Double-peak pore-structure polymer support, and preparation method and application thereof

A structural polymer, bimodal pore technology, applied in animal cells, vertebrate cells, tumors/cancer cells, etc., can solve the problems of insufficient pore size accuracy, porosity, poor connectivity between tubes and pores, and uneven pore size distribution. To achieve the effect of improving the connectivity between the tube holes, low cost and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

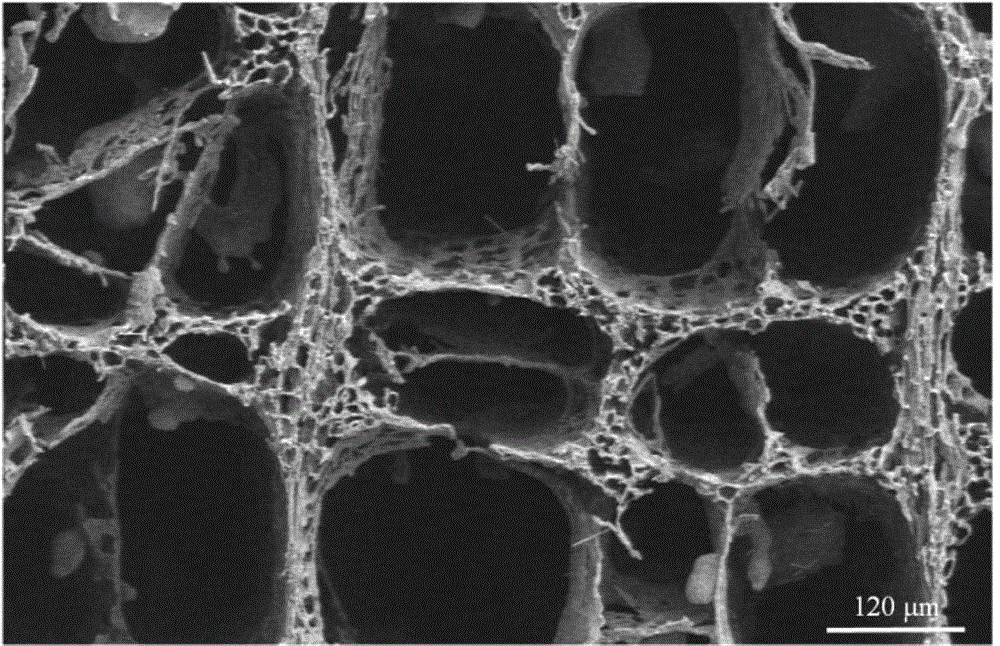

[0033] The preparation method of bimodal pore structure polymer scaffold comprises the following steps:

[0034] 1) Preparation of negative porous sodium chloride: the biological template Wisteria is processed into a cylindrical sample, and the sample is impregnated with a saturated NaCl solution and then dried to obtain a NaCl / vine complex, and the operation of impregnating and drying is repeated until NaCl The mass ratio of NaCl to rattan in the rattan compound is 200:100, then the NaCl / rattan compound is dried at 120°C and placed in a muffle furnace, and the temperature is raised from room temperature to 350°C at a rate of 1°C / min And keep it warm for 4 hours, then rise to 790° C. with a heating rate of 10° C. / min, and drop to room temperature with the furnace after 40 minutes of heat preservation, to obtain the negative mold porous sodium chloride of rattan;

[0035]2) Preparation of water-soluble porogen particles: mix powdered sodium chloride and absolute ethanol, ball ...

Embodiment 2

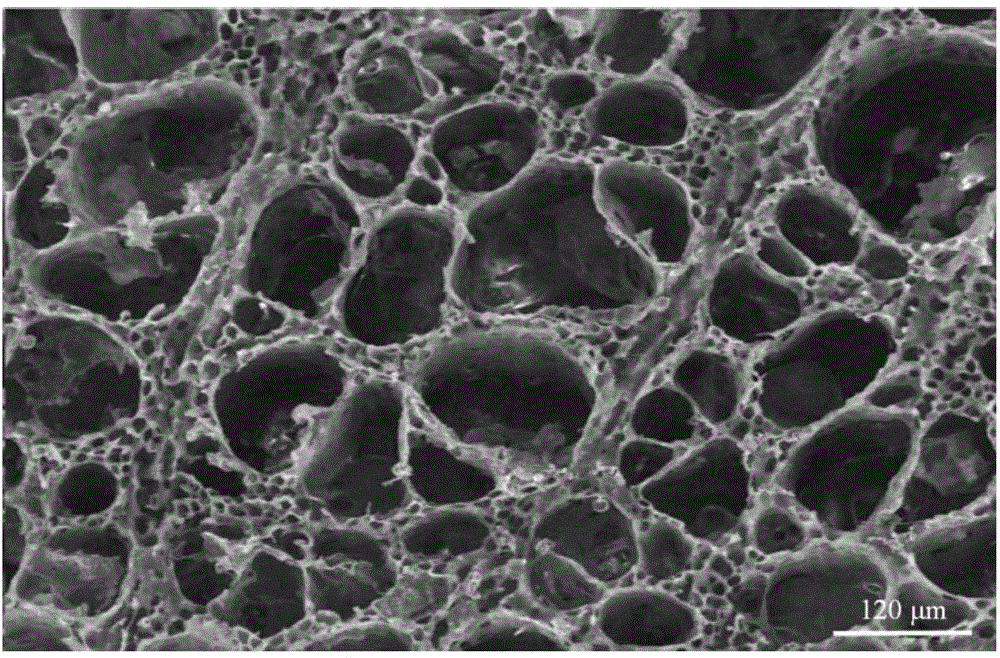

[0040] The preparation method of bimodal pore structure polymer scaffold comprises the following steps:

[0041] 1) Preparation of negative porous sodium chloride: the biological template wisteria is processed into a cylindrical sample, and the sample is impregnated with a saturated NaCl solution and then dried to obtain a NaCl / vine complex, and the operation of impregnating and drying is repeated until the NaCl The mass ratio of NaCl and rattan in the rattan composite is 180:100, and then the NaCl / rattan composite is dried at 120°C and placed in a muffle furnace, and the temperature is raised from room temperature to 350°C at a rate of 2°C / min And keep it warm for 6 hours, then rise to 790° C. with a heating rate of 30° C. / min, drop to room temperature with the furnace after 2 hours of heat preservation, and obtain the negative mold porous sodium chloride of rattan;

[0042] 2) Preparation of water-soluble porogen particles: mix powdered potassium chloride and absolute ethan...

Embodiment 3

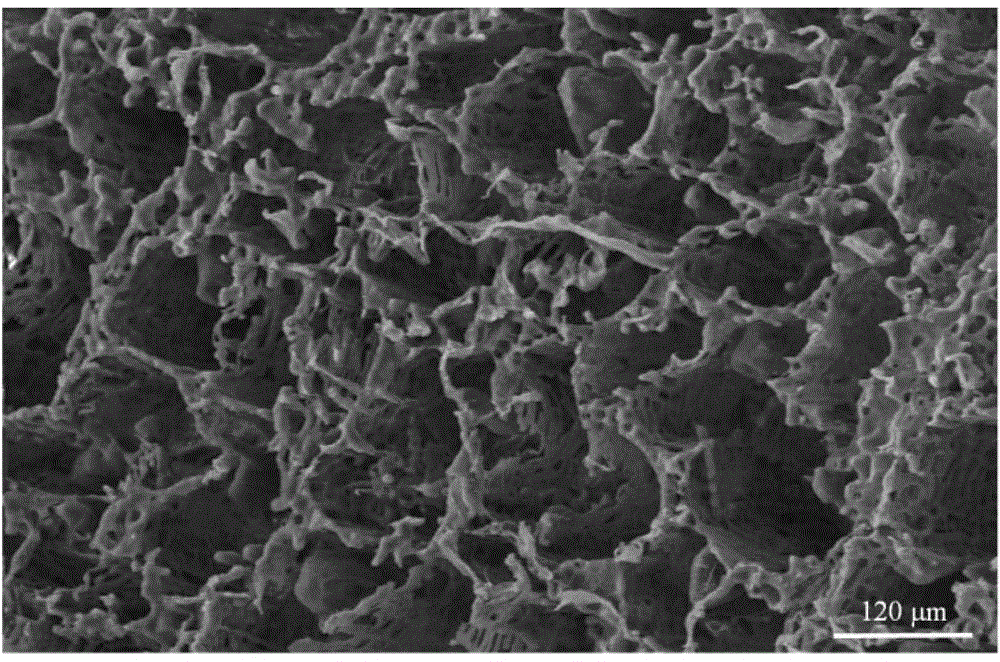

[0047] The preparation method of bimodal pore structure polymer scaffold comprises the following steps:

[0048] 1) Preparation of negative porous sodium chloride: the biological template wisteria is processed into a cylindrical sample, and the sample is repeatedly impregnated with saturated NaCl solution and then dried until the NaCl / Then the NaCl / vine composite was dried at 120°C and placed in a muffle furnace. First, the temperature was raised from room temperature to 350°C at a rate of 3°C / min and kept for 2 hours, and then at a rate of 15°C / min. The heating rate is raised to 790°C, and after 20 minutes of heat preservation, it is lowered to room temperature with the furnace, and the negative mold of the rattan is obtained. Porous sodium chloride;

[0049] 2) Preparation of water-soluble porogen particles: mix powdered sucrose and absolute ethanol, ball mill for 12 hours, and sieve to obtain 600-1250 mesh water-soluble porogen particles;

[0050] 3) Preparation of biopol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com