Continuous two-stage crushing type crusher

A crusher and crushing technology, applied in grain processing, etc., can solve the problems of high cost and complex structure, and achieve the effect of large coal passing, good crushing effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

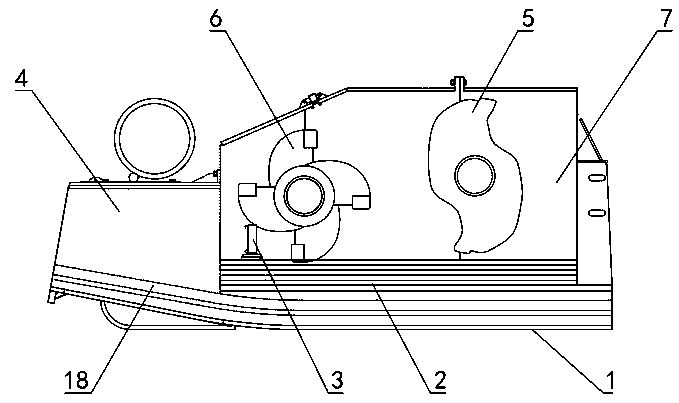

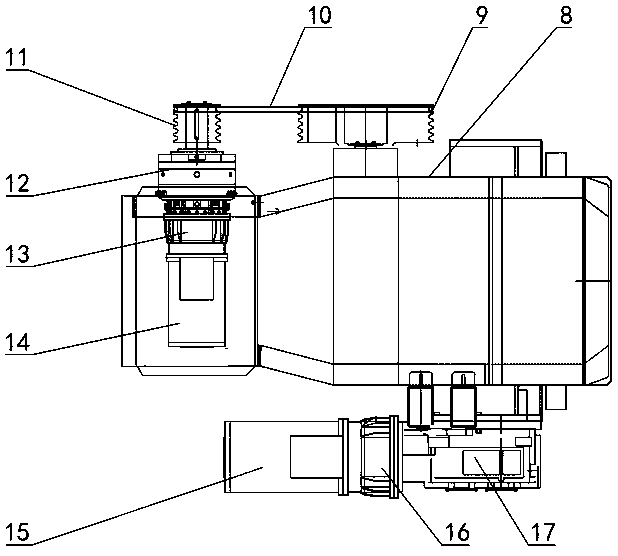

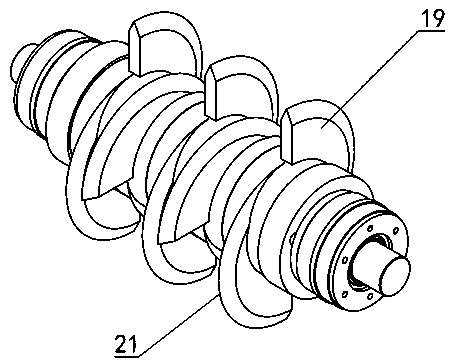

[0026] Figure 1~4 It is the best embodiment of this continuous two-stage crusher. Figure 1~4 The present invention will be further explained.

[0027] Reference figure 1 , The continuous two-stage crusher includes a main crusher box 8, a primary crushing hammer group 5, and a secondary crushing hammer group 6. Both ends of the crusher main box 8 are respectively provided with a crusher discharge trough 4 and Crusher feed chute 7, the bottom of the main box 8 of the crusher is equipped with the bottom groove 1 of the crusher, the primary crushing hammer group 5 and the secondary crushing hammer group 6 are rotatably arranged in the main box 8 of the crusher. The hammer group 5 is set on the side close to the feed chute 7 of the crusher, the secondary crushing hammer set 6 is set on the side close to the discharge chute 4 of the crusher, and the primary crushing hammer set 5 and the secondary crushing hammer set 6 are connected The power device that drives its work. The interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com