Reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and support layer, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of poor pollution resistance of reverse osmosis composite membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The preparation method of 2,3-propylene oxide sodium sulfonate is the same as in the literature (Fine Chemical Intermediates, Volume 35, Phase 1), and its detailed steps are as follows:

[0075]Dissolve 10g of sodium 3-chloro-2-hydroxypropanesulfonate in 40mL of water, and add NaOH solution (2.6gNaOH, 20mL of water) dropwise to the solution while stirring for 1.5h, then continue the reaction for 0.5h. Use 1mol / L hydrochloric acid to drop the solution to neutrality, then use a mixed solution of ethanol and water (3:1 in mass ratio) for recrystallization, and finally filter to obtain a white solid.

Embodiment 1

[0080] The reverse osmosis membrane diaphragm M1 that comparative example 1 makes is dipped in (taking solvent as 100 parts by weight, containing 5 parts of 2,3-epoxypropylene sodium sulfonate and 0.5 part of 2,4,6-tri(dimethyl In 20 parts of glycerol) aqueous solution of aminomethyl) phenol, immersion time is 30s. After taking it out, put the membrane into an oven at 70°C and heat for 5 minutes to obtain a dry reverse osmosis composite membrane. After storing the reverse osmosis membrane at normal temperature and in a dry state for 7 days, the pollution-resistant reverse osmosis membrane N1 was obtained. The thickness of the anti-pollution layer was 35 nm.

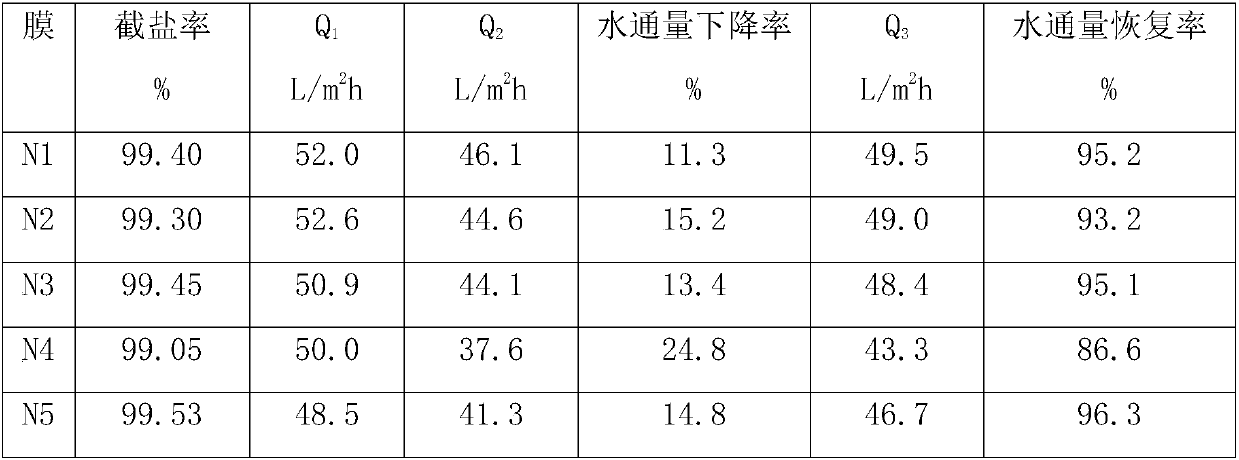

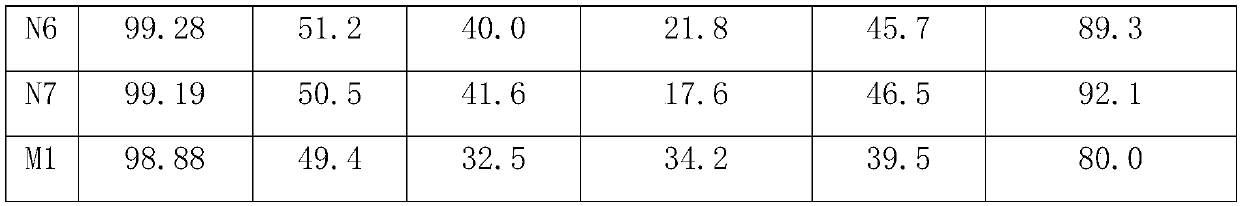

[0081] After immersing the obtained composite reverse osmosis membrane N1 in water for 24 hours, the water flux and the desalination rate of NaCl (2000ppm) were measured at a pressure of 1.55MPa and a temperature of 25°C. The results are shown in Table 1. And under the same temperature and pressure conditions, its fouli...

Embodiment 2

[0083] The reverse osmosis membrane diaphragm that comparative example 1 makes is dipped in (taking solvent as 100 parts by weight, containing 3 parts of 2,3-epoxypropylene sodium sulfonate and 1 part of 2,4,6-tris(dimethylamino In 10 parts of sucrose) aqueous solution of methyl) phenol, the immersion time is 1 min. After taking it out, put the membrane into a 40°C oven and heat for 10 minutes to obtain a dry reverse osmosis composite membrane. After the reverse osmosis membrane was stored at normal temperature and in a dry state for 3 days, the pollution-resistant reverse osmosis membrane N2 was obtained. The thickness of the anti-contamination layer was 21 nm.

[0084] After immersing the obtained composite reverse osmosis membrane N2 in water for 24 hours, the water flux and the desalination rate of NaCl (2000ppm) were measured at a pressure of 1.55MPa and a temperature of 25°C. The results are shown in Table 1. And under the same temperature and pressure conditions, its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com