MOF membrane material for extracting uranium from water as well as preparation method and application of MOF membrane material

A membrane material, MOF technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as slow adsorption speed, increased time and cost of uranium extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing an MOF membrane material for extracting uranium from water, comprising the following steps:

[0026] A) immersing the polymer base material in an organic solution of maleic anhydride, and performing irradiation treatment to obtain a polymer base grafted with maleic anhydride;

[0027] B) mixing the zirconium salt, the cyano-modified organic ligand and the polymer substrate grafted with maleic anhydride in the step A), and reacting to obtain the MOF grafted material;

[0028] The cyano-modified organic ligand is prepared according to the following steps:

[0029] Mix the organic ligand and alkaline reagent in water, adjust the pH value to 5.0-5.5, then add acrylonitrile and hydroquinone, heat the system to react, then adjust the pH value to 2.0-3.0, filter and wash the solid and drying to obtain a cyano-modified organic ligand;

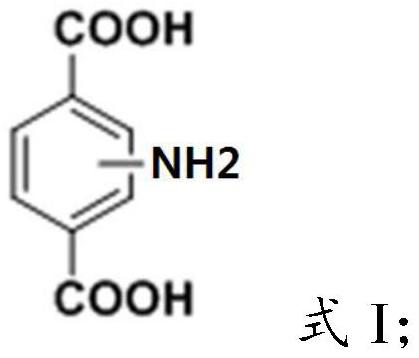

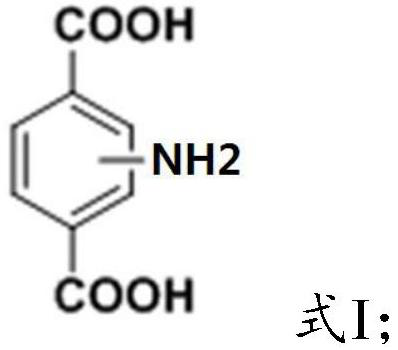

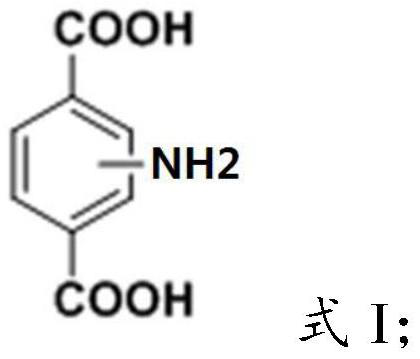

[0030] The organic ligand has a structure shown in formula I:

[0031]

[0032] C) subjecti...

Embodiment 1

[0058] Dissolve 4mmol of 2-aminoterephthalic acid and 6mmol of sodium hydroxide in 50mL of water. Add 10 mmol of acrylonitrile and 0.1 mmol of hydroquinone to the solution, stir and dissolve, and react at 100 degrees Celsius for 12 hours. After the reaction is over, add 30% hydrochloric acid to the system to fully separate out the precipitate, filter the precipitate, wash the precipitate with water and petroleum ether, and dry the precipitate in an oven at 60°C to obtain the cyano-modified ligand: 2- Cyanoterephthalic acid.

[0059] A 0.42 mm thick polypropylene non-woven fabric (PP) was ultrasonically cleaned in acetone, dried at 60°C and packed into an aluminum foil bag. Configure the maleic anhydride / tetrahydrofuran solution with a mass fraction of 50% at room temperature, then add the maleic anhydride solution and polypropylene non-woven fabric to the aluminum foil bag, make the maleic anhydride solution completely submerge the substrate, heat seal the aluminum foil bag a...

Embodiment 2

[0063] ZrCl 4 (3.0mmol) and 2-cyanoterephthalic acid (3.0mmol) are added in 60mlDMF by the molar ratio of 1:1, add reaction kettle after mixing evenly, with 10 pieces of polypropylene grafted maleic anhydride in embodiment 1 Non-woven fabric (4*4cm 2 ) is also added to the reactor, ZrCl 4 and the ratio of the total molar mass of 2-cyanoterephthalic acid to the area of the MOF membrane is 37.5 μmol / cm 2 . React at 120°C for 24h. The obtained MOF membrane was ultrasonically cleaned with DMF and ethanol, and dried to obtain a MOF membrane. The synthesized MOF membrane was immersed in the ethanol solution of hydroxylamine hydrochloride and ethylenediamine, wherein the molar ratio of hydroxylamine hydrochloride to ethylenediamine was 1:1, and hydroxylamine hydrochloride was a saturated solution. The system was heated to reflux at 70°C, and after 30 hours of reaction, the membrane was taken out, ultrasonically cleaned with ethanol, and dried at 60°C to obtain a highly loaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com