Preparation method of modified polyacrylonitrile forward osmosis membrane

A polyacrylonitrile-based membrane, polyacrylonitrile technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of decreased salt interception rate, lack of technical inspiration, and large contact angle, etc., to achieve Increased salt interception rate and water flux, broadened application range, and improved pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

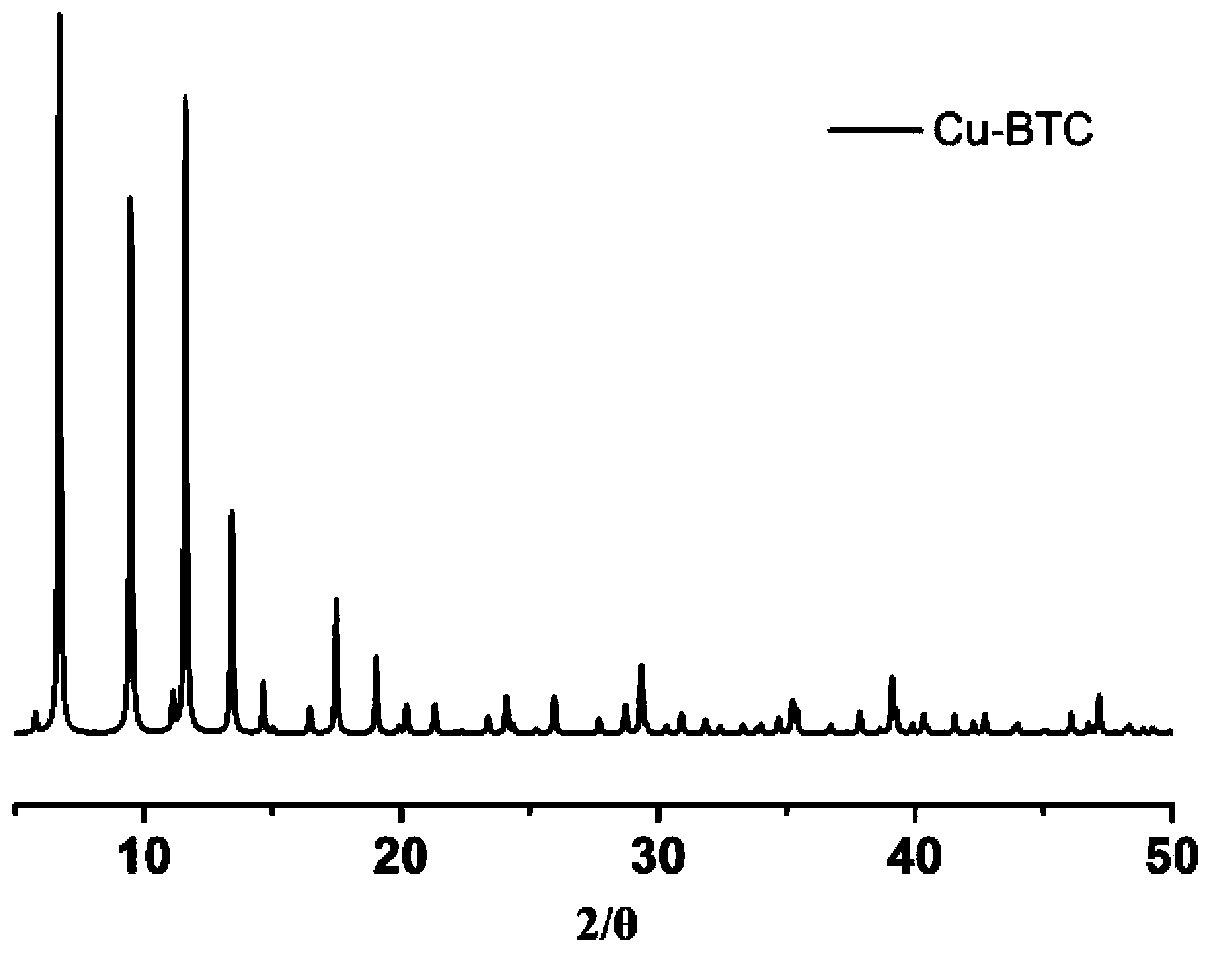

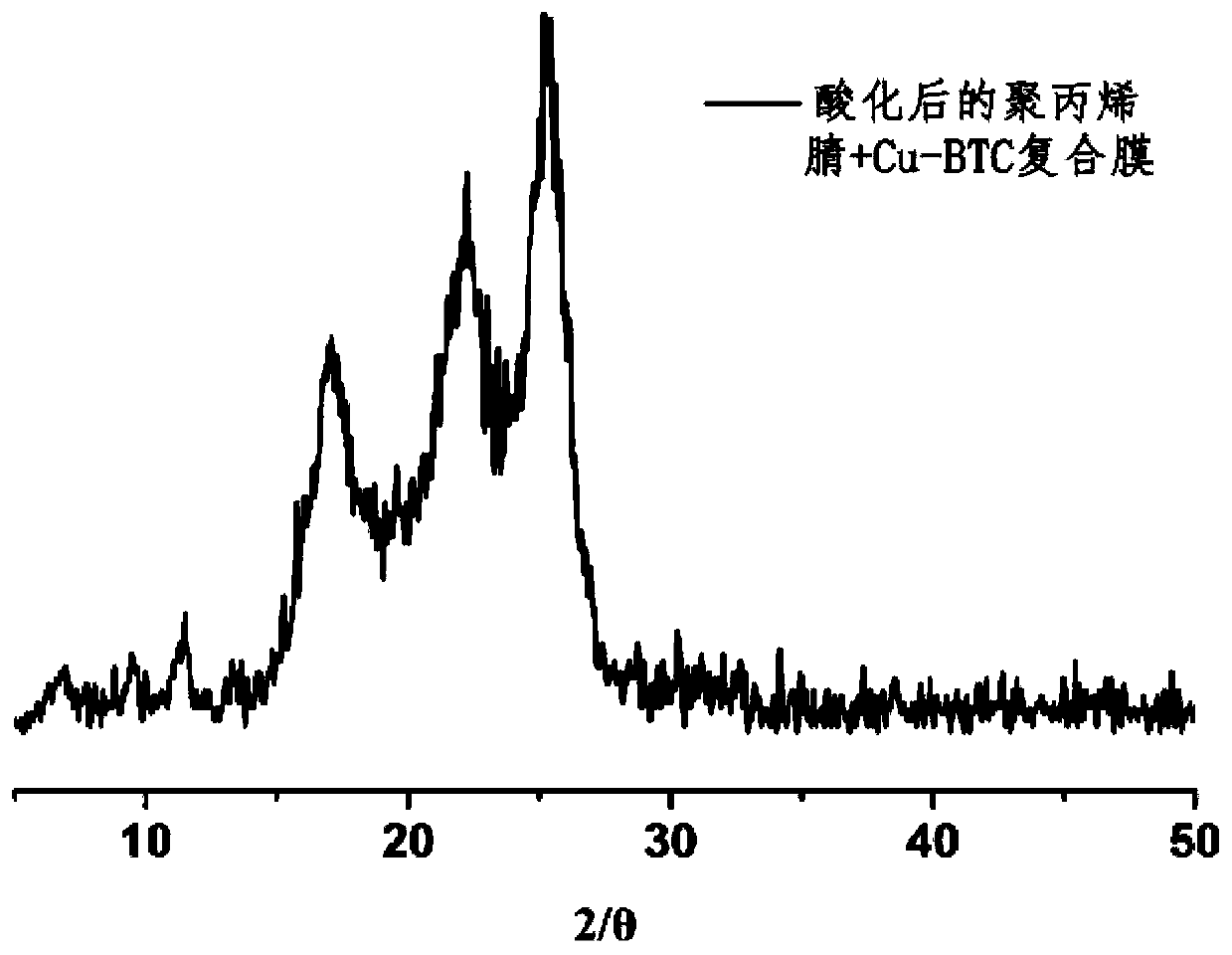

Embodiment 1

[0049] A preparation method of a modified polyacrylonitrile forward osmosis membrane, the specific steps are as follows:

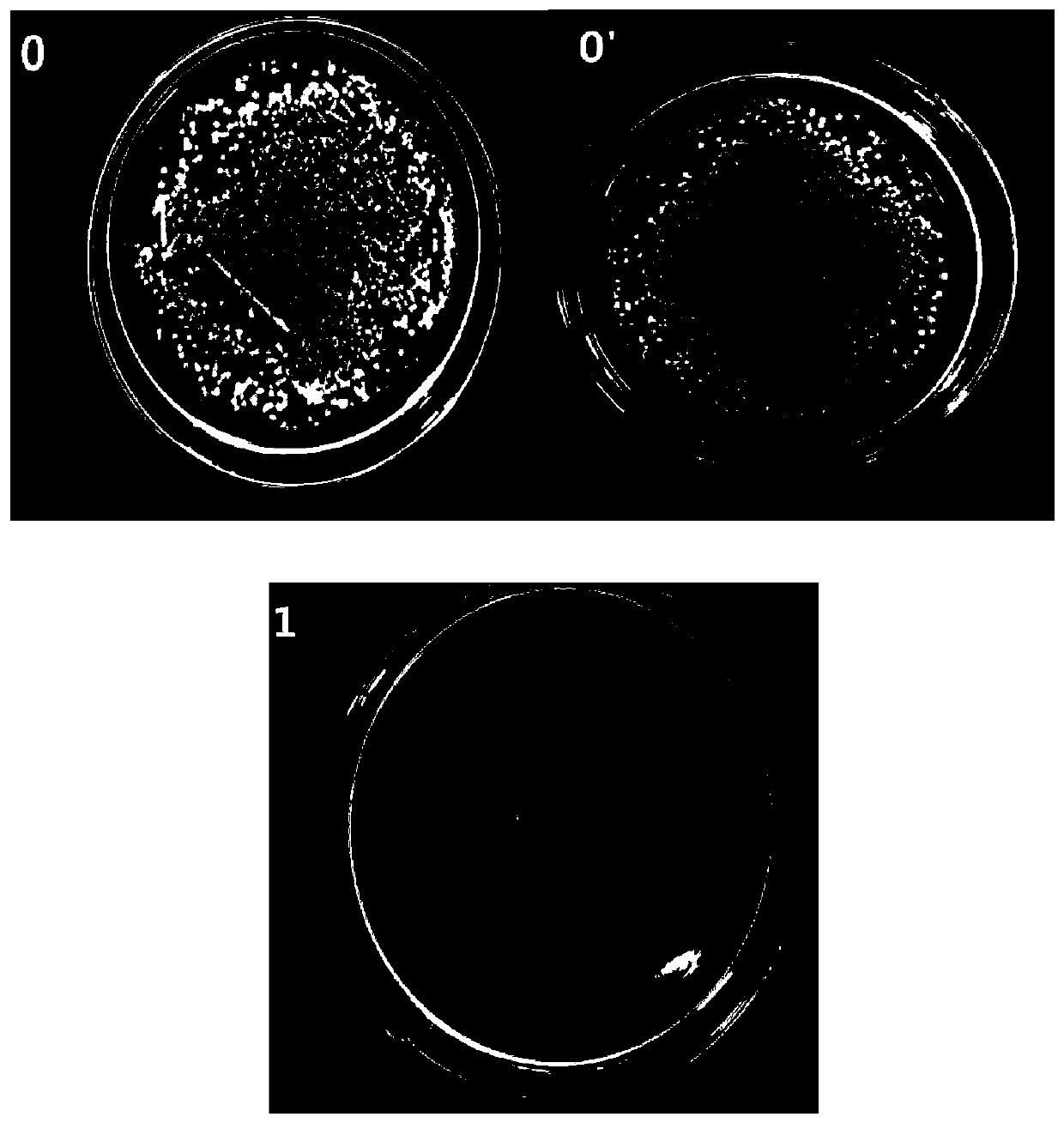

[0050] (1) Pretreatment of polyacrylonitrile-based membrane

[0051] Cut the polyacrylonitrile ultrafiltration membrane to be modified into a square piece of 8cm×8cm, soak it in ultrapure aqueous solution for 24 hours at room temperature, take out the soaked membrane after 24 hours, and then use ultrapure water repeatedly Rinse 5 times, and after the rinsing is completed, dry it in an electric blast drying oven at 40°C for subsequent use.

[0052] (2) Hydrolytic modification of polyacrylonitrile-based membrane: alkalization process

[0053] Weigh 40.0 g of NaOH on an electronic balance and place it in a 500 mL beaker, add 500 mL of ultrapure water into the beaker, stir evenly with a glass rod, and prepare a 2.0 mol / L NaOH solution for later use. Put the polyacrylonitrile ultrafiltration membrane to be modified in a petri dish, and add the prepared NaOH s...

Embodiment 2

[0062] A preparation method of a modified polyacrylonitrile forward osmosis membrane, the specific steps are as follows:

[0063] (1) Pretreatment of polyacrylonitrile-based membrane

[0064] Cut the polyacrylonitrile ultrafiltration membrane to be modified into a square piece of 8cm×8cm, soak it in ultrapure aqueous solution for 24 hours at room temperature, take out the soaked membrane after 24 hours, and then use ultrapure water repeatedly Rinse 5 times, and after the rinsing is completed, dry it in an electric blast drying oven at 40°C for subsequent use.

[0065] (2) Hydrolytic modification of polyacrylonitrile-based membrane: alkalization process

[0066] Weigh 40.0 g of NaOH on an electronic balance and place it in a 500 mL beaker, add 500 mL of ultrapure water into the beaker, stir evenly with a glass rod, and prepare a 2.0 mol / L NaOH solution for later use. Put the polyacrylonitrile ultrafiltration membrane to be modified in a petri dish, and add the prepared NaOH s...

Embodiment 3

[0075] A preparation method of a modified polyacrylonitrile forward osmosis membrane, the specific steps are as follows:

[0076] (1) Pretreatment of polyacrylonitrile-based membrane

[0077] Cut the polyacrylonitrile ultrafiltration membrane (commercial membrane) to be modified into a square piece of 8cm×8cm, soak it in ultrapure aqueous solution for 24h at room temperature, take out the soaked membrane after 24h, and use it after taking it out Rinse with ultrapure water 5 times repeatedly, and dry in an electric blast drying oven at 40°C for later use.

[0078] (2) Hydrolytic modification of polyacrylonitrile-based membrane: alkalization process

[0079] Weigh 40.0 g of NaOH on an electronic balance and place it in a 500 mL beaker, add 500 mL of ultrapure water into the beaker, stir evenly with a glass rod, and prepare a 2.0 mol / L NaOH solution for later use. Put the polyacrylonitrile ultrafiltration membrane to be modified in a petri dish, and add the prepared NaOH soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com