Modified semi-aromatic polyamide membrane and preparation method thereof

A technology of aromatic polyamide membrane and semi-aromatic polyamide, which is applied in the field of modified semi-aromatic polyamide membrane and its preparation, can solve the problems of poor salt interception effect, hindering industrial implementation, and poor selectivity of semi-aromatic polyamide membrane. Achieve easy handling, enhanced electrostatic interaction, and outstanding anti-pollution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

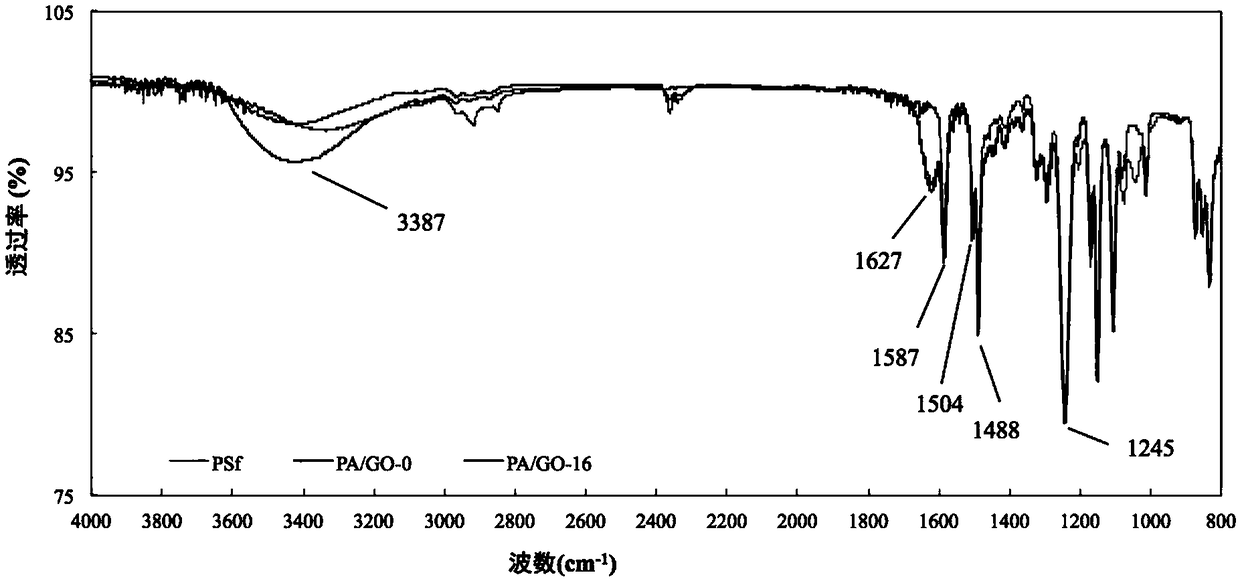

[0043] A kind of preparation method of modified semi-aromatic polyamide membrane as above, comprises the following steps:

[0044] 1. Dissolve graphene oxide nanosheets in water, disperse them by ultrasonication for 20 minutes to form a 0.1% graphene oxide stock solution, and soak the polysulfone ultrafiltration membrane in deionized water for 24 hours for later use.

[0045] 2. Adding different amounts of graphene oxide into 0.02 g / mL piperazine aqueous solution to obtain graphene oxide-containing piperazine aqueous phase solution with a ratio of 0.004 wt % graphene oxide.

[0046] 3. Pour the piperazine aqueous phase solution containing graphene oxide onto the surface of the polysulfone ultrafiltration membrane, take it out after immersion for 2 minutes, and remove the excess solution on the membrane surface with a rubber roller.

[0047] 4. After drying in air for 1 min, pour the n-hexane solution dissolved with 0.001 g / mL trimesoyl chloride onto the membrane and keep it fo...

Embodiment 2

[0051] Adopt the same preparation method as Example 1, the difference is that: in the piperazine aqueous phase solution containing graphene oxide, the mass fraction of graphene oxide is 0.008wt%, the modified semi-aromatic polyamide film finally obtained Make PA / GO-8.

Embodiment 3

[0053] Adopt the same preparation method as Example 1, the difference is: in the piperazine aqueous phase solution containing graphene oxide, the mass fraction of graphene oxide is 0.016wt%, the modified semi-aromatic polyamide film finally obtained Make PA / GO-16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com