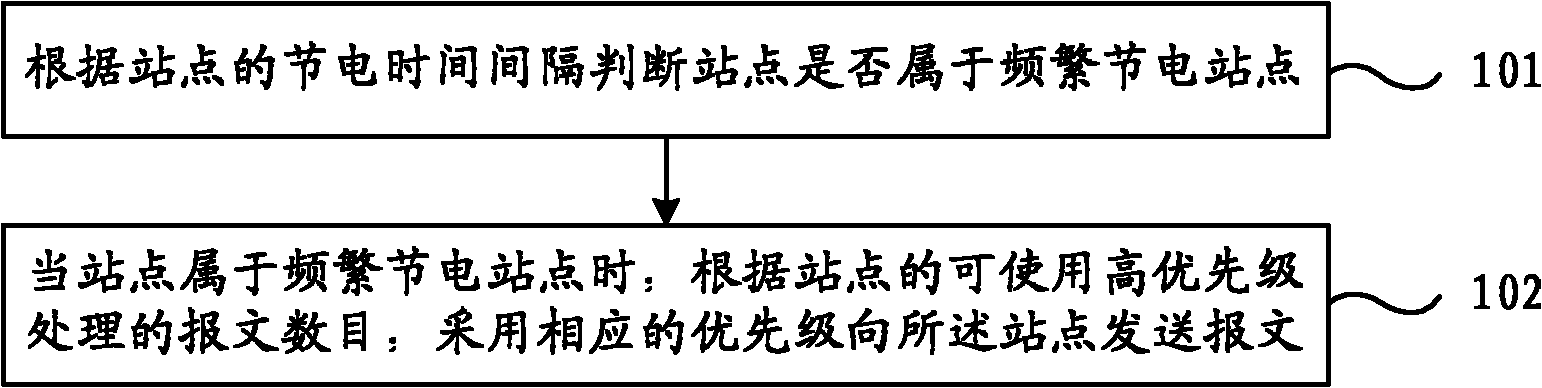

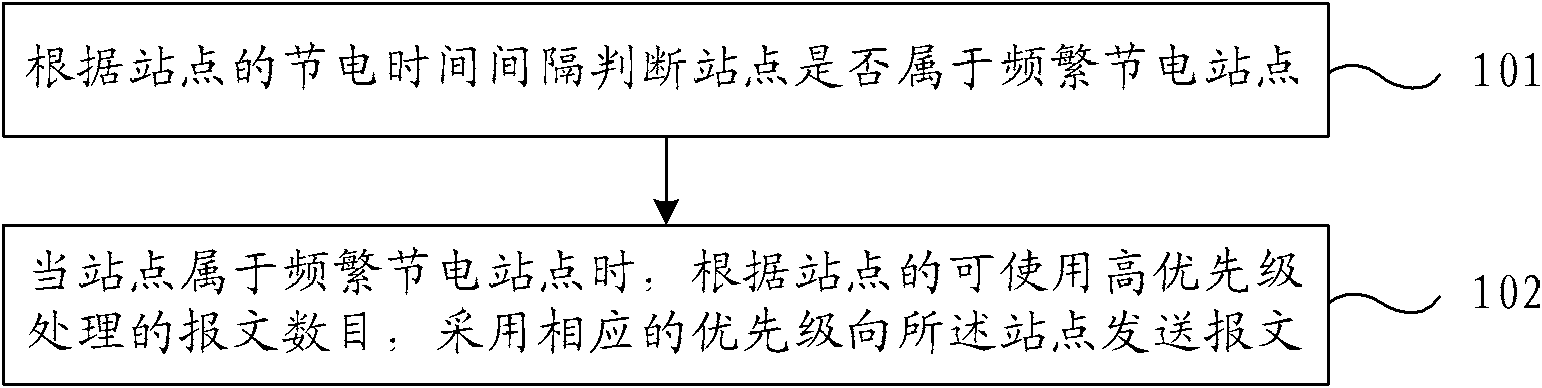

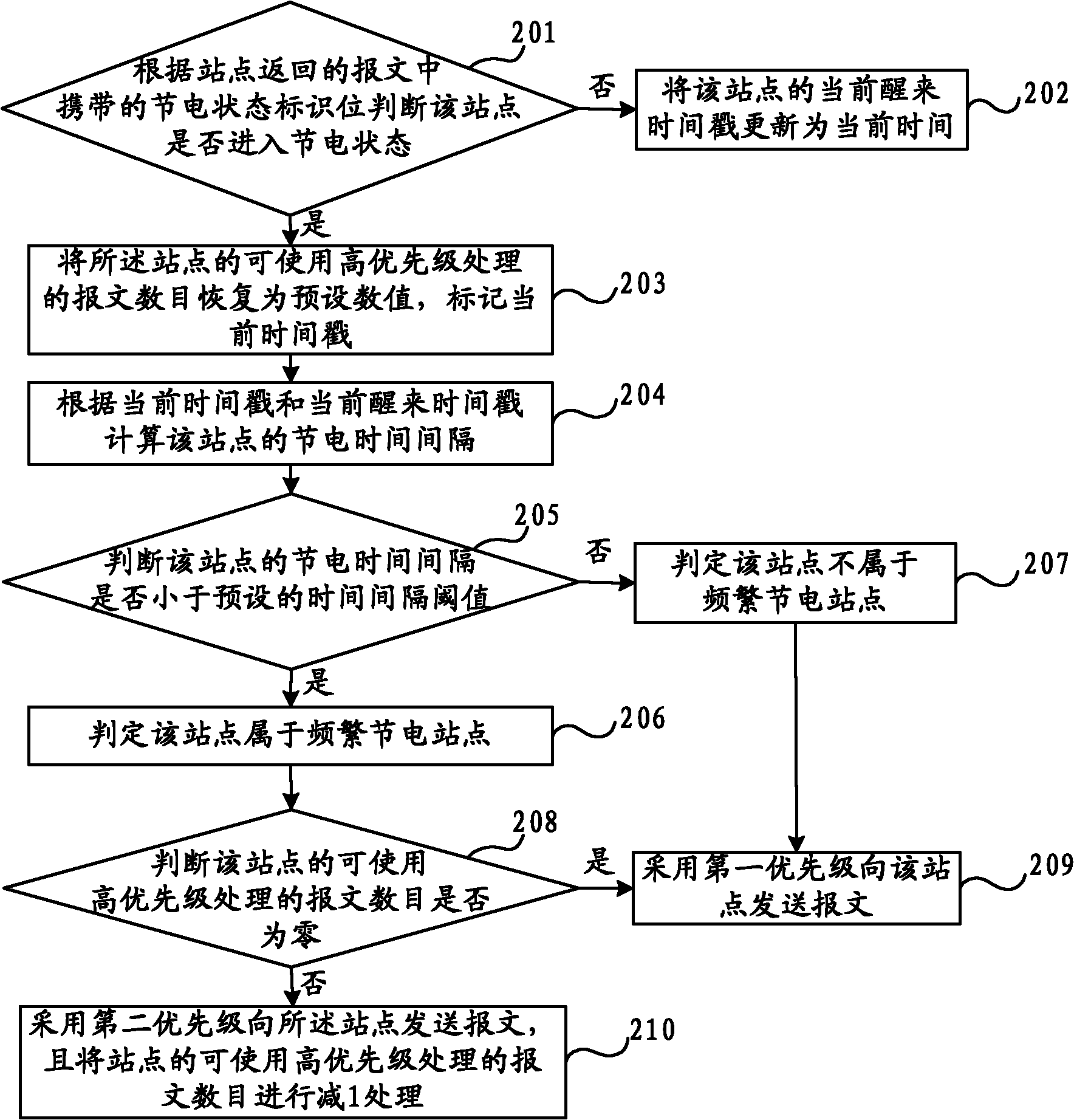

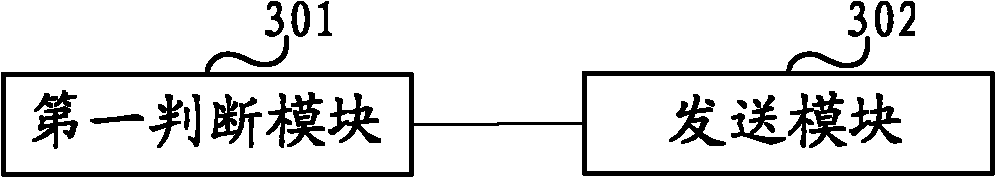

Message processing method, message processing device and communication equipment

InactiveCN102223298ASolve the problem of excessive delayDoes not affect network performanceData switching networksTime delaysPower saving

The invention provides a message processing method, a message processing device and communication equipment. The method comprises the following steps of: judging whether a station belongs to frequent power-saving stations according to a power saving time interval of the station; and when the station belongs to the frequent power-saving stations, sending messages to the station by using corresponding priority according to the number of the messages, which can be processed by using high priority, of the station. The device comprises a first judging module and a sending module. The communication equipment comprises the message processing device. By the invention, the problem of overlong time delay caused by sending the messages to the frequent power-saving stations by using a normal queue when a plurality of users share and occupy channels in the prior art is solved, and the network performance of a system and the whole throughout cannot be influenced.

Owner:RUIJIE NETWORKS CO LTD

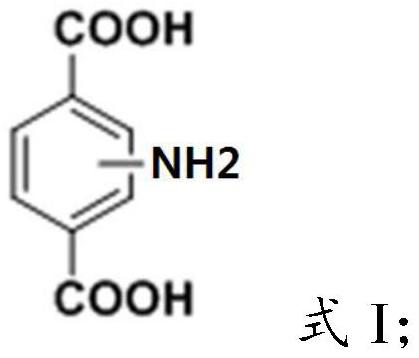

MOF membrane material for extracting uranium from water as well as preparation method and application of MOF membrane material

ActiveCN113813928AImprove adsorption capacityIncrease the speed of uranium extractionOther chemical processesFibre typesMetal-organic frameworkPhysical chemistry

The invention provides a preparation method of an MOF membrane material for extracting uranium from water. The method comprises the following steps: modifying a ligand, then preparing a metal organic framework material UiO-66-CN, and finally, converting cyano groups in the material into amidoxime to selectively adsorb uranium, thereby greatly enhancing the adsorption capacity, selectivity and uranium extraction speed of uranium. According to the invention, a MOF layer is grown on the surface of a microporous polymeric membrane (such as a polypropylene non-woven fabric) in situ, so the stability of the material is improved, and the material is easy to recycle and post-process. The microporous structure of the polymeric membrane only supports the MOF layer with a nanometer thickness and does not affect the flux of the MOF layer, so a liquid permeation speed is greatly increased, and a uranium extraction speed is increased. The invention further provides the MOF membrane material for extracting uranium in water and application of the MOF membrane material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Message processing method, message processing device and communication equipment

InactiveCN102223298BSolve the problem of excessive delayDoes not affect network performanceData switching networksTime delaysComputer module

The invention provides a message processing method, a message processing device and communication equipment. The method comprises the following steps of: judging whether a station belongs to frequent power-saving stations according to a power saving time interval of the station; and when the station belongs to the frequent power-saving stations, sending messages to the station by using corresponding priority according to the number of the messages, which can be processed by using high priority, of the station. The device comprises a first judging module and a sending module. The communication equipment comprises the message processing device. By the invention, the problem of overlong time delay caused by sending the messages to the frequent power-saving stations by using a normal queue when a plurality of users share and occupy channels in the prior art is solved, and the network performance of a system and the whole throughout cannot be influenced.

Owner:RUIJIE NETWORKS CO LTD

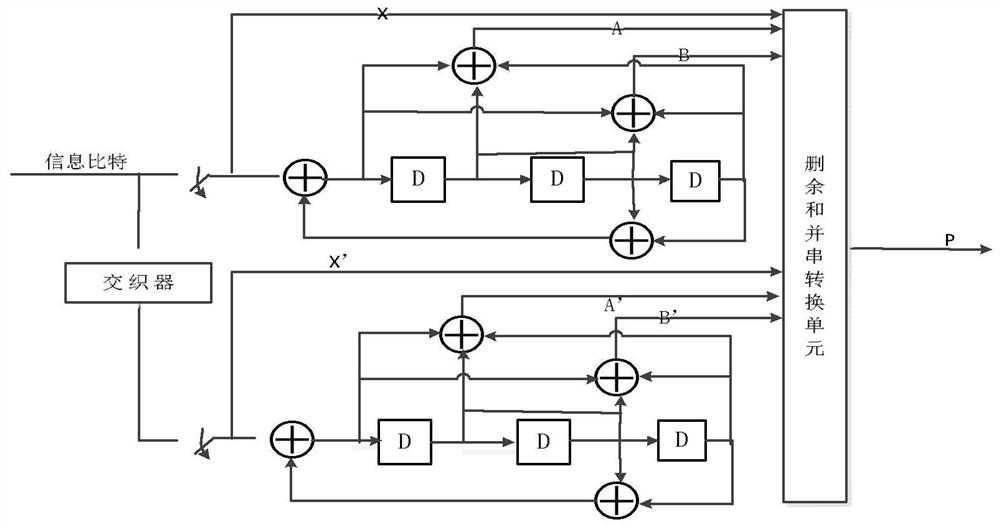

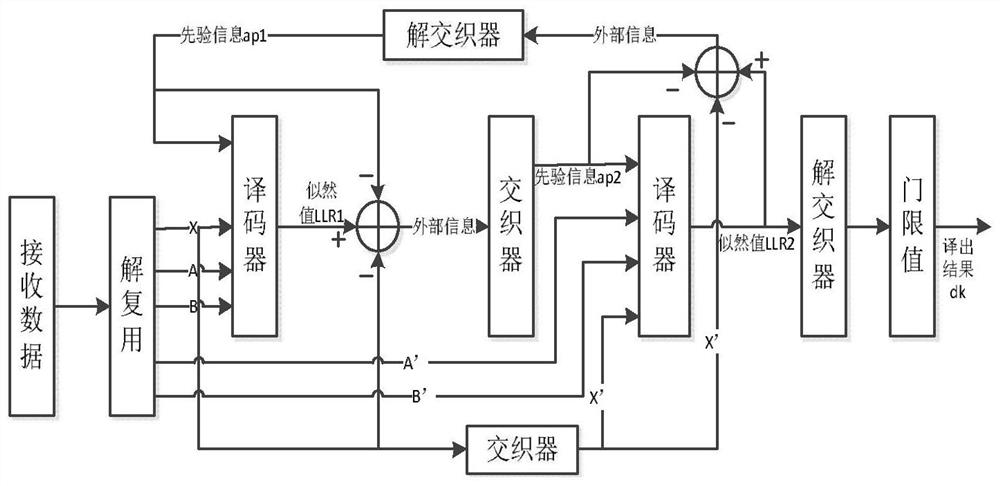

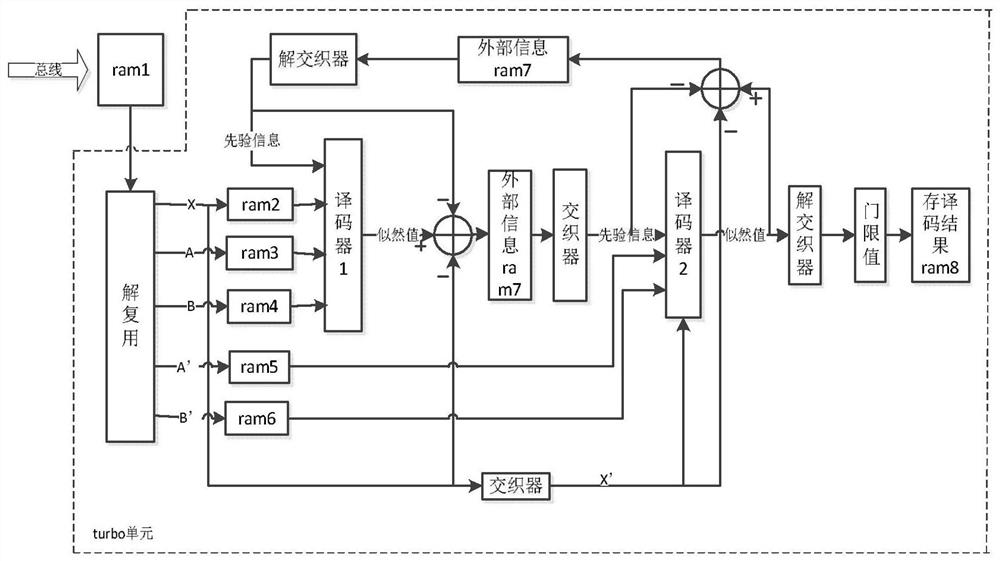

Turbo decoding storage method and device and decoder based on ram bus

ActiveCN111865336BReduce overheadSave storage spaceError correction/detection using turbo codesForward error control useComputer architectureRandom access memory

The present invention provides a Turbo decoding storage method based on a RAM bus, which saves the hardware overhead of Turbo decoding without loss of performance and speed; including: 1) setting the first random access memory ram1 to receive bus data; 2) setting the second random access memory ram2; after receiving a group of data from the bus, demultiplexing is performed, and the information bits are stored in the second random access memory ram2; 3) the check digit after demultiplexing is Store in the first random access memory ram1, reuse ram1; 4) Store the decoding result of the decoding output in the first random access memory ram1, and reuse ram1 again. The invention also provides a Turbo decoding storage device and a decoder using the storage method.

Owner:NAV TECH CO LTD

PCB water bactericide

InactiveCN104186541ASolve environmental pressurePrevent growth metabolismBiocideDisinfectantsSodium bicarbonateSURFACTANT BLEND

The invention provides a PCB water bactericide which is characterized by being prepared from sodium polysulfide, sodium bicarbonate, methacrylate, amide, a surfactant and purified water. The PCB water bactericide has a good sterilization effect and has a rapid sterilization function under a certain concentration, the one-time killing rate is close to 100 percent, and the amount of washing water can be reduced by 1 / 3 to 2 / 3.

Owner:刘院明

Catalytic cracking process for reducing content of olefin in gasoline

InactiveCN1141361CReduce olefin contentReduce yieldCatalytic crackingGas compressorReaction temperature

A catalytic cracking process for lowering the olefin content of gasoline features that the condensed oil of rich gas compressor and / or the light gasoline fraction pumped from the top of stablizing tower are filled in the lifting tube reactor at the uppers tream of raw oil nozzle, or in conjunctino with the raw oil from raw oil nozzle to make it in contact with regenerated catalyst and take part in reaction, the resultant flows upward along the lifting tube, the oil gas is quickly separated from the catalyst at outlet of lifting tube to recover the resultant, and the catalyst is stripped and regenerated for reuse. The content of olefin can be reduced by 10-20 v%.

Owner:CHINA PETROLEUM & CHEM CORP +1

A database system and database access method

ActiveCN110019468BSolve the problem of tps dropDoes not affect throughputDatabase management systemsSpecial data processing applicationsData segmentConcurrency control

The embodiment of the present invention discloses a database system and a database access method. The database system includes: a SQL engine for receiving a first transaction, the first transaction includes corresponding first data; a switching unit for determining the first data The heat of the segment; the first data segment is the database data segment where the first data falls when the first transaction is executed, and the heat of the first data segment is the number of transactions canceled per unit time in the history of the first data segment accounting for all operations The ratio of the number of transactions; the concurrency control selection unit, when the heat of the first data segment is greater than the first threshold, select the first concurrency control unit; the first concurrency control unit, used to determine whether there is a second transaction, when there is no second During the transaction, the first transaction is executed; wherein, the data read by the first transaction is the data written by the second transaction, and the time when the second transaction writes data is later than the time when the first transaction reads data.

Owner:HUAWEI TECH CO LTD

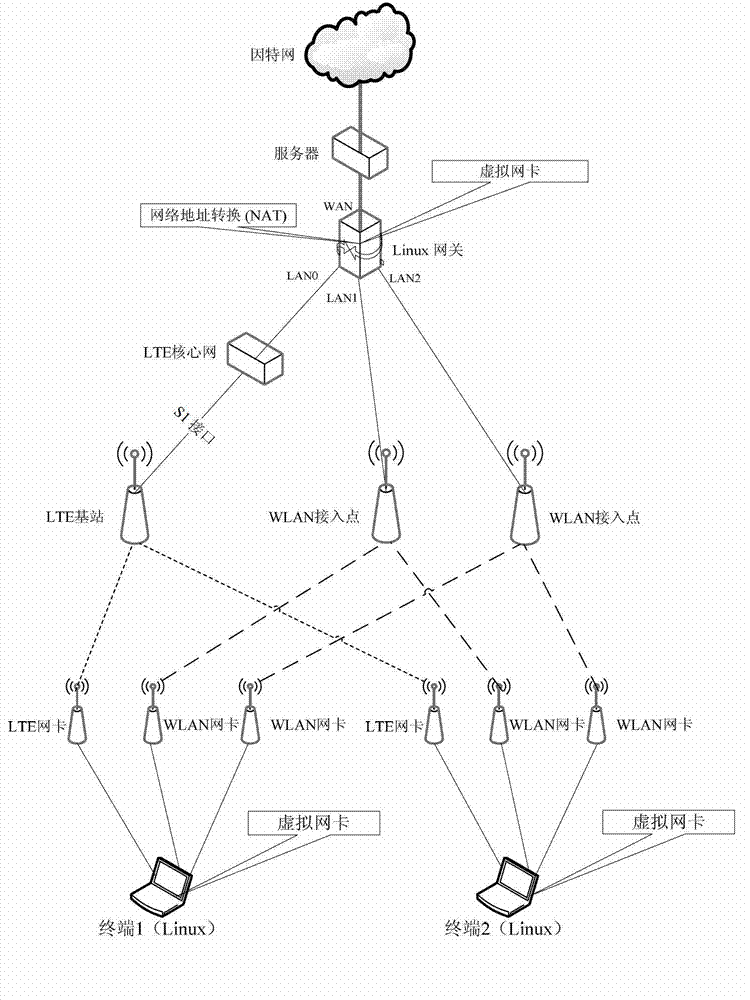

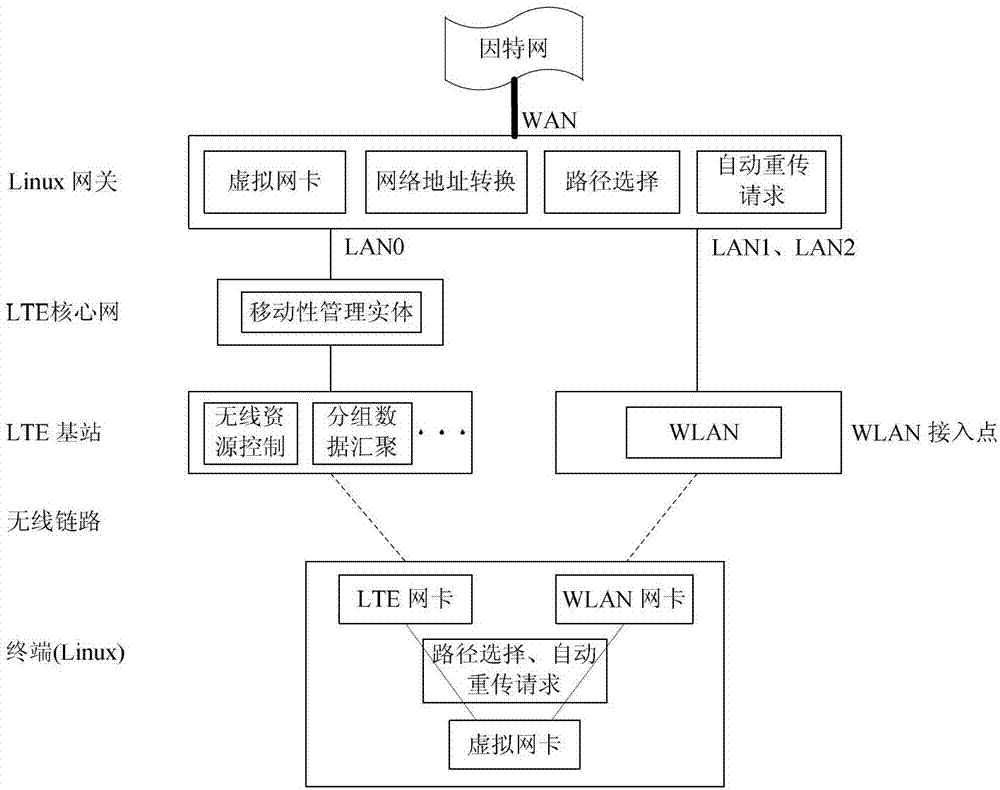

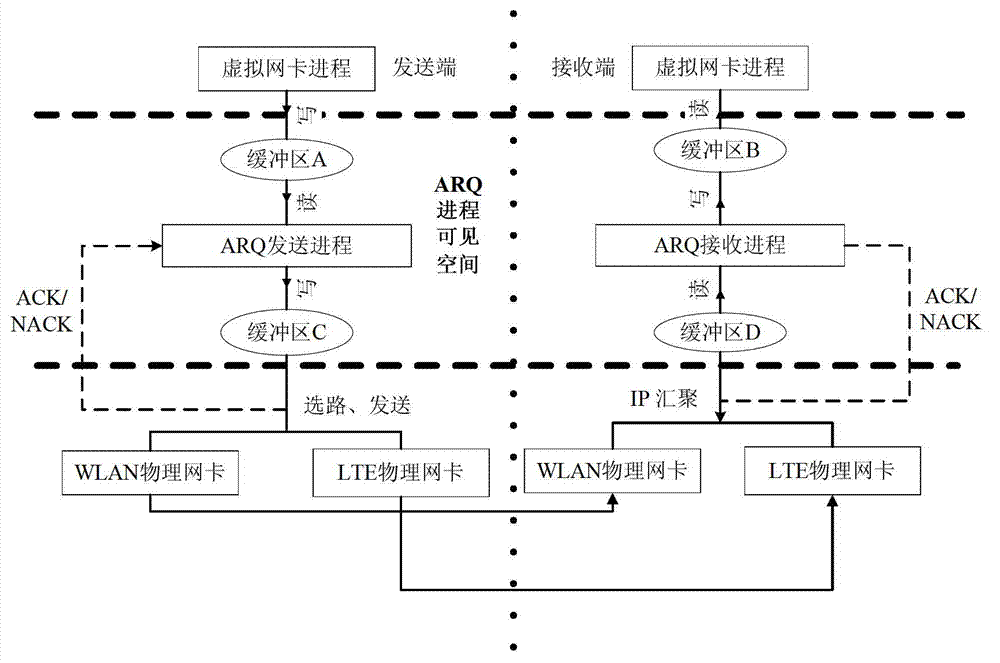

Cross-layer ARQ (Automatic Repeat Request) method in LTE-WLAN (Long Term Evolution and Wireless Local Area Network) heterogeneous wireless network system

InactiveCN103001751BReduce loss rateAvoid out-of-order arrival problemsError prevention/detection by using return channelNetwork traffic/resource managementPacket lossClosed loop feedback

The invention relates to a cross-layer ARQ (Automatic Repeat Request) method in an LTE-WLAN (Long Term Evolution and Wireless Local Area Network) heterogeneous wireless network system. The cross-layer ARQ method comprises the steps of: respectively adding a virtual network interface card between a terminal of the LTE-WLAN heterogeneous wireless network system and a DLL (Data Link Layer) as well as a network layer of a gateway to virtualize a fixed IP (Internet Protocol) for an application layer at the upper side and shield influences from different physical links of a bottom layer at the lower side; and realizing an ARQ protocol on an IP layer by utilizing a closed loop feedback system. The cross-layer ARQ protocol provided by the invention solves the problems of data packet loss or disordered arrival caused by switching of the terminal in an LTE-WLAN heterogeneous wireless network environment efficiently, prevents the TCP link from entering into a congestion control state and performing a rapid recovery or slow start process to affect the link transmission performance seriously due to the loss or disorder of the data packet. The cross-layer ARQ method in the LTE-WLAN heterogeneous wireless network system, disclosed by the invention, has the advantages of well guaranteeing quality of data transmission between the terminal of the heterogeneous network system and the gateway, providing the transmission layer with reliable services and enabling a terminal user to obtain high-speed and smooth communication experience in the heterogeneous wireless network environment.

Owner:HUAZHONG UNIV OF SCI & TECH

A data compression method, device and system

ActiveCN104753626BImprove weight removal rateDoes not affect throughputDigital data information retrievalTransmissionData compressionData stream

The embodiment of the invention discloses a data compression method. The method comprises the following steps: acquiring target network data; setting a data segmentation parameter of the target network data according to the redundancy rate of a network application data stream to which the target network data belongs; performing data segmentation on the target network data according to the set data segmentation parameter to obtain at least one target data block; comparing the at least one target data block with data blocks in a database in sequence; and deleting the target data blocks which are the same as the data blocks in the database. The embodiment of the invention also discloses equipment and a system. The embodiment of the invention further discloses equipment and a system. Through adoption of the method, the equipment and the system, the data block partitioning granularity can be set according to the redundancy rate corresponding to the network application data stream, so that the data deduplication rate is increased under the situation of not influencing the throughput rate.

Owner:HUAWEI TECH CO LTD

Evaporation system and evaporation process capable of online descaling and continuous operation

ActiveCN105999750BImprove work efficiencyReduce processing costsEvaporation with vapour compressionEvaporator regulation/controlThermodynamicsEngineering

The invention discloses an evaporating system capable of conducting online descaling and working continuously and an evaporating process. The evaporating system comprises n evaporating units, each evaporating unit is composed of an evaporator E and a steam-water separation mechanism S, the n evaporating units are connected in a feed liquor series-connection or parallel-connection evaporation mode to form the complete evaporating system, secondary steam generated by the n evaporating units shares one steam compression machine for pressurization and temperature raising, and a high-temperature steam main pipe is connected out of the steam compression machine and connected to high-temperature steam inlet pipes on the evaporating units in parallel; a liquid inlet pipe of the second-level / set evaporating unit is simultaneously connected with the first-level / set concentrate outlet pipe and a stoste inlet pipe; a concentrate main pipe is arranged, all the evaporating units except the first level / set evaporating unit are connected with the concentrate main pipe, the concentrate main pipe segment between the liquid inlet pipe and the concentrate output pipe of each evaporating unit is provided with a concentrate valve, valves on related inlet pipes and outlet pipes are controlled to isolate the evaporating units to be cleaned, and evaporating work of the system is not affected.

Owner:广州中科鑫洲科技有限公司 +1

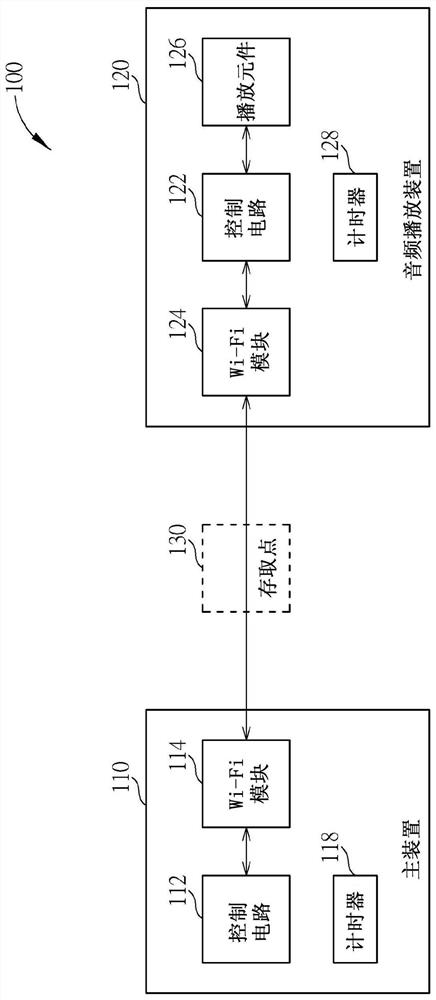

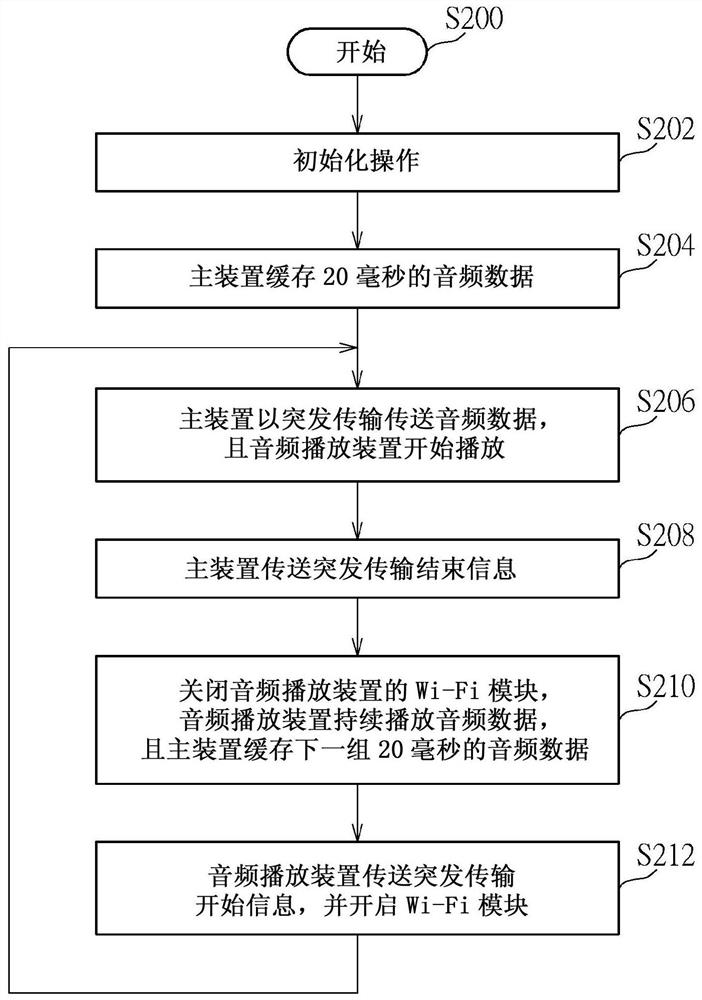

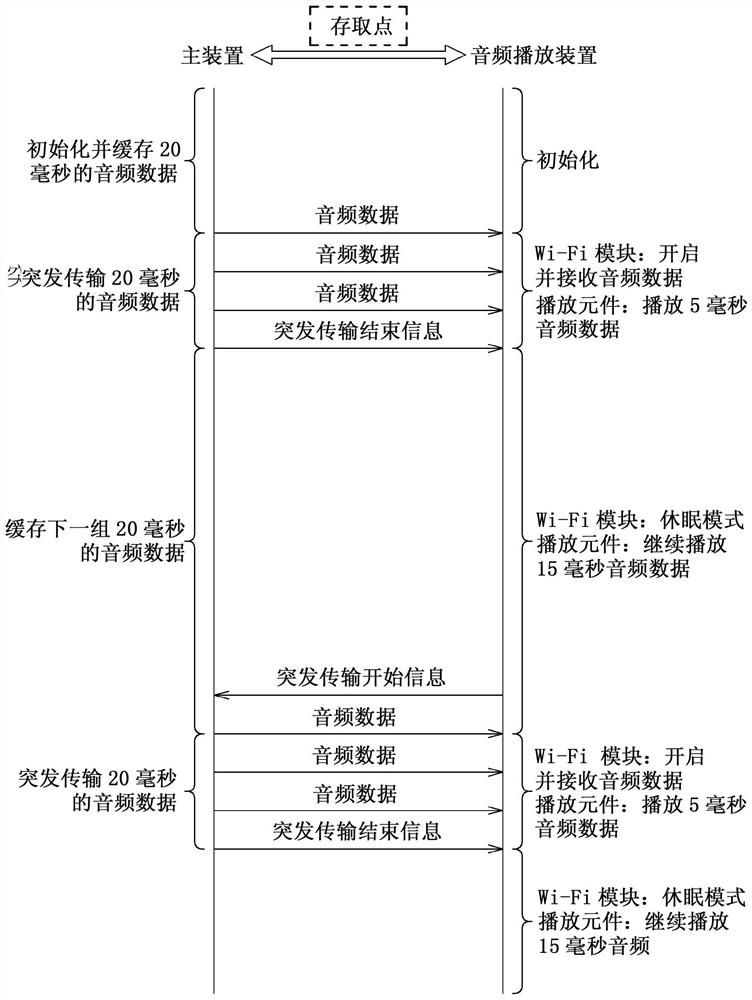

Method for controlling audio playback device and related control circuit

ActiveCN111479194BOperation controlWill not affect normal operationPower managementSignal processingBurst transmissionCommunication control

The present invention relates to a method for controlling an audio playback device and a related control circuit. The invention discloses a method for controlling an audio playback device, which comprises the following steps: controlling an electronic device to use a first wireless communication module to perform wireless communication with the audio playback device; controlling the electronic device to use a burst The mode of transmission is to use only a part of the time in a time range to transmit an audio data to the audio playback device; control the audio playback device to continuously play the audio data within the time range; and when the audio playback device completes After the audio data is received, a second wireless communication module of the audio playback device is controlled to enter a sleep mode.

Owner:REALTEK SEMICON CORP

Sterilizing and alga killing agent for treating washing water generated in printed circuit board manufacturing process

ActiveCN104186540ASolve environmental pressurePrevent growth metabolismBiocideFungicidesSodium bicarbonatePrinted circuit board

The invention provides a sterilizing and alga killing agent for treating washing water generated in a printed circuit board manufacturing process. The sterilizing and alga killing agent is characterized by being prepared from sodium polysulfide, sodium bicarbonate, methacrylate, amide, a surfactant and pure water. The sterilizing and alga killing agent has a favorable sterilizing effect and has a rapid sterilizing function at a certain concentration, and the single-time killing rate is approximate to 100%; and the dosage of the washing water can be reduced by 1 / 3 to 2 / 3.

Owner:广东恒锦通科技有限公司

Sewage treatment membrane with high pollution removal efficiency and preparation method thereof

ActiveCN110538578BLarge specific surface areaMany adsorption sitesMembranesSemi-permeable membranesChemical adsorptionMembrane surface

The invention discloses a sewage treatment membrane with high decontamination efficiency, which is made of the following raw materials in parts by weight: 60-70 parts of polyethersulfone resin, 4-6 parts of functional filler, 9-11 parts of modified polymer, porogen 20-24 parts of agent, 400-500 parts of N,N-dimethylformamide; the invention also discloses the preparation method of the sewage treatment membrane. The sewage treatment membrane of the present invention is a polyethersulfone membrane prepared by using a porogen, which not only has high acid and alkali resistance, but also has good interception performance; the polyethersulfone resin is modified by a modified polymer, which not only can Form a stable hydration layer on the surface of the membrane, and can form low-adhesion micro-regions, endow the membrane surface with excellent pollution release self-cleaning ability, will not affect the flux of the membrane, thereby improving the decontamination efficiency of the membrane; through the membrane raw material Adding functional fillers can not only exert physical and chemical adsorption, but also exert photocatalysis, have strong sewage treatment capacity, and effectively improve the treatment efficiency of the membrane.

Owner:苏州清溪环保科技有限公司

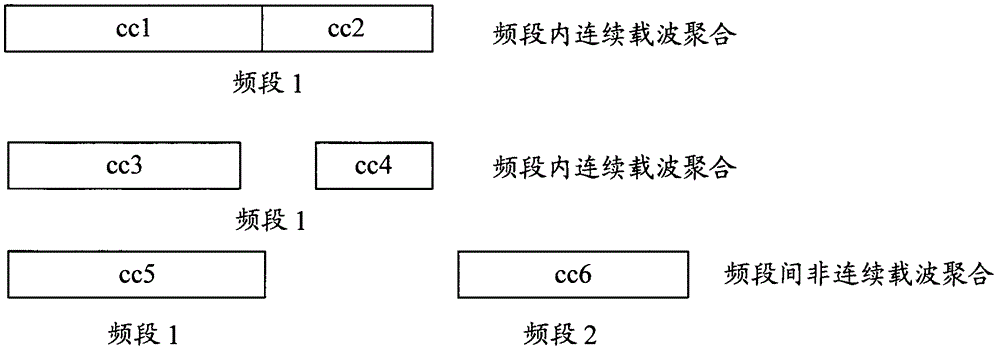

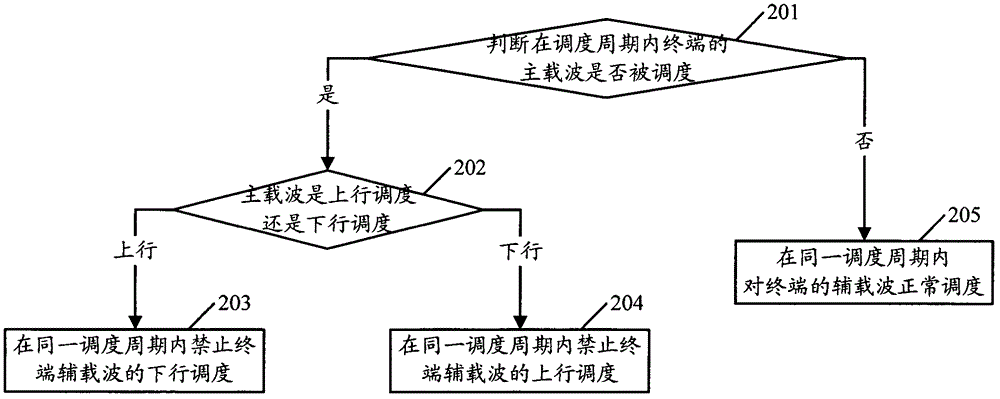

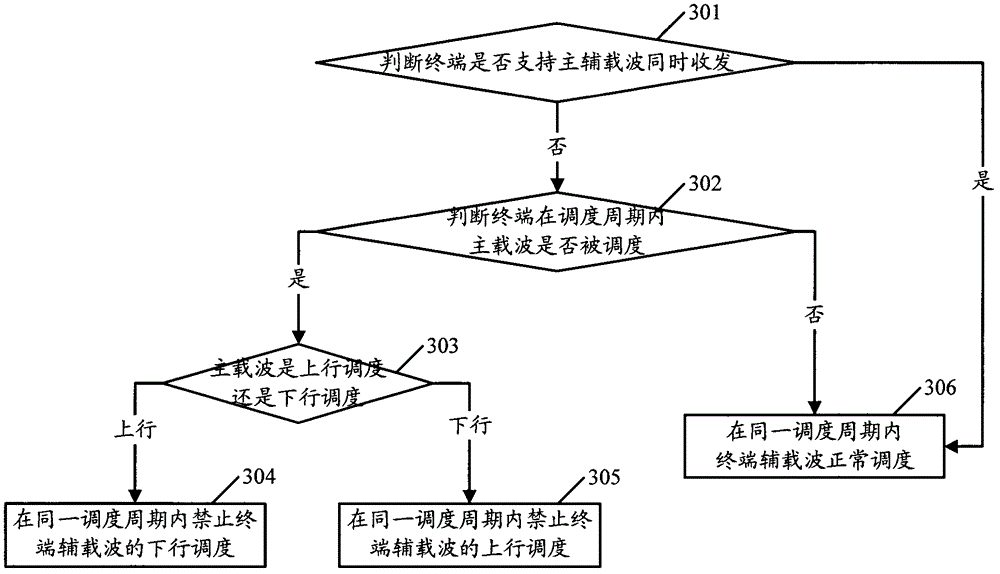

Scheduling method, system and device in carrier aggregation system

ActiveCN102548007BAvoid mutual interferenceGuaranteed transmission performanceWireless communicationComputer networkCarrier signal

The embodiment of the invention discloses a scheduling method, system and equipment in a carrier aggregation system. The scheduling method comprises the following steps of: configuring a main carrier and an auxiliary carrier for a terminal; and scheduling the auxiliary carrier of the terminal according to the condition of scheduling the main carrier by the terminal. According to the scheduling method, system and equipment disclosed by the invention, interference among different carriers in the terminal in the carrier aggregation system is effectively reduced on the premise of ensuring the system throughput in the carrier aggregation system.

Owner:CHINA MOBILE COMM GRP CO LTD

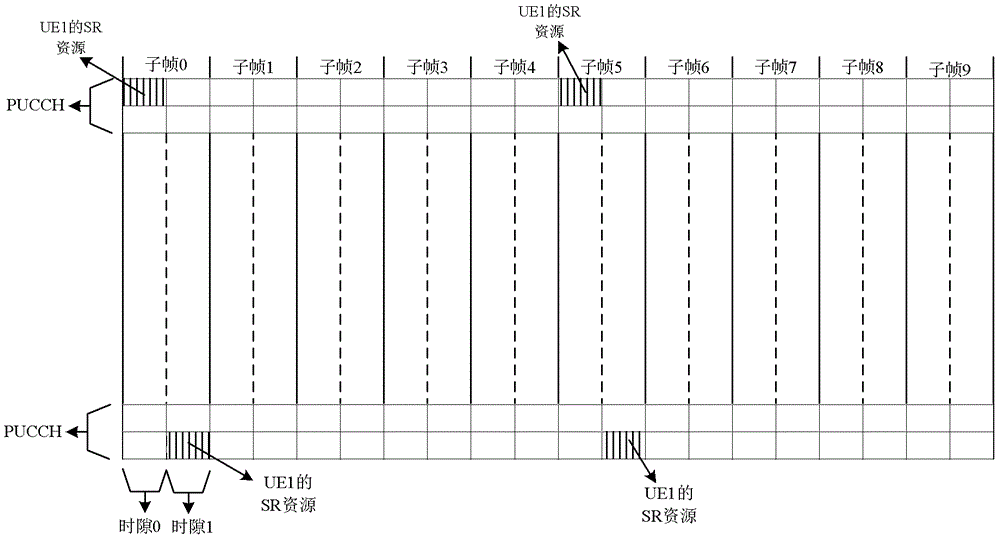

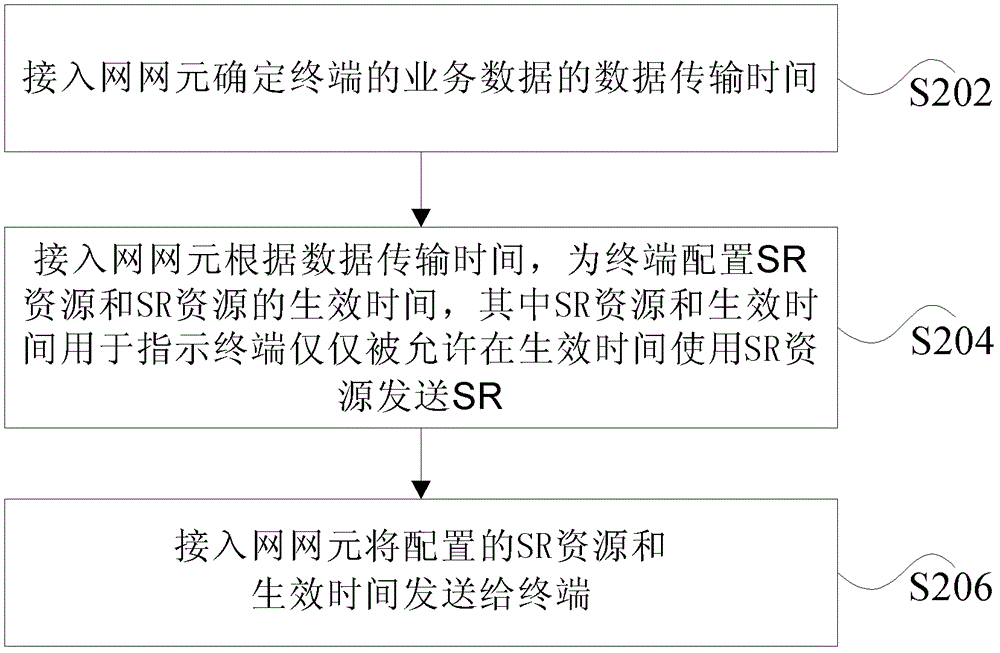

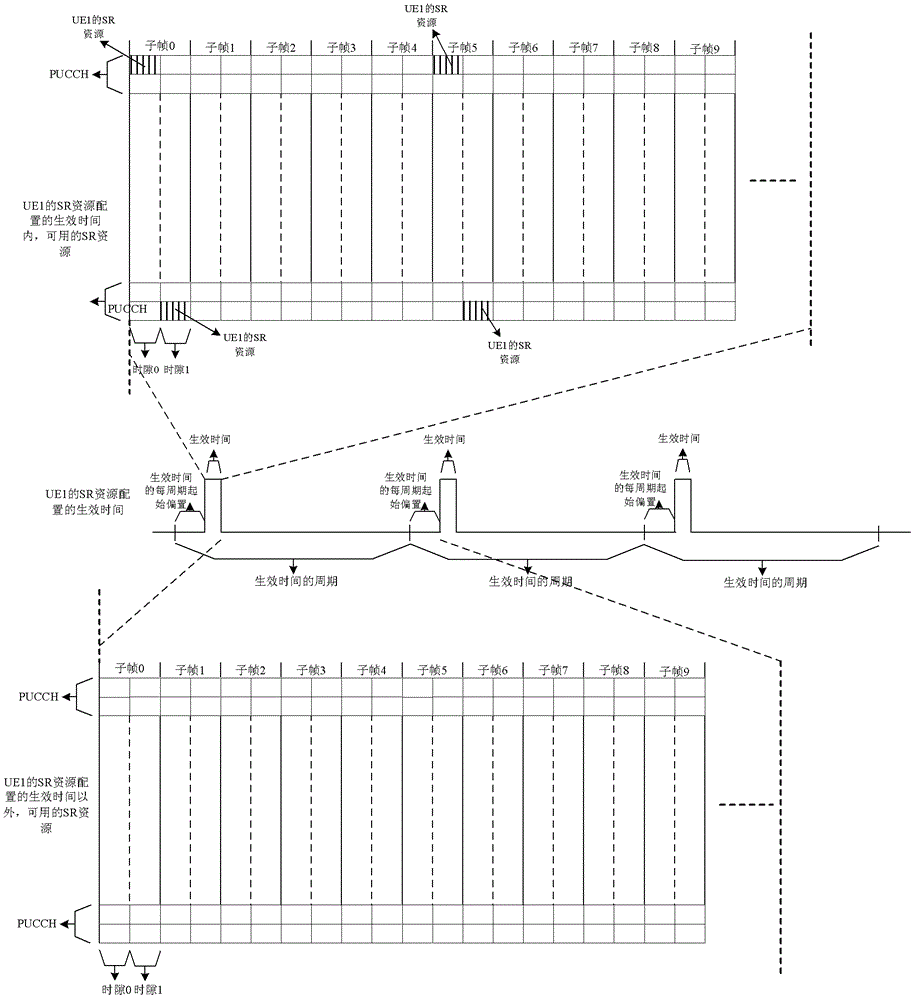

Radio resource scheduling request configuration method and device

ActiveCN102932920BImprove efficiencyDoes not affect throughputWireless communicationAccess networkTime to effect

Disclosed are a radio resource scheduling request configuration method and device. The method includes: a network element of an access network determining the data transmission time of service data of a terminal; the network element of the access network configuring an SR resource and an effective time thereof for the terminal according to the data transmission time, wherein the SR resource and the effective time are used for indicating that the terminal is only allowed to use the SR resource to send an SR within the effective time; and the network element of the access network sending to the terminal the configured SR resource and effective time. One aspect of the present invention can ensure that the terminal uses the SR resource to send an SR within the effective time, thus not affecting the throughput of the terminal, nor increasing additional signalling overhead; another aspect can ensure that the SR resource is used by other terminals at other moments instead of within the effective time, thus improving the utilization efficiency of the SR resource.

Owner:ZTE CORP

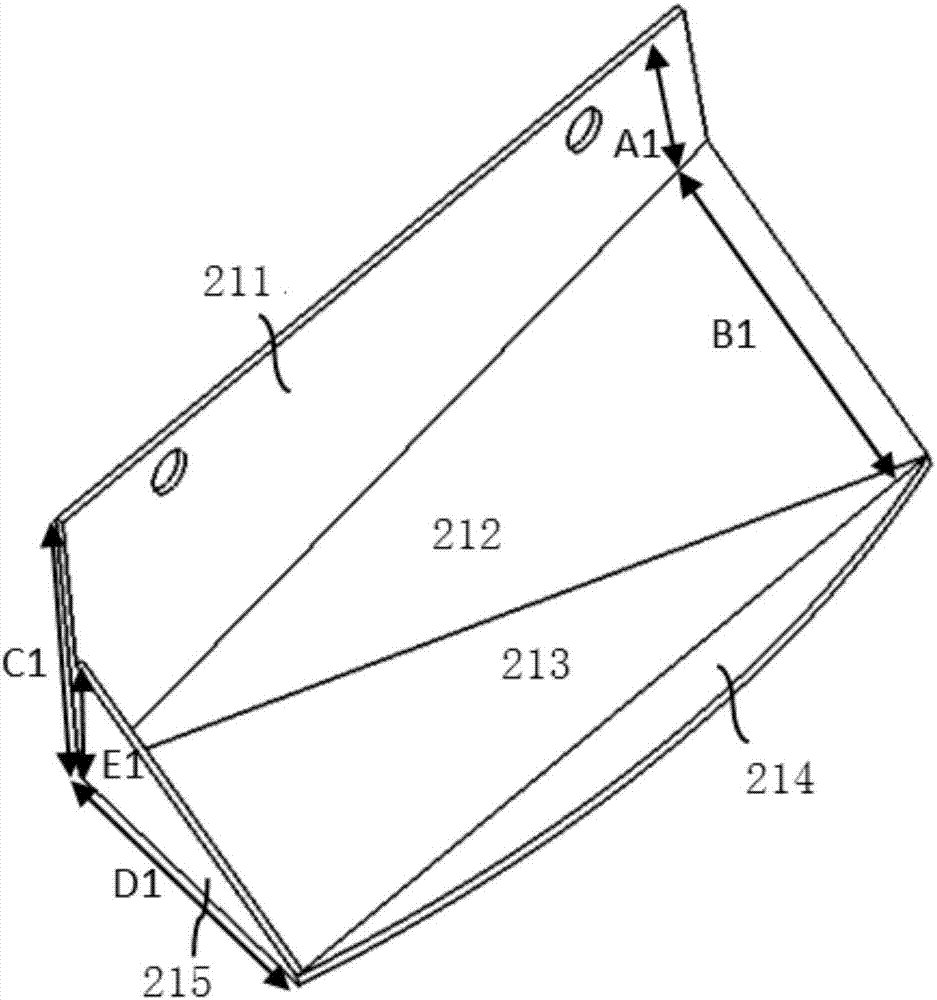

Blade structure, drying drum and drying equipment

ActiveCN107504779AIncrease lift heightImprove uniformityDrying solid materialsDrying machines with non-progressive movementsRetention timeEngineering

The invention relates to a blade structure, a drying drum and drying equipment. The blade structure comprises a drum body; multiple blades are arranged in the drum body; an included angle between a datum line of an assembly base of each blade and the axis of the drum body is gradually increased from a material inlet end to a material outlet end of the drum body; a first end of each blade is not lower than a second end of each blade; the first end of each blade is close to the material outlet end of the drum body; and the second end of each blade is close to the material inlet end of the drum body. By adopting the blade arrangement mode and structure provided by the embodiment of the invention, a material passing amount in the drum body is not affected, and lifting height of materials and uniformity of scattering of the materials can also be improved; and retention time of the materials in the drum body is prolonged, and the contact area between the materials and hot smoke is increased, so that heat exchange efficiency is enhanced.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

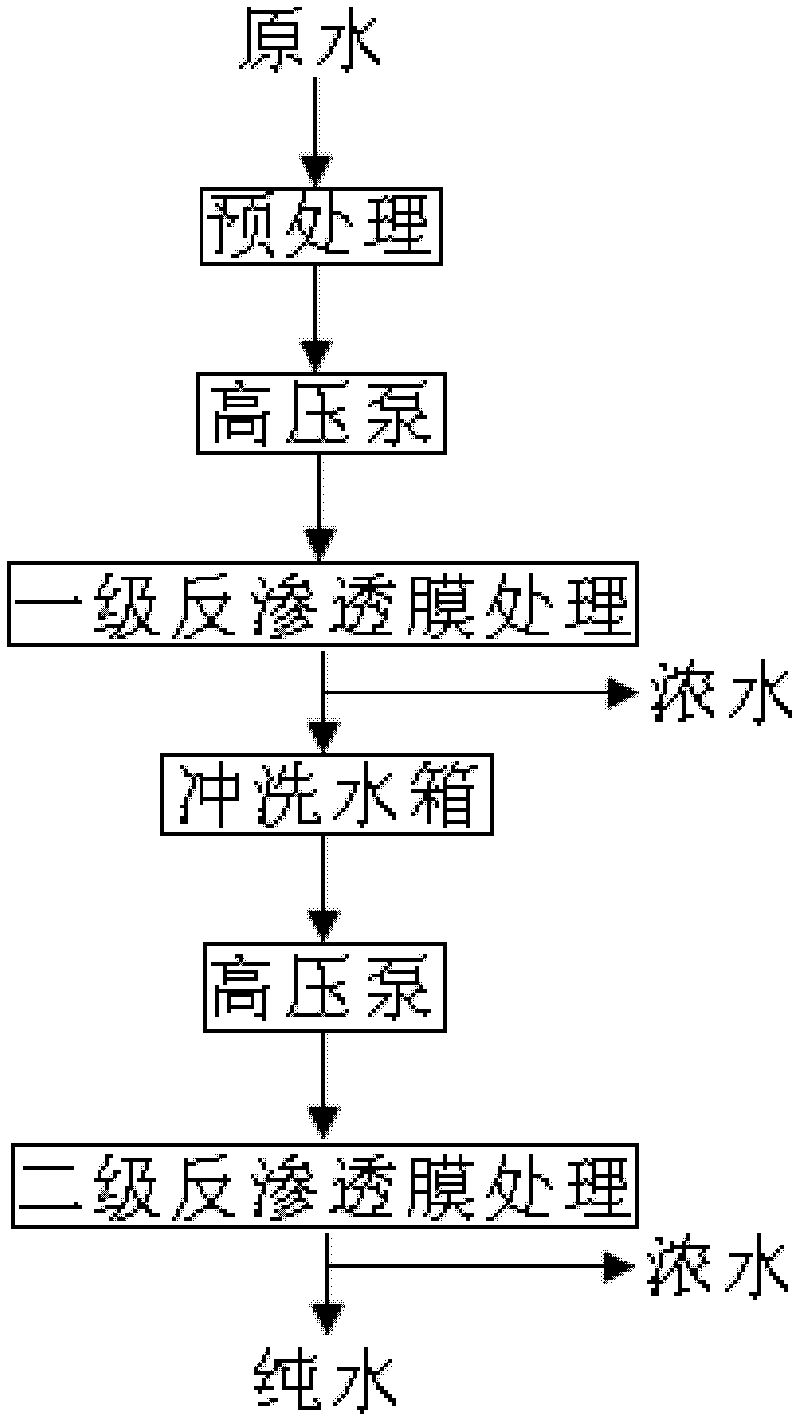

A method for extracting low-phosphorus oxytetracycline finished product from oxytetracycline fermentation liquid

InactiveCN106380422BImprove qualityDoes not affect process controlCarboxylic acid amide separation/purificationWater storage tankOxytetracycline

The invention discloses a method for extracting a low-phosphorus-content oxytetracycline finished product from an oxytetracycline fermentation broth and relates to the technical field of oxytetracycline production. The method comprises the steps of a, preparing the purified water, wherein the indexes of the purified water are as follows: the pollution index SDI thereof smaller than or equal to 4, the residual chlorine thereof smaller than or equal to 0.1 mg / L and the conductivity thereof smaller than 1.1 us / cm at the temperature of 25 DEG C; storing the prepared purified water in a purified water storage tank for later use; b, preparing a fermentation diluent; c, processing filter materials; d, conducting the decoloration treatment; e, extracting an oxytetracycline wet crystal; f, dephosphorizing the oxytetracycline wet crystal, and washing the oxytetracycline wet crystal in a separated plate frame by using the purified water stored in the purified water storage tank through a circulation loop by means of a circulation pump, so as to fully dissolving phosphorus impurities in the wet crystal in the purified water, wherein the phosphorus impurities are carried away by the circulated purified water and the effect of removing phosphorus impurities is realized; h, drying the oxytetracycline wet crystal to obtain the oxytetracycline finished product. According to the invention, phosphorus impurities in the oxytetracycline finished product can be effectively removed.

Owner:河北健民淀粉糖业有限公司

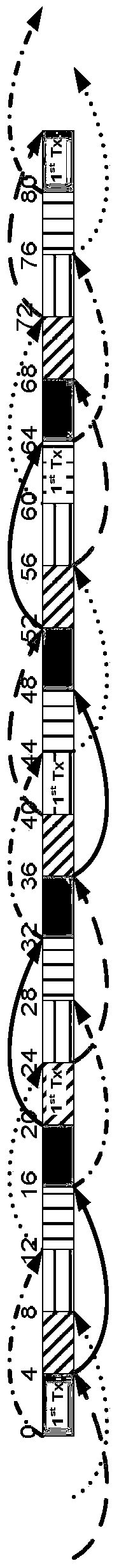

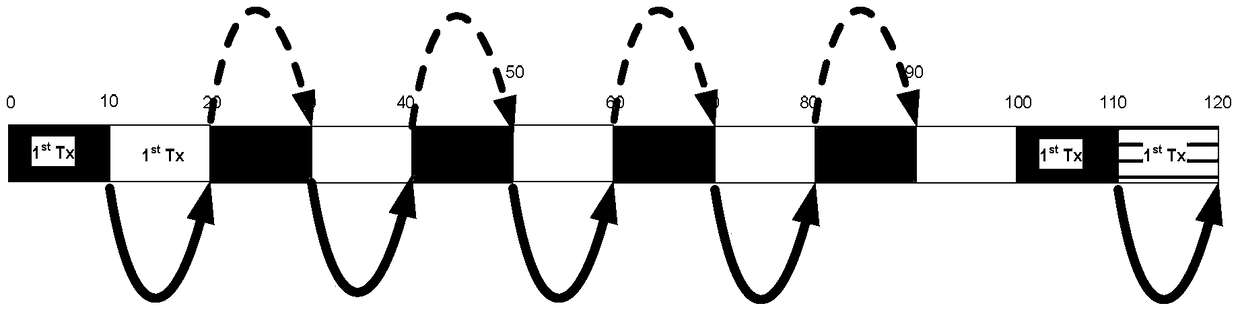

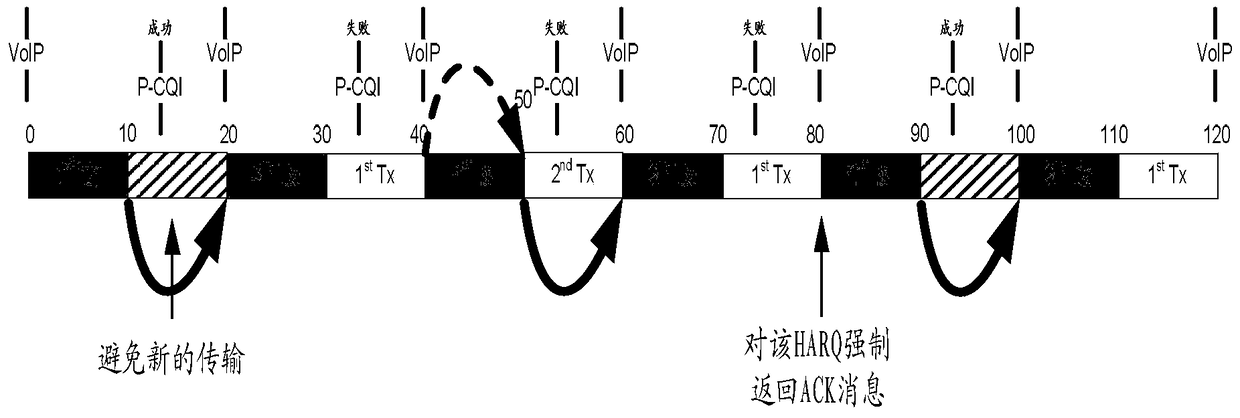

A p-cqi transmission method and device for tti bundled users

ActiveCN104753651BDoes not affect throughputAffects throughputError prevention/detection by using return channelInformation transmissionComputer science

The purpose of the present invention is to provide a P-CQI transmission method and device for TTI bundled users. Among them, the present invention judges whether the transmission subframe of the next P-CQI information conflicts with a TTI bundled transmission / retransmission, and when the two collide, abandons the conflicted TTI bundled transmission / retransmission to ensure that the next P-CQI information is received. - P‑CQI information. According to the solution of the present invention, on the one hand, it can solve the problem in the prior art that the eNB may not receive P-CQI information for a long time when TTI bundling is enabled, so that the downlink throughput will not be affected; on the other hand, By discarding only TTI bundling transmission / retransmission that collides with the transmission subframe of P‑CQI information, the uplink throughput of TTI bundling users can be less affected.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com