Preparation method for nanofiber photothermal film

A nanofiber, photoinduced technology, applied in the field of membrane distillation, can solve the problems of difficulty in expanding application and high energy consumption, and achieve the effects of simple preparation process, strong controllability of membrane performance, and obvious photothermal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing a nanofiber photothermal film, which is characterized in that the method comprises the following steps:

[0018] A. Preparation of spinning solution: prepare a polymer solution with a mass fraction of 9-18%, add nano-inorganic particles with infrared thermal effect accounting for 1-10% of the solution mass, disperse evenly through ultrasonic vibration and magnetic stirring, and obtain after degassing spinning solution;

[0019] The nano-inorganic particles are oxides with infrared thermal effect, specifically antimony-doped tin oxide (ATO), indium antimony oxide (ITO), silicon dioxide (SiO 2 ) or titanium dioxide (TiO 2 ) at least one; the average particle size of nano-inorganic particles is 30 ~ 50nm; preferably ATO, ATO is made of SnO 2 and SbO 2 Composition, its mass ratio is SnO 2 :SbO 2 =9:1~19:1, the average particle size is 30~50nm, the crystal structure is tetragonal phase, the particle shape is spherical, and t...

Embodiment 1

[0026] A. Preparation of spinning solution: Weigh 5g of polyvinylidene fluoride (model: 761), dissolve it in N,N-dimethylacetamide at a temperature of 70°C and prepare a solution with a mass fraction of 15%; add nano-ATO ( SnO 2 :SbO 2 =9:1) 0.33g (accounting for 1% of the mass of the solution), then add 0.017g of lithium chloride (accounting for 0.05% of the mass of the solution), disperse evenly after ultrasonic vibration and magnetic stirring for 4 hours, and let it stand for defoaming for 12h , to obtain spinning solution;

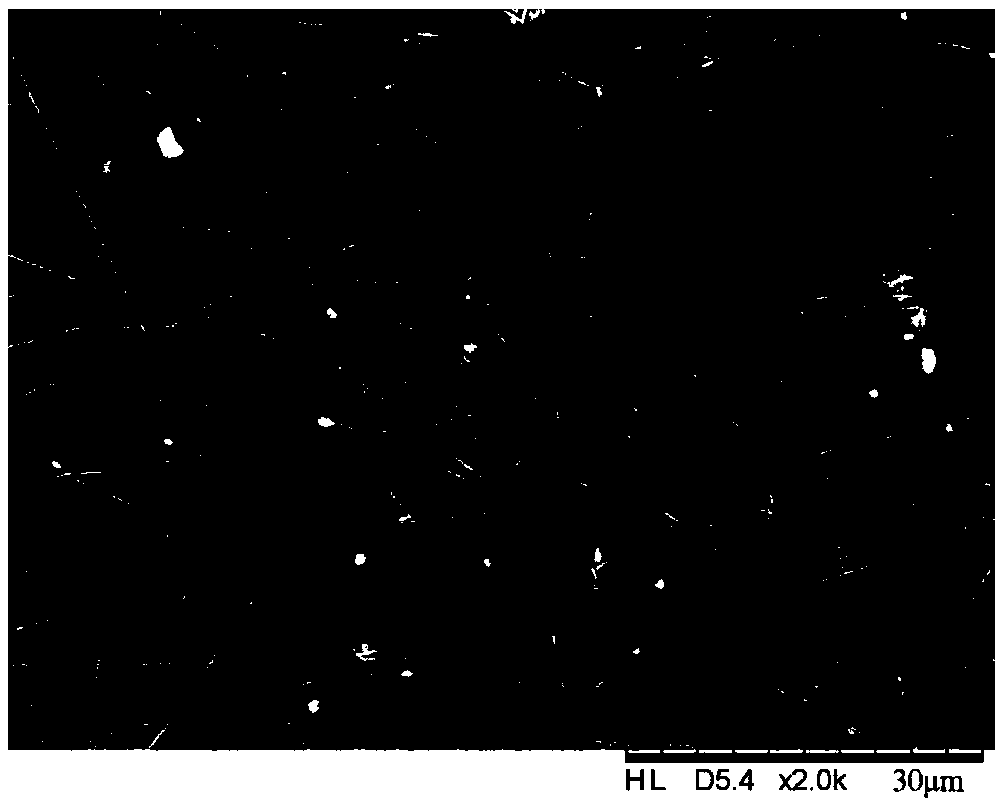

[0027] B. Preparation of nascent nanofiber photothermal film: Add the spinning liquid described in step A into three 5ml electrospinning syringe devices, and perform electrospinning with multiple needles. Set the spinning parameters as follows: the voltage is 25KV, the distance between the spinneret and the receiver is 10cm, the extrusion speed is 0.5mL / h, the drum speed is 400r / min, and the humidity is 70%. After 8 hours of electrospinning, it is re...

Embodiment 2

[0031] A. Preparation of spinning solution: Weigh 5g of polyvinylidene fluoride (model: 761), dissolve it in N,N-dimethylacetamide at a temperature of 70°C and prepare a solution with a mass fraction of 15%; add nano-ATO ( SnO 2 :SbO 2 =95:5) 1g (accounting for 3% of the solution mass), then add 0.017g lithium chloride (accounting for 0.05% of the solution mass), disperse evenly after ultrasonic vibration and magnetic stirring for 4 hours, let stand for defoaming for 12h, obtain spinning solution;

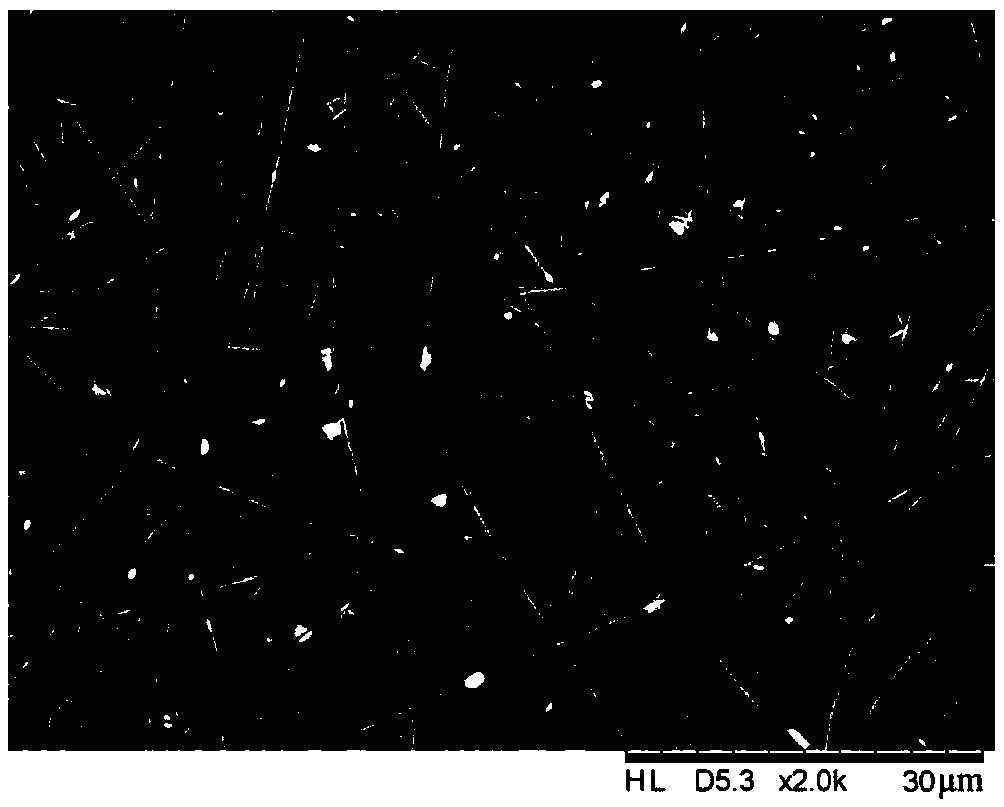

[0032] B. Preparation of nascent nanofiber photothermal film: Add the spinning liquid described in step A into three 5ml electrospinning syringe devices, and perform electrospinning with multiple needles. Set the spinning parameters as follows: the voltage is 25KV, the distance between the spinneret and the receiver is 10cm, the extrusion speed is 0.5mL / h, the drum speed is 400r / min, and the humidity is 70%. After 8 hours of electrospinning, it is removed from the drum, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com