Process for online increase of chill pipeline to refined-desulfurization pre-hydrogenation catalyst

A catalyst and pre-hydrogenation technology, applied in the chemical industry, can solve the problems of large venting volume, long time required, and large impact on LNG output, so as to avoid parking vulcanization and reduce production loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

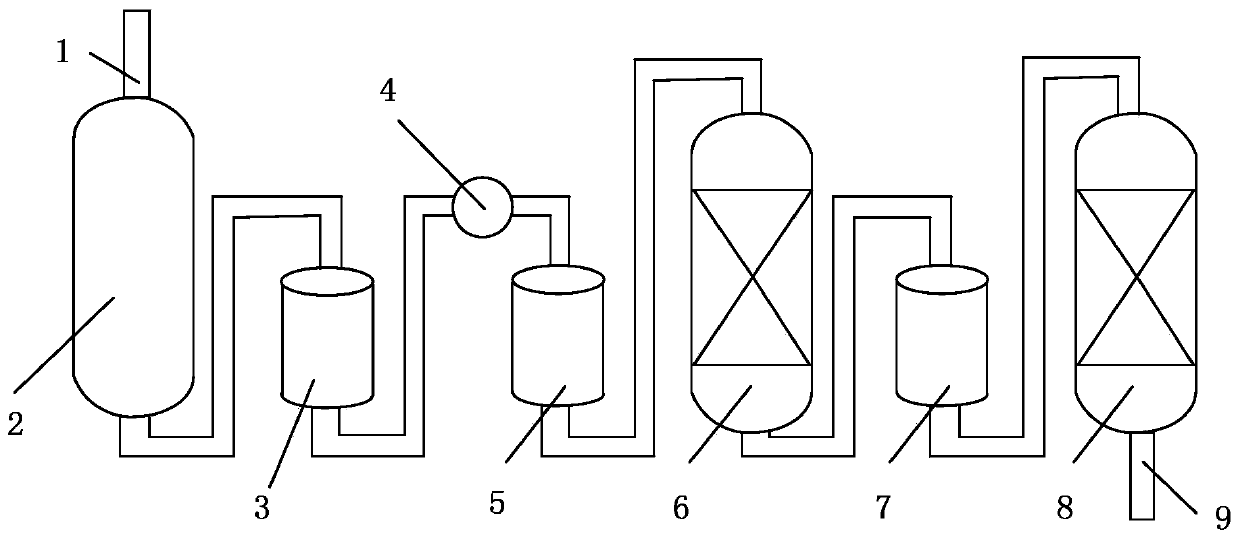

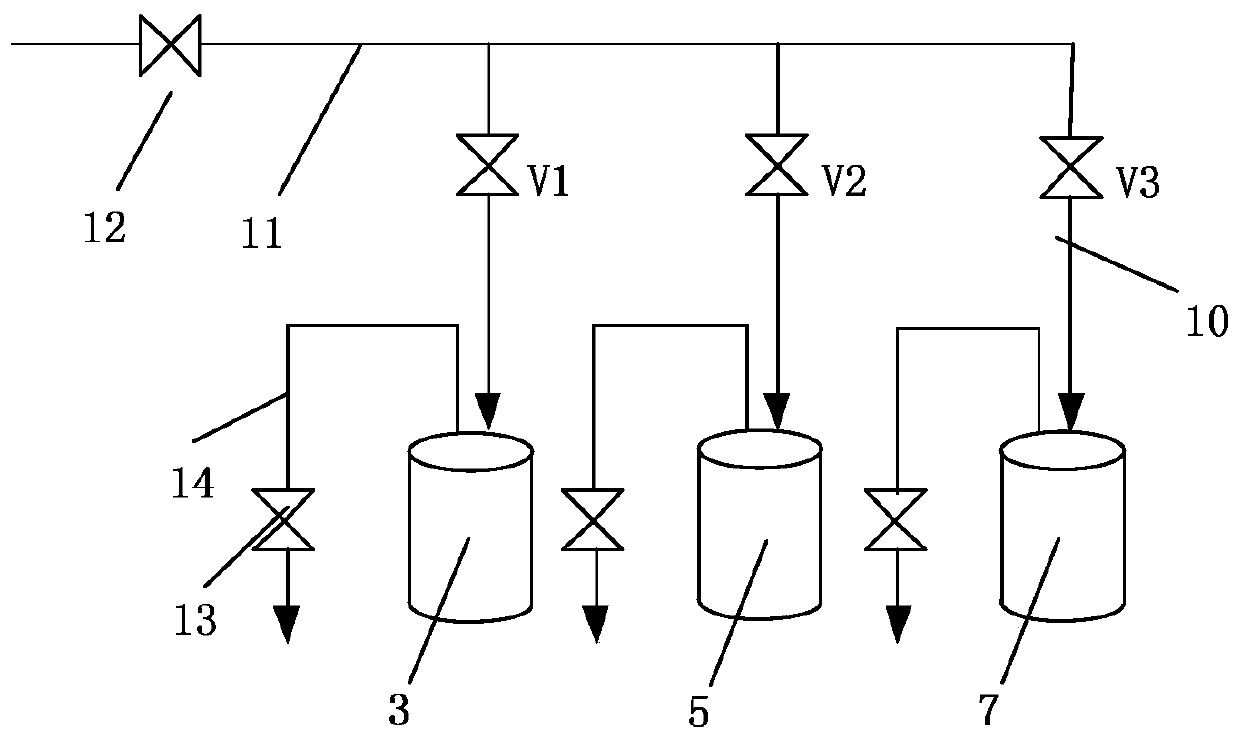

[0022] Such as figure 1 , 2 As shown in the present invention, a process for adding a cold-shock pipeline online to a fine desulfurization pre-hydrogenation catalyst includes a heating furnace 2 for preheating coke oven gas, a pre-hydrogenation process for removing substances harmful to the catalyst Converter 3, primary hydroconverter 5, primary zinc oxide desulfurizer 6, secondary hydroconverter 7, secondary zinc oxide desulfurizer 8, and chilled shock main pipe 11 for transporting chilled gas. The heating furnace 2 is provided with an air inlet 1 for feeding coke oven gas, the secondary zinc oxide desulfurizer 8 is provided with a gas outlet 9 for discharging LNG, and the cooling main pipe 11 is provided with a plurality of branch pipes 10 , the other end of the branch pipe 10 is respectively introduced into the tank inlets of the hydrogenation pre-converter 3, the primary hydroconverter 5, and the secondary hydroconverter 7 to control the temperature of the bed and prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com