A kind of preparation method of high solid content low viscosity waterborne polyurethane emulsion

A technology of water-based polyurethane and high solid content, applied in the field of preparation of water-based polyurethane emulsion, can solve problems such as difficulty in increasing the solid content of water-based polyurethane emulsion, and achieve the effects of improving space utilization, high solid content and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Get 1.52g dimethylolpropionic acid (DMPA), 20g polypropylene glycol (PPG, ), 0.55g 1,4-butanediol (BDO) and mix well, heat up to 80°C, add 13.34g isophorone diisocyanate (IPDI), dropwise add 0.04g catalyst dibutyltin dilaurate (T-12) , kept at 80°C for about 4 hours, stopped heating and added 12ml of acetone to dilute, lowered the temperature to 30°C, added 1.50g of neutralizing agent triethylamine (TEA), and reacted for 30min to obtain the first prepolymer. Under stirring at 800r / min, add 89ml of water to the first prepolymer, and then add 1.35g of ethylenediamine (EDA), after chain extension reaction and emulsification for 1 hour, the solvent acetone is removed by rotary evaporation, and a small particle size water-based polyurethane emulsion is prepared. WPU-S.

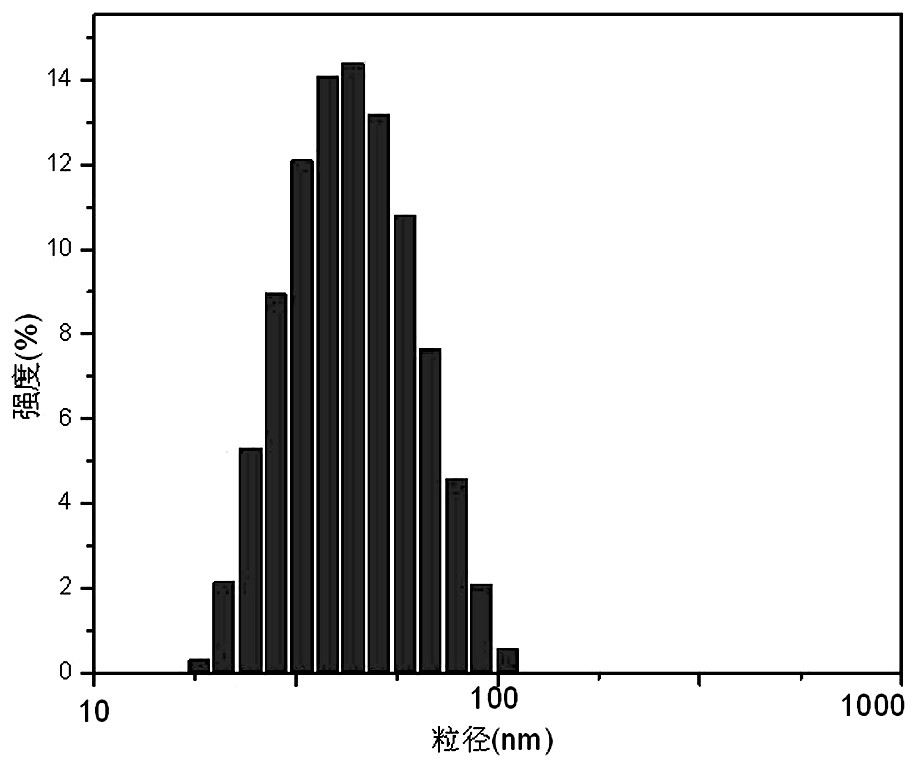

[0034] figure 1 The particle size distribution diagram of WPU-S prepared above is given. It can be seen that WPU-S presents a unimodal distribution, and its average particle size is 43nm. After testing, ...

Embodiment 2

[0038] Take 0.75g DMPA, 20gPPG ( ), 1.10g of BDO, mixed evenly, heated up to 80°C, added 11.67g of IPDI, added dropwise 0.04g of T-12, kept at 80°C for about 4 hours, stopped heating and added 11ml of acetone to dilute, cooled to 30°C, added 0.53g of TEA, The reaction was carried out for 30 minutes to obtain the second prepolymer. Under stirring at 800r / min, add 26ml of water and 23g of the water-based polyurethane emulsion WPU-S prepared in Example 1 dropwise to the second prepolymer, then add 0.90g of EDA, perform chain extension reaction and emulsify for 1 hour, and then remove it by rotary evaporation. The solvent acetone was used to prepare high solid content and low viscosity waterborne polyurethane emulsion WPU-H2.

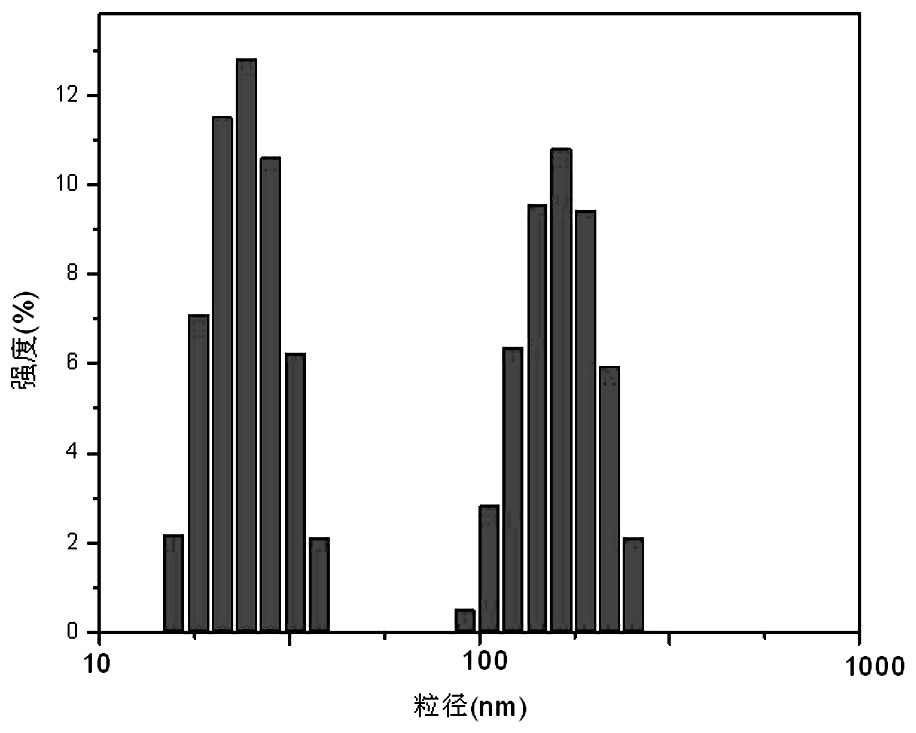

[0039] image 3 The particle size distribution diagram of WPU-H2 prepared above is given. Because the relative molecular weight of the second prepolymer is relatively small and the viscosity is low, although the content of acetone added is less than tha...

Embodiment 3

[0041] Take 0.66g DMPA, 20gPPG ( ), 1.13g of BDO, mixed evenly, heated up to 80°C, added 10.00g of IPDI, added dropwise 0.04g of T-12, kept at 80°C for about 4 hours, stopped heating and added 11ml of acetone to dilute, cooled to 30°C, added 0.51g of TEA, The reaction was carried out for 30 minutes to obtain the second prepolymer. Under stirring at 800r / min, add 24.2ml of water and 22g of the water-based polyurethane emulsion WPU-S prepared in Example 1 dropwise to the second prepolymer, then add 0.45g of EDA, chain extension reaction and emulsification for 1h, then rotary steam The solvent acetone was removed to prepare high solid content and low viscosity waterborne polyurethane emulsion WPU-H3.

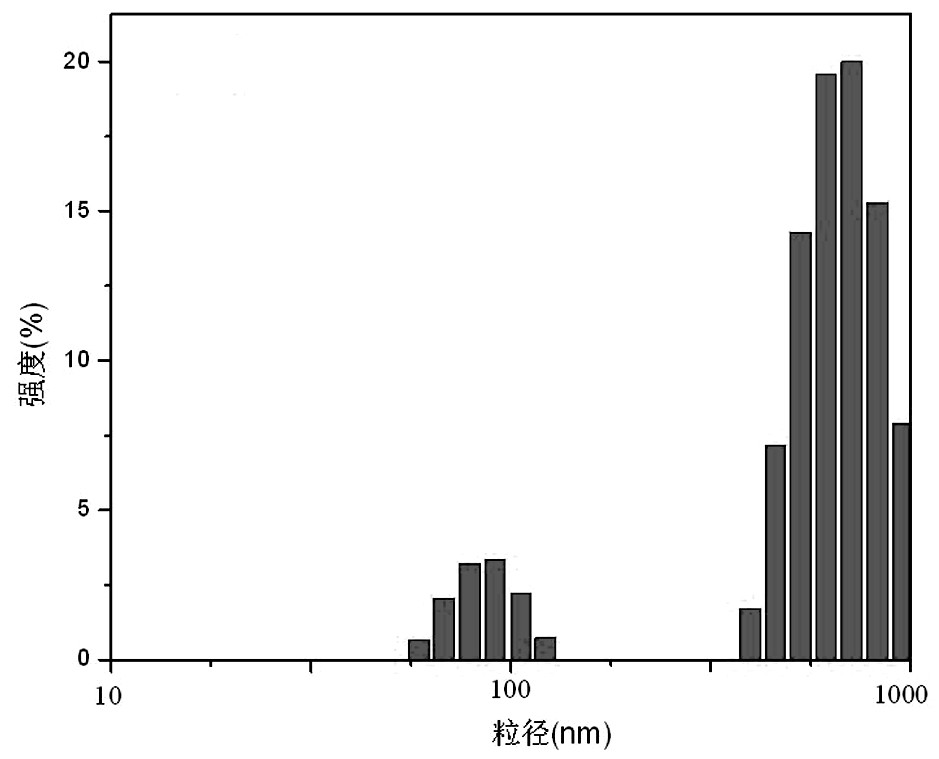

[0042] Figure 4 The particle size distribution diagram of WPU-H3 prepared above is given. Compared with Example 2, the relative molecular weight of the prepared second prepolymer is larger, but the content of acetone added is the same, so the viscosity of the system is larger,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com