Patents

Literature

45results about How to "Improve salt interception rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

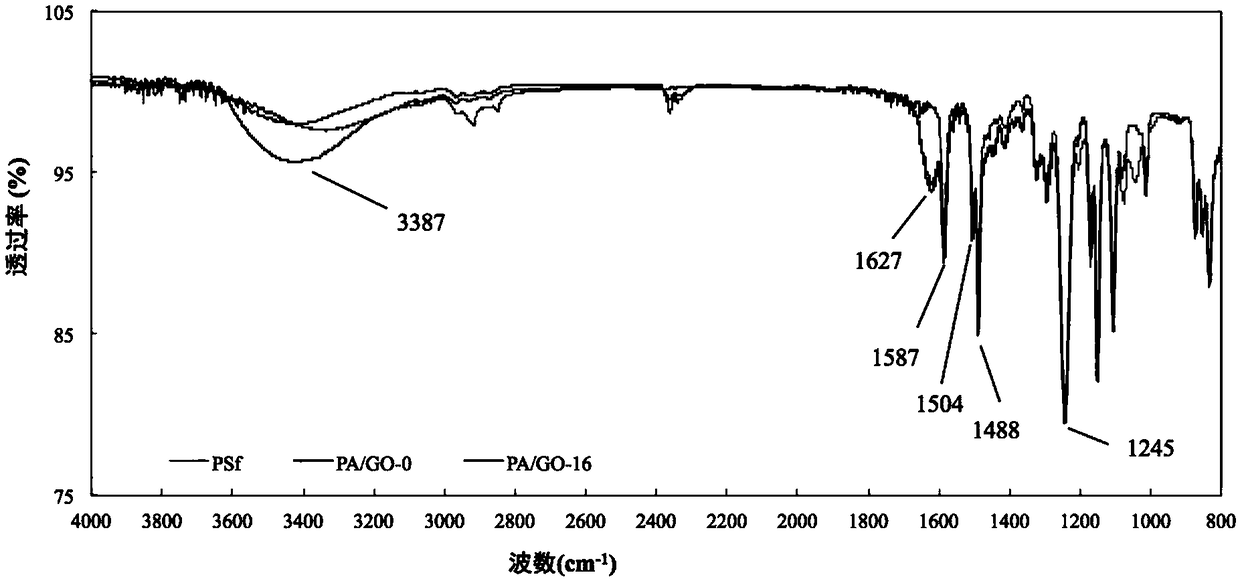

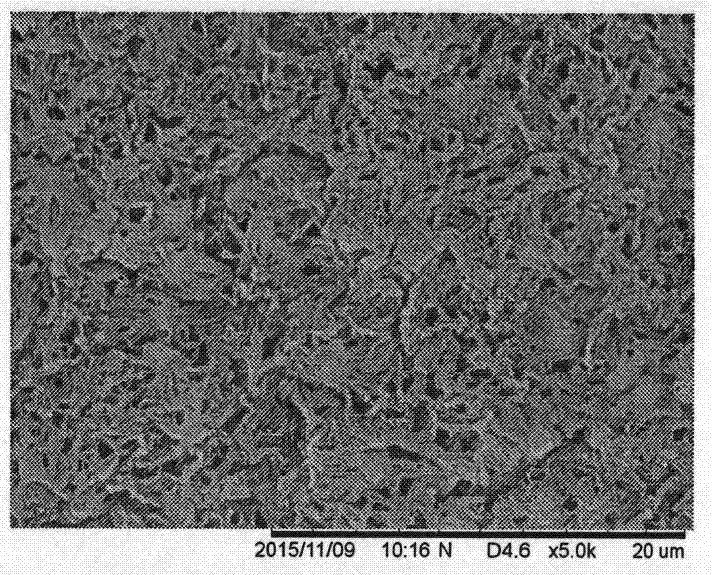

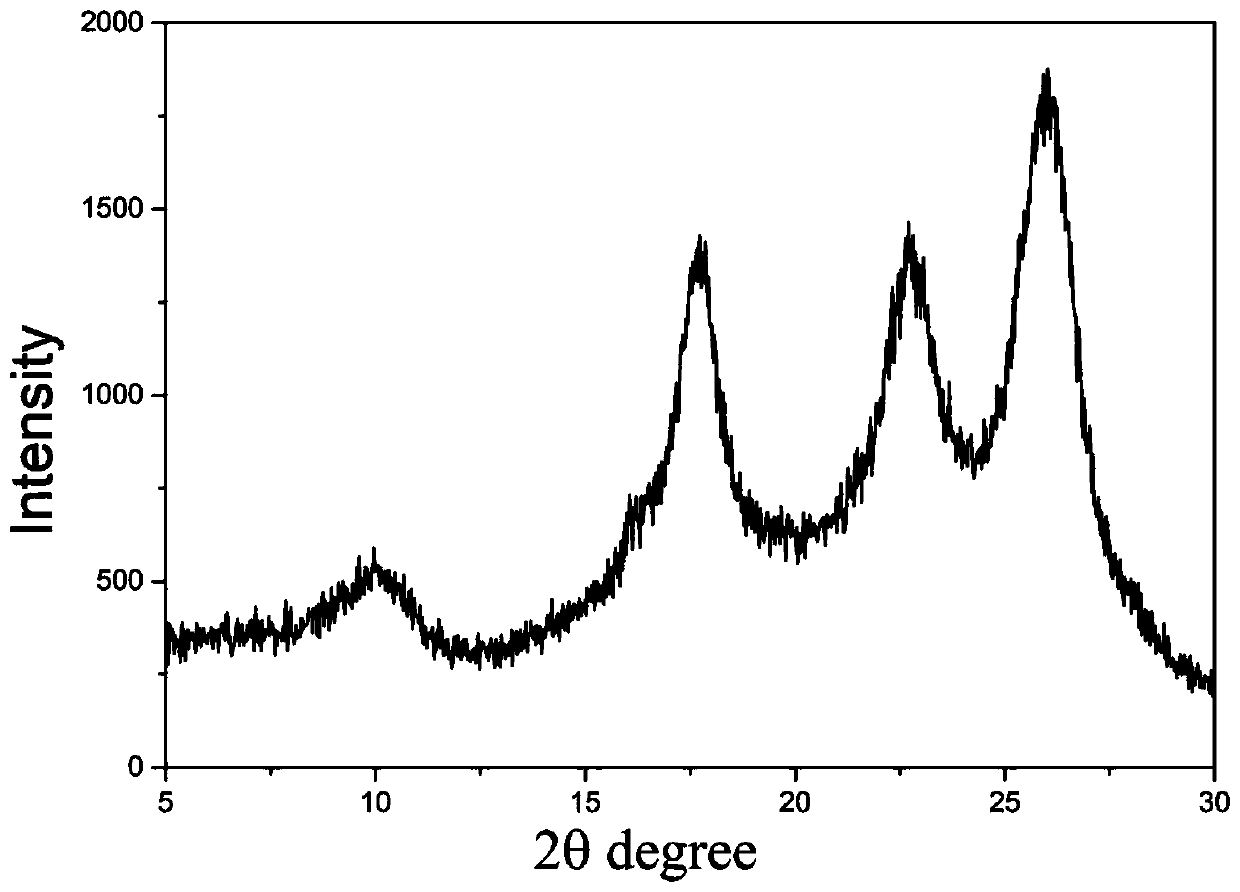

Preparation method of graphene oxide composite nano filter membrane

ActiveCN103736400AImprove throughputImprove desalination performanceSemi-permeable membranesOxide compositeMembrane surface

The invention relates to a preparation method of a graphene oxide composite nano filter membrane, and belongs to the technical field of separation membrane preparation. The preparation method of the graphene oxide composite nano filter membrane comprises the following steps: (1) preparing a graphene oxide water liquid; (2) preparing a graphene oxide cross linking liquid; and (3) preparing the graphene oxide composite nano filter membrane. The graphene oxide composite nano filter membrane provided by the invention has the characteristics that the surface of the membrane has a great deal of free carboxyl and hydroxy, the hydrophilicity is high, the flux is high, meanwhile, the charge on the surface of the membrane is negative, the salt cutting ratio is effectively improved, the flux and a desalting effect of the nano filter membrane are remarkably improved, and the graphene oxide composite nano filter membrane has the good large-scale industrialized application prospects.

Owner:OCEAN UNIV OF CHINA

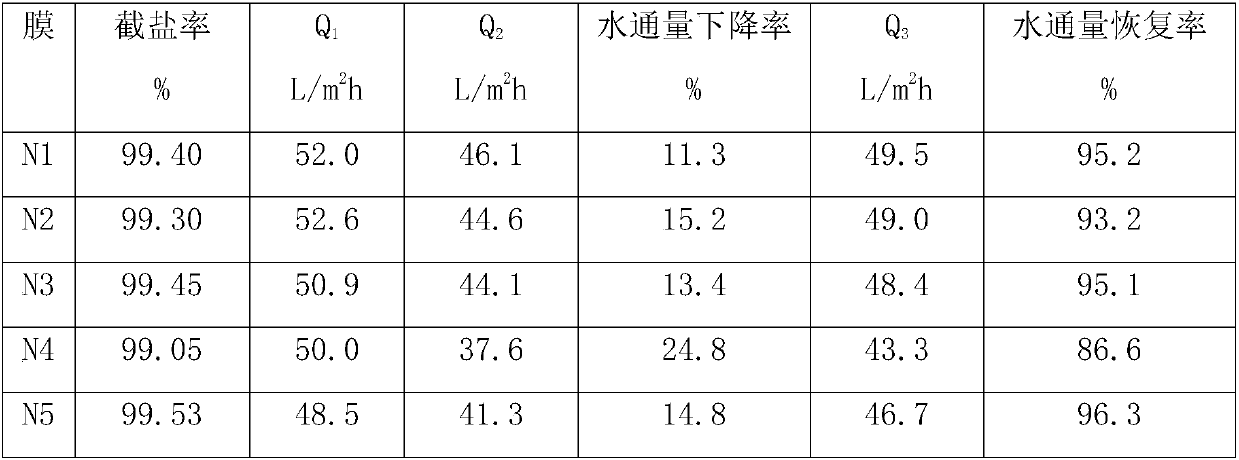

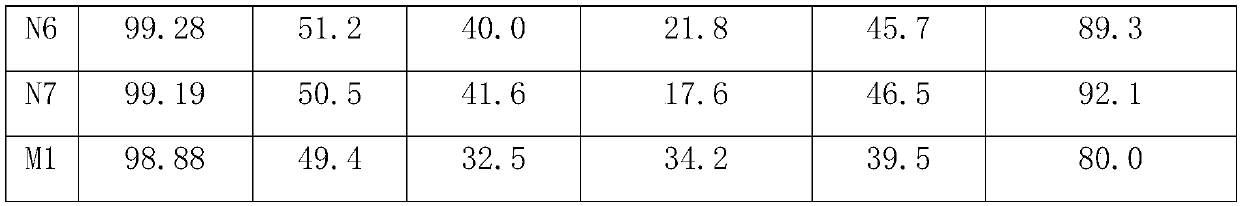

Pollution-resistant polyamide composite membrane and preparation method thereof

InactiveCN103480284AExtended service lifeIncrease water fluxSemi-permeable membranesZinc compoundsNanoparticle

The invention discloses a pollution-resistant polyamide composite membrane which comprises a nonwoven fabric layer, a porous support layer, a polyamide layer and a pollution-resistant layer which are stacked sequentially, wherein the pollution-resistant layer comprises a polymer compounding inorganic nano particles; the inorganic nano particles are modified or unmodified inorganic nano particles, and preferably are at least one kind of the nano particles of silver, silver compound, modified silver, modified silver compound, copper, copper compound, modified copper, modified copper compound, zinc, zinc compound, modified zinc, modified zinc compound, titanium, titanium compound, modified titanium and modified titanium compound. The invention also provides a preparation method of the pollution-resistant polyamide composite membrane and an application of the pollution-resistant polyamide composite membrane in the field of liquid separation.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Preparation method of composite forward osmosis membrane

ActiveCN103962015AImprove salt interception rateHigh water fluxSemi-permeable membranesWater channelCellulose acetate

The invention provides a preparation method of a composite forward osmosis membrane. A nanotube and cellulose triacetate are combined, the nanotube has a good water channel, the transferring speed of water molecules in the forward osmosis membrane is increased, the water flux in a forward osmosis process is greatly improved, the saline ion interception capability is improved, and the salt intercepting rate of the forward osmosis membrane is improved due to the special cavity structure of the nanotube. The invention also provides the composite forward osmosis membrane prepared by the method. The composite forward osmosis membrane has high water flux and high salt intercepting rate.

Owner:ETERNAL GUANGDONG TECH ELECTRIC CO LTD

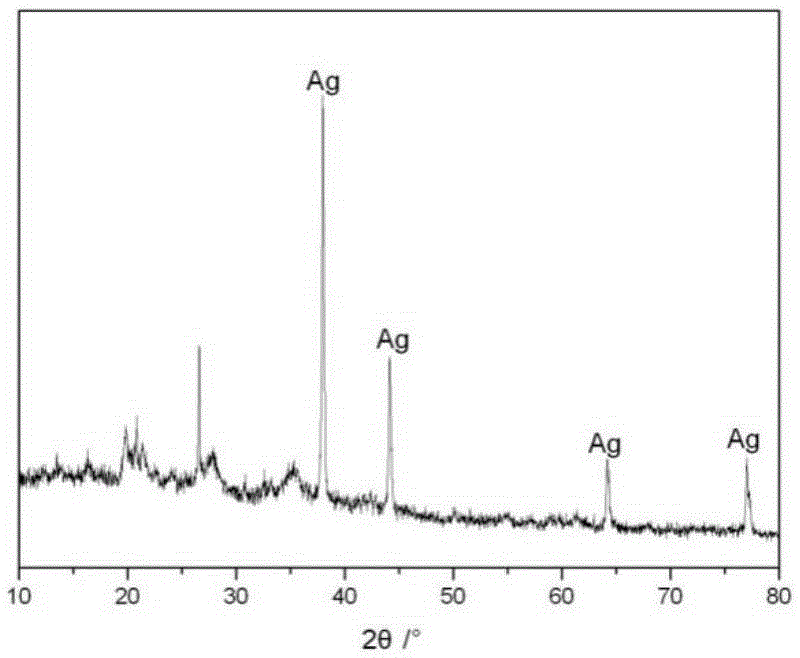

Antibacterial reverse osmosis composite membrane and preparation method and application thereof

InactiveCN106621851AImprove antibacterial propertiesExtended service lifeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisReverse osmosisAntibacterial agent

The invention relates to an antibacterial reverse osmosis composite membrane, which comprises a reverse osmosis membrane and a polymer cross-linking coating. An antibacterial agent in the polymer cross-linking coating is composite inorganic powder containing nano-silver. In the composite inorganic powder, mass ratio of silver to attapulgite is 10 / 100-100 / 100, and particle size of nano-silver is 3-100 nm. The invention also relates to a preparation method of the antibacterial reverse osmosis composite membrane. The antibacterial reverse osmosis composite membrane provided by the invention has advantages of good antibacterial property, long life, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano-filtration membrane, preparation method and applications of thereof

ActiveCN109692584AImprove salt interception rateIncrease crosslink densityMembranesWater/sewage treatment bu osmosis/dialysisCross-linkFiltration membrane

The invention relates to the field of separation membranes, particularly to a nano-filtration membrane and a preparation method thereof, and applications of the nano-filtration membrane in water treatment processes. The nano-filtration membrane comprises a support layer and a polyamide separation layer, wherein one surface of the polyamide separation layer is attached to the support layer, the other surface of the polyamide separation layer is cross-linked with a polyphenol-based compound, and the polyphenol-based compound is chelated with polyvalent metal cations. According to the present invention, tannic acid reacts with the residual amino group in the polyamide separation layer so as to increase the cross-linking density of the polyamide surface, and the cross-linking degree of the membrane surface is further increased through the chelating action between the polyvalent metal cations and the tannic acid, such that the salt retention rate of the membrane is significantly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

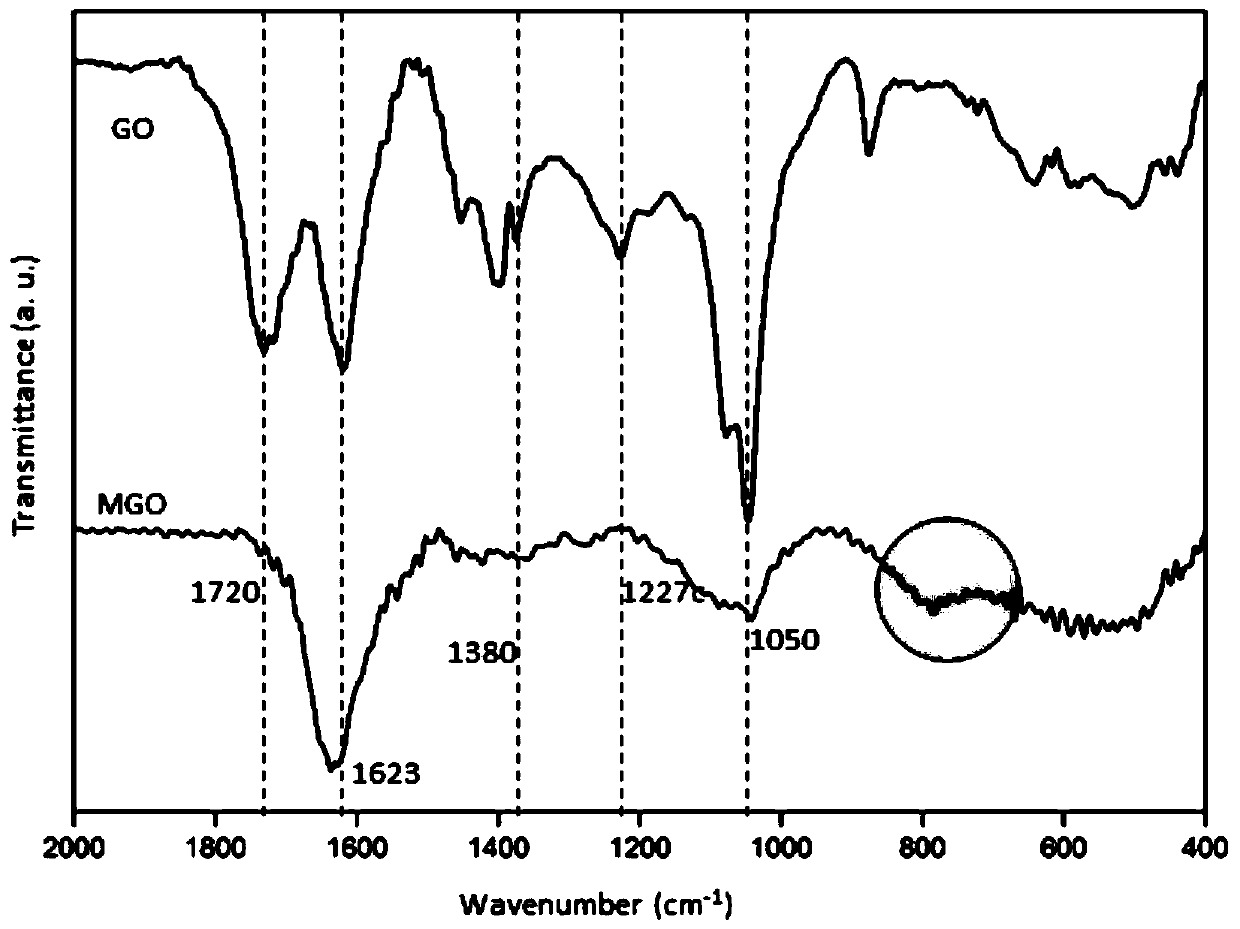

Modified wholly aromatic polyamide membrane and preparation method thereof

InactiveCN108568217AImprove surface topographySurface morphology thinSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationPolyamide

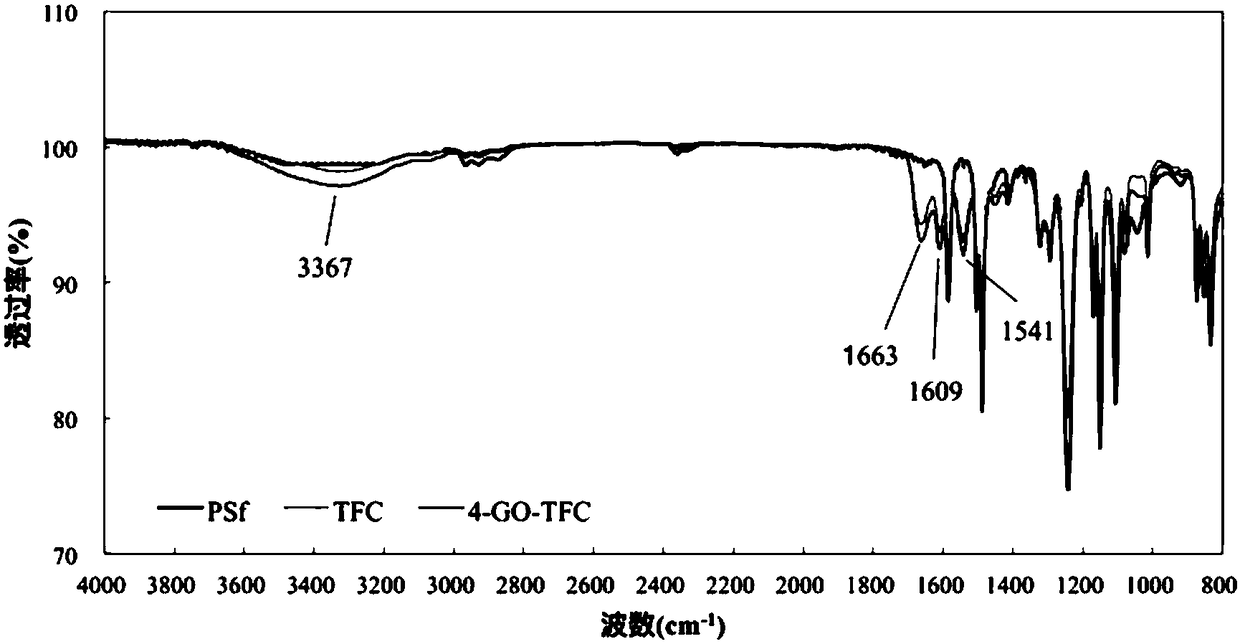

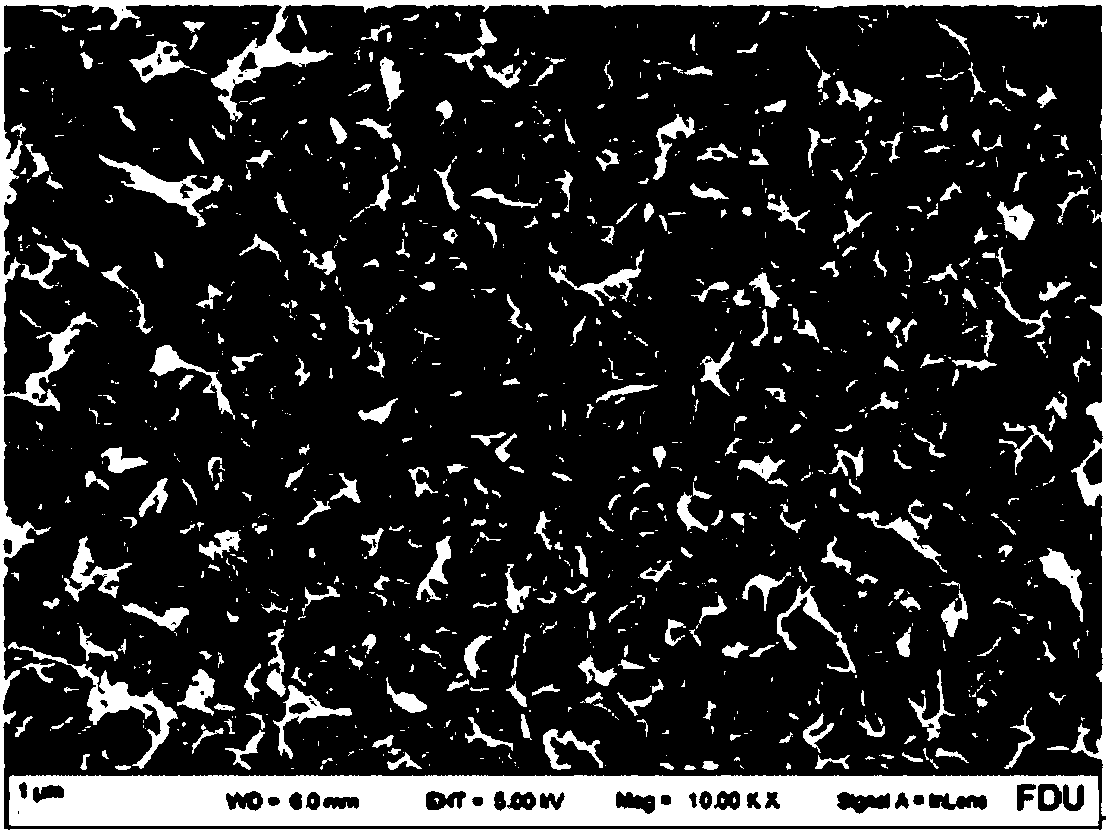

The invention relates to a modified wholly aromatic polyamide membrane and preparation thereof. The preparation method comprises the following steps: (1) placing graphene oxide in water, carrying outultrasonic dispersion to obtain a graphene oxide stock solution, and adding the graphene oxide stock solution in a m-phenylenediamine aqueous solution to obtain a m-phenylenediamine water-phase solution which contains graphene oxide; (2) dipping a polysulfone ultrafiltration membrane in the m-phenylenediamine aqueous solution which contains the graphene oxide, then taking out the polysulfone ultrafiltration membrane and removing the excessive m-phenylenediamine aqueous solution which contains the graphene oxide on the surface of the polysulfone ultrafiltration membrane, dipping the polysulfoneultrafiltration membrane in a n-hexane solution of trimesoyl chloride, and reacting to form a wholly aromatic polyamide active layer to obtain an initial membrane; and (3) washing the initial membrane, soaking the initial membrane in a sodium carbonate solution, and finally taking out the initial membrane and drying the initial membrane to obtain the modified wholly aromatic polyamide membrane. Compared with the prior art, the modified wholly aromatic polyamide membrane is good in hydrophilic performance, large in membrane flux and high in pollution resistance.

Owner:TONGJI UNIV

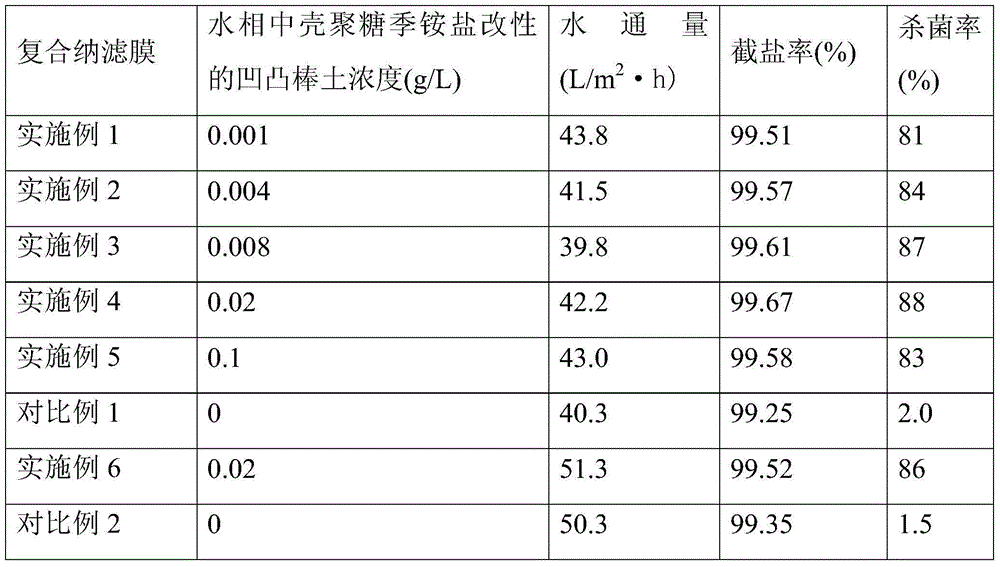

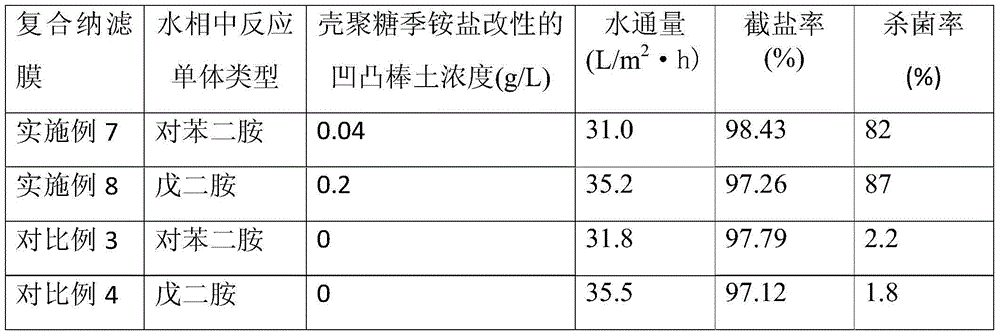

Antibacterial composite nanofiltration membrane with high salt rejection rate and preparation method of antibacterial composite nanofiltration membrane

InactiveCN104548951AImprove antibacterial propertiesThe experiment process is simpleSemi-permeable membranesRejection rateNanofiltration

The invention discloses an antibacterial composite nanofiltration membrane with high salt rejection rate and a preparation method of the antibacterial composite nanofiltration membrane. The composite nanofiltration membrane contains attapulgite modified by a chitosan quaternary ammonium salt. The preparation method comprises the following steps: (1) enabling a porous support layer to be in contact with a water phase solution of a compound containing two or more reactive amino groups; (2) removing the excess water phase solution on the porous support layer after water phase infiltration; (3) enabling the porous support layer after the treatment in step (2) to be in contact with an organic phase solution of an acyl chloride compound containing two or more acyl chloride groups; (4) volatilizing the organic phase solution and further enabling the porous support layer to be in contact with the water phase solution of the compound containing two or more reactive amino groups and the attapulgite modified by the chitosan quaternary ammonium salt; (5) performing heat treatment and washing with water to obtain the antibacterial composite nanofiltration membrane. The antibacterial composite nanofiltration membrane disclosed by the invention can improve antibacterial performance and salt rejection rate on the basis of keeping considerable water flux.

Owner:CHINA PETROLEUM & CHEM CORP +1

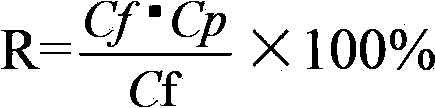

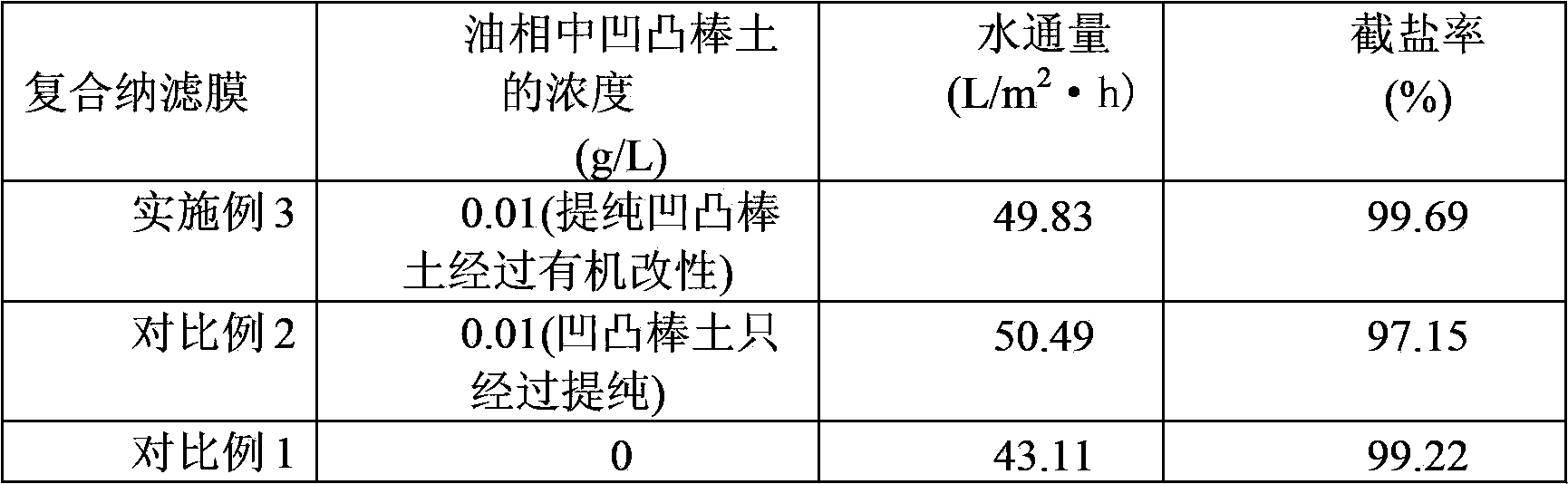

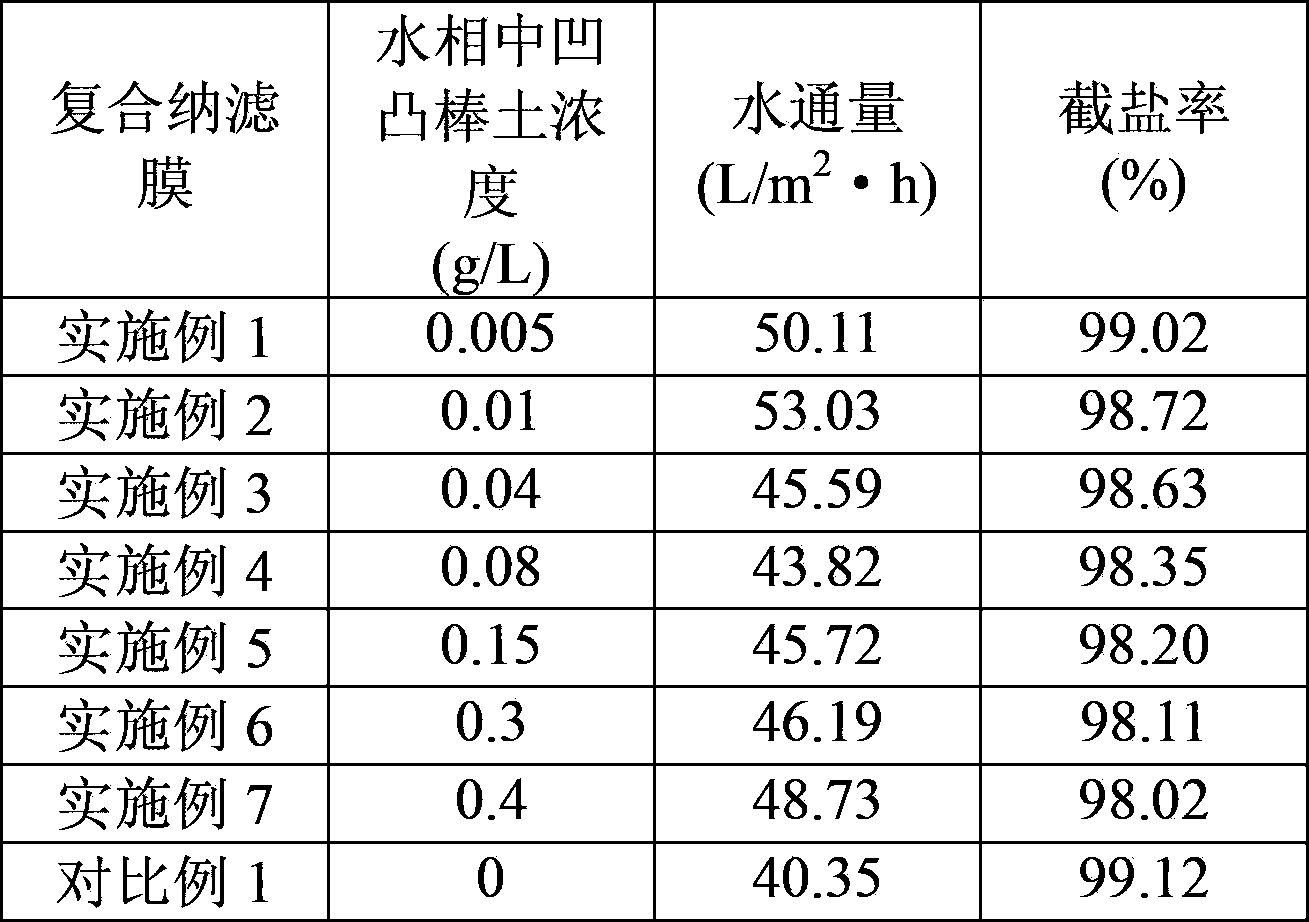

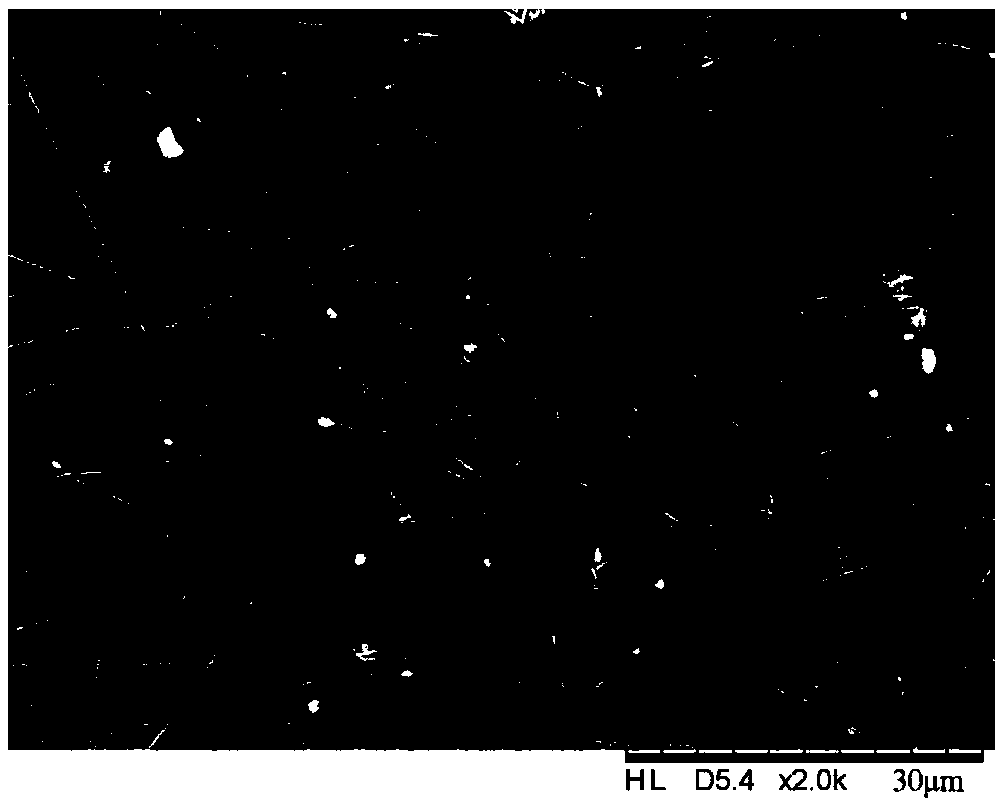

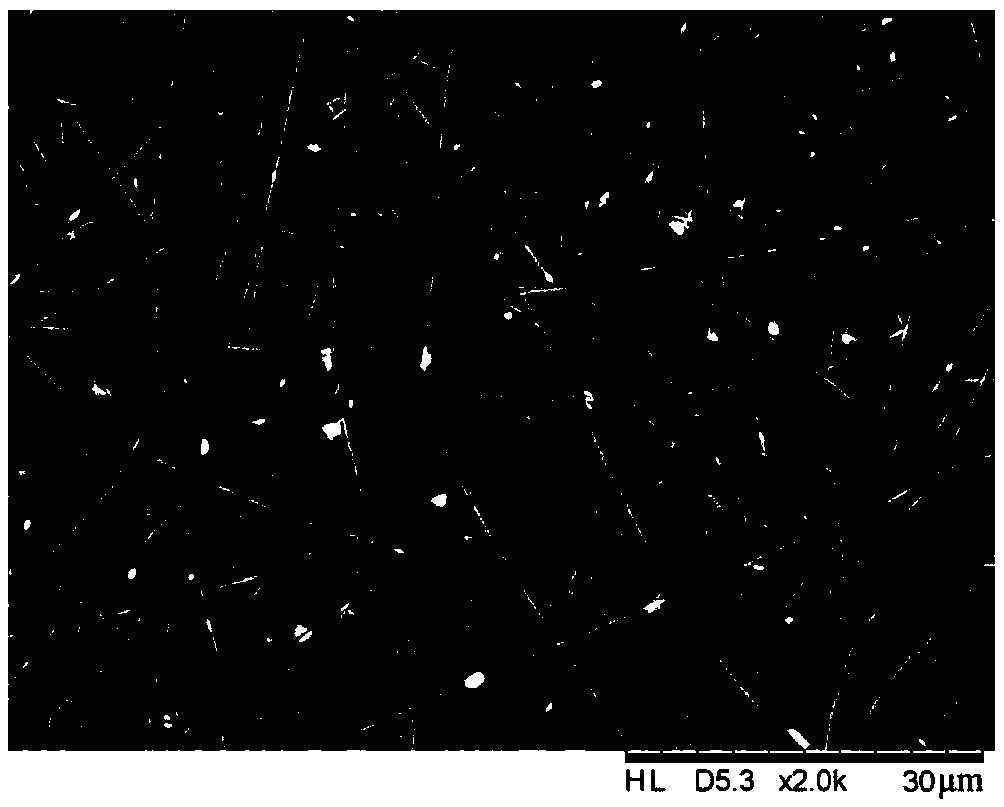

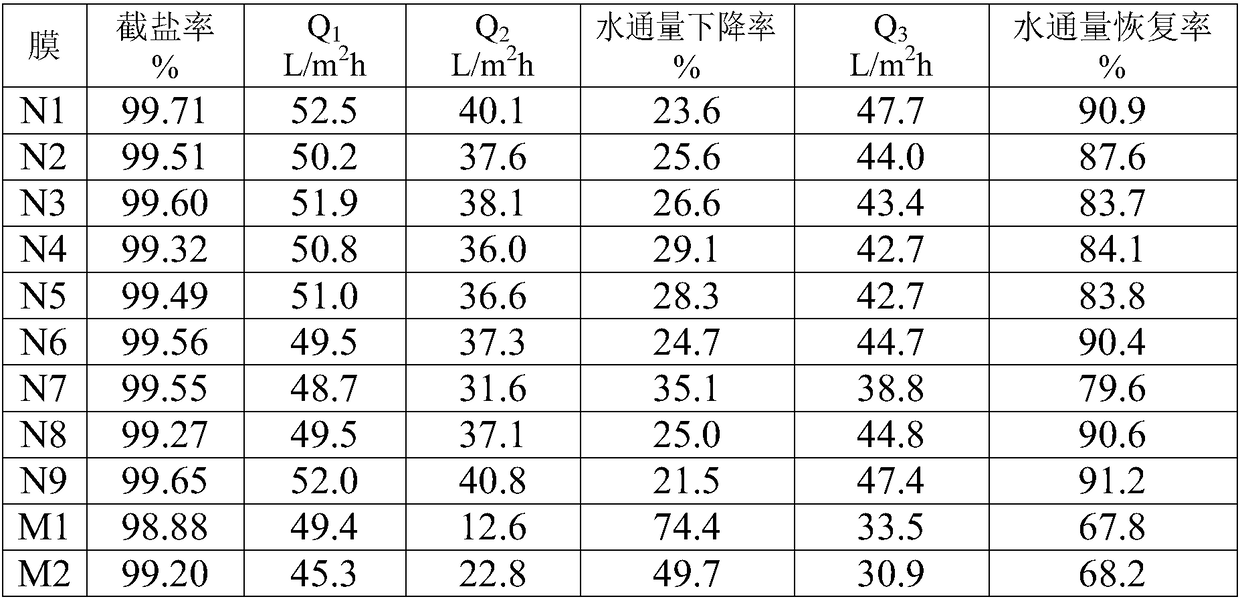

Composite nanofiltration membrane containing organically modified attapulgite and preparation method thereof

ActiveCN103785297AIncreased water fluxImprove salt interception rateSemi-permeable membranesNanofiltrationAmmonium

The invention discloses a composite nanofiltration membrane containing organically modified attapulgite and a preparation method thereof. The nanofiltration membrane is prepared by: (1) contacting a porous polysulfone supporting layer and a water phase solution containing reaction monomers; (2) rolling the porous polysulfone supporting layer having been dipped in the water phase by a rubber roller to remove the excess water phase solution; (3) contacting the porous polysulfone supporting layer treated in the step (2) and an organic phase solution containing reaction monomers and the purified and organically modified attapulgite to obtain a composite membrane; and (4) drying the composite membrane, allowing the composite membrane to stand, and washing the composite membrane with water to obtain the composite nanofiltration membrane. The purified attapulgite modified with a quaternary ammonium salt is introduced in an interfacial polymerization process, thus enhancing permeability of the composite nanofiltration membrane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite nanofiltration membrane, and preparation method and applications thereof

ActiveCN110960991AEasy to prepareIncrease water fluxMembranesGeneral water supply conservationPhosphatePhytic acid

The invention belongs to the field of separation membranes, and discloses a composite nanofiltration membrane, and a preparation method and an applications thereof. The composite nanofiltration membrane comprises a support layer and a polyamide separation layer; the polyamide separation layer contains phytic acid and multivalent metal cations chelated with phytic acid. According to the composite nanofiltration membrane disclosed by the invention, phytic acid is introduced in an interfacial polymerization process, so that the phytic acid and amino form hydrogen bonds to be fixed in a polyamidelayer, the phytic acid in the polyamide layer is chelated through multivalent metal cations, and surface crosslinking is realized so as to improve the salt rejection rate; meanwhile, phosphate groupsin phytic acid molecules improve the hydrophilicity of the polyamide surface, and the water flux of the nanofiltration membrane is improved. Meanwhile, the preparation method of the composite nanofiltration membrane is simple and has a great industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

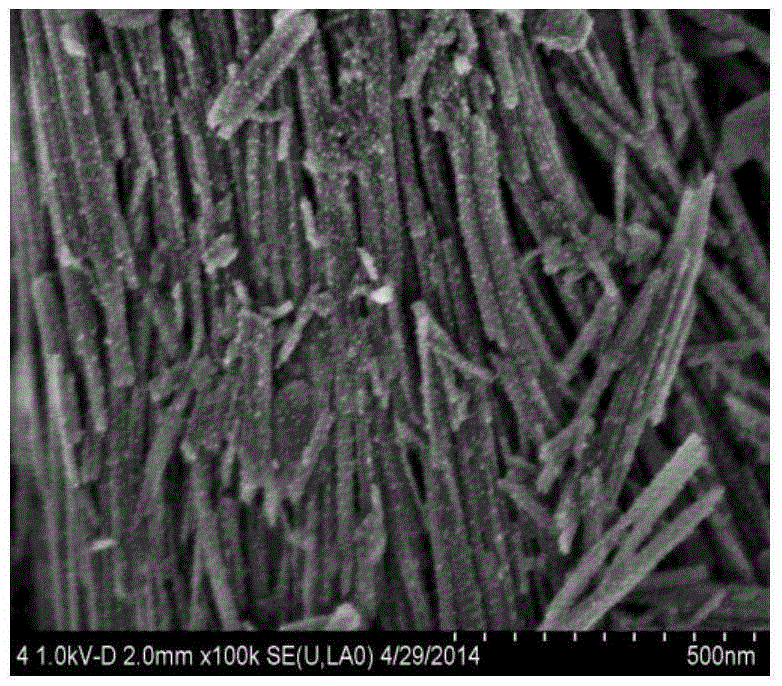

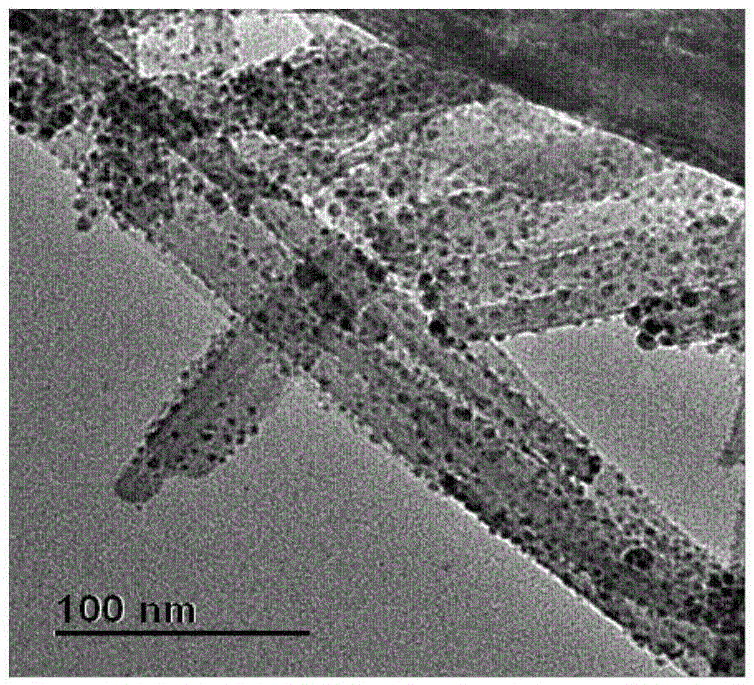

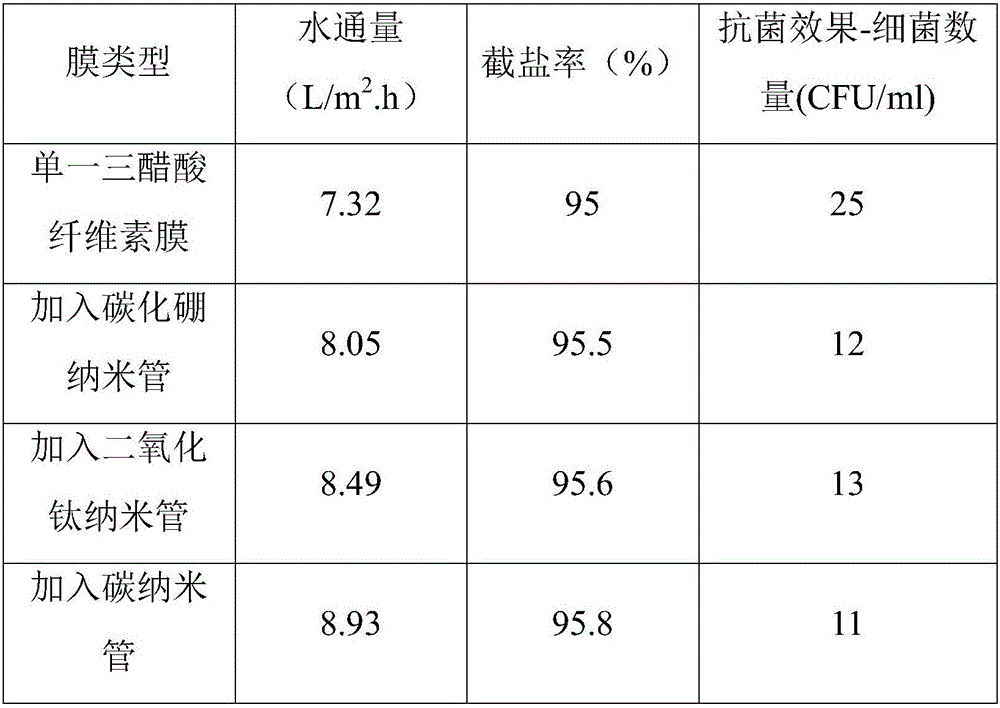

Composite forward osmosis membrane and preparation method thereof

InactiveCN105771680AHas antibacterial functionIncrease water fluxMembranesSemi-permeable membranesCompound aCellulose acetate

The invention provides a composite forward osmosis membrane. The composite forward osmosis membrane is prepared by compounding a membrane material and a supporting material; the membrane material is mainly formed by compounding a nano silver-loaded nanotube material and cellulose triacetate; the nanotube material is selected from one or more of boron carbide nanotube with hydrophilic groups, titanium dioxide nanotube with super hydrophilicity, and carboxylic carbon nanotube with hydrophilic groups. The composite forward osmosis membrane can improve the water flow rate, achieves high salt rejection capability, and has antibacterial effect. The invention further provides a preparation method of the composite forward osmosis membrane. The method comprises the following steps: firstly performing surface modification on the nanotube materials, and introducing hydrophilic groups; secondly, loading nano silver on the nanotube materials subjected to surface modification; thirdly, pretreating a supporting material; fourthly, preparing a membrane solution; fifthly, spreading the membrane solution onto the supporting material to obtain a membrane after scraping, coating the surface with gel after a solvent is volatilized, so as to prepare the composite membrane.

Owner:中科检测技术服务(嘉兴)有限公司

Modified semi-aromatic polyamide membrane and preparation method thereof

InactiveCN108404688AImprove charging effectEnhance electrostatic interactionMembranesSemi-permeable membranesUltrafiltrationPolyamide

The invention relates to a modified semi-aromatic polyamide membrane and a preparation method thereof. The modified semi-aromatic polyamide membrane includes the steps: (1) placing graphene oxide intowater, ultrasonically dispersing the graphene oxide in the water to obtain graphene oxide stock solution, and adding the graphene oxide stock solution into piperazine aqueous solution to obtain piperazine aqueous phase solution containing the graphene oxide; (2) soaking a polysulfone ultrafiltration membrane into the piperazine aqueous phase solution containing the graphene oxide, taking out thepolysulfone ultrafiltration membrane without excessive piperazine aqueous phase solution containing the graphene oxide on the surface of the polysulfone ultrafiltration membrane, soaking the taken outpolysulfone ultrafiltration membrane into normal hexane solution of trimesoyl chloride, and reacting mixture to form a semi-aromatic polyamide active layer to obtain an initial membrane; (3) flushingthe initial membrane, soaking the initial membrane into sodium carbonate solution, and taking out and drying the initial membrane to obtain the modified semi-aromatic polyamide membrane. Compared with the prior art, a prepared product has the advantages of high salt intercepting ability and selectivity and good pollution resistance.

Owner:TONGJI UNIV

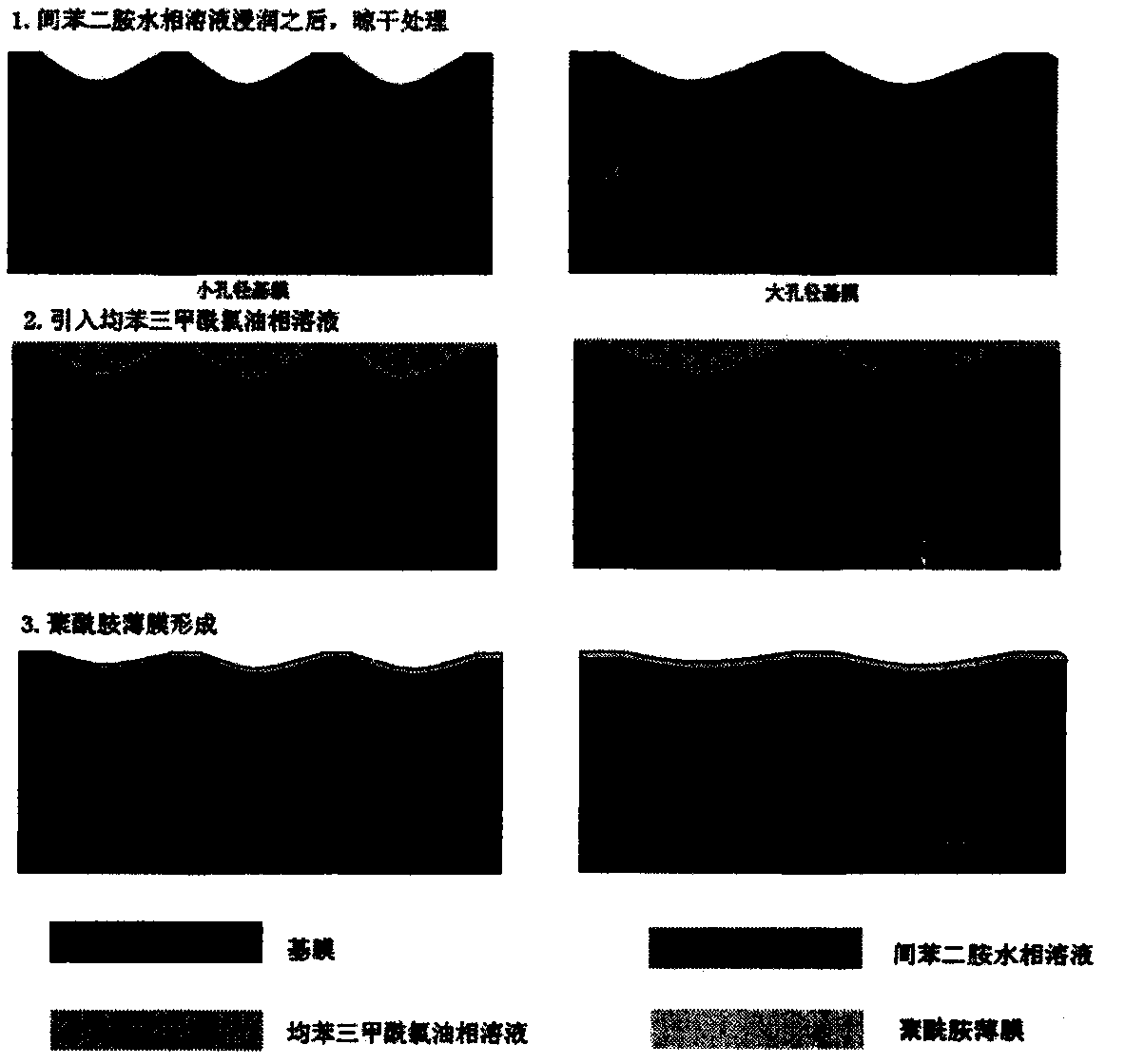

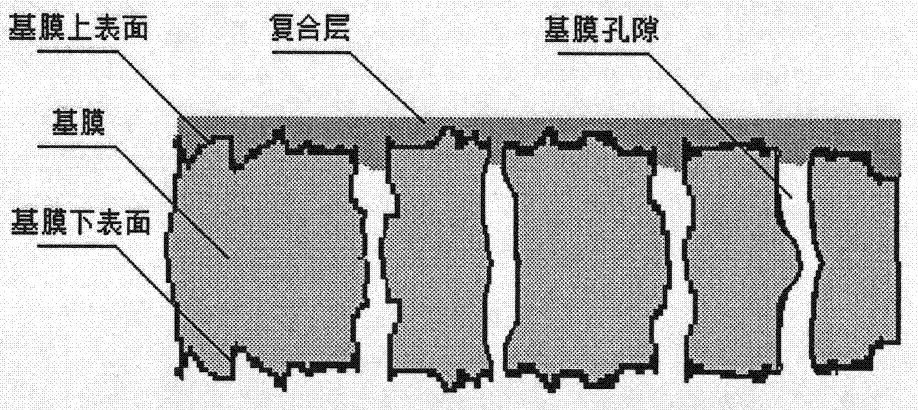

Forward osmosis composite membrane based on large-aperture base membrane, and production method thereof

ActiveCN108295667AGood high temperature resistanceShort mass transfer distanceMembranesSemi-permeable membranesUltrafiltrationChemistry

The invention discloses a forward osmosis composite membrane based on a large-aperture base membrane, and a production method thereof. The forward osmosis composite membrane is formed by the large-aperture base membrane and an ultrathin desalination layer; and a superhydrophilic micro-porous membrane having an aperture of 0.1-1 [mu]m and a porosity reaching up to 85% or more is used as the large-aperture base membrane, the large-aperture base membrane undergoes heat treatment, and then an aqueous solution of a polyamine active monomer and an oil phase solution of an acyl chloride active monomer form the ultrathin desalination polyamide layer on the surface of the base membrane through an interfacial polymerization technology. The production method effectively eliminates the adverse influences of currently adopted small-aperture ultrafiltration membrane structures as the base membrane on the performances of the forward osmosis composite membrane, solves the problem of unstable combination of the ultrathin desalination polyamide layer and the base membrane, greatly improves the intramembrane concentration polarization phenomenon, reduces the mass transfer distance and resistance, improves the water flux, the interception rate and the anti-pollution characteristic of the forward osmosis composite membrane, and has a good application prospect.

Owner:NINGBO UNIV

Attapulgite-contaiing composite nanofiltration membrane and making method thereof

ActiveCN103785307AIncrease water fluxGood dispersionSemi-permeable membranesDiameter ratioNanofiltration

The invention discloses an attapulgite-contaiing composite nanofiltration membrane and a making method thereof. The nanofiltration membrane contains attapulgite with a length / diameter ratio of 20 or less, the attapulgite has a rod-shaped or fibrous structure, and has hollow nanometer tunnels, and the diameter of the attapulgite is 10-20nm. The method comprises the following steps: 1, a porous support membrane contacts with a water phase solution containing a reaction monomer and the attapulgite; 2, the porous support membrane infiltrated in the water phase solution is rolled to remove the superfluous water phase solution; 3, the porous support membrane obtained after the processing in step 2 contacts with an organic phase solution containing another reaction monomers to obtain a composite membrane; and 4, the composite membrane obtained in step 3 is dried, the dried composite membrane undergoes heat treatment, and the obtained composite membrane is washed by water to obtain the attapulgite-contaiing composite nanofiltration membrane. The making method greatly improves the nanofiltration flux of the composite nanofiltration membrane, maintains the high retention rate of the composite nanofiltration membrane, and substantially reduces the application running cost of the composite nanofiltration membrane.

Owner:CHINA PETROLEUM & CHEM CORP +1

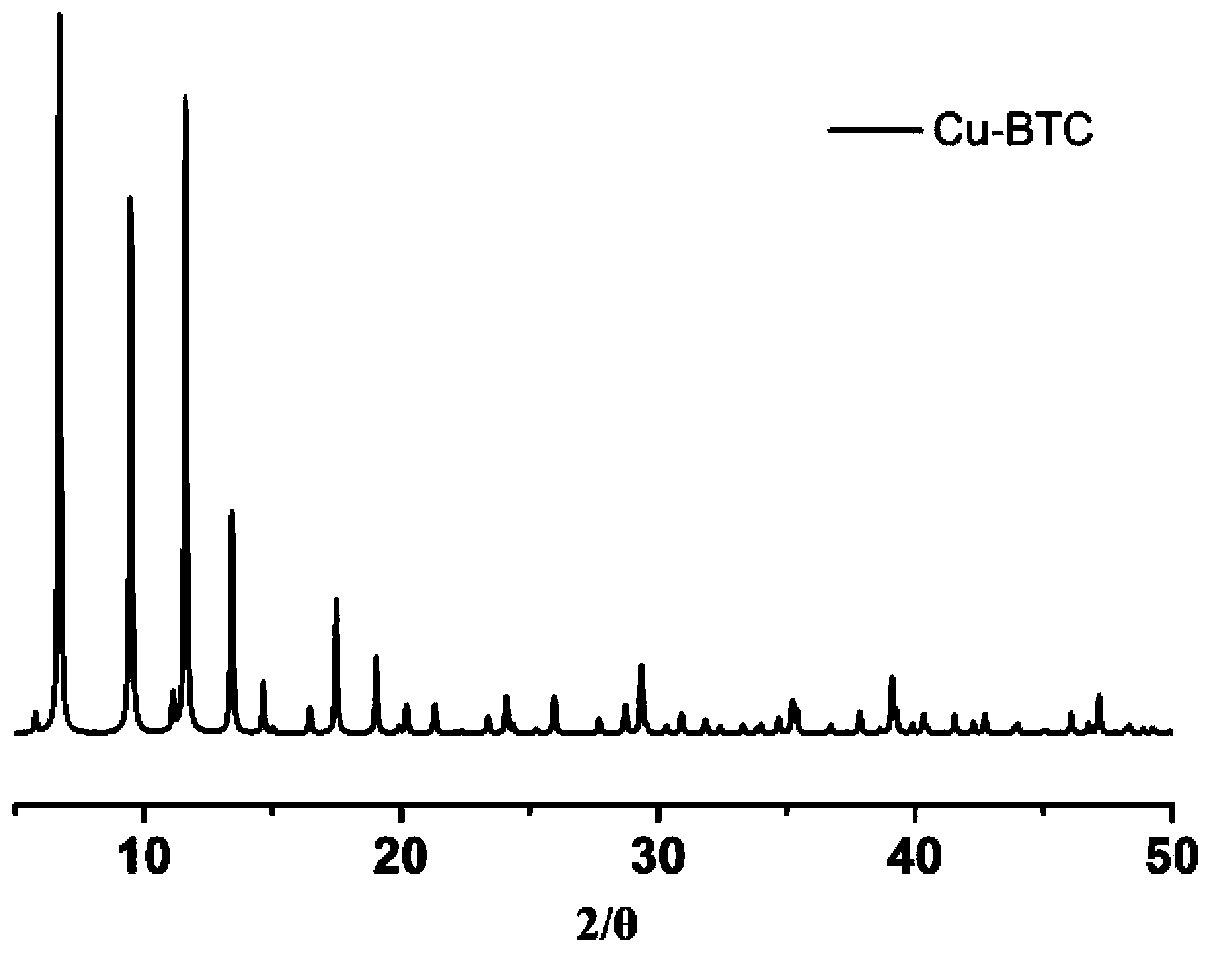

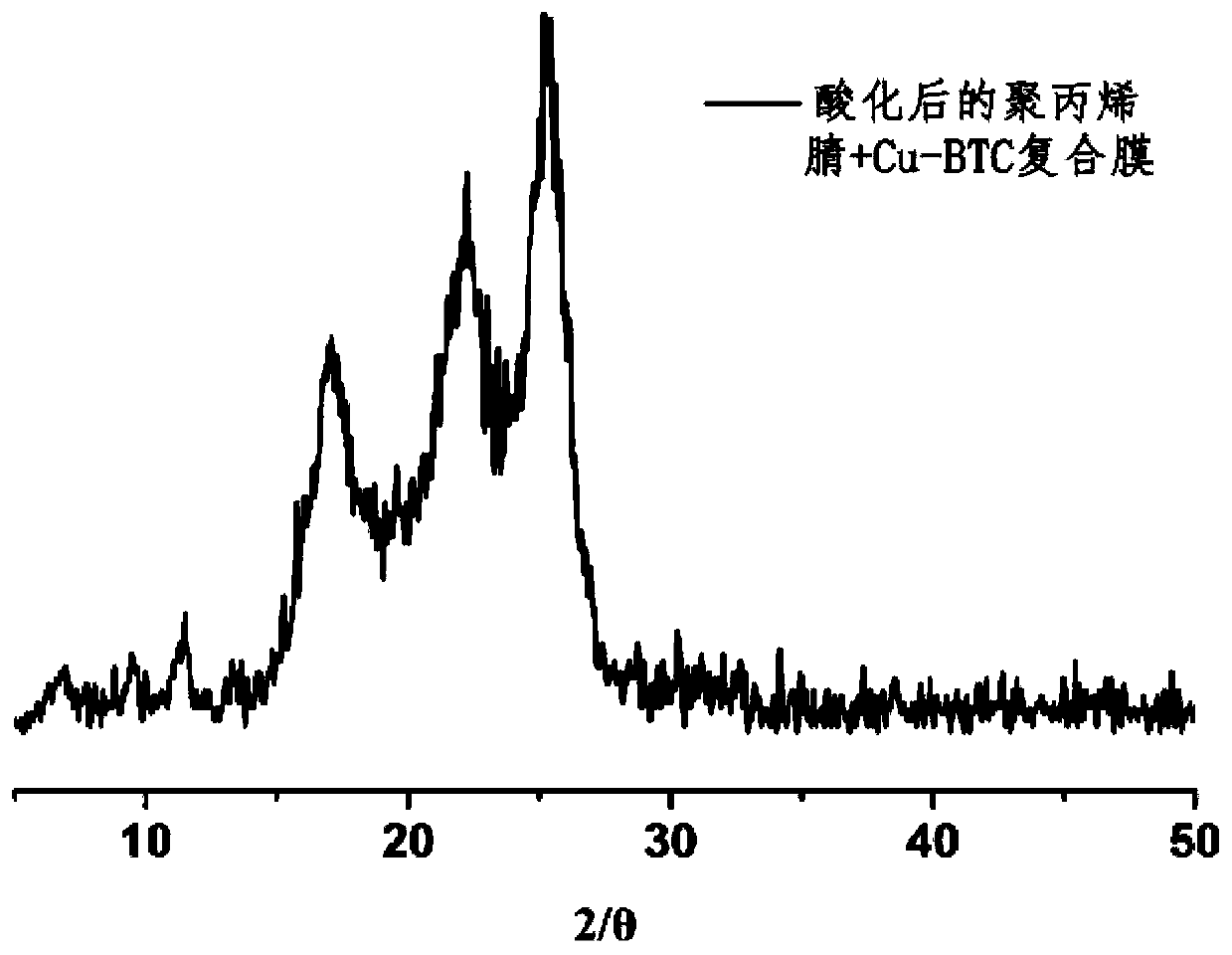

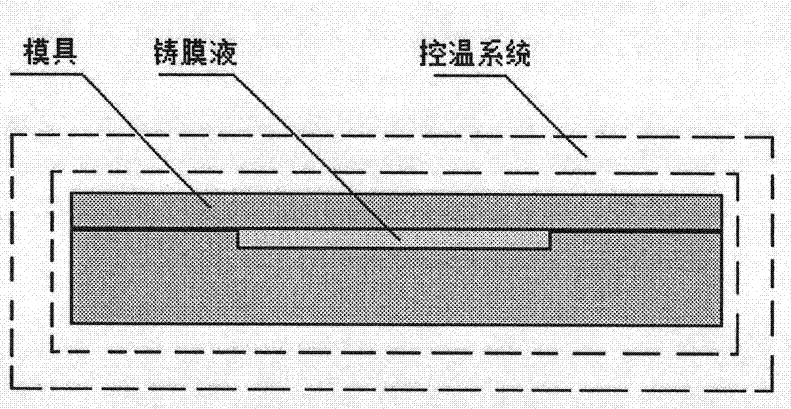

Preparation method of modified polyacrylonitrile forward osmosis membrane

The invention belongs to the field of new materials and relates to a preparation method of modified polyacrylonitrile forward osmosis membrane. The forward osmosis membrane is obtained by carrying outchemical modification on PAN, naOH, HCl and the like are used for modifying a PAN film, then, a MOFs material Cu-BTC with a porous structure is introduced, a layer-by-layer self-assembly method is used, a continuous compact Cu-BTC film layer is obtained on the surface of the film, therefore, the performance of the membrane is better improved, the salt rejection rate and the organic pollutant separation efficiency of the membrane are improved, meanwhile, the water flux of the membrane is not influenced, both the salt rejection rate and the water flux are improved, meanwhile, the membrane has good tolerance to an organic solvent, acid and alkali, and the application range of a modified separation membrane is widened. Meanwhile, the smooth surface of the material is not beneficial to breeding of bacteria, and the pollution resistance of the modified separation membrane can be improved.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

Preparation method for composite forward osmosis membrane based on interfacial polymerization

ActiveCN107297156AStrong anti-pollutionGood chemical stabilitySemi-permeable membranesPorosityPolyvinyl alcohol

The invention relates to a preparation method for a composite forward osmosis membrane based on interfacial polymerization. Polyvinyl alcohol is used as a hydrophilic modification material of polyvinylidene fluoride, caprolactam is used as a diluent, and a thermally induced phase separation method is applied to prepare a hydrophilic modified polyvinylidene fluoride base membrane under a relatively low temperature condition, the base membrane is symmetrical in structure and high in porosity, and the upper and lower surfaces are rough and have micropore structures; and m-phenylenediamine is used as a water-phase monomer, trimesoyl chloride is used as an oil-phase monomer, and interfacial polymerization is performed on the surface of the polyvinylidene fluoride base membrane to prepare the composite forward osmosis membrane with excellent chemical stability. The composite forward osmosis membrane is high in water flux and low in reverse osmosis percentage of salts, and the composite forward osmosis membrane has the advantages of higher strength, acid resistance and alkali resistance, high hydrophilcity, high anti-pollution ability, compact composite layers, firm combination and uneasiness to fall off.

Owner:NINGBO UNIV

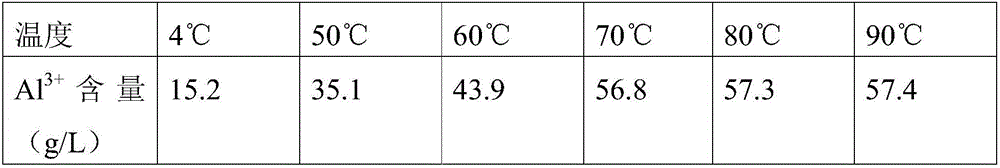

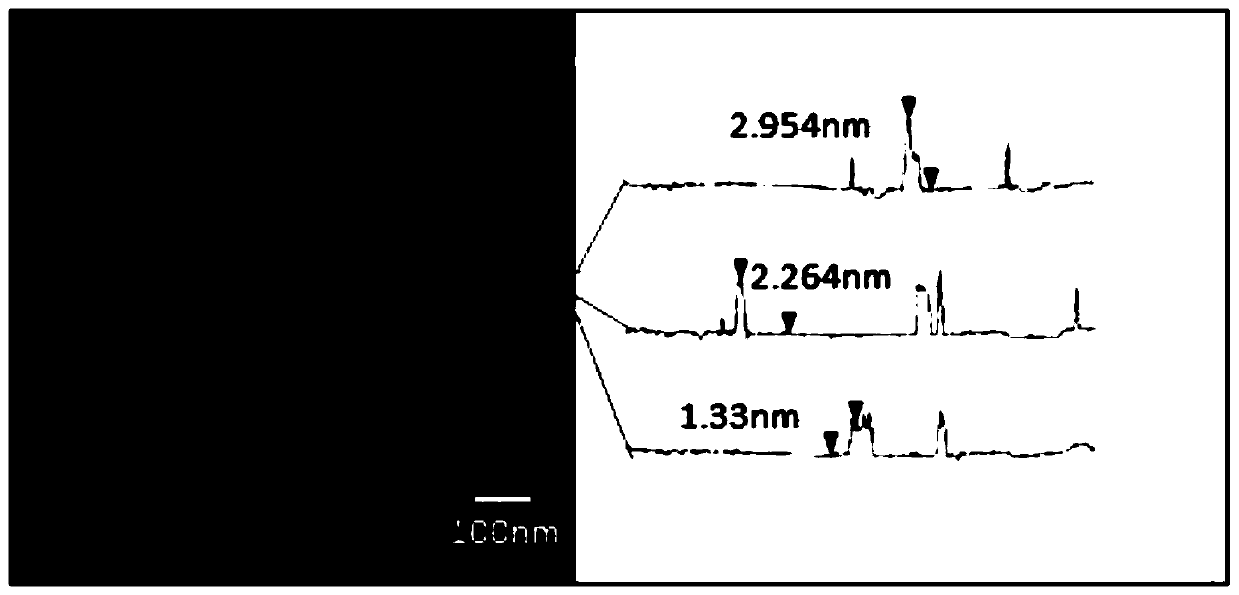

Polyaluminum ferric silicate, and method for preparing polyaluminum ferric silicate from aluminum ash

InactiveCN106378012AHas antibacterial functionIncrease water fluxSemi-permeable membranesMembranesFerricSilicate

The invention provides a method for preparing polyaluminum ferric silicate from aluminum ash. The method comprises the following steps: mixing the aluminum ash with hydrochloric acid, carrying out a reaction, mixing the obtained substance with iron-containing waste acids, adding a first alkali solution, heating and stirring the obtained solution, gradually adding water glass in the stirring process in order to carry out a reaction, and ageing the above obtained reaction product after the reaction ends in order to obtain the polyaluminum ferric silicate. The invention also provides the polyaluminum ferric silicate prepared through using the method.

Owner:四川科龙达环保股份有限公司

Multilayer cross-linked graphene oxide as well as preparation method and application thereof

ActiveCN110394070AImprove stabilityImprove salt interception rateUltrafiltrationGrapheneCross-linkFilling materials

The invention discloses a multi-layer cross-linked graphene oxide prepared by adopting an assembling-cross-linking-dispersing method. The preparation method comprises the following steps: firstly, filtering a graphene oxide aqueous solution by a filter pressing method under the action of a cross-linking agent, and then heating and cross-linking the graphene oxide; and finally, carrying out ultrasonic and dialysis treatments on the cross-linked self-assembled graphene oxide to obtain the multilayer cross-linked graphene oxide. The method has the advantages of mild conditions, no need of complexspecial ultralow temperature synthesis equipment, improvement of the stability of graphene oxide, and environmental protection. Meanwhile, the multi-layer cross-linked graphene oxide is added into the polyamide reverse osmosis membrane as a nano filling material, so that the polyamide reverse osmosis membrane has good salt rejection rate and water flux.

Owner:OCEAN UNIV OF CHINA

Preparation method for nanofiber photothermal film

ActiveCN108771984AStrong performance controllabilitySimple preparation processDistillationDistillationElectrospinning

The invention discloses a preparation method for nanofiber photothermal film, which includes the following steps: A, preparing polymer solution with a mass fraction of 9-18%, adding inorganic nano particles with infrared thermal effect accounting for 1-10% of the mass of the solution, then adding inorganic conductive particles accounting for 0.01-0.1% of the mass of the solution,carrying out ultrasonic vibration and magnetic stirring, and obtaining spinning solution after performing defoaming; B. carrying out electrostatic spinning on the spinning solution obtained in Step A to obtain the nanofiber photothermal film; C. carrying out post process on the nanofiber photothermal film obtained in Step B to optimize the film structure. The method has the advantages of simple preparation process,strong controllability of film performance, obvious photothermal effect, and the prepared film can get a very good result in film distillation process with permeation flux being maximumly improved byabout 3 times, and salt rejection rate is kept at 99% or above.

Owner:华景微纳科技(苏州)有限公司

Reverse osmosis membrane and preparation method and application thereof

PendingCN109289552AImprove hydrophilicityImprove salt interception rateMembranesGeneral water supply conservationEpoxyReverse osmosis

The invention relates to the field of separation membranes and discloses a reverse osmosis membrane, a preparation method of the reverse osmosis membrane and an application of the reverse osmosis membrane in a water treatment process. The reverse osmosis membrane includes a support layer and a polyamide separation layer, wherein one surface of the polyamide separation layer is bonded to the support layer and the other surface is subjected to surface modification by an ammonium salt containing an epoxy group, so that an epoxy group in the ammonium salt containing the epoxy group crosslinks withthe polyamide. The reverse osmosis membrane provided by the invention improves the hydrophilicity of the membrane by crosslinking the ammonium salt containing an epoxy group on the surface of the polyamide membrane, makes the surface of the membrane carry a positive charge, and improves the anti-pollution ability of the membrane to cationic surfactant or other positively charged pollutants. Moreover, the epoxy group in the ammonium salt containing epoxy group crosslinks with polyamide, which increases the crosslinking density of the reverse osmosis membrane separation layer and further improves the salt interception rate of the membrane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-performance cellulose triacetate forward osmosis membrane

InactiveCN105749765AImprove hydrophilicityEasy accessSemi-permeable membranesMembranesFiberGlass sheet

The invention relates to a preparation method of a high-performance cellulose triacetate forward osmosis membrane. The preparation method comprises the following steps: (1) preparing membrane casting fluid which is prepared from cellulose triacetate, N-methylpyrrolidinone, acetone and lactic acid: adding the lactic acid into a binary mixed solvent of the acetone and the N-methylpyrrolidinone, performing ultrasonic treatment for 1-10min to ensure that the lactic acid and the binary mixed solvent are sufficiently and uniformly mixed, then adding a membrane material, namely the cellulose triacetate, controlling the temperature to 30-60 DEG C, and performing mechanical stirring for dissolving so as to obtain the uniform membrane casting fluid; (2) performing sufficient deaeration on the membrane casting fluid at 30-60 DEG C, and performing membrane scraping on a glass plate; (3) immersing the glass plate with a thin layer of the membrane casting fluid in a gel coagulation bath of 10-50 DEG C, performing phase separation and membrane formation, then soaking the glass plate in deionized reclaimed water for 3-8d, after surplus solvents are removed, taking out the glass plate, and performing natural airing so as to obtain the cellulose triacetate forward osmosis membrane. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the technological process is simple, requirements on equipment are low, preparation conditions are easy to control, and besides, mass production is easy to perform.

Owner:SHANGHAI INST OF TECH

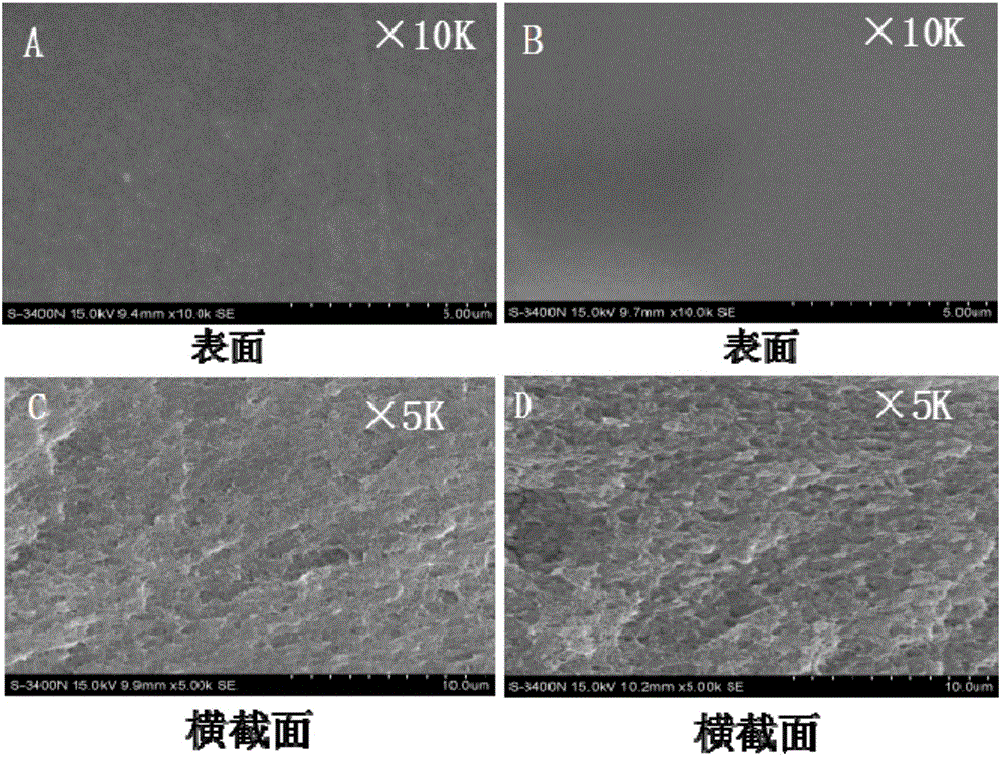

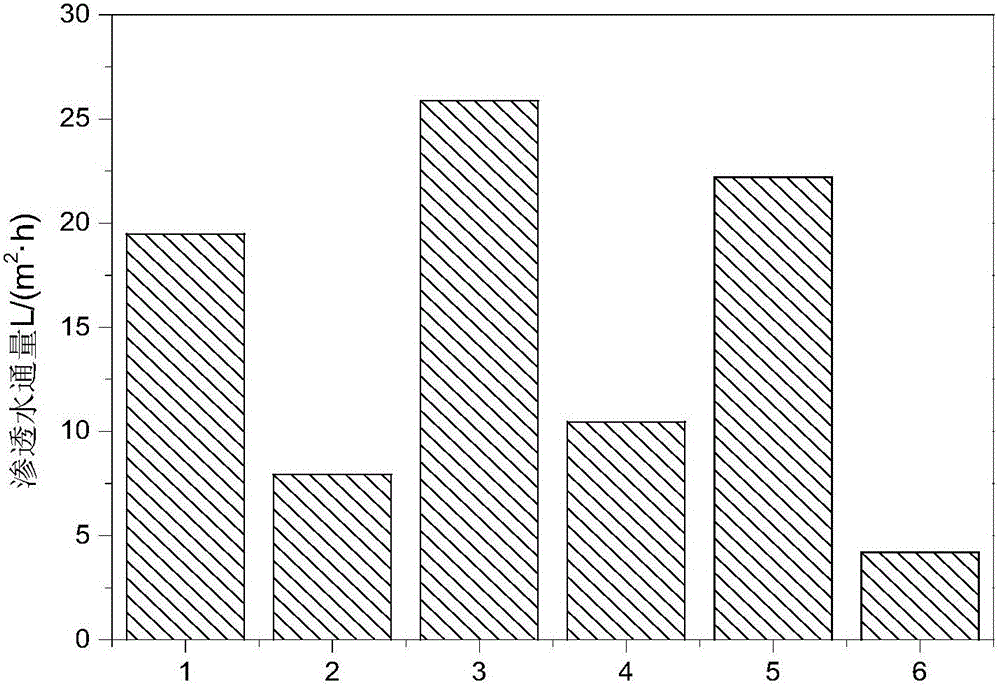

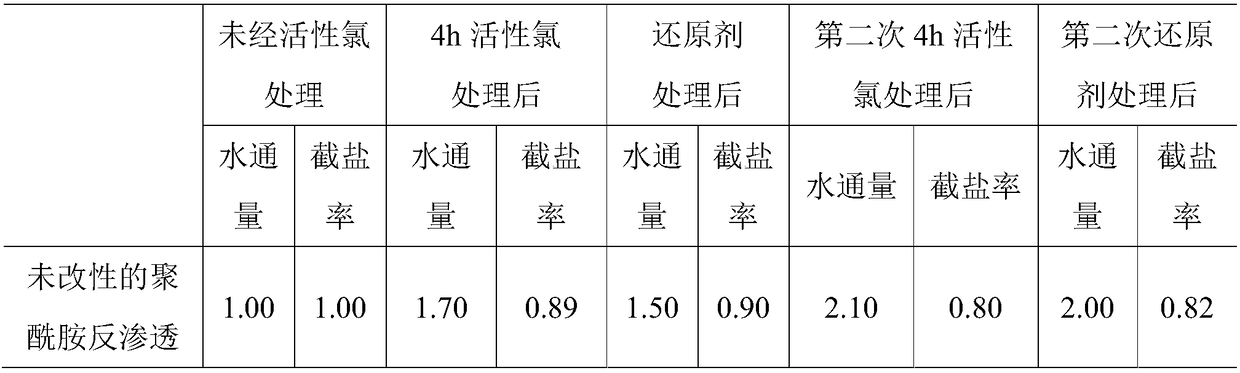

Preparation method of chlorine-resistant pollution-resistant polyamide reverse osmosis membrane

InactiveCN108939935AChlorine and stain resistantEasy to separateMembranesReverse osmosisNanofiberPolyamide

The invention discloses a preparation method of a chlorine-resistant pollution-resistant polyamide reverse osmosis membrane and relates to a preparation method of the polyamide reverse osmosis membrane. The invention aims at solving the problems of poor chlorine resistance, poor pollution resistance and no cyclic reversibility of the existing modified polyamide reverse osmosis membrane. The preparation method comprises the following steps of: (1) preparation of organic nanofiber dispersing liquid; (2) preparation of MOFs water dispersing liquid; (3) preparation of the chlorine-resistant pollution-resistant modified polyamide reverse osmosis membrane. The preparation method disclosed by the invention is used for preparing the chlorine-resistant pollution-resistant polyamide reverse osmosismembrane.

Owner:HARBIN INST OF TECH

Reverse osmosis membrane and preparation method thereof

InactiveCN110917903AImprove hydrophilicityImprove salt interception rateMembranesReverse osmosisEpoxyActive agent

The invention discloses a reverse osmosis membrane and a preparation method thereof. The reverse osmosis membrane comprises a support layer, a separation layer and a pollution-resistant layer, whereinthe support layer, the separation layer and the pollution-resistant layer are sequentially stacked from inside to outside, the separation layer has a cross-linked polyamide structure and is obtainedby carrying out interfacial polymerization on polyamine and polyacyl chloride, and the pollution-resistant layer is formed by branching and polymerizing 2,3-epoxypropane sodium sulfonate to the surface of polyamide through heat treatment under the action of a curing accelerator. According to the preparation method, 2,3-epoxypropane sodium sulfonate is branched and polymerized to the surface of a polyamide membrane, so that the hydrophilicity of the membrane is improved, the surface of the membrane is negatively charged, and the anti-pollution capability of the membrane to anionic surfactants or other negatively charged pollutants is improved; and the epoxy group is subjected to a self-polymerization reaction under the action of an accelerator to form a compact polymer layer, so that the hindering effect on salt ion penetration is improved so as to improve the salt rejection rate of the membrane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of anti-pollution nanofiltration membrane used for water purifying machines

InactiveCN106512727AImprove structural strengthExtended service lifeMembranesSemi-permeable membranesNanofiltrationUltimate tensile strength

The invention relates to a production method of an anti-pollution nanofiltration membrane used for water purifying machines. The method comprises the following steps: 1, producing a supporting layer from tubular steel wire meshes; 2, covering the surface of the produced supporting layer with a porous carrier layer; 3, covering the surface of the porous carrier with a nanofiltration membrane layer; and 4, coating the external surface of the nanofiltration membrane layer with a protection layer, reacting the protection layer with the nanofiltration membrane layer through using a PVA-water solution with the concentration of 11-15%, and drying the obtained layers in a vacuum drying box to produce the anti-pollution nanofiltration membrane used for water purifying machines. The production method of the anti-pollution nanofiltration membrane used for water purifying machines allows the nanofiltration membrane to be produced by compounding the supporting layer, the porous carrier layer, the nanofiltration membrane layer and the protection layer, so the method guarantees the nanofiltration efficiency, enhances the structure strength of the nanofiltration layer, prolongs the service life of the nanofiltration layer, prolongs the service time, and reduces the cost.

Owner:苏州富艾姆工业设备有限公司

Nanofiltration membrane as well as preparation method and application thereof

PendingCN113634136AImprove hydrophilicityImprove salt interception rateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPhytic acidPolyamide

The invention relates to a nanofiltration membrane, a preparation method thereof and application of the nanofiltration membrane in the field of water treatment. The nanofiltration membrane comprises a supporting layer and a polyamide separation layer which are attached to each other, and phytic acid is chelated on the surface of the polyamide separation layer. The polyamide separation layer and the phytic acid are chelated and crosslinked, so that the phytic acid is chelated on the surface of the separation layer. The phytic acid and amino groups on the surface of the polyamide functional layer are subjected to chelation cross-linking reaction, so that the cross-linking density of the polyamide separating layer is improved, and the hindering effect on salt ion permeation is enhanced; on the other hand, after the surface of the polyamide is modified by phytic acid, the hydrophilicity of the membrane is improved, and permeation of water molecules is facilitated. In addition, the nanofiltration membrane provided by the invention has excellent salt rejection rate and water permeability, the preparation method is simple, and the nanofiltration membrane has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of composite forward osmosis membrane

ActiveCN103962015BImprove salt interception rateImprove interception effectSemi-permeable membranesWater channelCellulose acetate

The invention provides a preparation method of a composite forward osmosis membrane. A nanotube and cellulose triacetate are combined, the nanotube has a good water channel, the transferring speed of water molecules in the forward osmosis membrane is increased, the water flux in a forward osmosis process is greatly improved, the saline ion interception capability is improved, and the salt intercepting rate of the forward osmosis membrane is improved due to the special cavity structure of the nanotube. The invention also provides the composite forward osmosis membrane prepared by the method. The composite forward osmosis membrane has high water flux and high salt intercepting rate.

Owner:ETERNAL GUANGDONG TECH ELECTRIC CO LTD

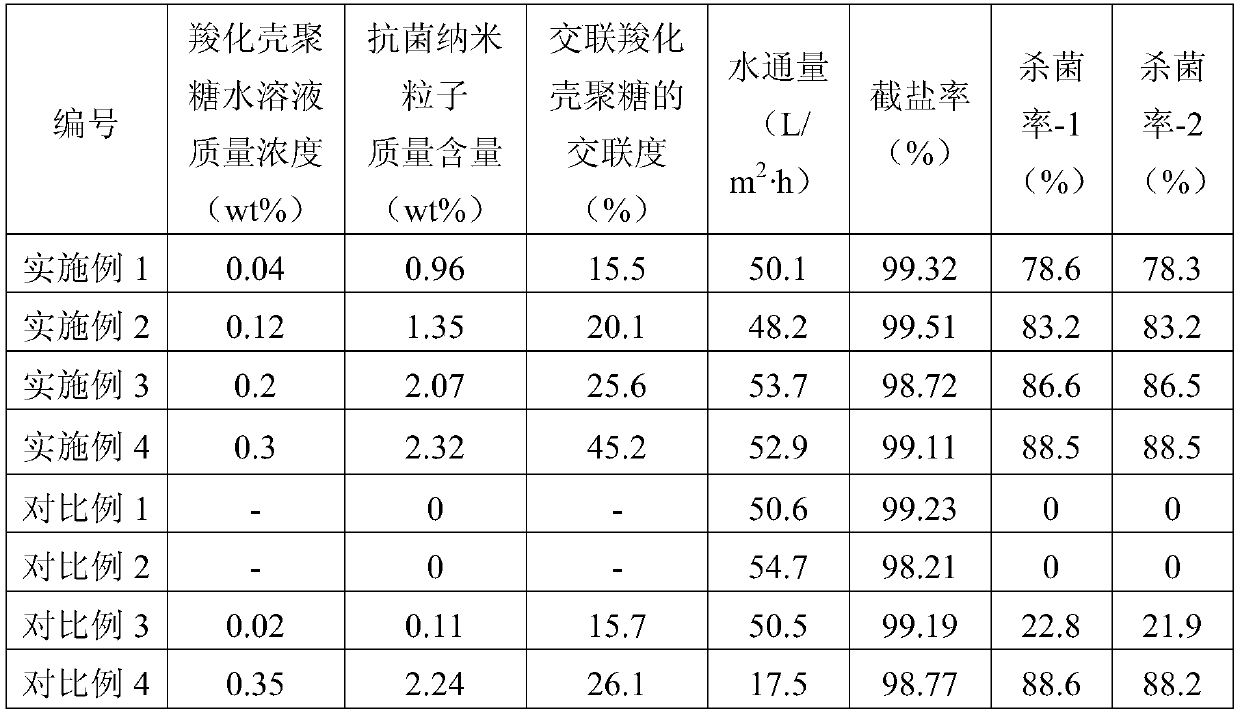

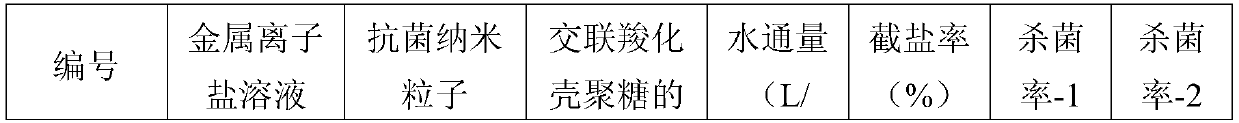

A kind of antibacterial thin-layer composite film and preparation method thereof

ActiveCN107537330BEasy to prepareReduce manufacturing costSemi-permeable membranesComposite filmChitosan coating

The invention relates to an antibacterial thin-layer composite film and a preparation method thereof. The preparation method comprises: carrying out infiltration treatment on the surface of the function layer of a thin-layer composite film by using a carboxylated chitosan coating solution, drying to obtain a carboxylated chitosan film positioned on the surface of the function layer, carrying out infiltration treatment on the carboxylated chitosan film by using a salt solution corresponding to the metal ions in antibacterial nanoparticles and a cross-linking agent solution, and carrying out heat treatment to prepare the antibacterial thin-layer composite film with the cross-linking structure. According to the present invention, the preparation method is simple, the production cost is low, and the prepared antibacterial thin-layer composite film has advantages of high water flux, good antibacterial property and strong antibacterial persistence, and has good industrialized production baseand broad application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

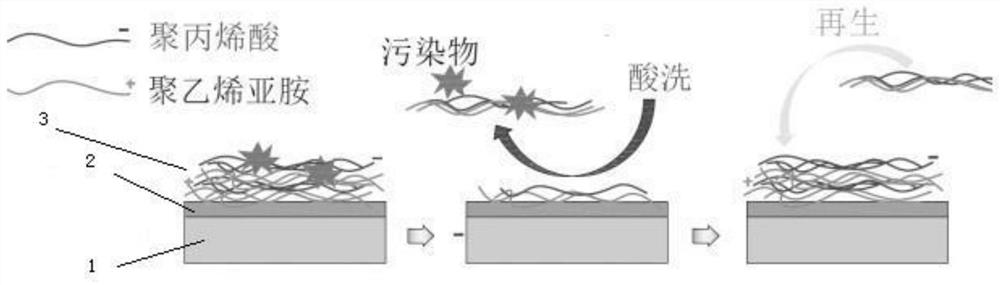

Preparation method and regeneration method of renewable polyelectrolyte membrane for forward osmosis technology

ActiveCN107715708BReduce pollutionStrong ability to intercept saltMembranesSemi-permeable membranesPoly ethyleneElectrolyte

The invention discloses a preparation method of a renewable polyelectrolyte membrane for forward osmosis technology and a regeneration method thereof. Polydopamine is used for modification of polyethersulfone surface and a selection layer is formed, layer-by-layer self-assembly technology is used for growth of polyethyleneimine and polyacrylic acid on the surface of the selection layer, and a regeneration layer is formed. The polyelectrolyte membrane employs polydopamine as the selection layer, inner concentration polarization is effectively reduced, and risk of membrane pollution is reduced;after membrane flux of the polyelectrolyte membrane is reduced due to membrane pollution, hydrochloric acid can be used for cleaning the regeneration layer, and the self-assembly technology is used for recovering interception performance of the membrane; the electrolyte membrane has low energy consumption and high water recovery rate for treating waste water containing salt; the surface hydrophilicity of the membrane is good, and pollution resistance and corrosion resistance are good, and working life is longer.

Owner:江苏海壹环境科技有限公司

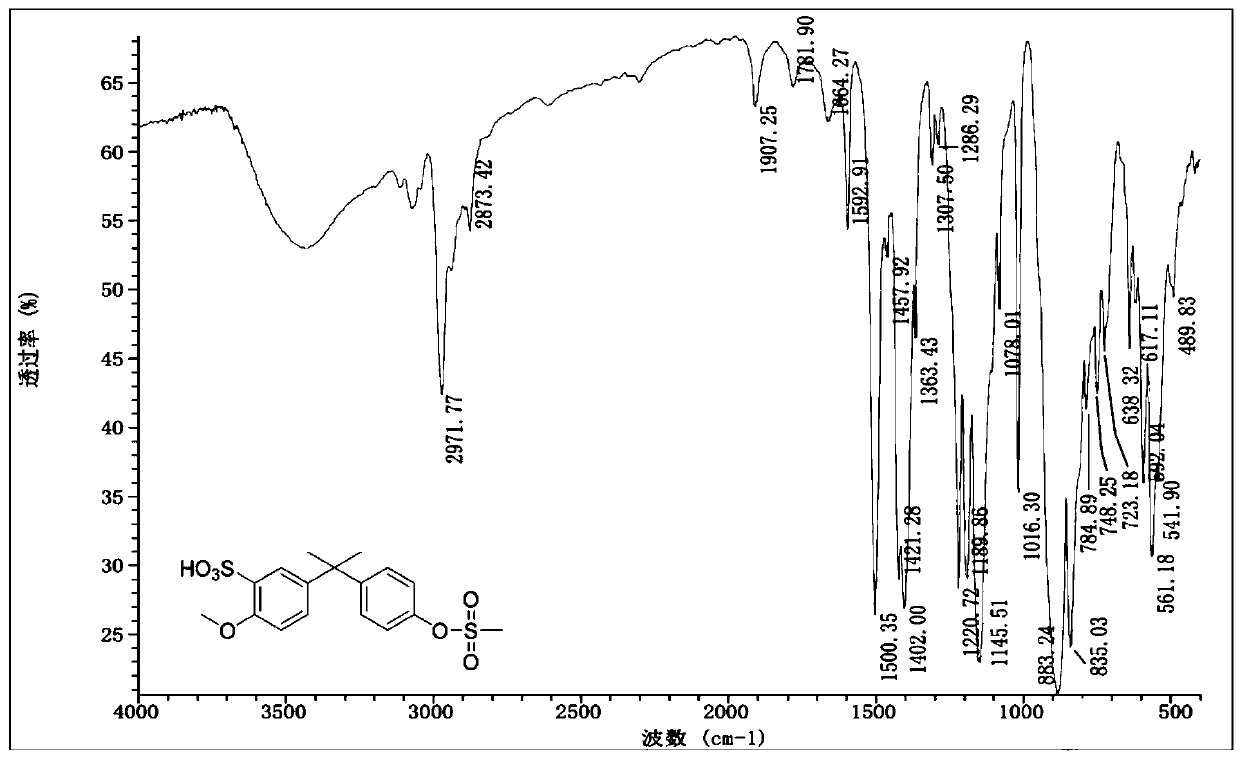

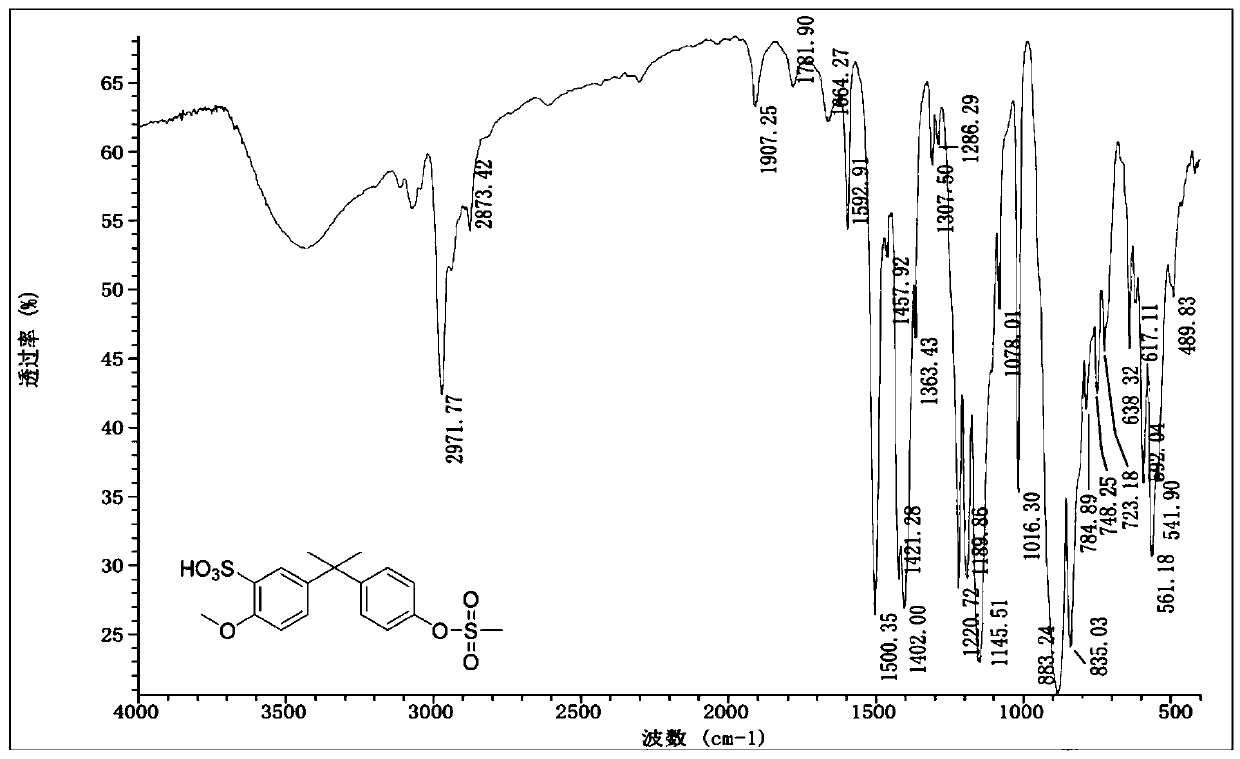

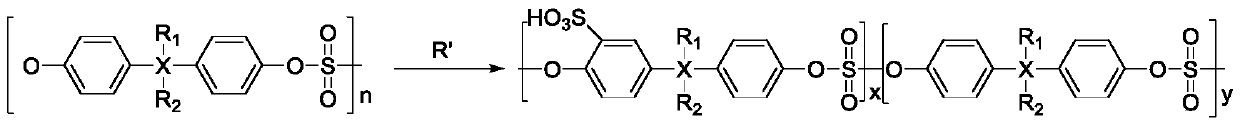

Synthesis method for preparing sulfonated polysulfurate (polyurethane) from polysulfurate (polyurethane) polymer

InactiveCN111116914AGood acid and alkali resistanceImprove hydrophilicityPolymeric surfacePolymer science

The invention discloses a synthesis method for preparing sulfonated polysulfurate (polyurethane) from a polysulfurate (polyurethane) polymer, and belongs to the technical field of macromolecules. Thesulfonated polysulfate is prepared from polysulfate (ammonia). The polysulfate obtained after sulfonation has good hydrophilicity under the condition of maintaining the original properties of the polymer, and the surface charge property of the polymer is enhanced. When applied to the fields of water treatment membranes and the like, the sulfonated polysulfurate (polyurethane) effectively improve the properties such as salt rejection rate and the like of the polymer, and has a positive effect on application of the polysulfate compound to the fields of water treatment and the like.

Owner:内蒙古图微新材料科技有限公司

Composite film and preparation method and application thereof

InactiveCN111760472AIncrease crosslink densityGood antibacterial effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer sciencePolyamide

The invention discloses a composite membrane, a preparation method thereof and application of the composite membrane in a water treatment process. The composite membrane comprises a supporting layer,a reinforcing layer and a polyamide separation layer, wherein the supporting layer is a polymer porous membrane, one surface of the supporting layer is attached to the reinforcing layer, the other surface of the supporting layer is attached to one surface of the polyamide separation layer, and the other surface of the polyamide separation layer is a guanidyl-containing surface modification layer.According to the composite membrane provided by the invention, guanidyl is introduced into the surface of the polyamide membrane in a grafting or crosslinking manner, so that the salt rejection rate and the antibacterial activity of the membrane are improved, and the composite membrane can run for a long time while the performance is kept stable.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of graphene oxide composite nanofiltration membrane

ActiveCN103736400BImprove throughputImprove desalination performanceSemi-permeable membranesCross-linkOxide composite

The invention relates to a preparation method of a graphene oxide composite nano filter membrane, and belongs to the technical field of separation membrane preparation. The preparation method of the graphene oxide composite nano filter membrane comprises the following steps: (1) preparing a graphene oxide water liquid; (2) preparing a graphene oxide cross linking liquid; and (3) preparing the graphene oxide composite nano filter membrane. The graphene oxide composite nano filter membrane provided by the invention has the characteristics that the surface of the membrane has a great deal of free carboxyl and hydroxy, the hydrophilicity is high, the flux is high, meanwhile, the charge on the surface of the membrane is negative, the salt cutting ratio is effectively improved, the flux and a desalting effect of the nano filter membrane are remarkably improved, and the graphene oxide composite nano filter membrane has the good large-scale industrialized application prospects.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com