Forward osmosis composite membrane based on large-aperture base membrane, and production method thereof

A large pore size, composite membrane technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of low porosity, poor hydrophilicity, low water flux, etc. The effect of short mass transfer distance and increased water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

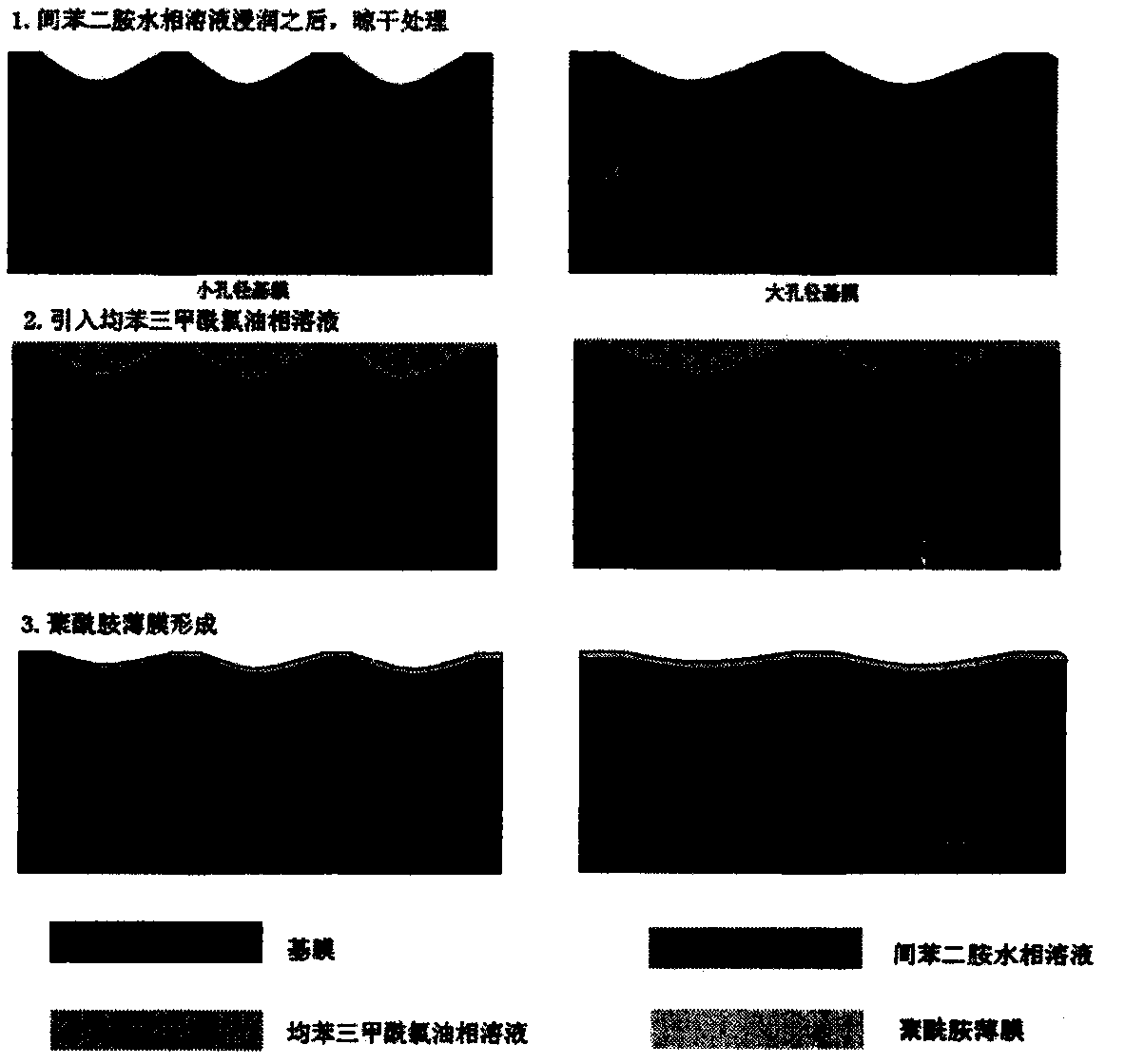

[0030] Step 1: The polytetrafluoroethylene microporous membrane with a pore size of 0.2 μm, a porosity of 89%, and a thickness of 50 μm prepared by a biaxial stretching method is prepared by a physical modification method of coating polyvinyl alcohol to prepare a super-hydrophilic large-pore base membrane. The water dynamic contact angle of the film drops to 0 degrees within 3 seconds. Put the base film in an oven at 80°C, heat treatment and set it for 20 minutes;

[0031] Step 2: Weigh 1g of m-phenylenediamine, 0.05g of sodium lauryl sulfate, and 0.25g of triethylamine, dissolve them in 48.7g of water, make a water phase monomer solution and put it in a water bath at 15°C; weigh 0.1 g of trimesoyl chloride was dissolved in 49.9 g of n-hexane to make an oil phase monomer solution and placed in a water bath at 15°C;

[0032] Step 3: Put the above base film in the interface polymerization mold, add deionized water to the mold to wet the base film, then remove the excess deioniz...

Embodiment 2

[0035] Step 1: The polytetrafluoroethylene microporous membrane with a pore size of 0.45 μm, a porosity of 91%, and a thickness of 40 μm prepared by the biaxial stretching method is prepared by a physical modification method of coating polyvinyl alcohol to prepare a super-hydrophilic large-pore base membrane. The water dynamic contact angle of the film drops to 0 degrees within 2 seconds. Put the base film in an oven at 100°C, heat treatment and set it for 10 minutes;

[0036] Step 2: Weigh 1.2g of m-phenylenediamine, 0.06g of sodium lauryl sulfate, and 0.34g of triethylamine, dissolve them in 48.4g of water, make a water phase monomer solution and put it in a water bath at 11°C; weigh Take 0.15 g of trimesoyl chloride, dissolve it in 49.85 g of n-hexane to make an oil phase monomer solution, and put it in a water bath at 11°C;

[0037] Step 3: Put the above base film in the interface polymerization mold, add deionized water to the mold to wet the base film, then remove the e...

Embodiment 3

[0040] Step 1: The polytetrafluoroethylene microporous membrane with a pore size of 0.65 μm, a porosity of 93%, and a thickness of 30 μm prepared by a biaxial stretching method is prepared by a physical modification method of coating polyvinyl alcohol to prepare a super-hydrophilic large-pore base membrane. The water dynamic contact angle of the film drops to 0 degrees within 2 seconds. Put the base film in an oven at 120°C, heat treatment and set it for 5 minutes;

[0041] Step 2: Weigh 0.75g of m-phenylenediamine and 0.25g of triethylamine, dissolve them in 49g of water, make a water phase monomer solution and put it in a water bath at 20°C; weigh 0.15g of trimesoyl chloride, dissolve in Prepare an oil phase monomer solution in 49.85g of ethylcyclohexane and put it in a water bath at 20°C;

[0042] Step 3: Put the above base film in the interface polymerization mold, add 2% glycerin aqueous solution to the mold to wet the base film, then remove the excess wetting liquid on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com