Catalytic cracking process for reducing content of olefin in gasoline

An olefin content, catalytic cracking technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problem of no process method, and achieve the effect of reducing flexibility, reducing olefin content, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

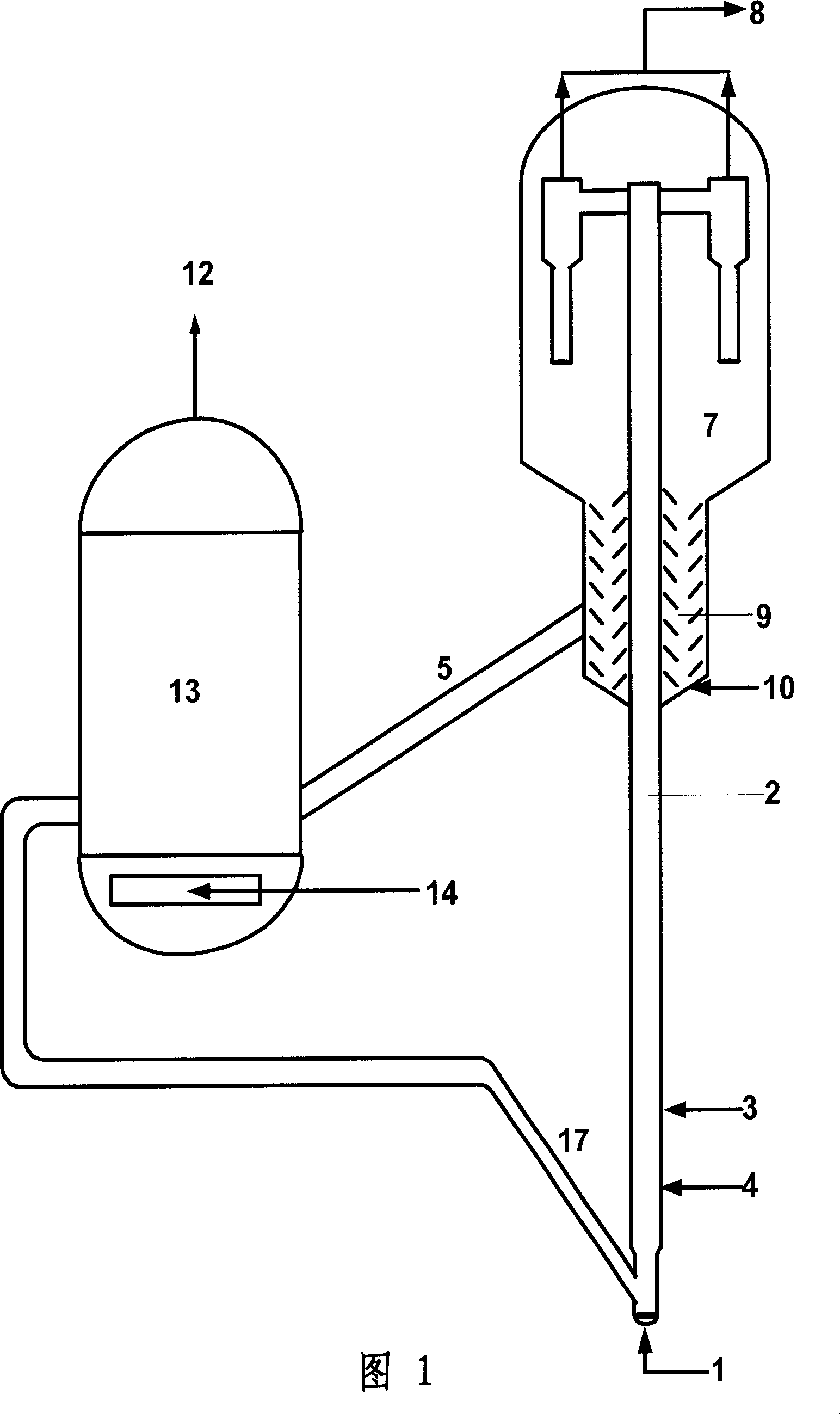

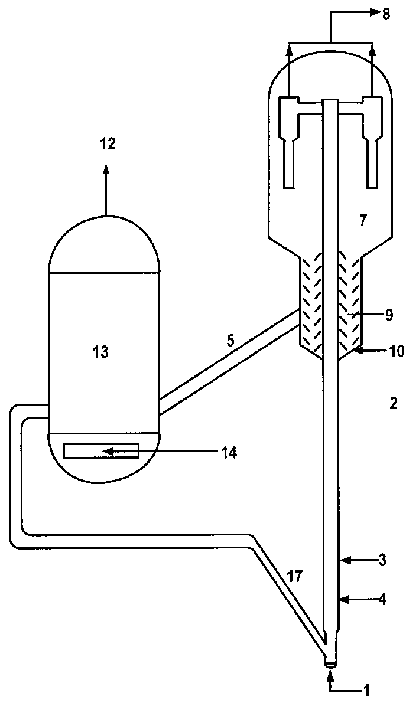

Image

Examples

Embodiment 1

[0053] This example shows that the method provided by the present invention can significantly reduce the olefin content of catalytically cracked gasoline, and has little impact on the processing capacity and product distribution of the device.

[0054] In a set of 1 million tons / year riser catalytic cracking unit, the imported wax oil mixed with residual oil shown in Table 2 is used as raw material, and LV-23 catalyst produced by Lanzhou Refinery and Chemical General Plant Catalyst Factory and GraceDavison Company are used. The mixed agent of Ramcat catalyst, its properties are shown in Table 3, carry out the industrial test of method provided by the invention. The light gasoline fraction used is the fraction with an end boiling point less than 130°C extracted from the upper part of the stabilizing tower, and its properties are shown in Table 4. The main operating conditions during the test are shown in Table 5, and the product distribution is shown in Table 6. The properties...

Embodiment 2

[0059] This example shows that the method provided by the present invention can significantly reduce the olefin content of catalytically cracked gasoline, and has little impact on the processing capacity and product distribution of the device.

[0060] In a riser catalytic cracking unit with a processing capacity of 16t / h, the Daqing atmospheric residue shown in Table 2 was used as the raw material, and the RAG catalyst industrially produced by the Qilu Petrochemical Company Catalyst Factory shown in Table 3 was used. An industrial trial of the method provided by the invention was carried out. The distillate of light gasoline used is the condensate oil of the gas-rich compressor, and its properties are shown in Table 4. The main operating conditions during the test are shown in Table 8, and the product distribution is shown in Table 9. The properties of gasoline products are shown in Table 10. For comparison, the main operating conditions, product distribution and properties...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com