Patents

Literature

74 results about "Thin-film composite membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

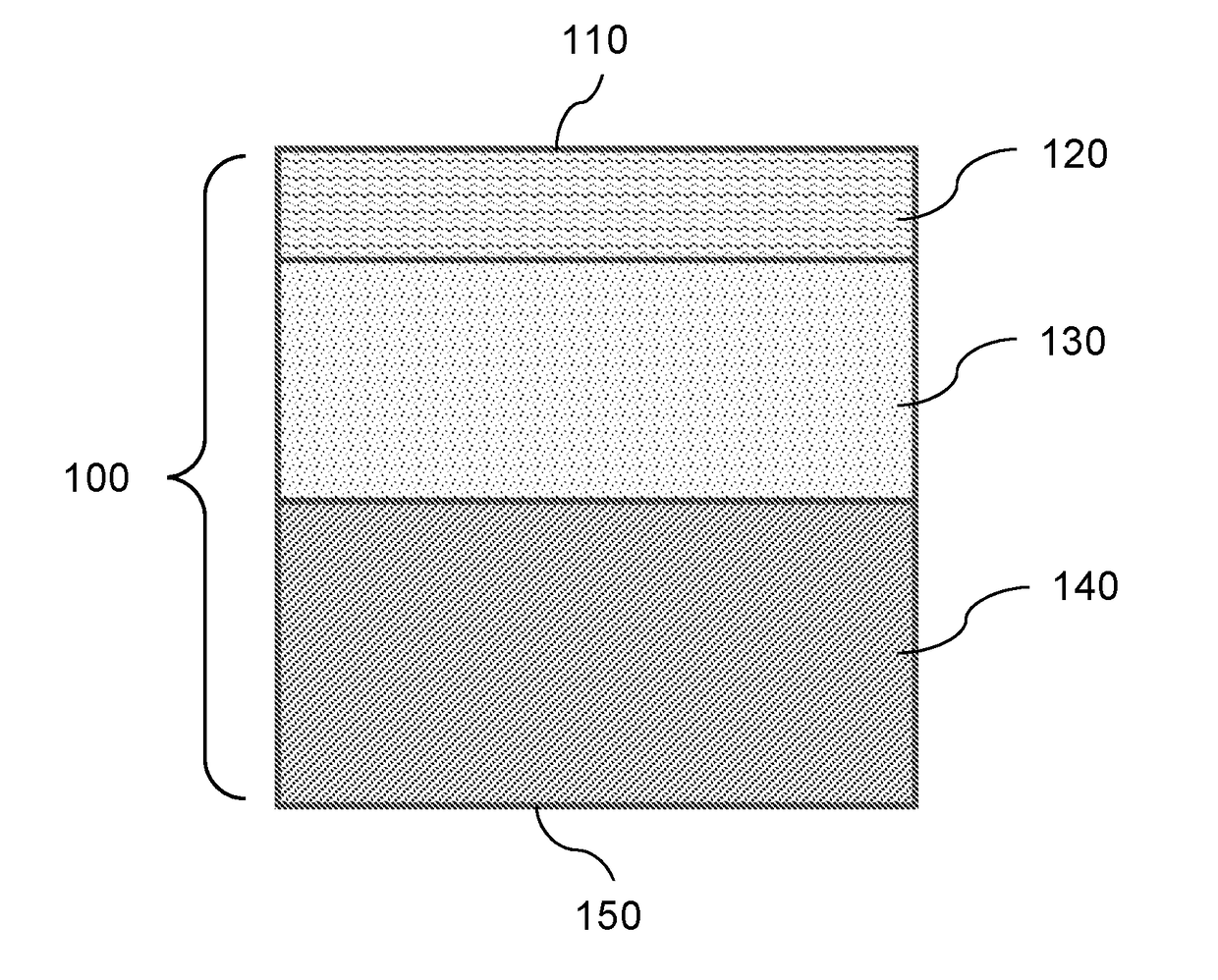

Thin-film composite membranes (TFC or TFM) are semipermeable membranes manufactured principally for use in water purification or water desalination systems. They also have use in chemical applications such as batteries and fuel cells. A TFC membrane can be considered as a molecular sieve constructed in the form of a film from two or more layered materials.

Composite Membranes and Membrane Systems and Methods For Production and Utilization Thereof

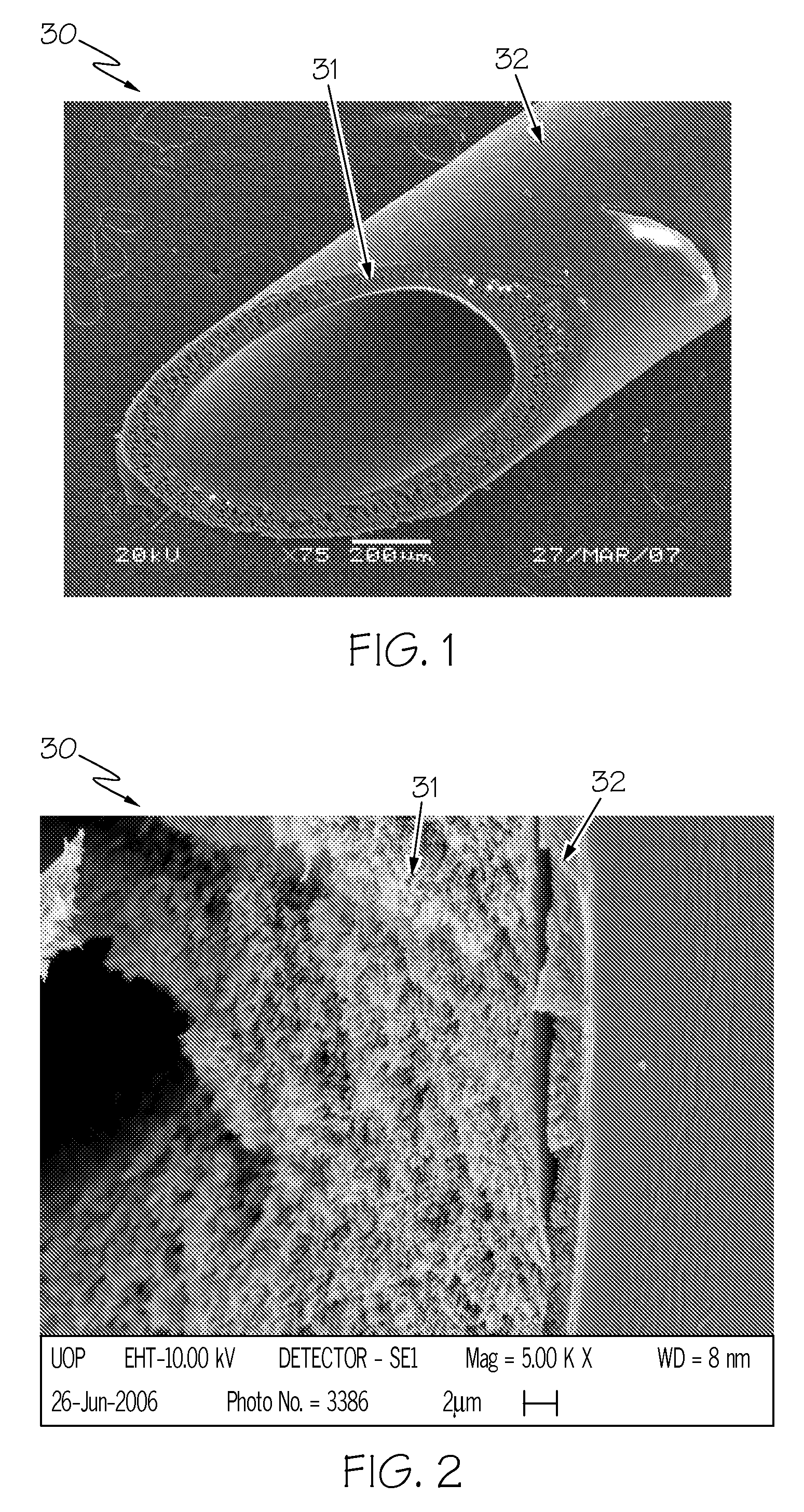

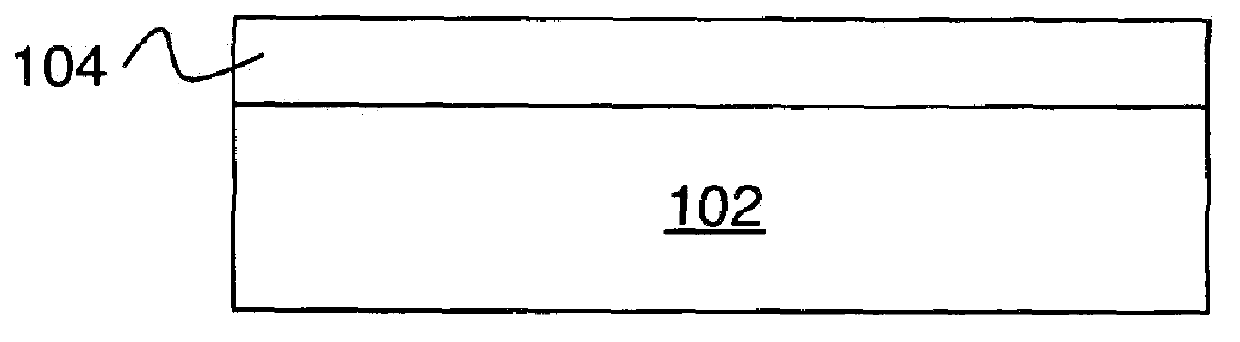

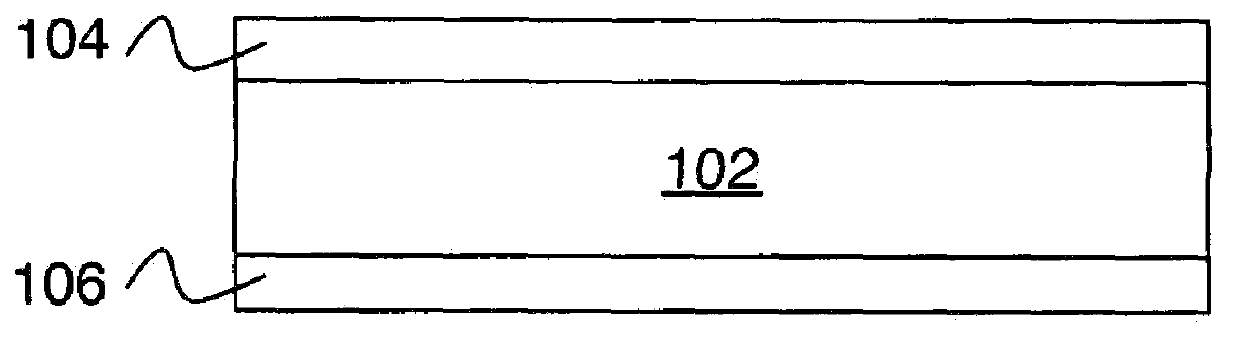

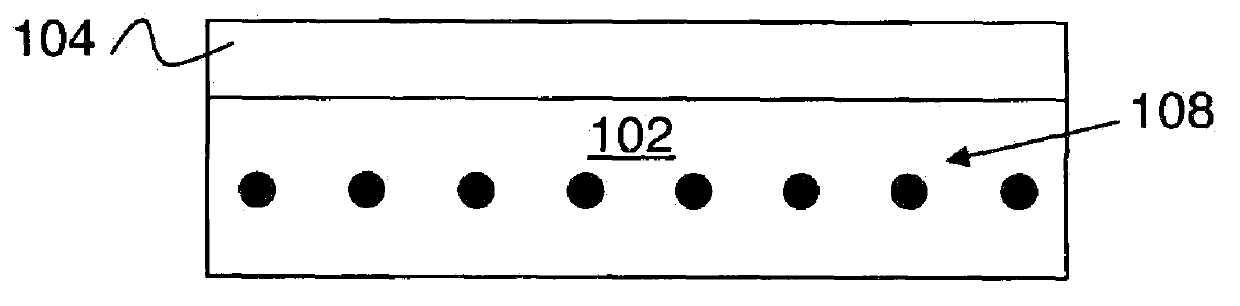

InactiveUS20080197070A1Easy to useImprove foulingSemi-permeable membranesMembranesHydrophilizationPolymer science

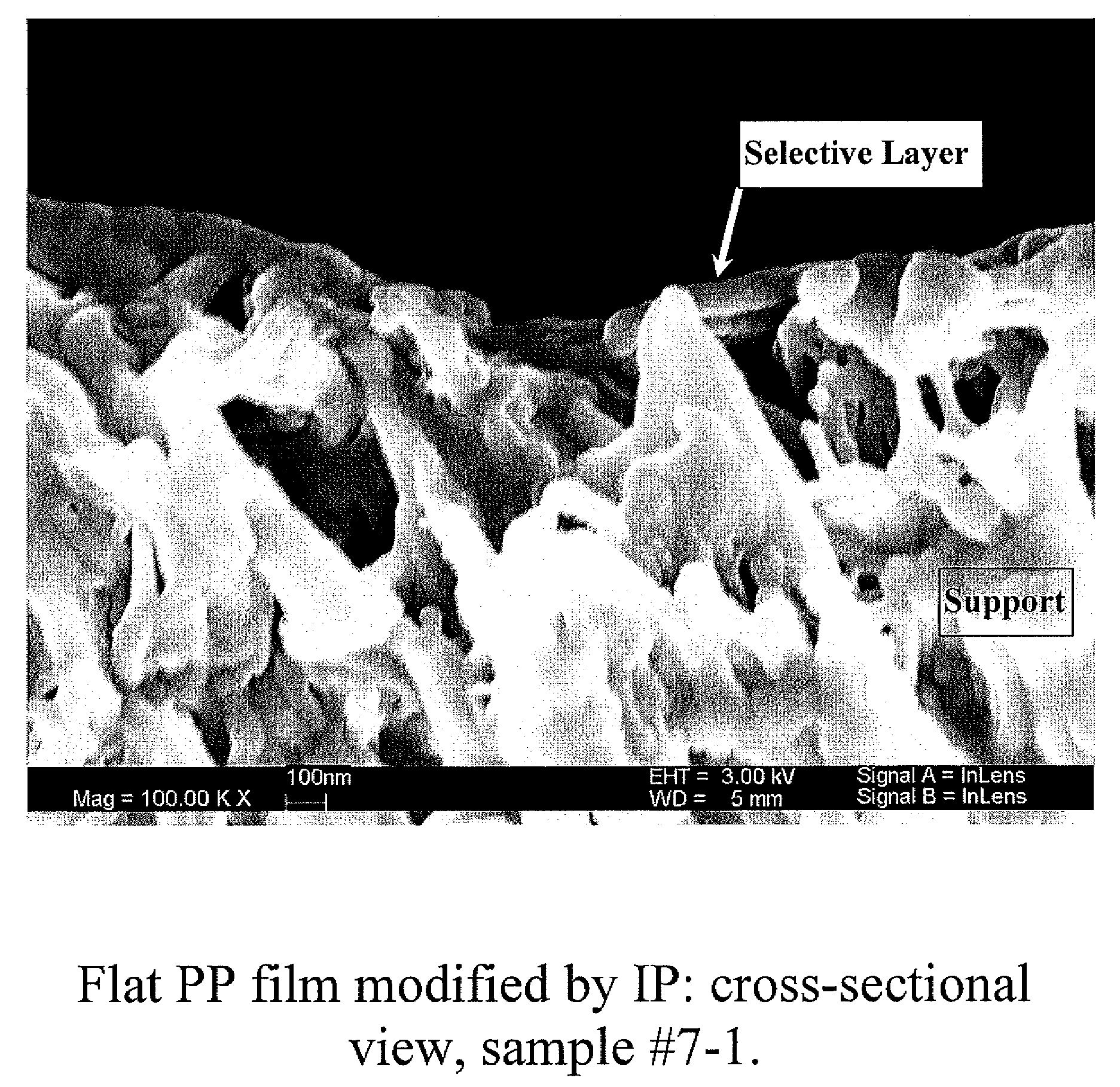

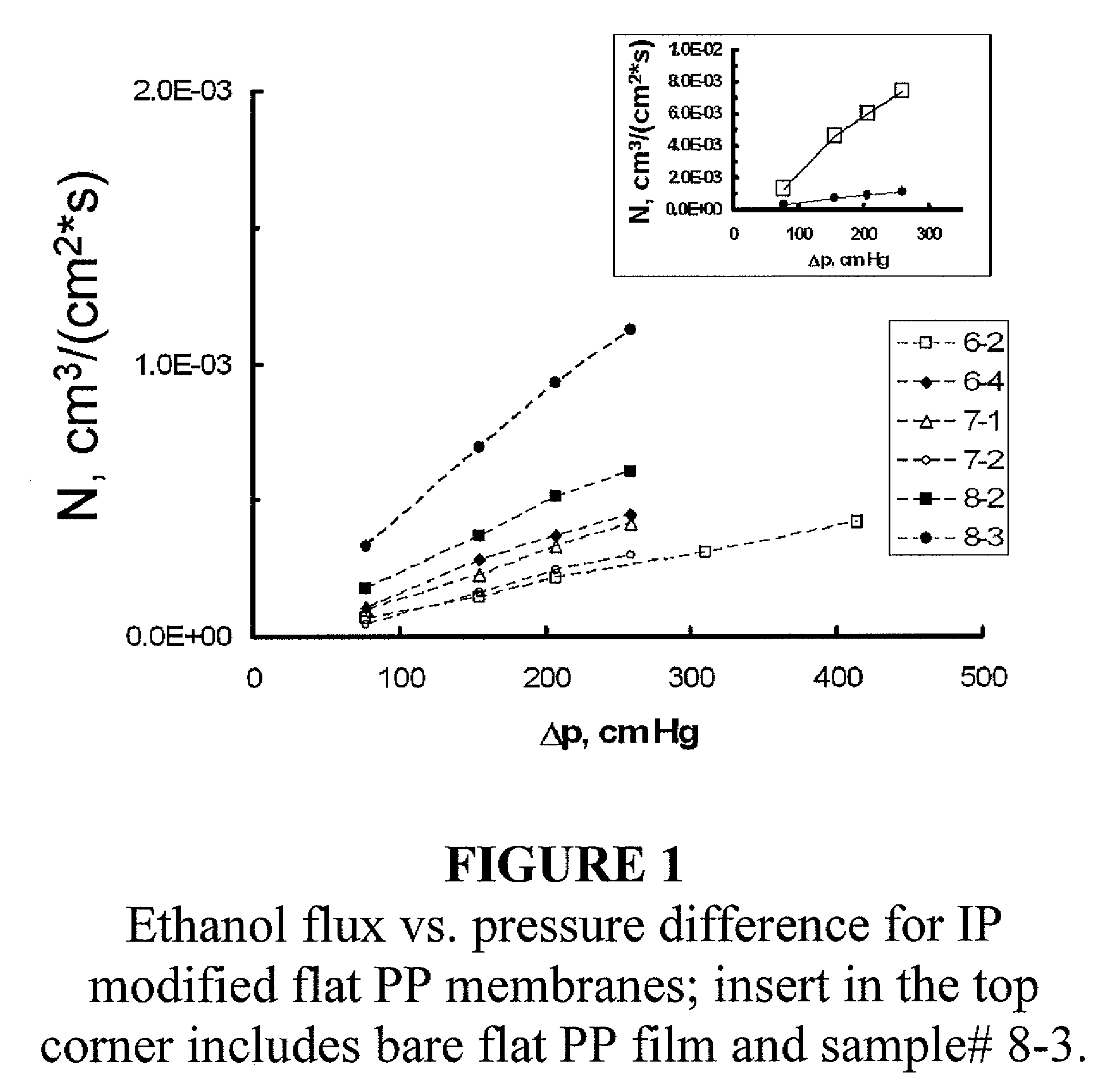

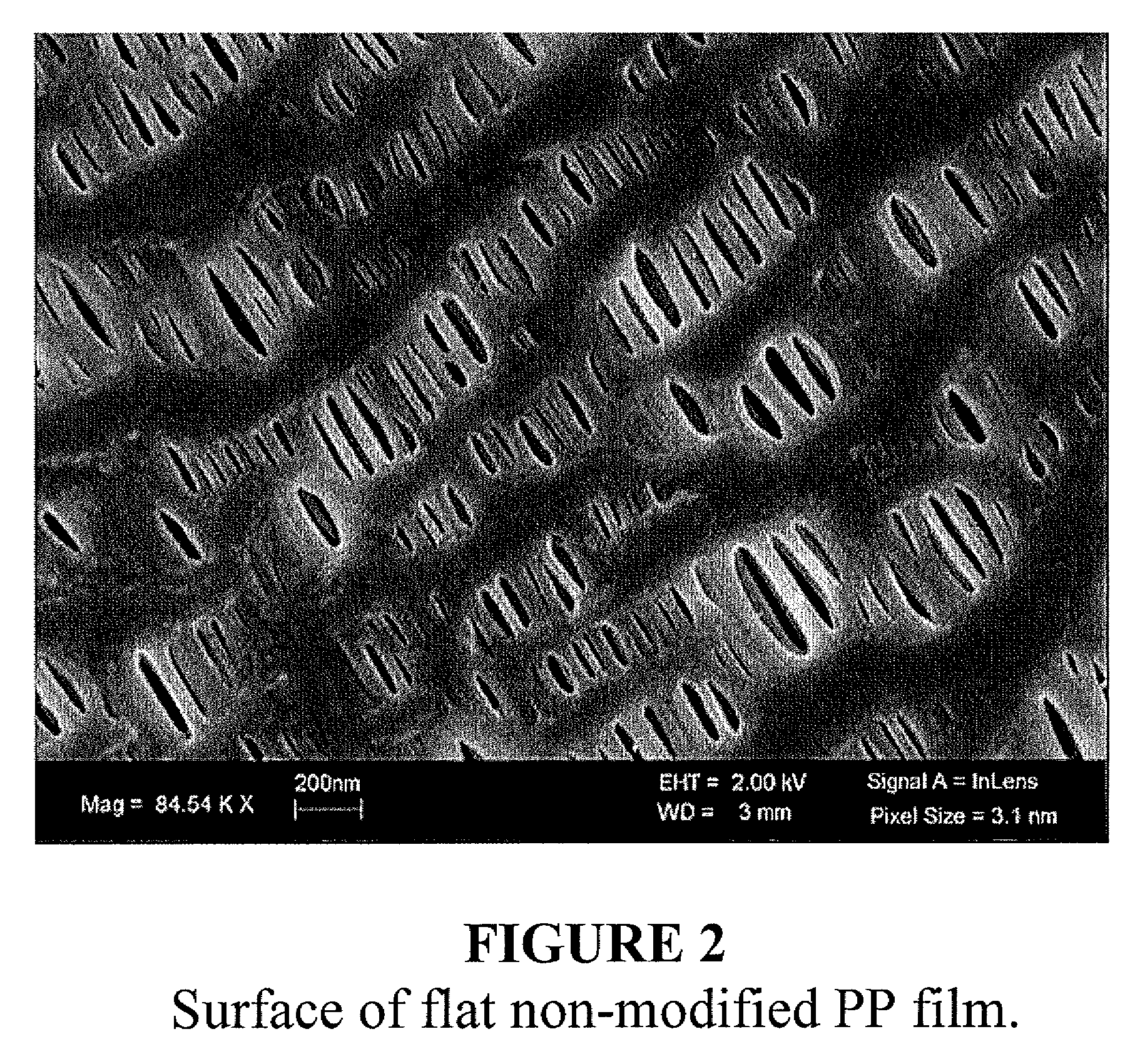

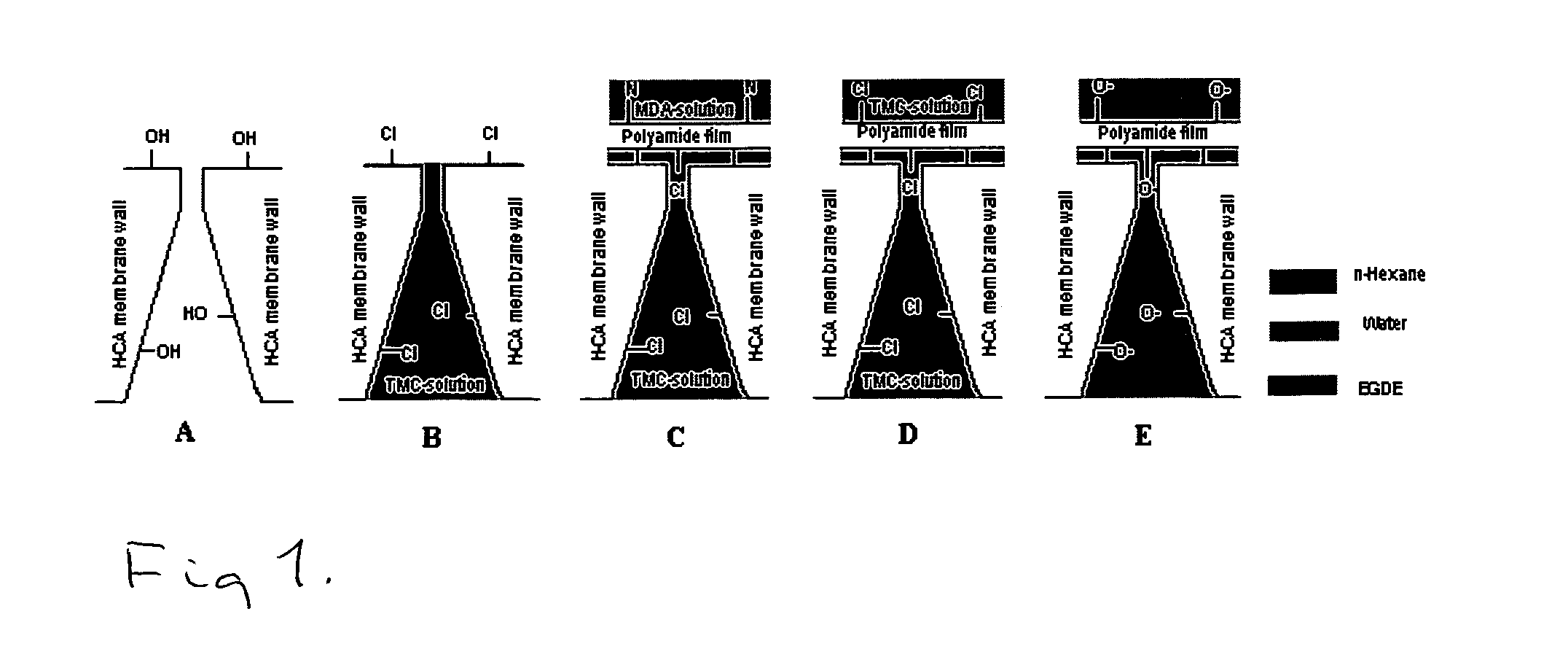

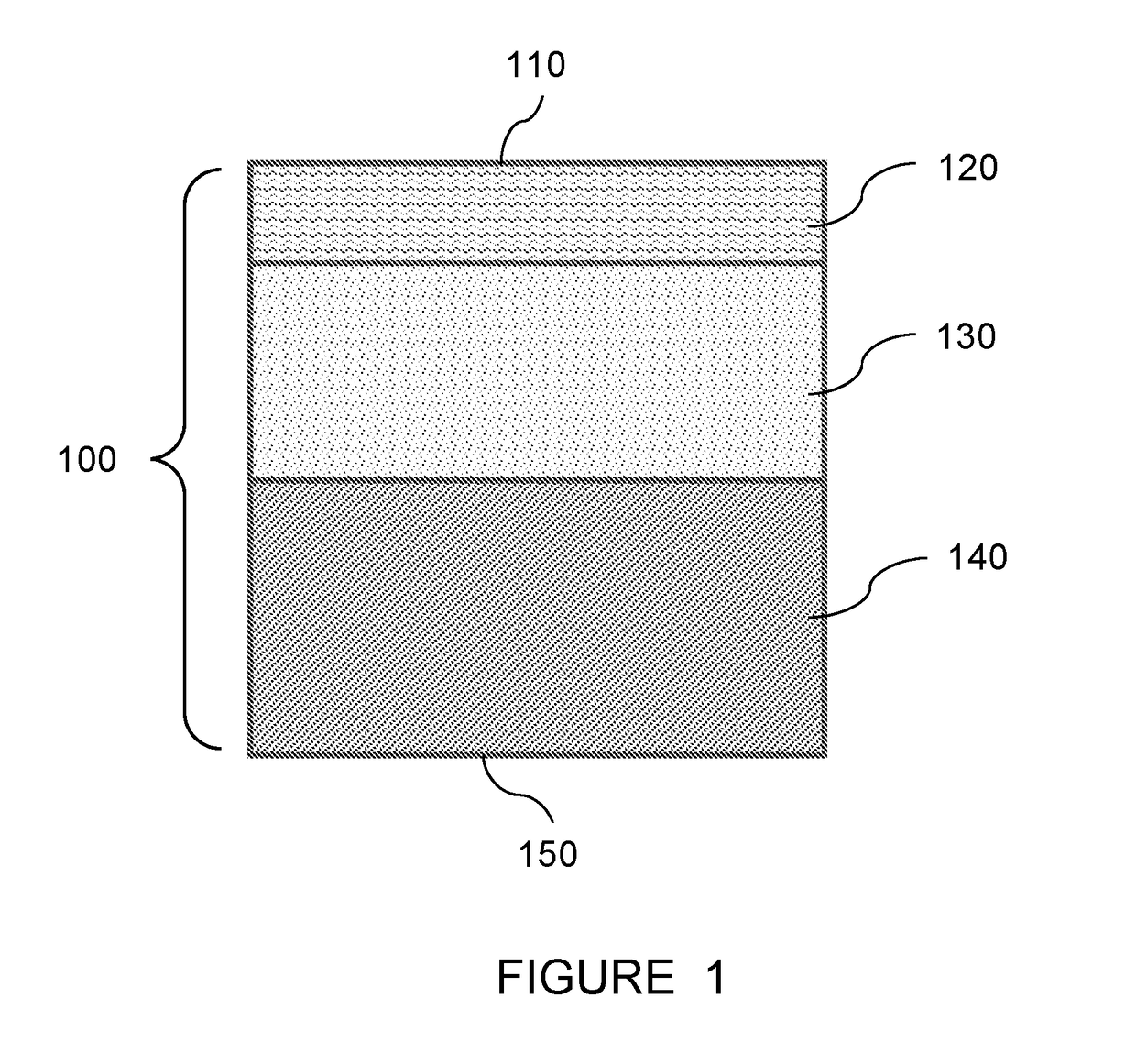

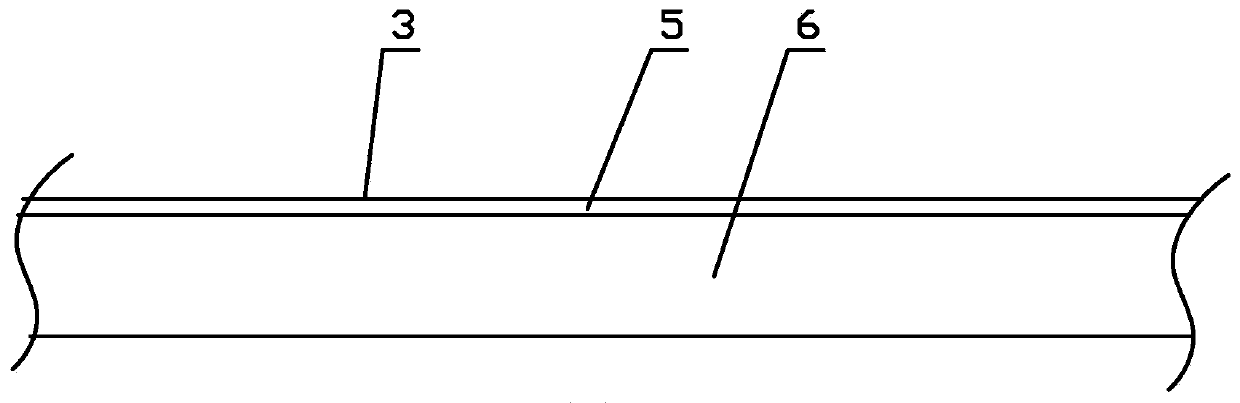

Thin film composite membranes on polyolefin structures may be prepared by interfacial polymerization on a polyolefin support. Polyolefin structures may have hollow and / or solid portions. The polyolefin structure may be hydrophilized prior to interfacial polymerization. The hydrophilized structure may also be treated with an aqueous monomer containing solution first, followed by the organic monomer containing solution. Alternatively, an organic monomer solution may be introduced first, followed by the aqueous monomer containing solution when treating a hydrophilized structure. The formed membrane may possess advantageous characteristics, including stability, hydrophilicity, predetermined pore sizes and / or solvent resistance.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Photo-crosslinked gas selective membranes as part of thin film composite hollow fiber membranes

A thin film composite membrane comprises a core layer and a sheath UV-crosslinked polymer layer. The thin film composite membrane is produced by the co-extrusion of two polymer solutions. The core layer and the sheath layer can be separately optimized. The sheath layer may be UV-crosslinked to provide stability and selectivity at the desired operating temperature of the composite membrane.

Owner:HONEYWELL INT INC

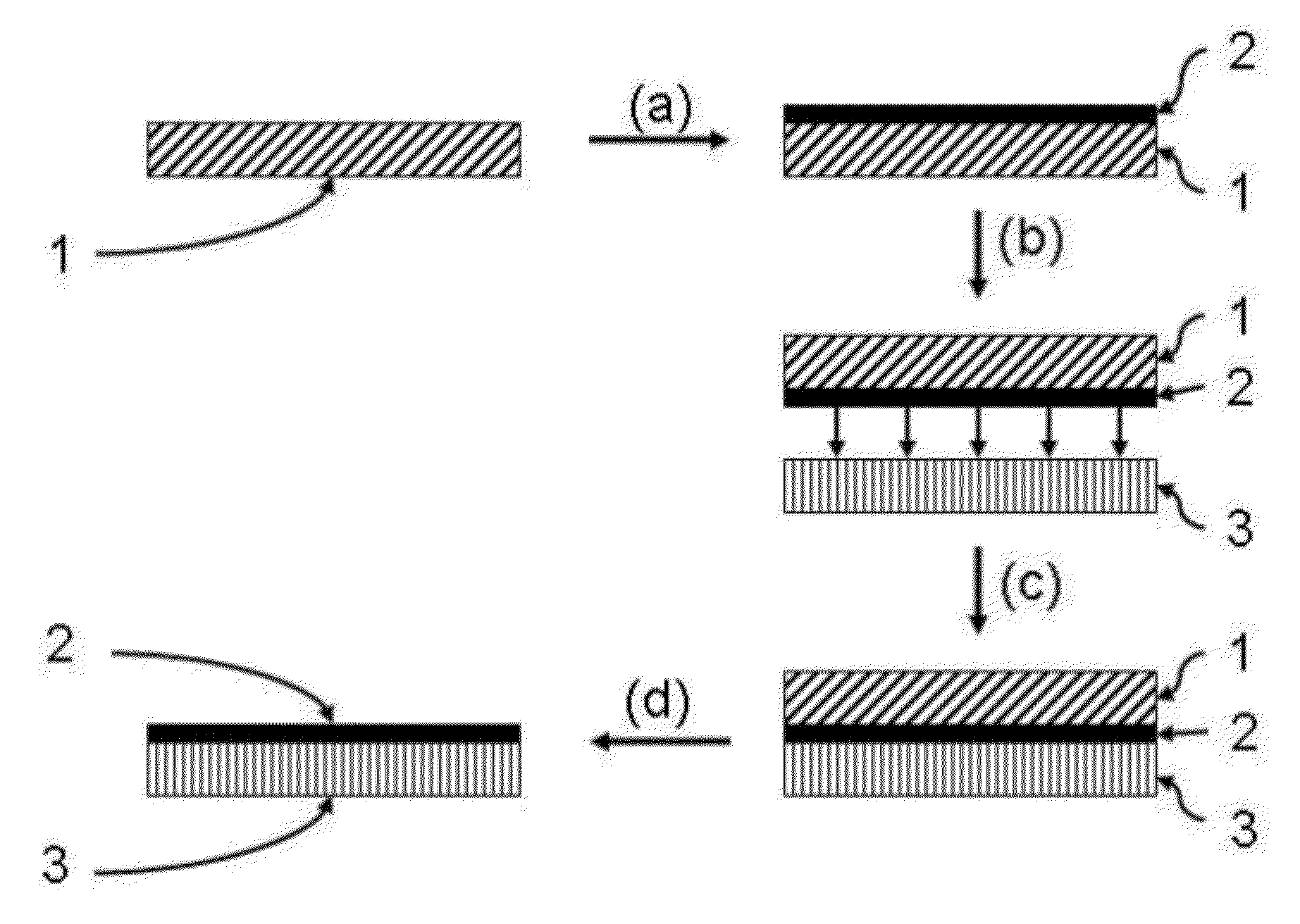

Method for synthesis of thin film composite membranes

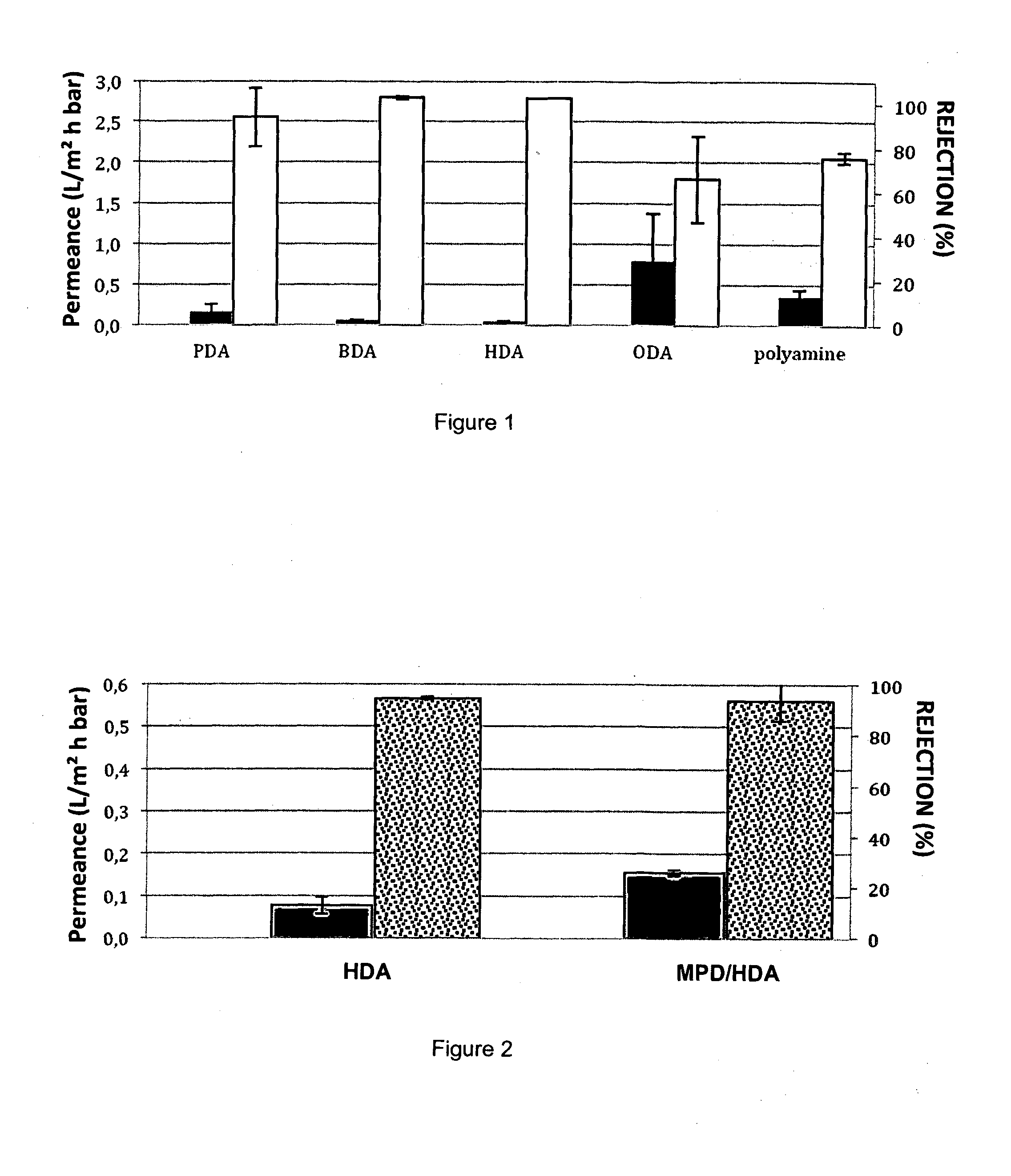

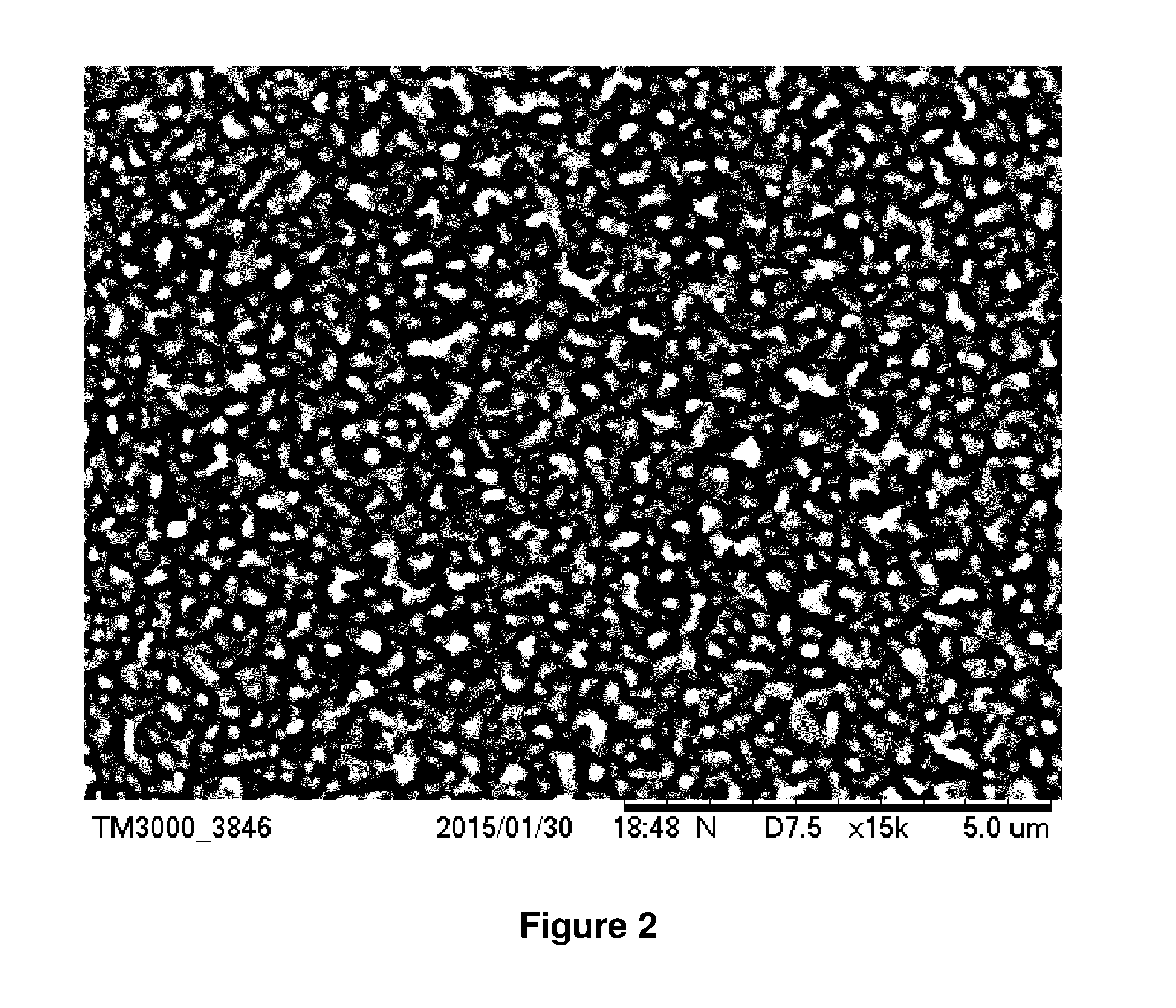

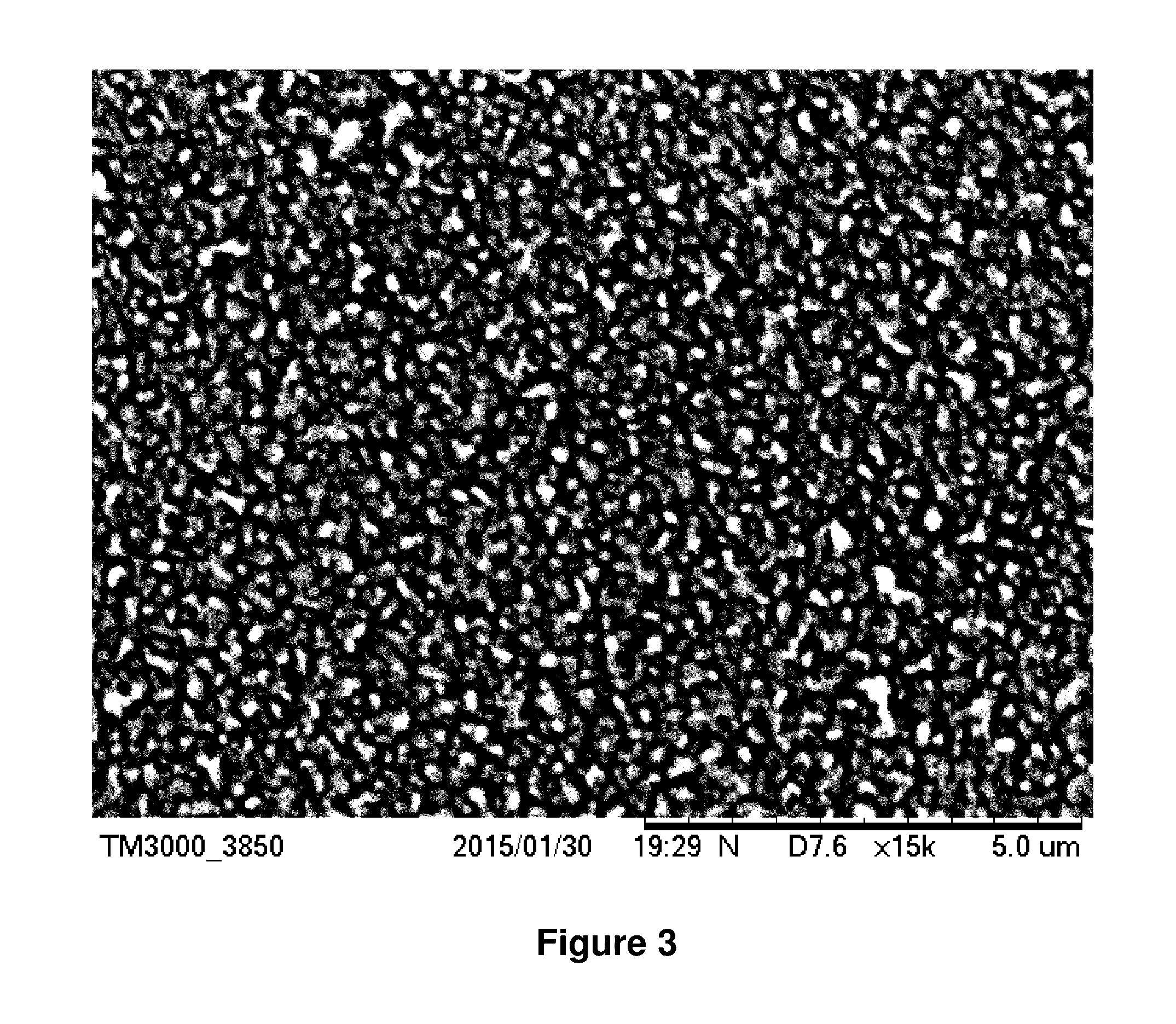

ActiveUS20150231572A1Improve the immunitySemi-permeable membranesMembranesPolymer scienceThin membrane

The present invention relates to improved methods for the preparation of thin film composite membranes by interfacial polymerization, preferably (organic) solvent resistant thin film composite membranes. More in particular the method of the present invention allows for the preparation of thin film composite membranes wherein a thin film is deposited on a porous crosslinked support. Said method comprises the one step solidification, impregnation and crosslinking of the porous support through phase inversion by immersion of the cast membrane polymer film in an (aqueous) solvent comprising a polyfunctional monomers.

Owner:KATHOLIEKE UNIV LEUVEN

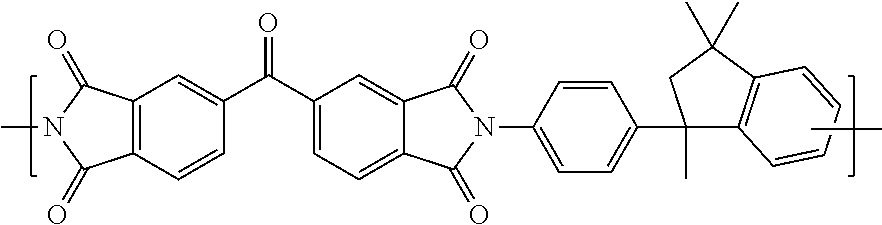

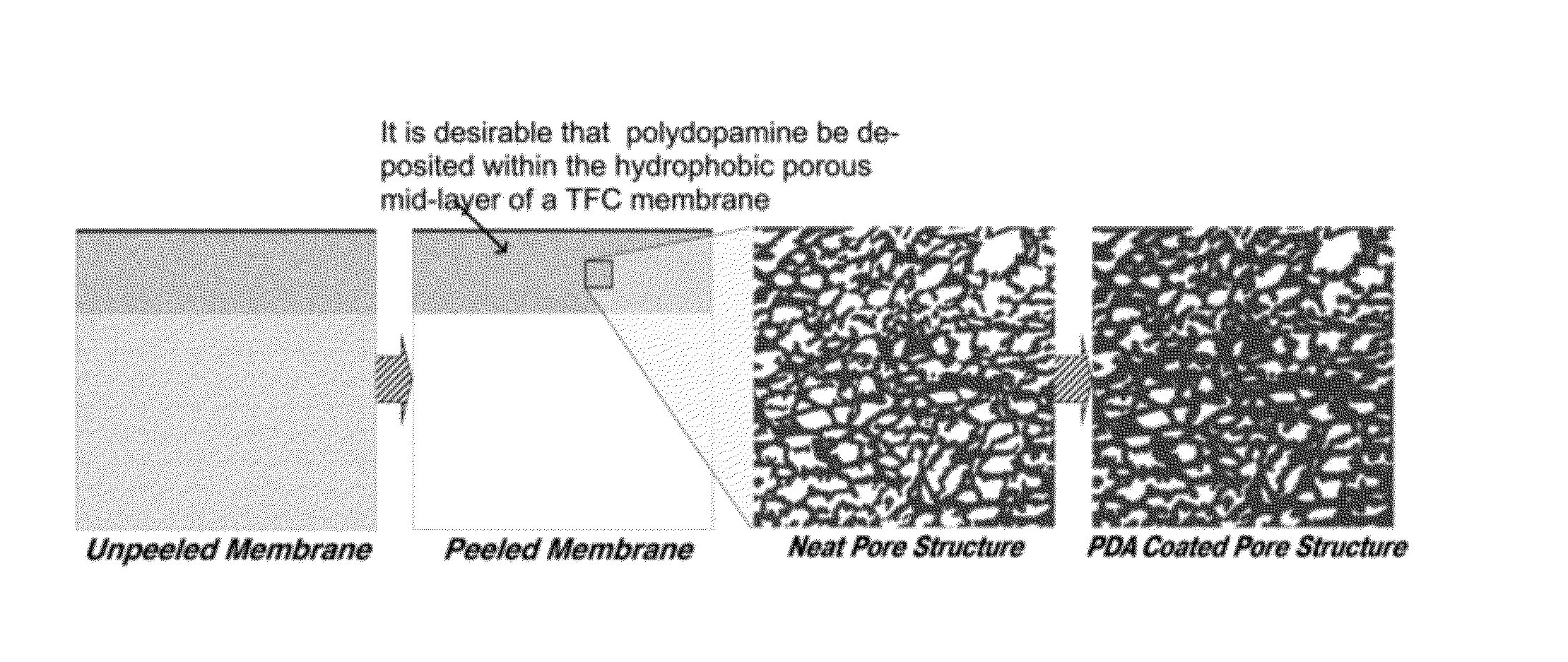

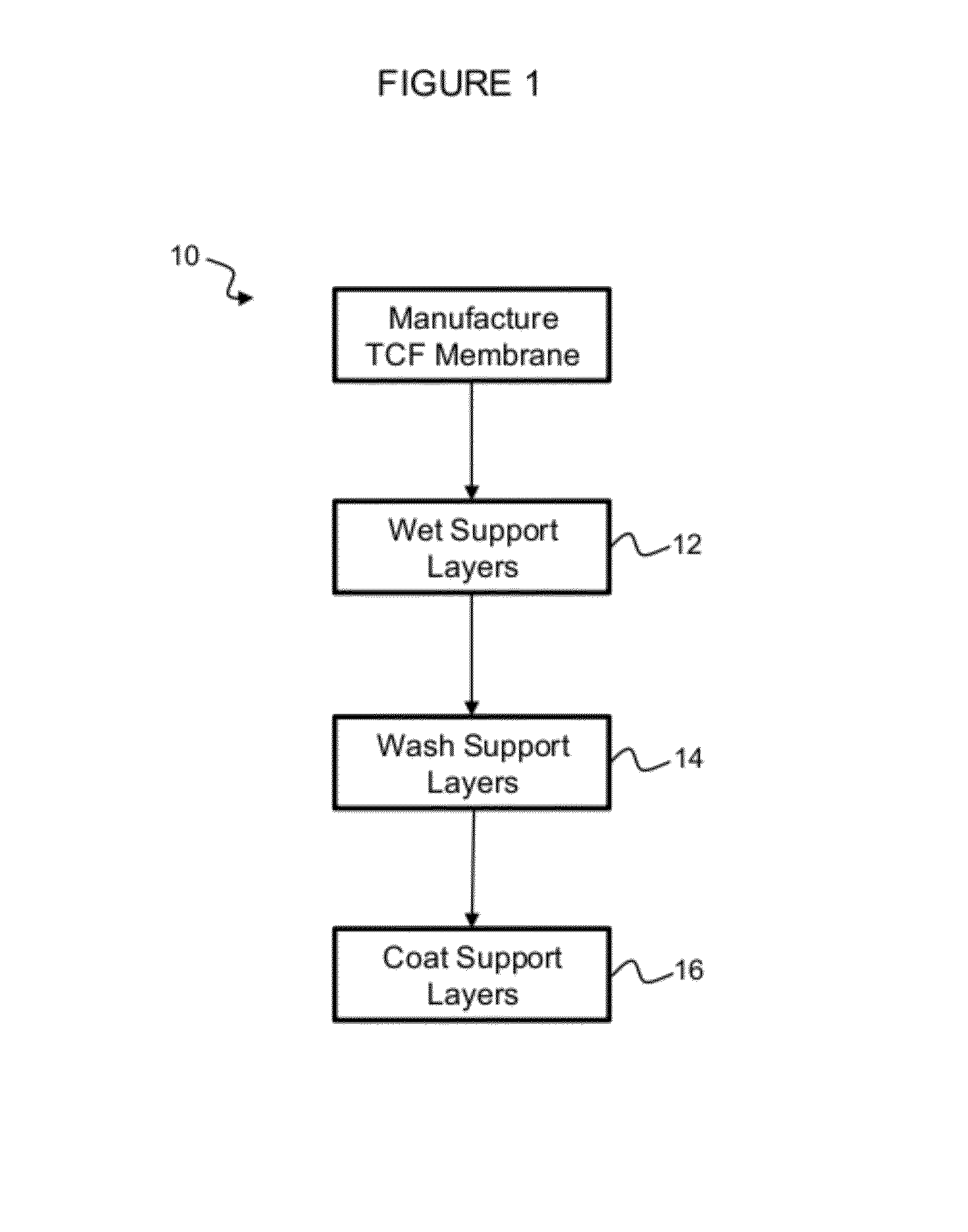

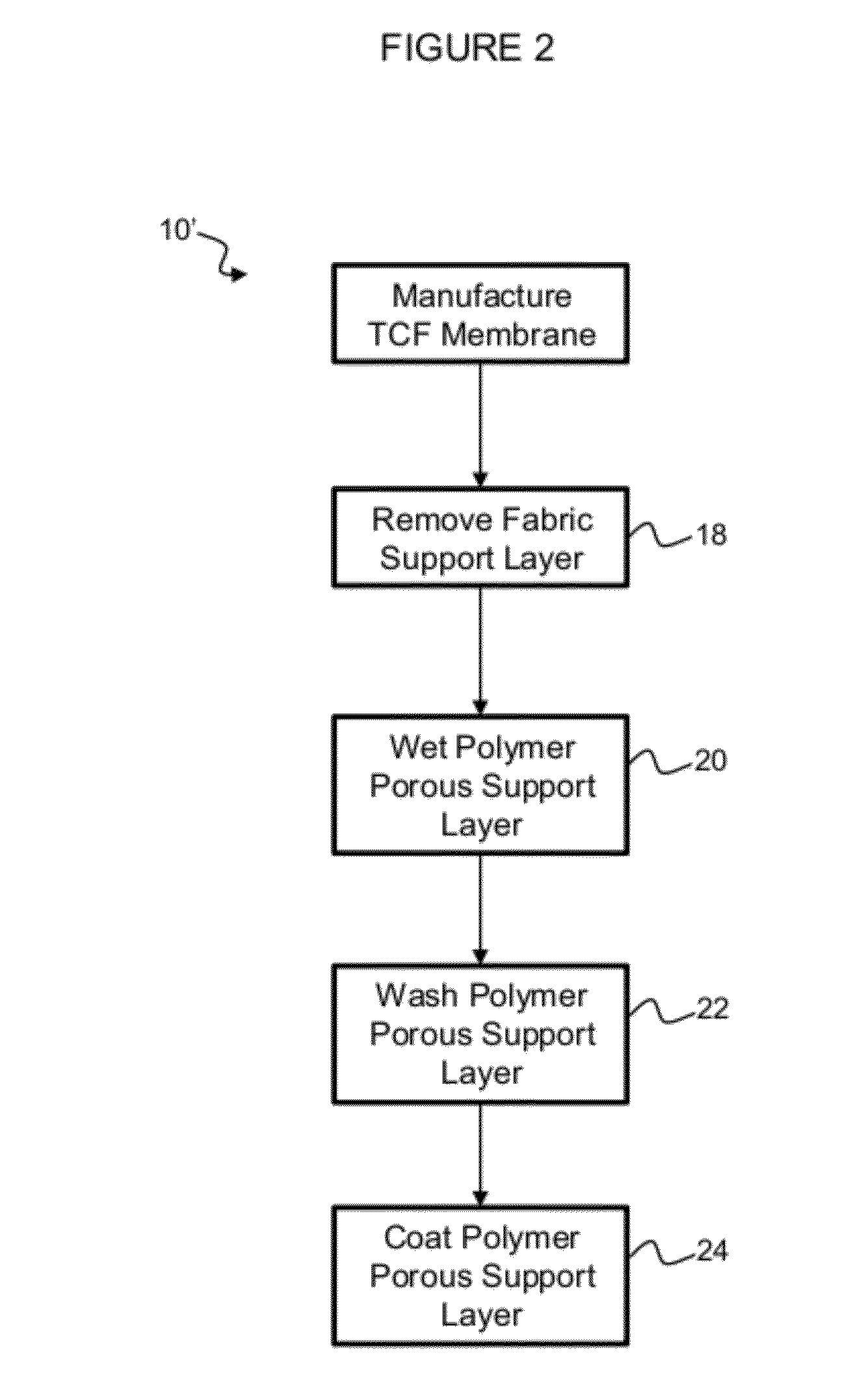

Method of modifying thin film composite membrane support structures for engineered osmosis applications

The disclosure provides a method of modifying thin film composite membrane support structures. In particular, the disclosure provides method of modifying thin film composite membrane support structures with poly(dopamine) for use with engineered osmosis applications.

Owner:UNIV OF TEXAS +1

Thin film composite membranes and their method of preparation and use

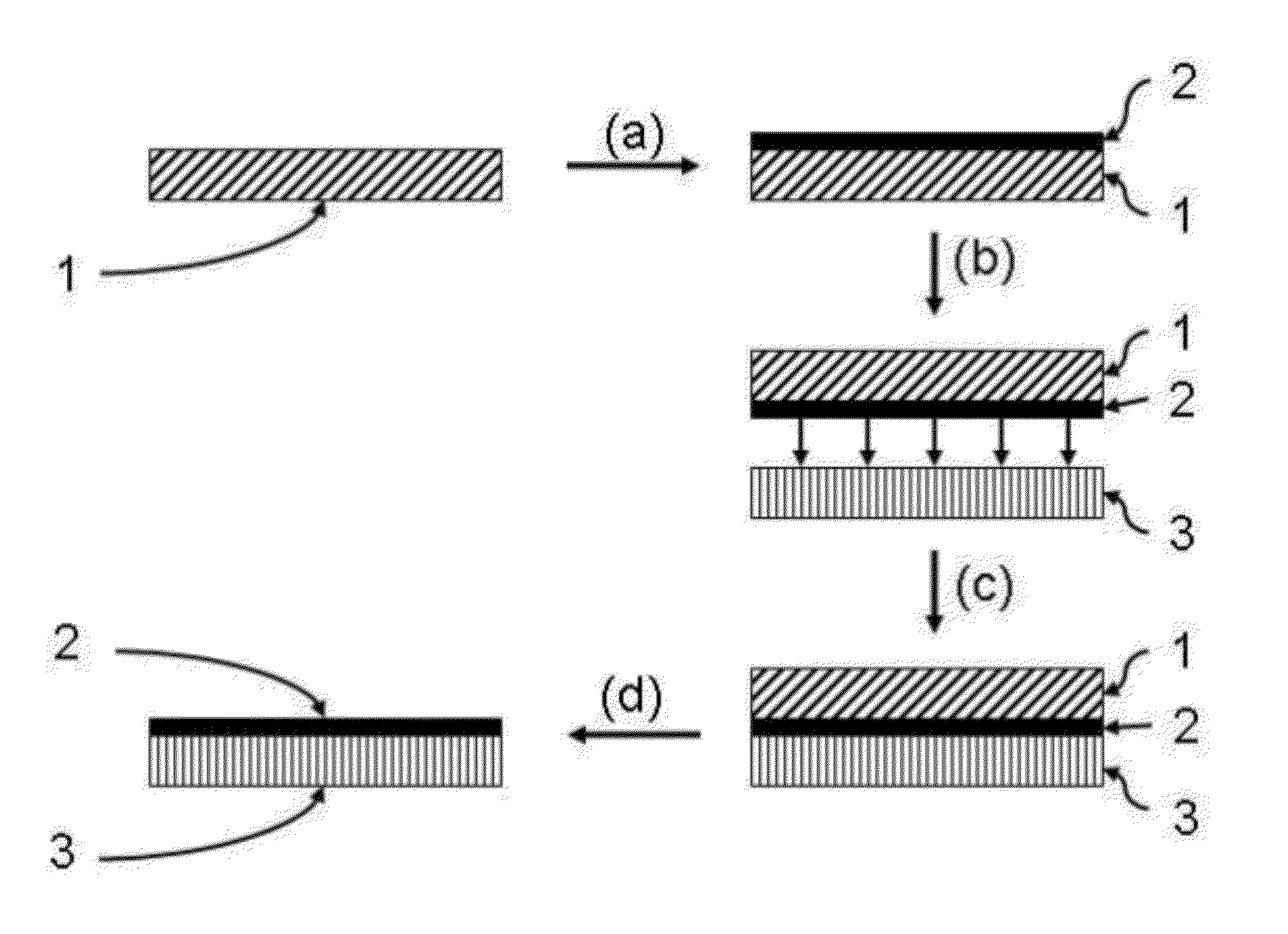

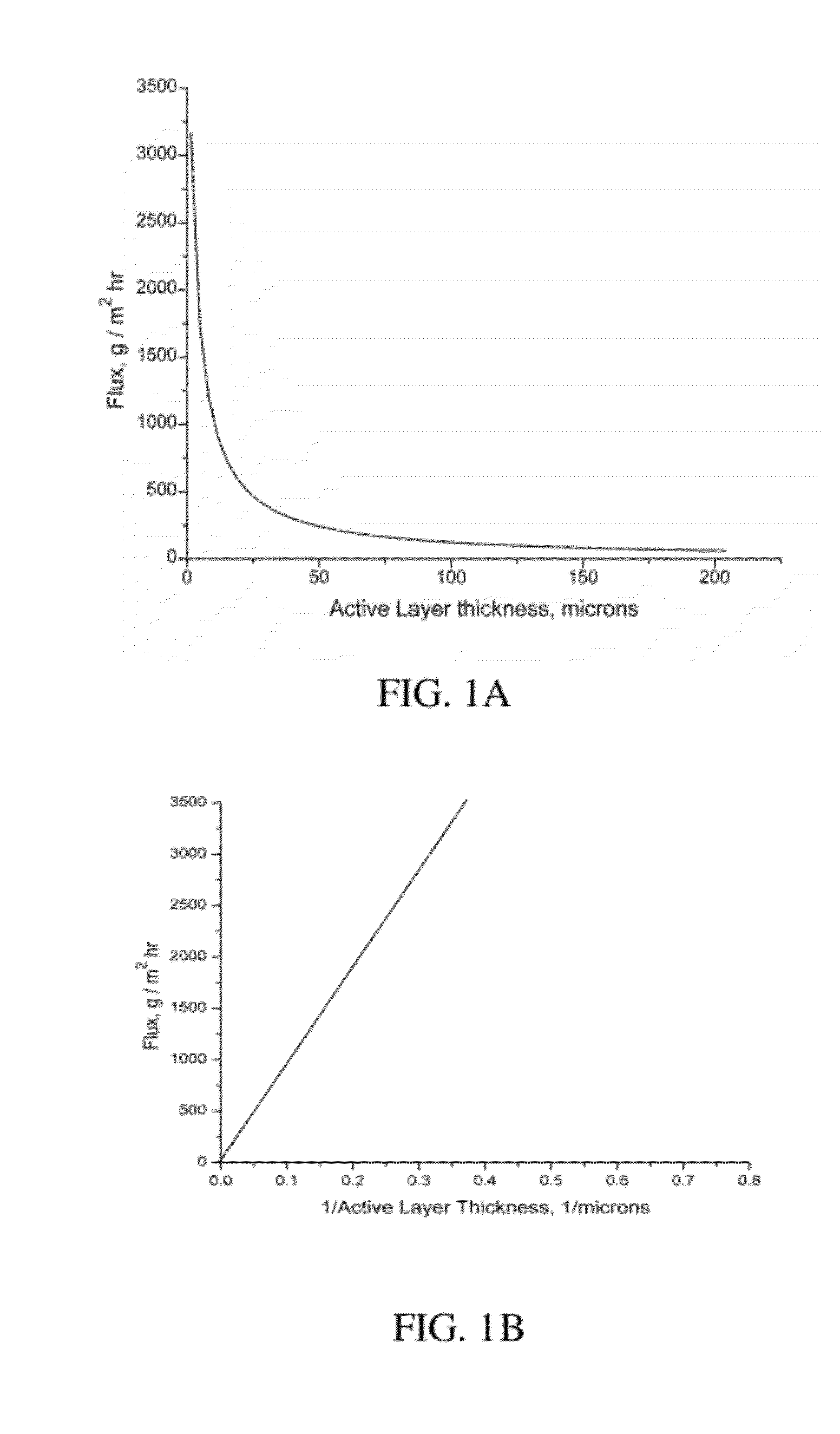

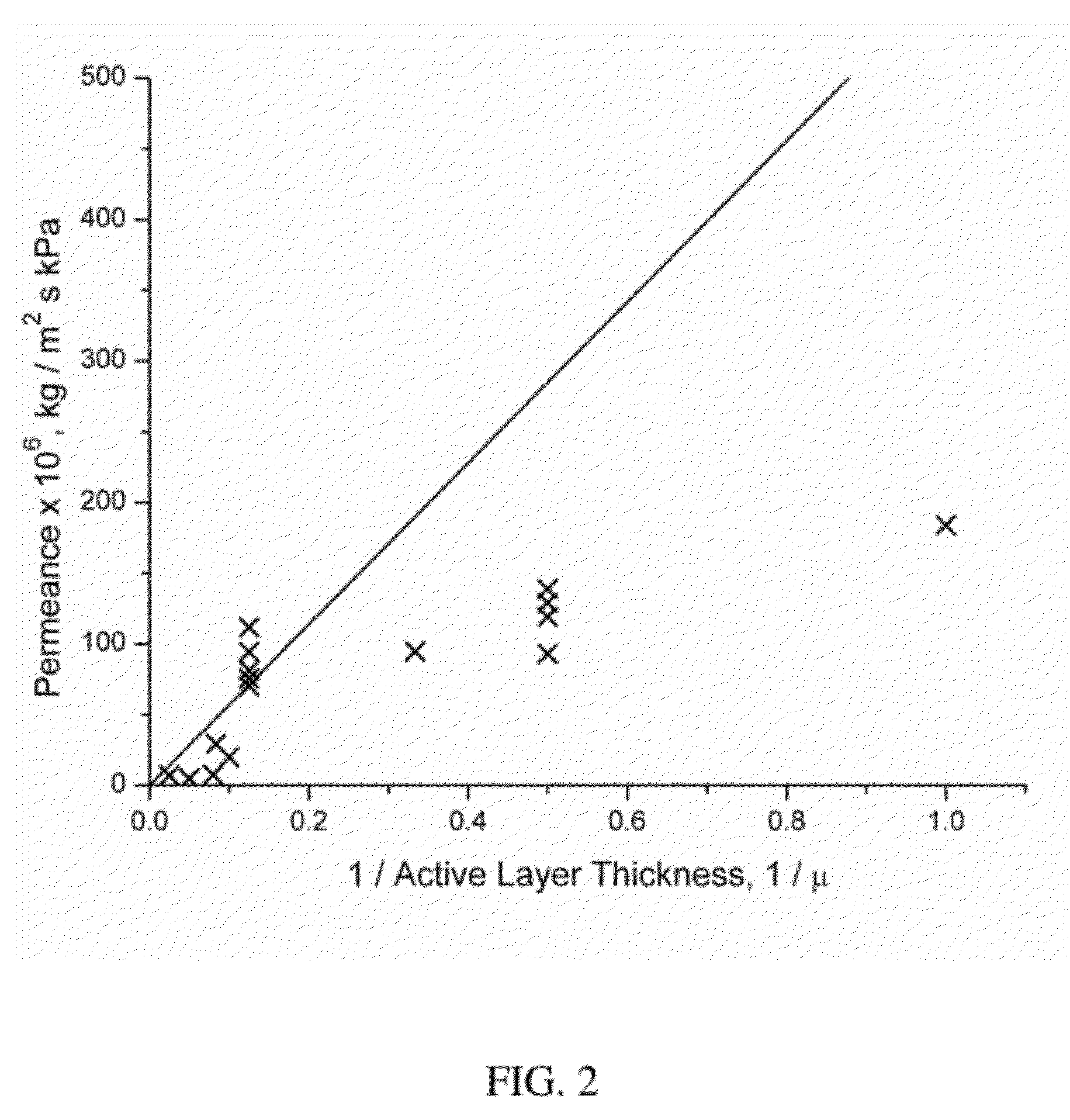

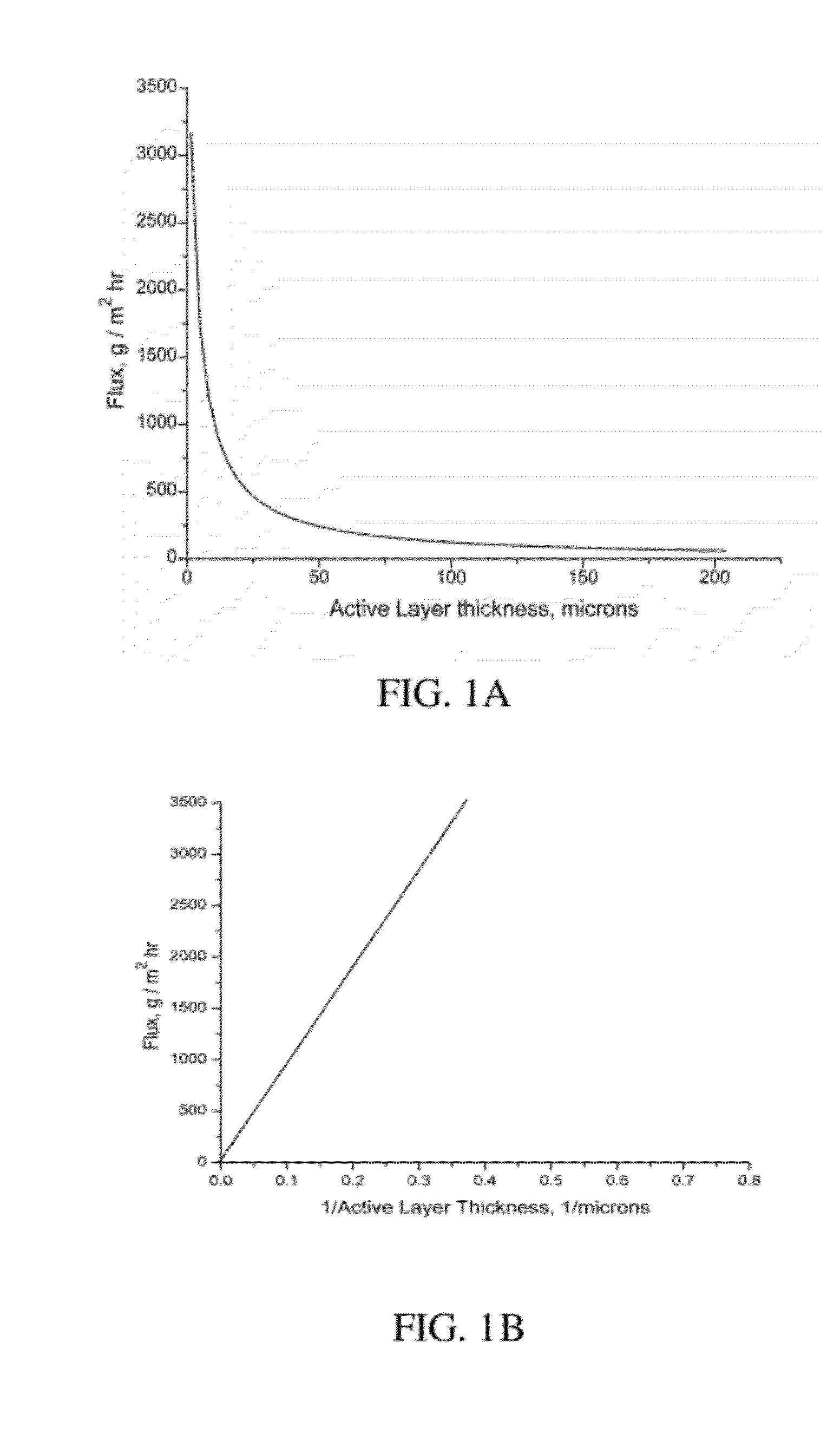

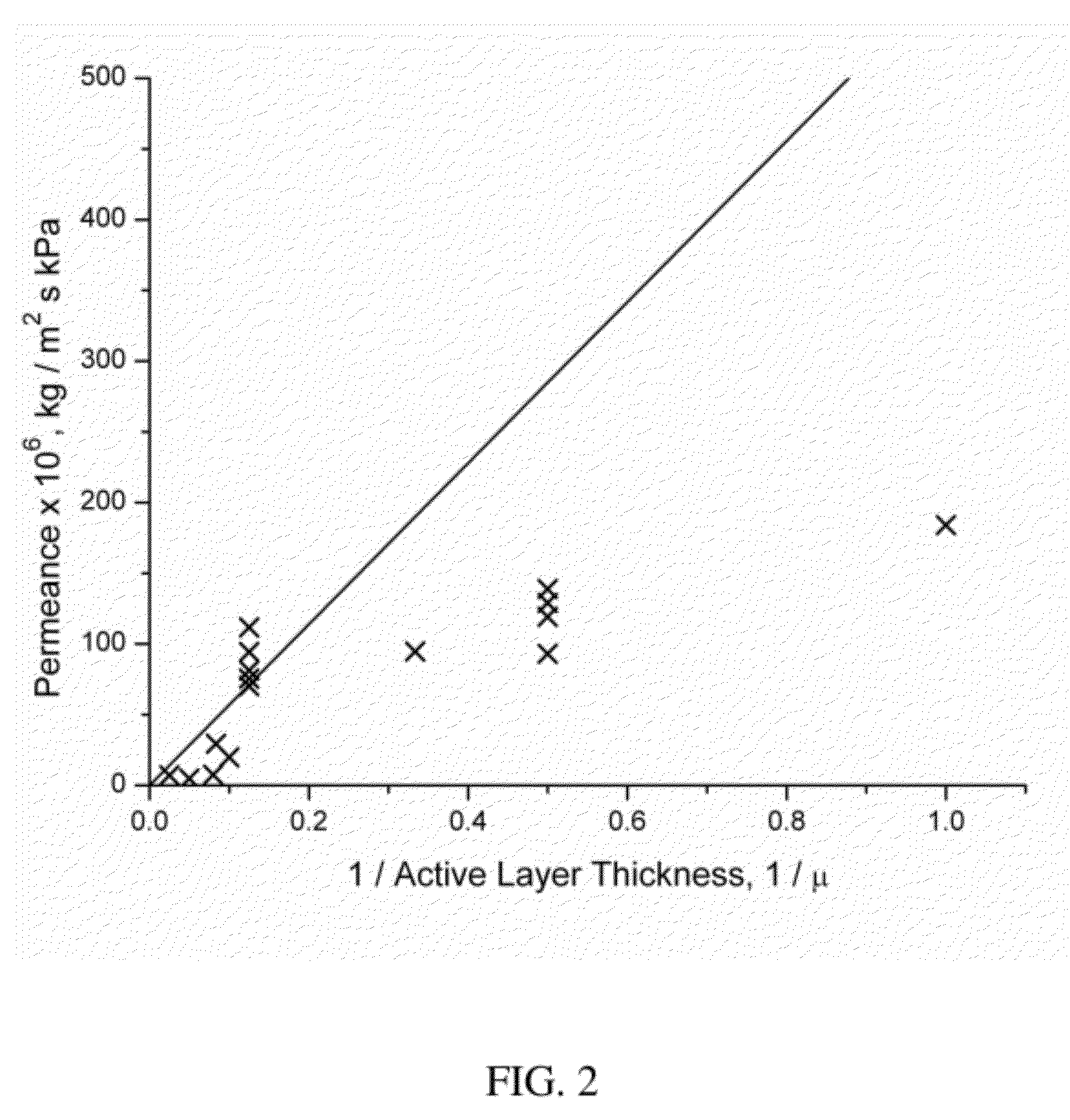

InactiveUS20120080147A1Adhesive processesSolid sorbent liquid separationMass transfer resistanceThin-film composite membrane

The present invention is a technique to fabricate thin-film composite perm-selective membranes by a transfer method. The composite membranes are useful in separating liquid, vapor or gaseous mixtures by selective permeation and reduce mass transfer resistance of the support layer. Selectivity and flux are improved by reduction of the mass transfer resistance of the support layer.

Owner:US SEC AGRI

Thin film composites

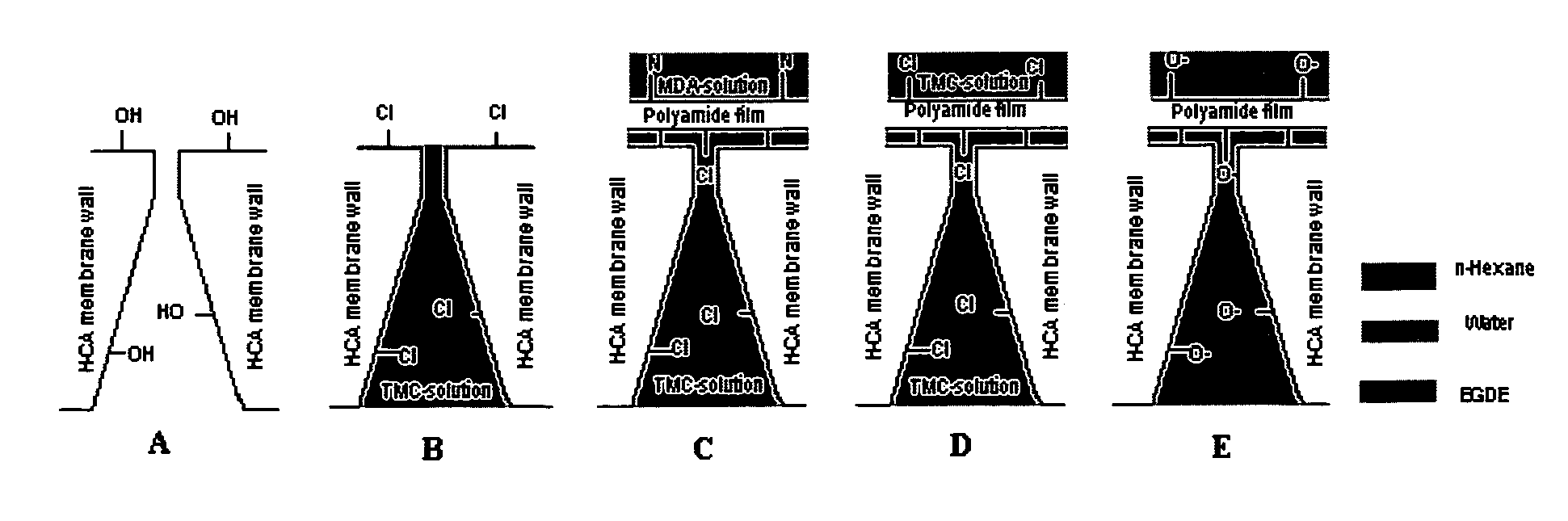

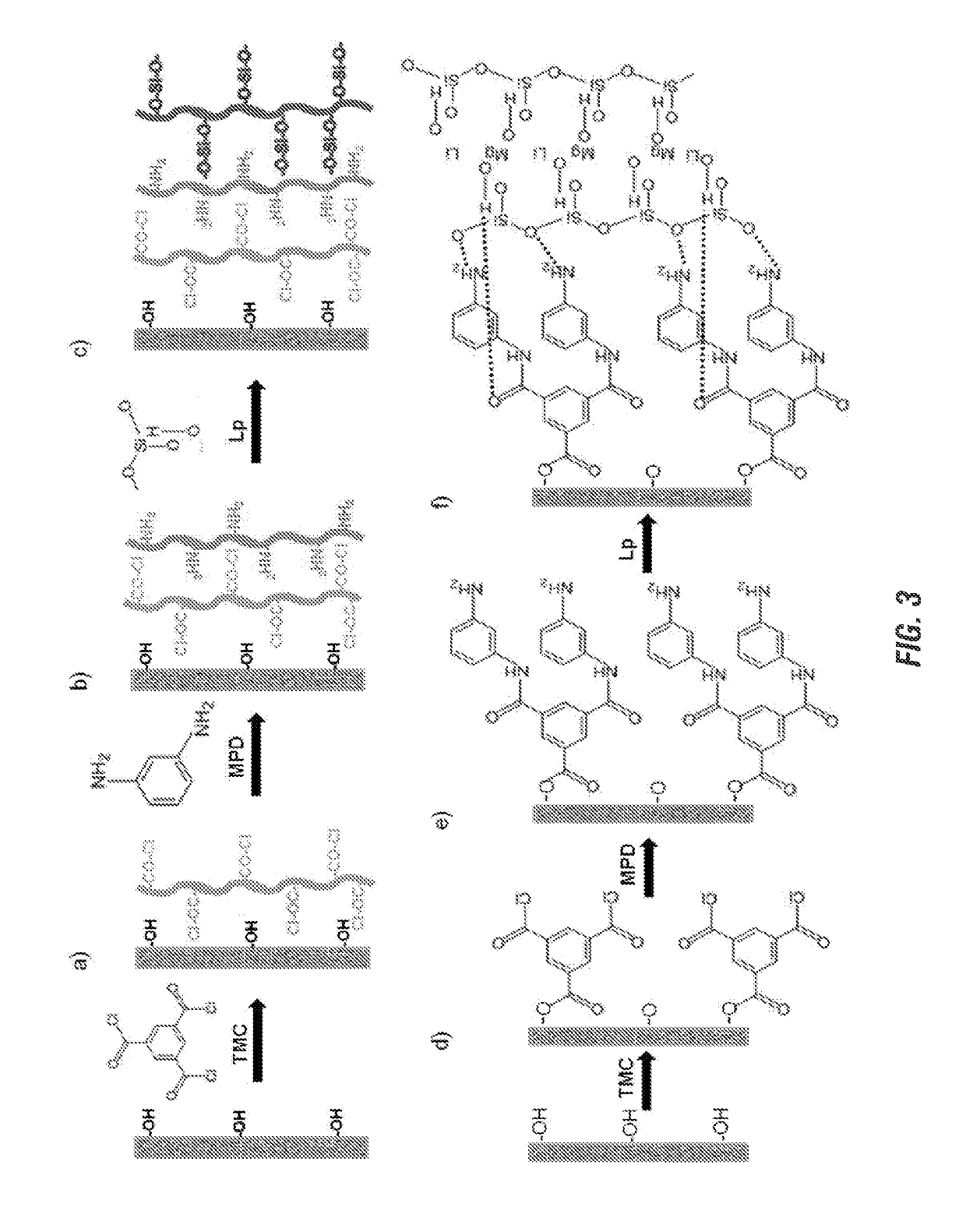

InactiveUS20130089727A1Provide stabilityTechnique is effectiveMembranesGeneral water supply conservationThin-film composite membraneAcyl halide

The present invention relates to a method for the production of thin film composite membranes by interfacial polymerisation, in particular through the reaction of polyfunctional acyl halides with polyfunctional amines where the polyfunctional acyl halide is applied first to the support medium.

Owner:NILSEN TOM NILS

Multilayer thin film nanocomposite membranes prepared by molecular layer-by-layer assembly

ActiveUS20190193033A1Rapid and steady and controlled growthSemi-permeable membranesMembranesFiberFiltration membrane

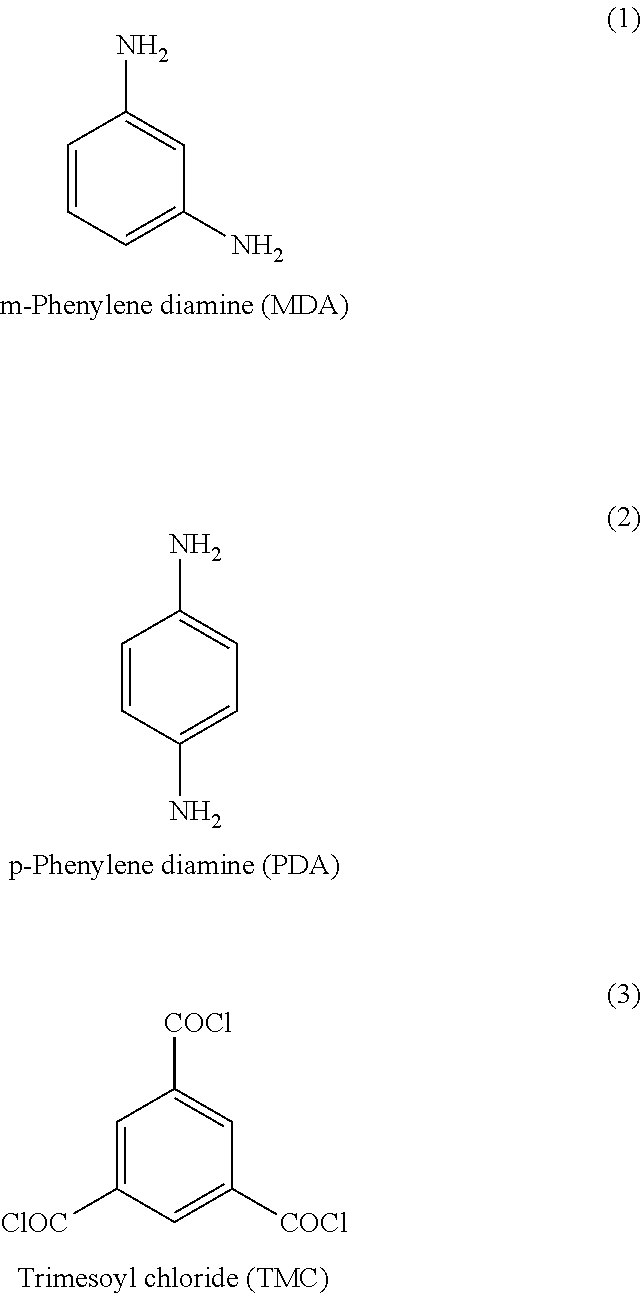

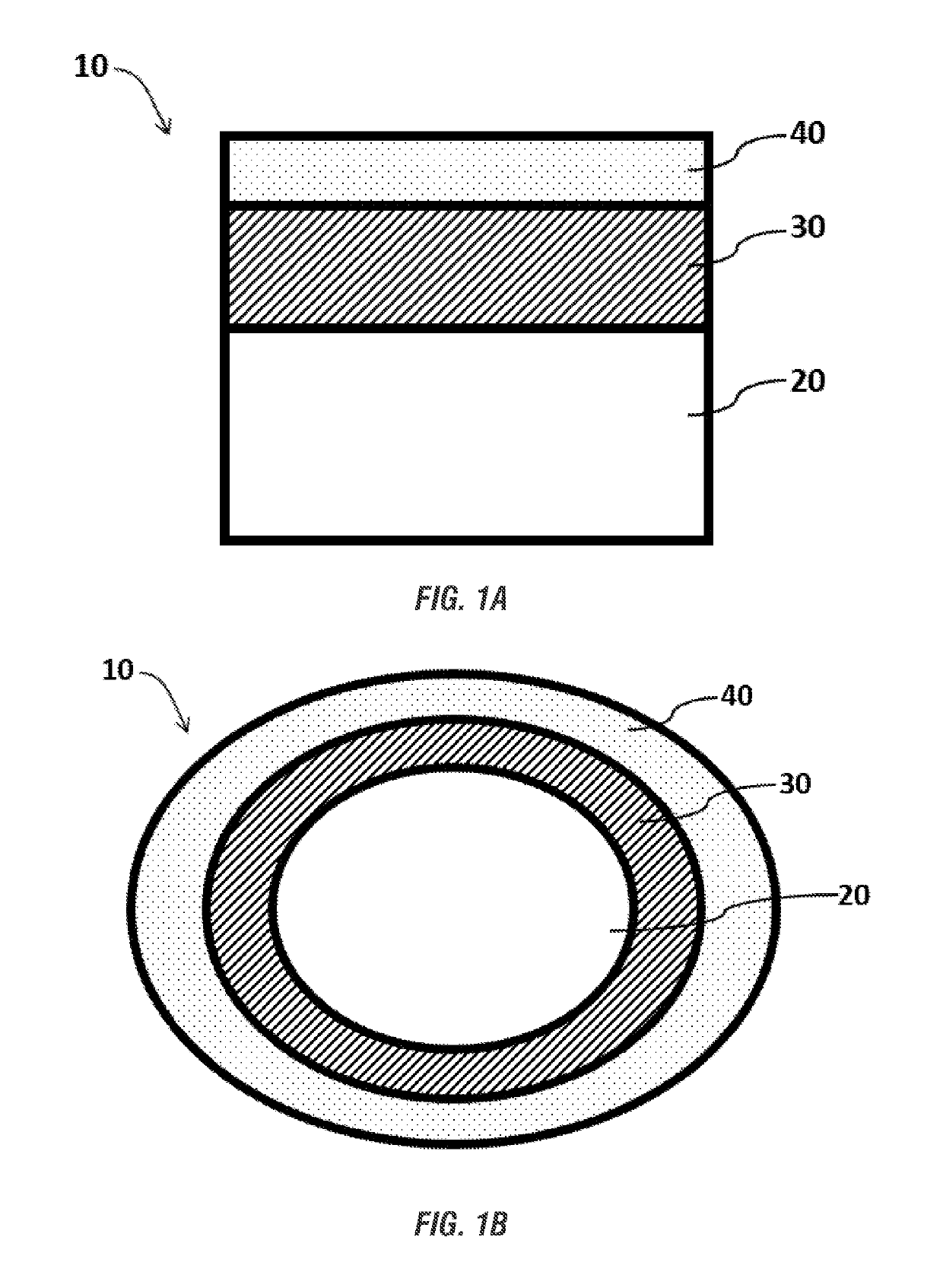

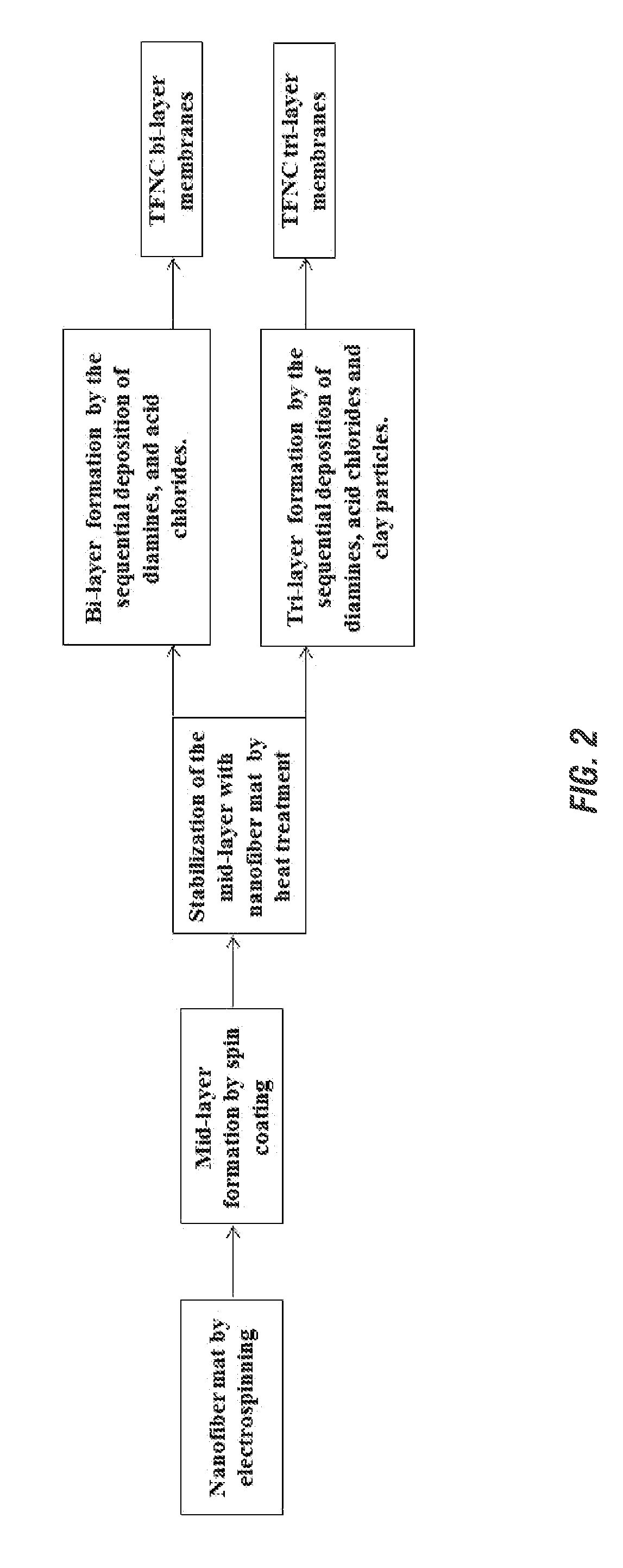

This invention relates thin film nanocomposites (TFNCs) and methods of preparing the same by molecular layer-by-layer assembly. The TFNCs comprise a porous nanofibrous support first layer coated with a mid-layer having an outer separating layer, wherein the out separating layer has one or more bilayers or trilayers. The TFNCs can be particularly suitable for use as filtration membranes for the separation of dissolved components from fluids such as ultrafiltration, nanofiltration, and reverse osmosis. Thus, embodiments of the invention also include filtration systems and methods of filtering.

Owner:SOUTH DAKOTA BOARD OF REGENTS

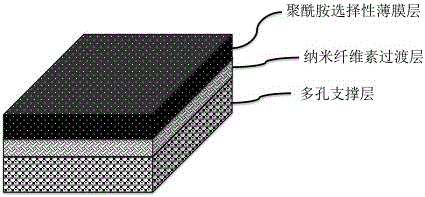

Composite thin membrane with multilayer composite structure and preparation method thereof

InactiveCN106739363ALow energy consumptionPromote formationSemi-permeable membranesLamination ancillary operationsElectrolysisFiltration membrane

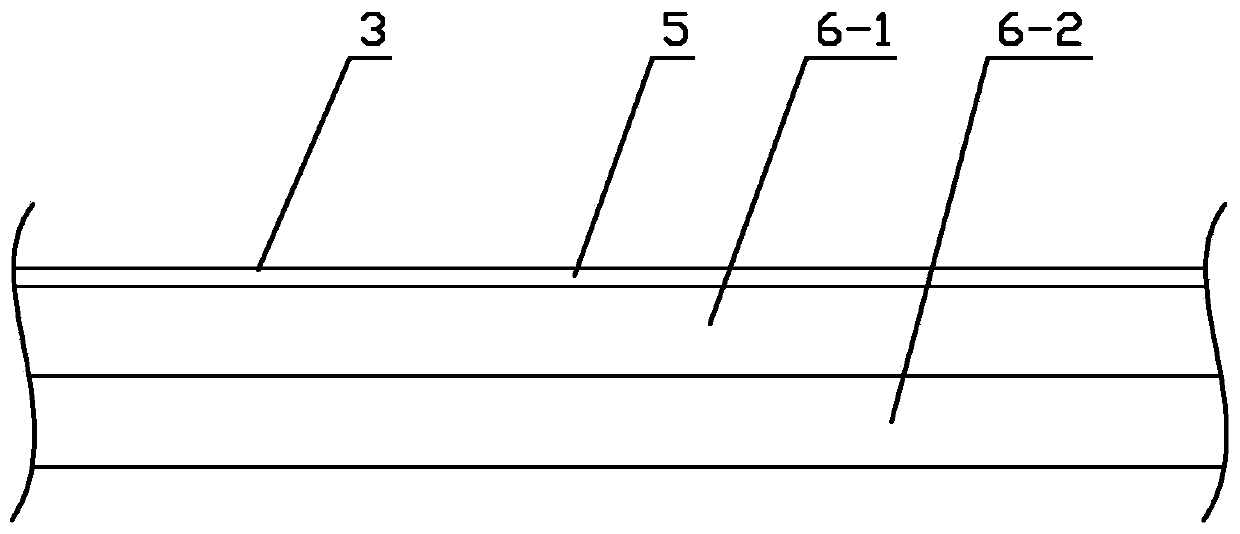

The invention belongs to the technical field of semi-permeable membrane separation processes, and relates to a composite thin membrane with a multilayer composite structure and a preparation method thereof. The composite thin membrane is formed by coating nano-cellulose and a transition layer which is formed from a polyelectrolyte by a layer-by-layer assembling method on a porous supporting layer substrate in sequence, and then coating a polyamide selective membrane layer which is formed through a common interface polymerization reaction method. A composite thin membrane structure can be applied to preparation of a nano-filtration membrane, a reverse osmosis membrane and a forward osmosis membrane. The application of the composite thin membrane with the multilayer composite structure comprises tap water purification, municipal water supply, sewage purification, brackish water desalination, seawater desalination, drink juice concentration process, dairy industry, blood dialysis medicine industry and semiconductor industry.

Owner:林小锋

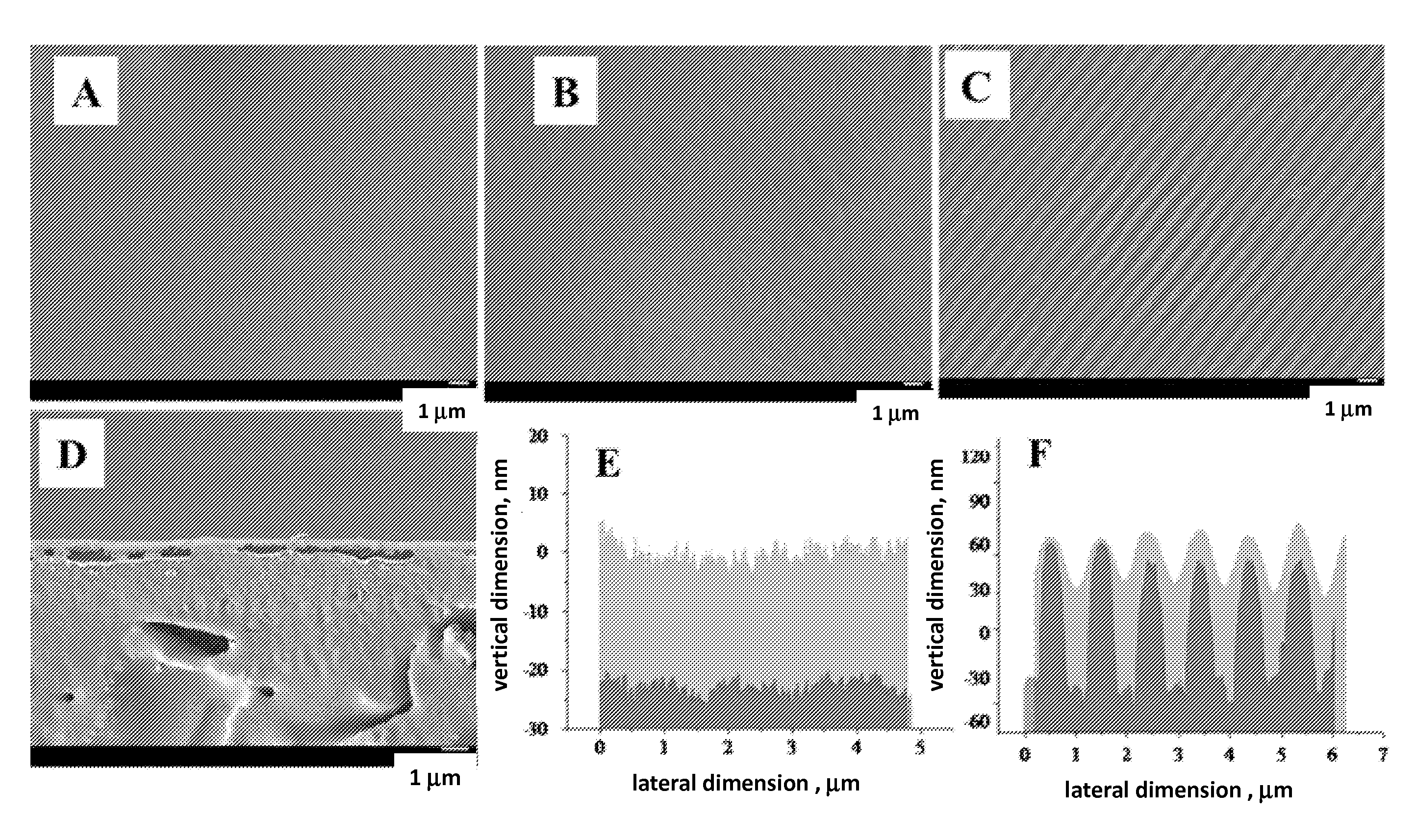

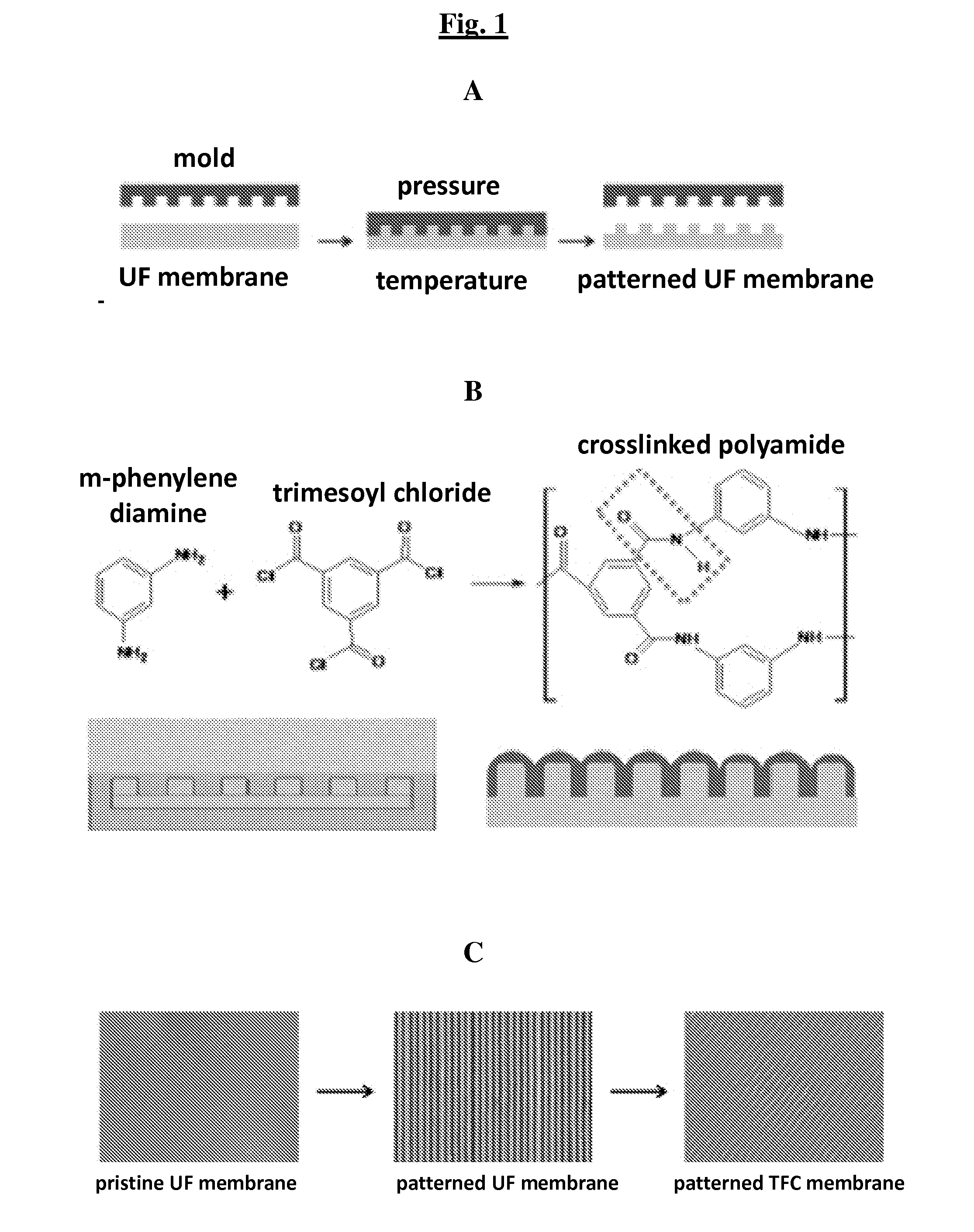

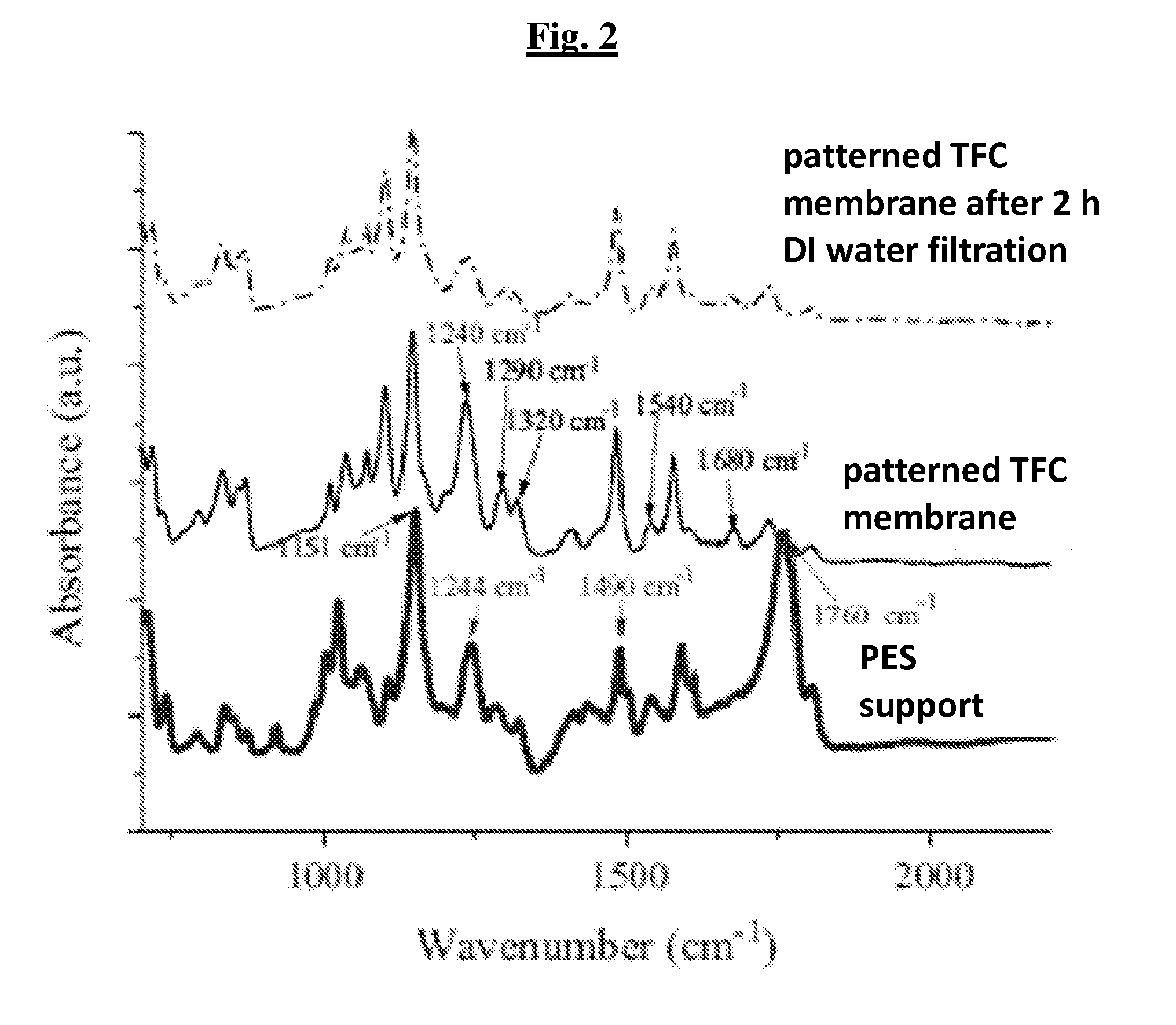

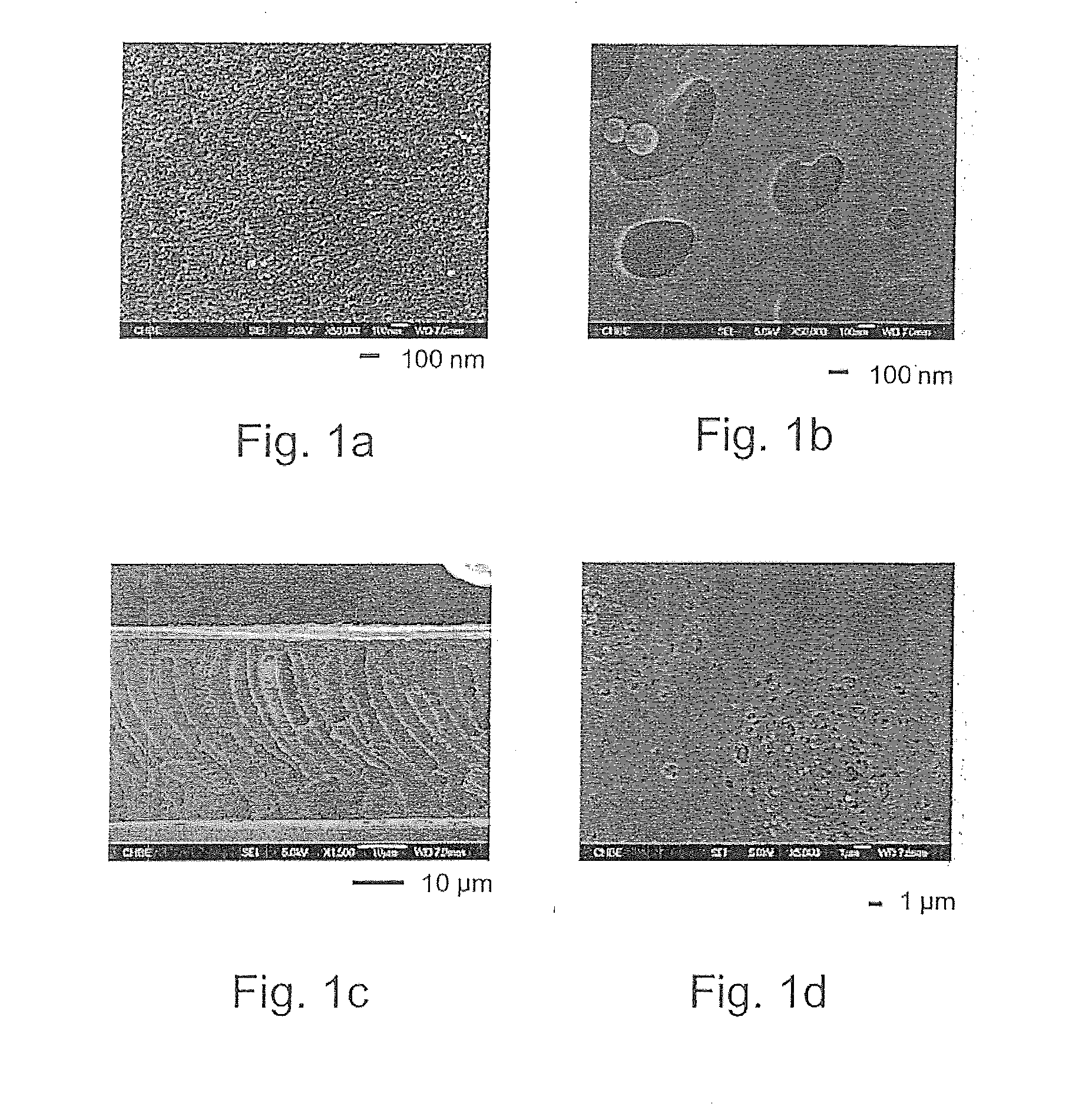

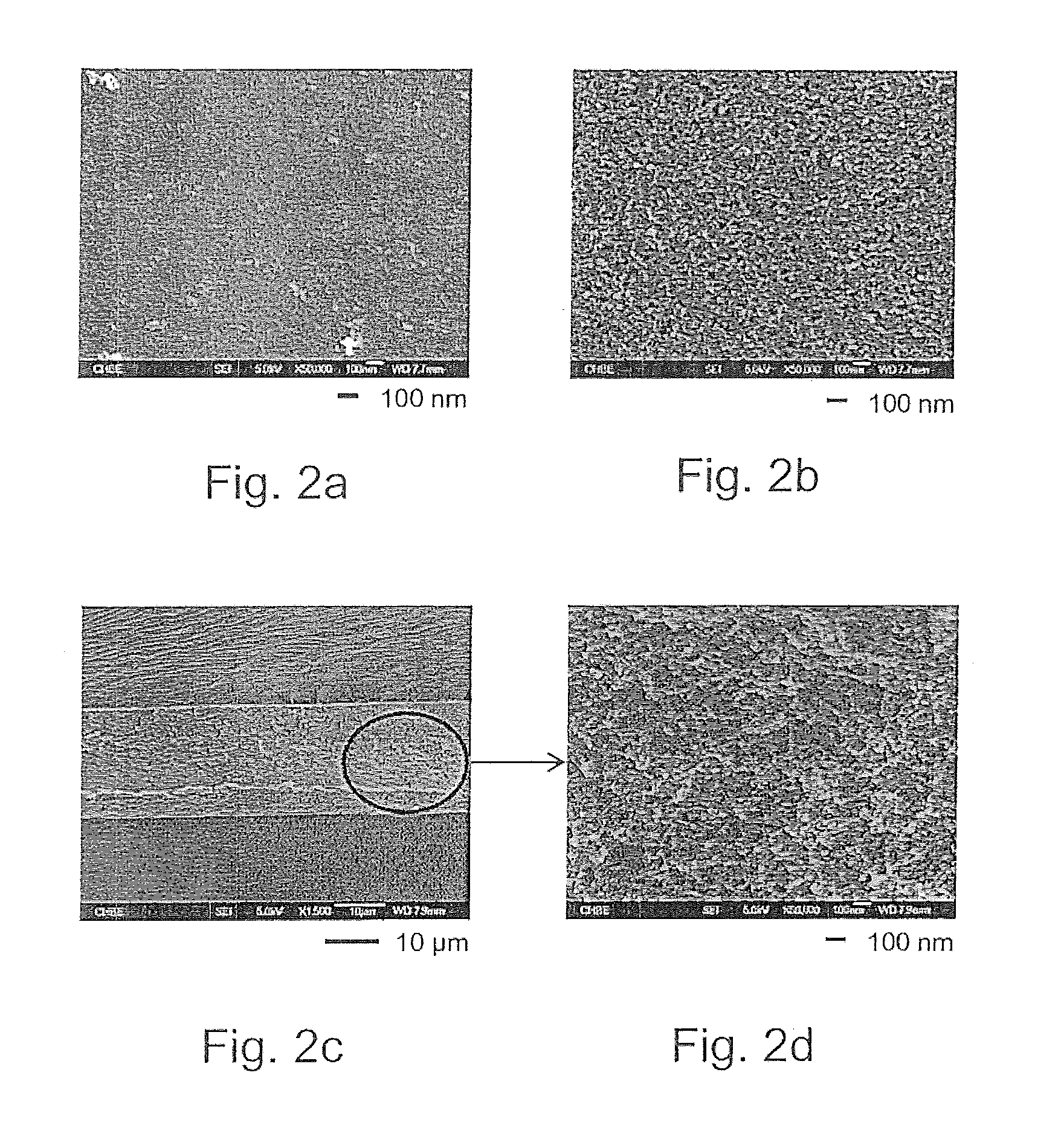

Novel nano-patterned thin film membranes and thin film composite membranes, and methods using same

The present invention includes a patterned thin film membrane and a patterned thin film composite membrane. The present invention also includes a method of making and using the patterned membranes of the invention.

Owner:UNIV OF COLORADO THE REGENTS OF

Composite membranes comprising sulfonated polyphenylenesulfone and their use in forward osmosis processes

InactiveUS20130341273A1Improve performanceHigh water fluxSolvent extractionDialysisCrystallographyThin-film composite membrane

The present invention is directed to thin film composite membranes (TFC membranes) comprising a substrate layer (S) based on a sulfonated polyphenylenesulfone, and a polyamide film layer (F) and further to a method for their preparation. Furthermore, the present invention is directed to osmosis processes, in particular to forward osmosis (FO) processes, using said membrane.

Owner:BASF AG +1

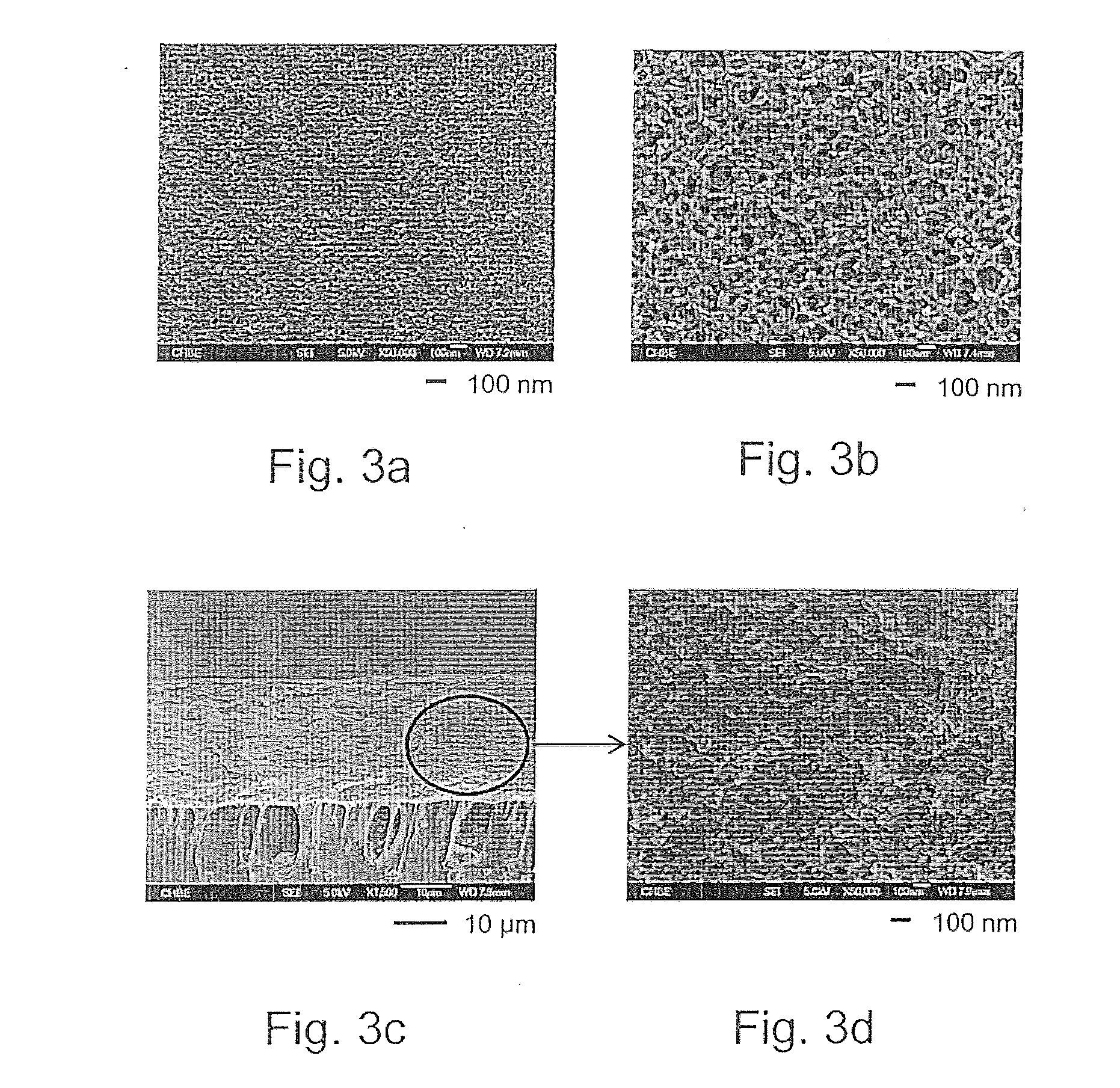

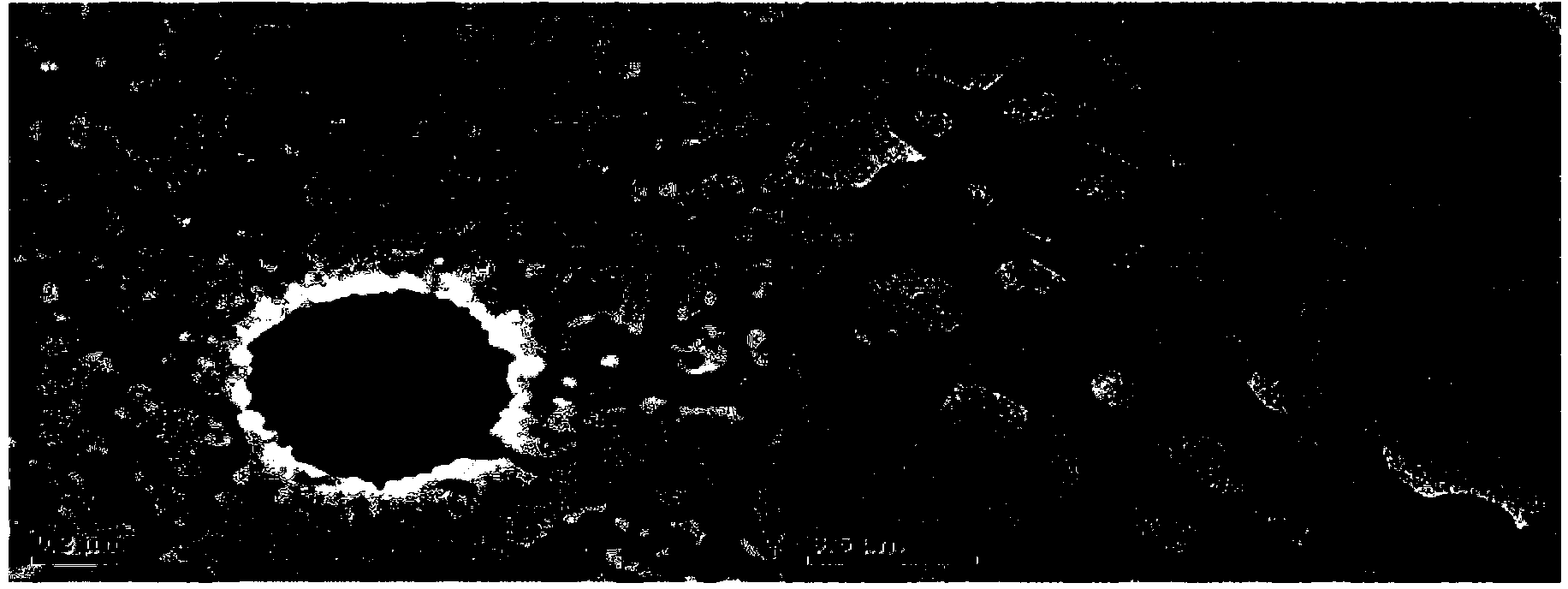

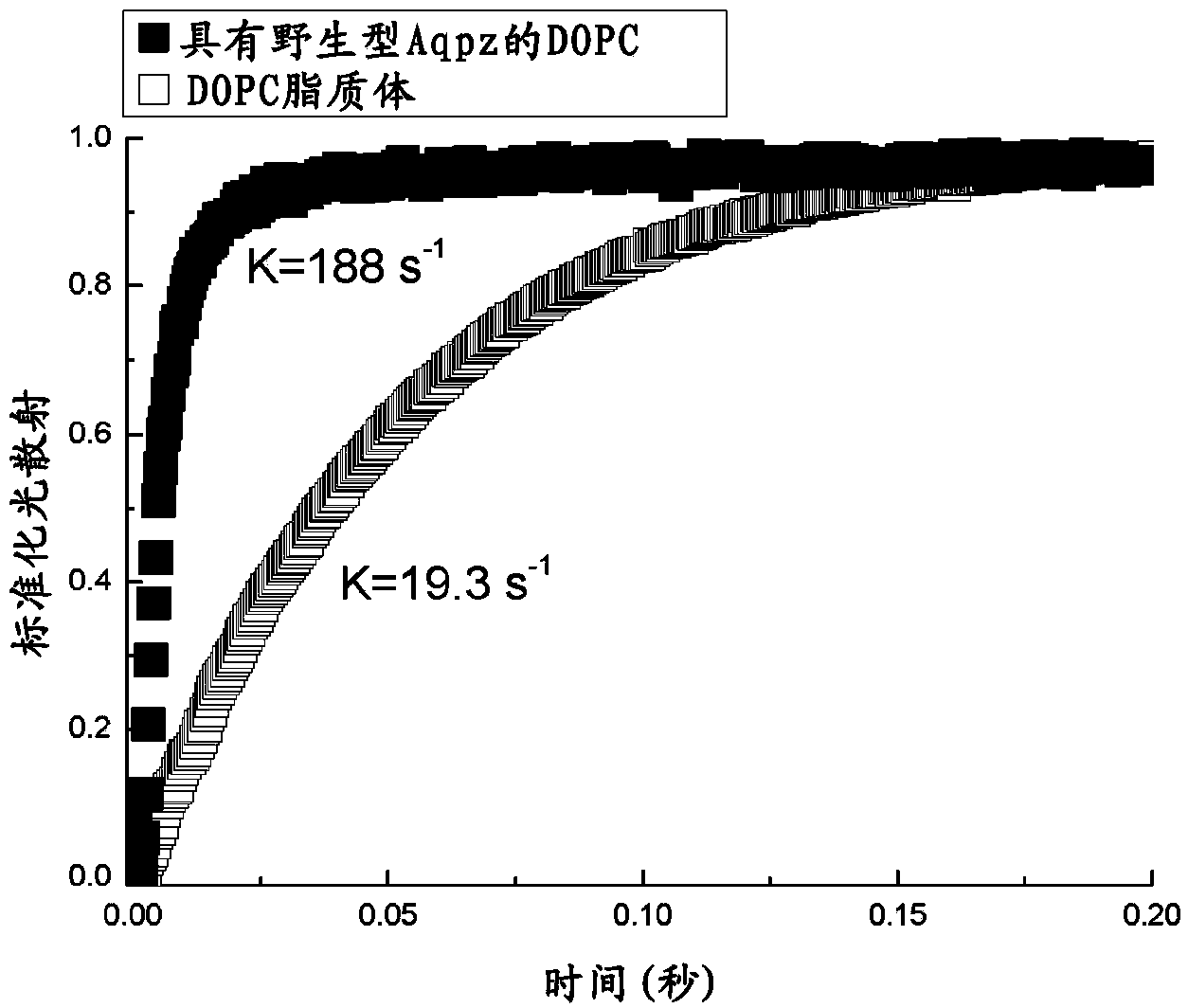

Aquaporin based thin film composite membranes

Present invention relates to a thin film composite membrane wherein a thin selective layer, having incorporated amphiphilic vesicles, is supported by a microporous substrate. A process of preparing the thin film composite membrane and its use are also disclosed.

Owner:NANYANG TECH UNIV

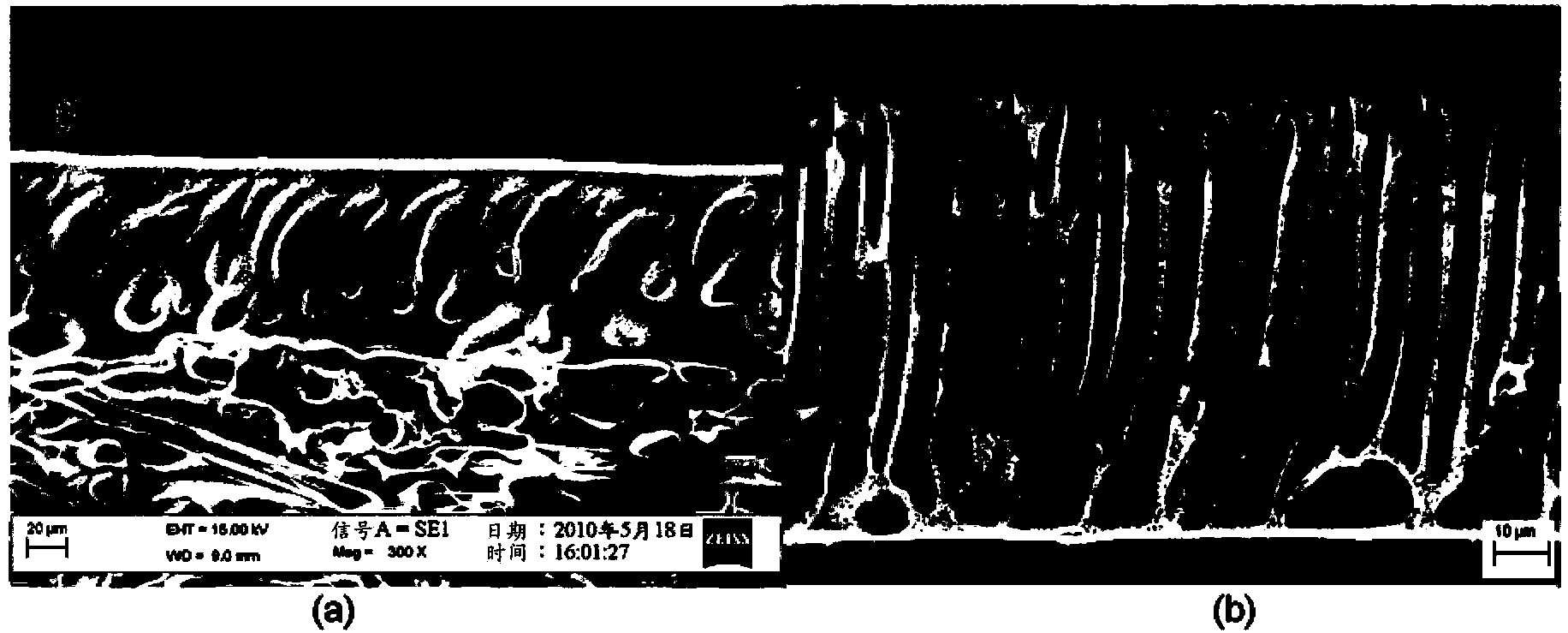

Thin film composite membranes for forward osmosis, and their preparation methods

ActiveCN103140278AGood processing characteristicsMaterial nanotechnologyMembranesHollow fibrePressure generation

Forward osmosis membranes having a hydrophilic support layer and a polyamide rejection layer in a thin film composite membrane are considered. Preferred support layer materials include aramid polymers and PVDF. A woven or non-woven mesh can be incorporated into the support layer to improve handling properties of the membrane. Flat sheet and hollow fiber configurations are possible. Antifouling techniques are provided. The polyamide layer can be formed on the hydrophilic support layer by interfacial polymerization. Applications include forward osmosis and pressure retarded osmosis applications, such as industrial product and / or waste concentration, hydration bags, energy / pressure generation, and controlled delivery of chemicals (e.g., for pharmaceutical applications).

Owner:海绵股份有限公司

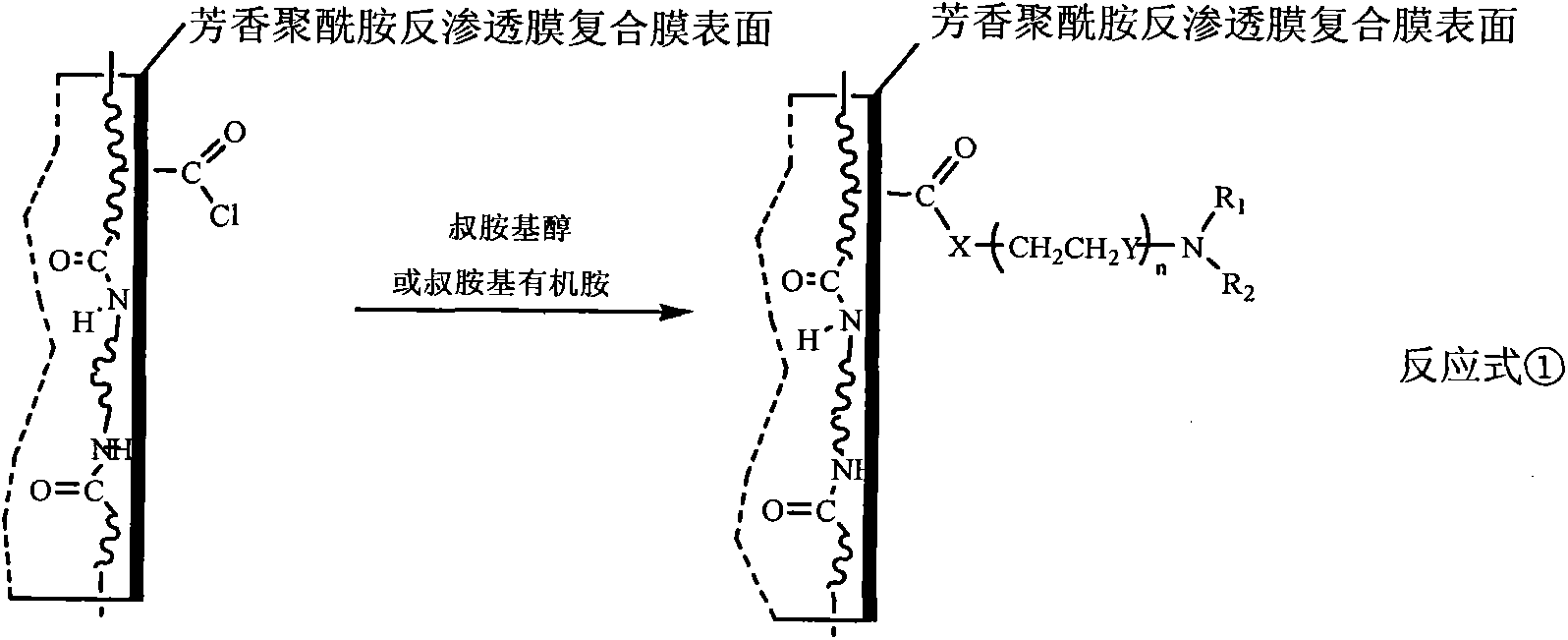

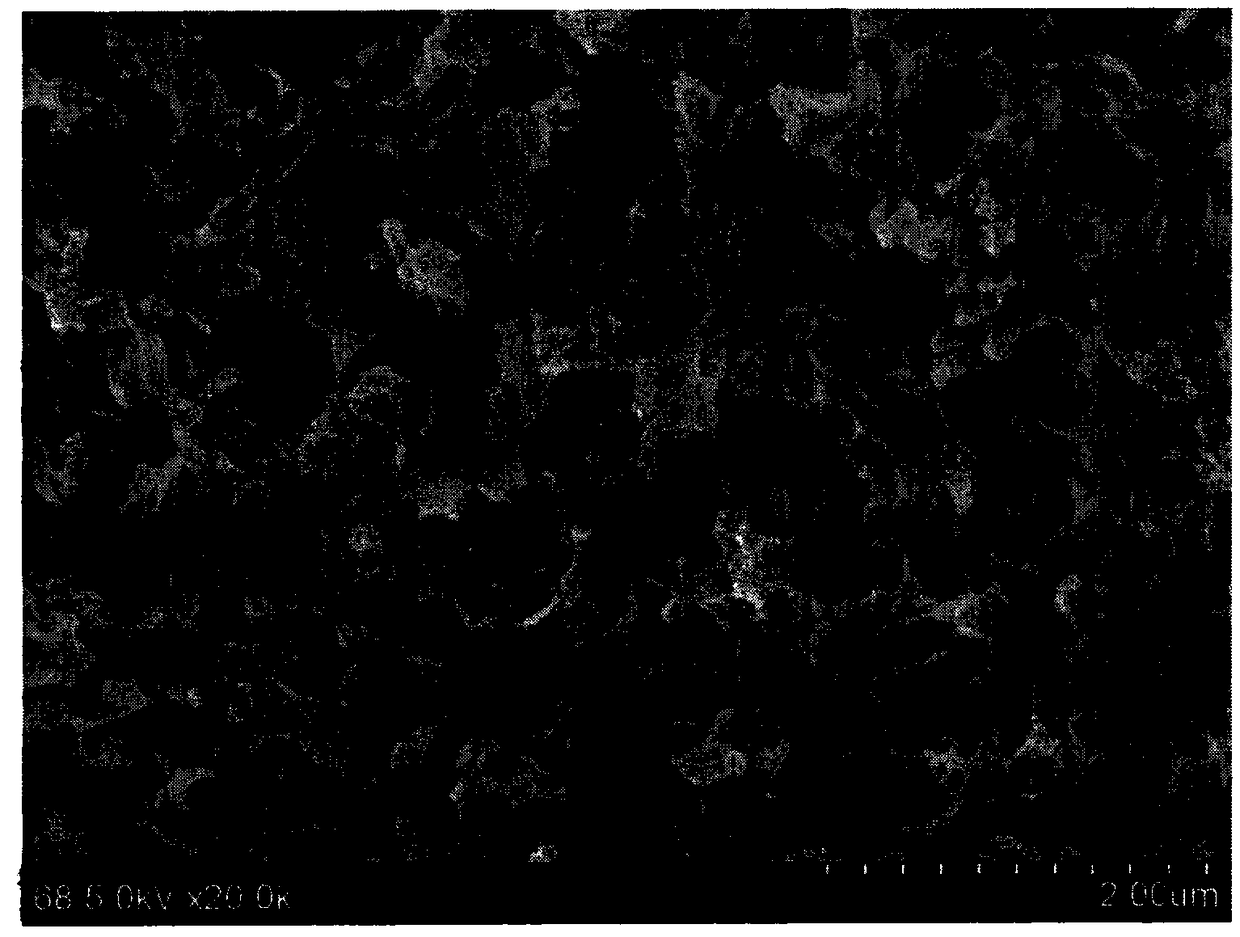

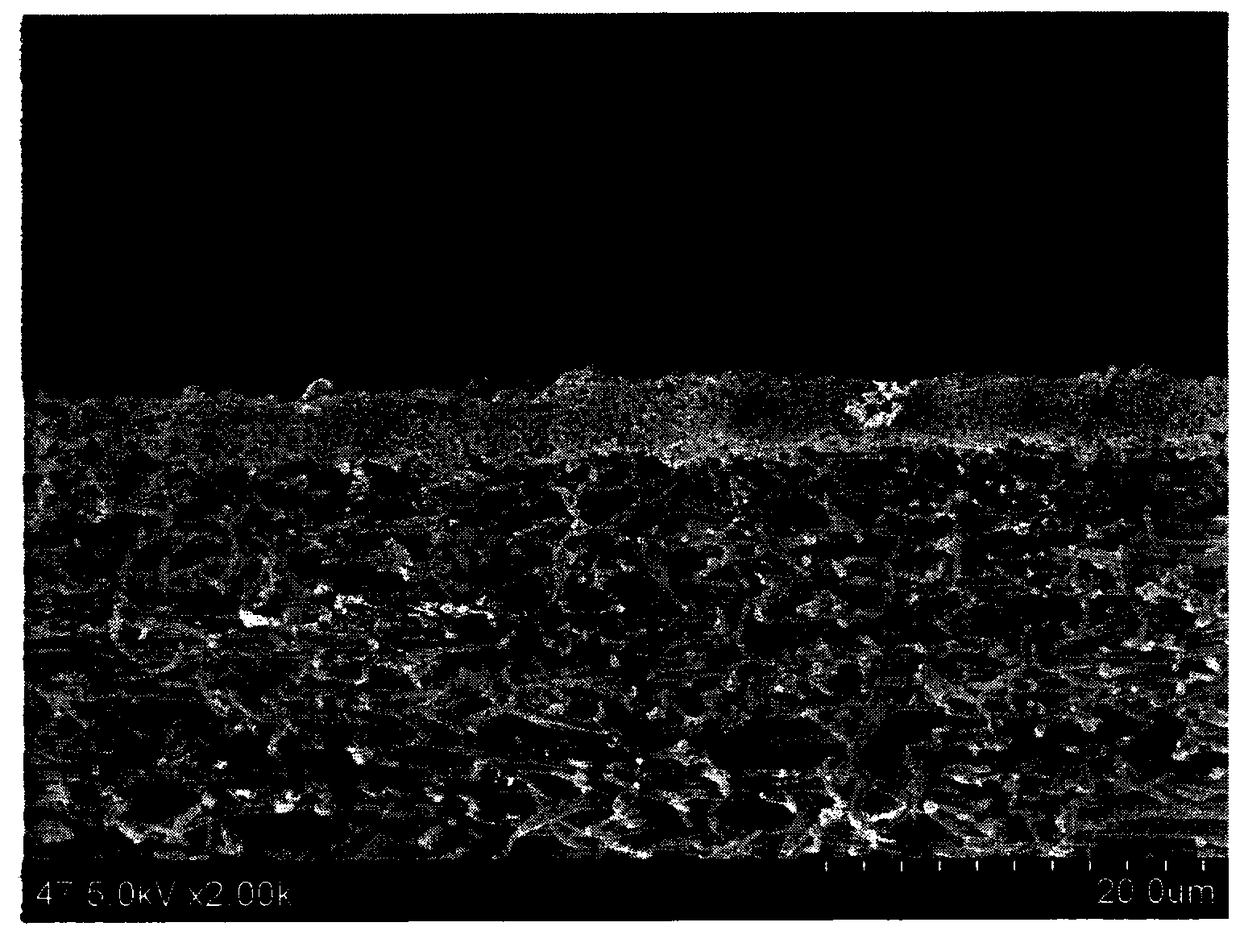

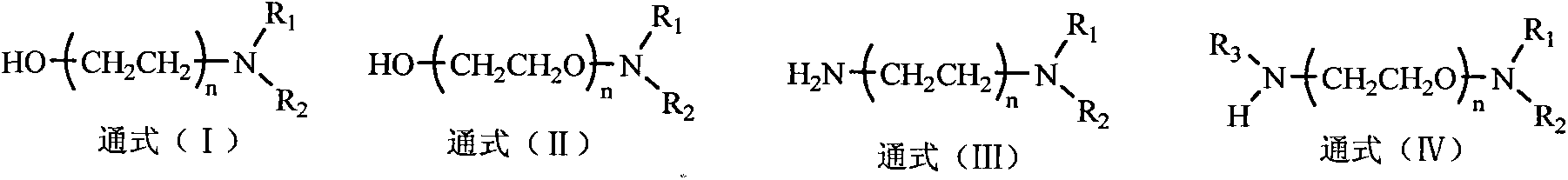

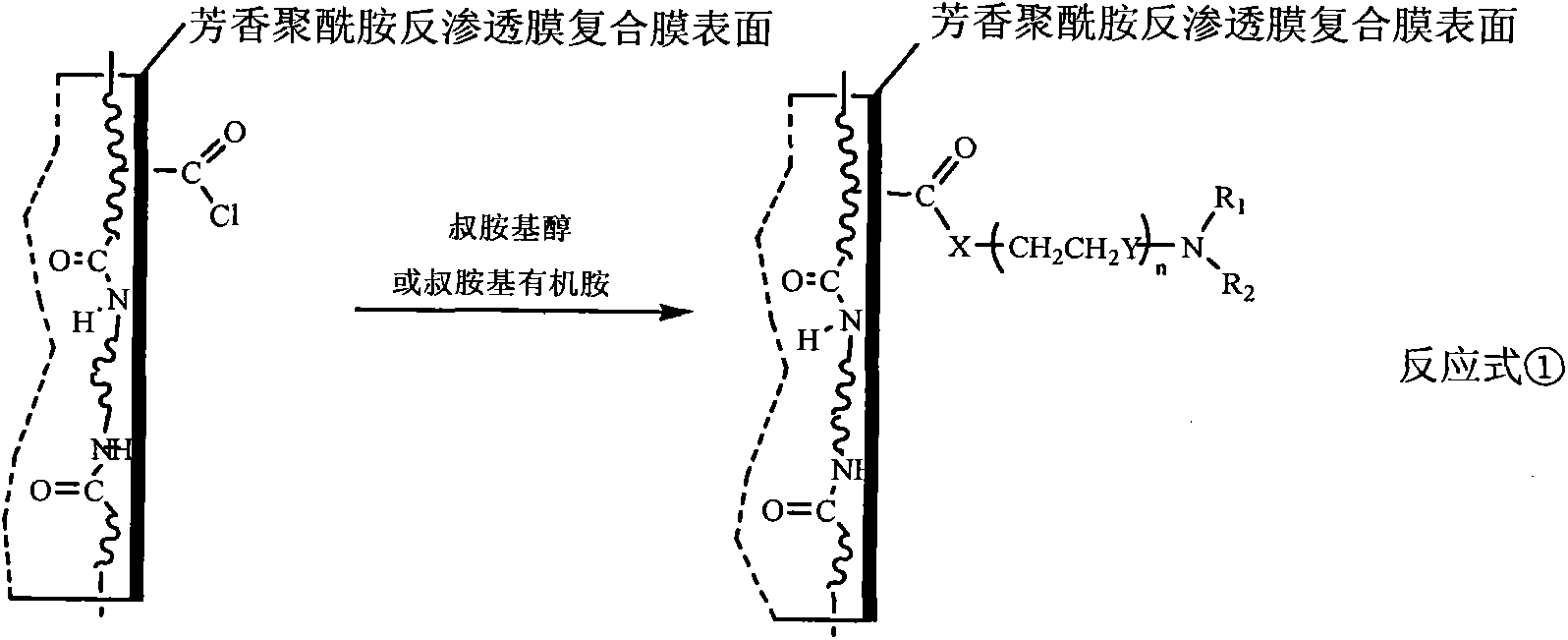

Method of surface functionalization of aramatic polyamides reverse osmosis thin film composite membrane

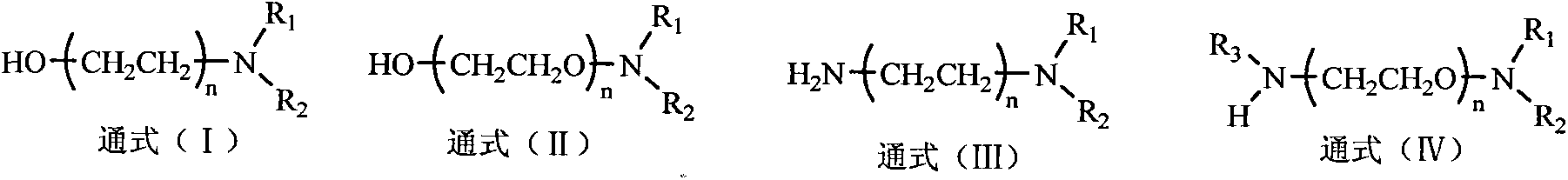

InactiveCN103349922ASimple methodEasy to industrializeSemi-permeable membranesAntibiosisSalicylaldehyde

The invention provides a method of surface functionalization of an aramatic polyamides reverse osmosis thin film composite membrane, which is particularly characterized in that (1) the method that salicylaldehyde and a quaternary ammonium salt functional group are 'cultivated' on the surface of the aramatic polyamides reverse osmosis thin film composite membrane in a dot matrix manner is simple, convenient and easy to operate, and the 'cultivation' density can be subjected to chemical regulation according to the requirement; (2) the uniformity of the surface which is modified by the quaternary ammonium salt and salicylaldehyde functional groups in a dot matrix manner of the aramatic polyamides reverse osmosis thin film composite membrane is high, and the cellular structure and permeability of the aramatic polyamides reverse osmosis thin film composite membrane are not changed; (3) the surface of the aramatic polyamides reverse osmosis thin film composite membrane is simplified by utilizing quaternary ammonium salt and salicylaldehyde functional groups, so that the hydrophilia of the aramatic polyamides reverse osmosis thin film composite membrane can be improved, the performances of antibiosis and sterilization are improved, and the aramatic polyamides reverse osmosis thin film composite membrane is protected from chemistry damage.

Owner:HUAIHAI INST OF TECH

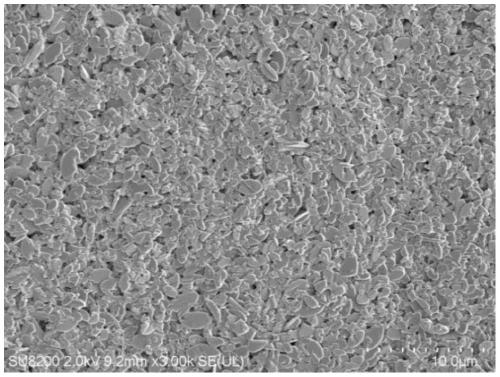

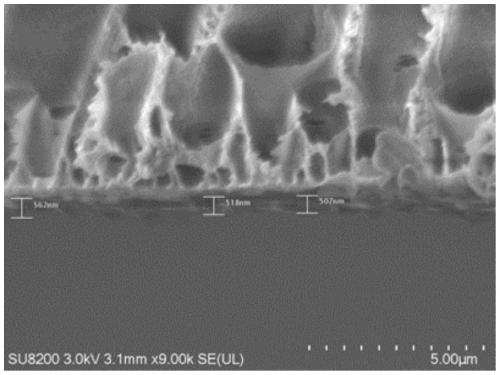

Super-hydrophobic nano-fiber composite membrane for membrane distillation and preparation method thereof

ActiveCN108607365AEasy to realize recyclingSimple manufacturing methodMembranesDistillationPorosityFiber

The invention discloses a super-hydrophobic nano-fiber composite membrane for membrane distillation and a preparation method thereof. The nano-fiber composite membrane has a double-layer structure andcomprises a base layer and a surface layer which are compounded with each other, wherein the base layer is a nano-fiber base film and the surface layer is a porous super-hydrophobic separation layer.The preparation method comprises the following steps: preparing a base layer by adopting a polymer solution electrostatic spinning method, and then carrying out hot pressing treatment; thermally dissolving a polyolefin material in a solvent and stirring them evenly, removing a solvent-rich phase under an external force of a vacuum-assisted suction filtration method, and depositing a polymer-richphase on the surface of the base layer; and then, adding a volatile polyolefin non-solvent to construct a nano-fiber composite membrane with a porous structure skin layer on a microscopic scale. The product membrane prepared by the method provided by the invention is efficient and durable, the preparation method is simple and feasible, the defects of high price, low porosity, low water vapor fluxand easy wetting of membrane pores of a traditional membrane distillation membrane can be obviously improved, and the large-scale modification of the existing membrane distillation membrane can be easily realized.

Owner:DONGHUA UNIV

Method of surface functionalization of aramatic polyamides reverse osmosis thin film composite membrane

The invention provides a method of surface functionalization of an aramatic polyamides reverse osmosis thin film composite membrane, which is particularly characterized in that (1) the method that salicylaldehyde and a quaternary ammonium salt functional group are 'cultivated' on the surface of the aramatic polyamides reverse osmosis thin film composite membrane in a dot matrix manner is simple, convenient and easy to operate, and the 'cultivation' density can be subjected to chemical regulation according to the requirement; (2) the uniformity of the surface which is modified by the quaternary ammonium salt and salicylaldehyde functional groups in a dot matrix manner of the aramatic polyamides reverse osmosis thin film composite membrane is high, and the cellular structure and permeability of the aramatic polyamides reverse osmosis thin film composite membrane are not changed; (3) the surface of the aramatic polyamides reverse osmosis thin film composite membrane is simplified by utilizing quaternary ammonium salt and salicylaldehyde functional groups, so that the hydrophilia of the aramatic polyamides reverse osmosis thin film composite membrane can be improved, the performances of antibiosis and sterilization are improved, and the aramatic polyamides reverse osmosis thin film composite membrane is protected from chemistry damage.

Owner:HUAIHAI INST OF TECH

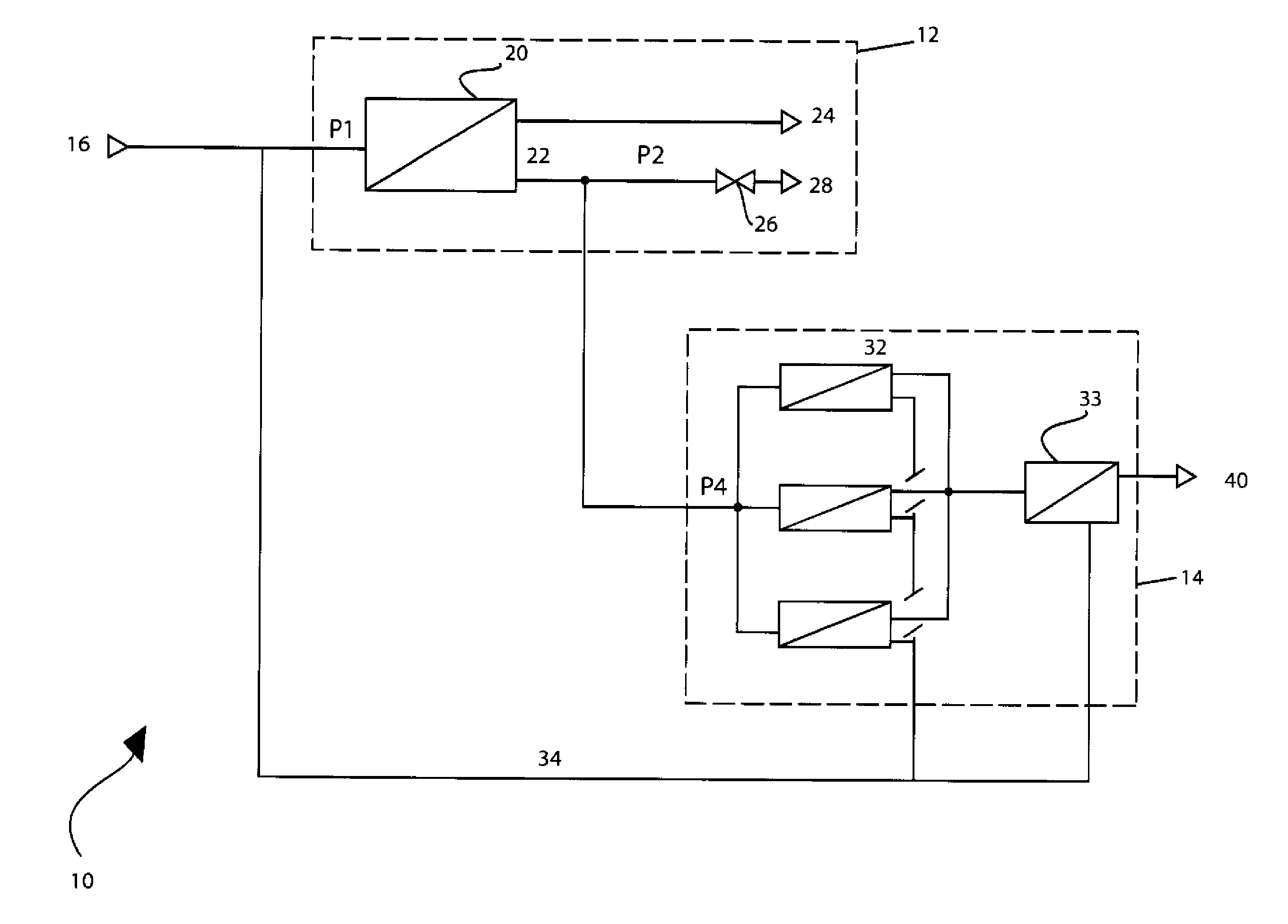

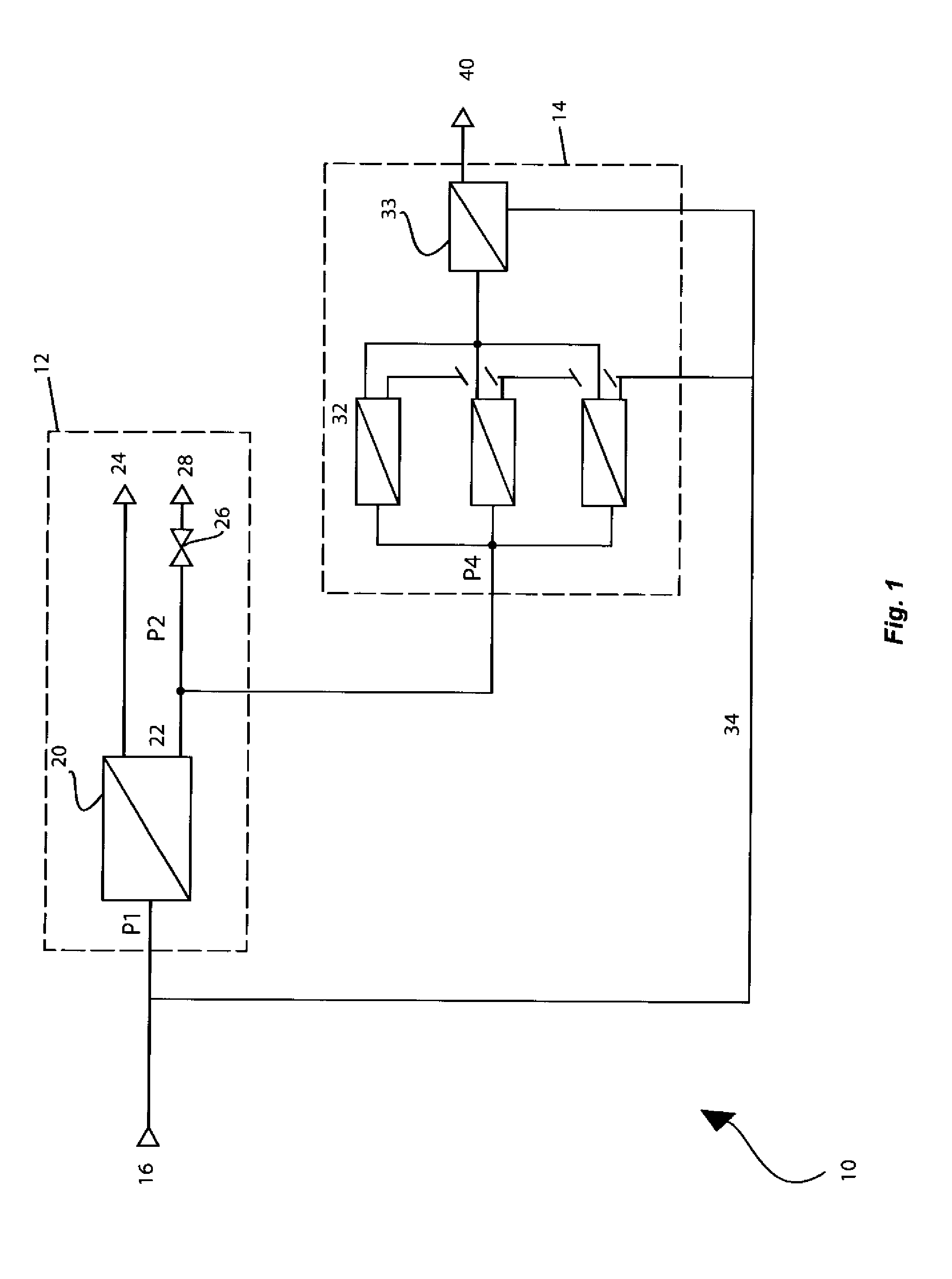

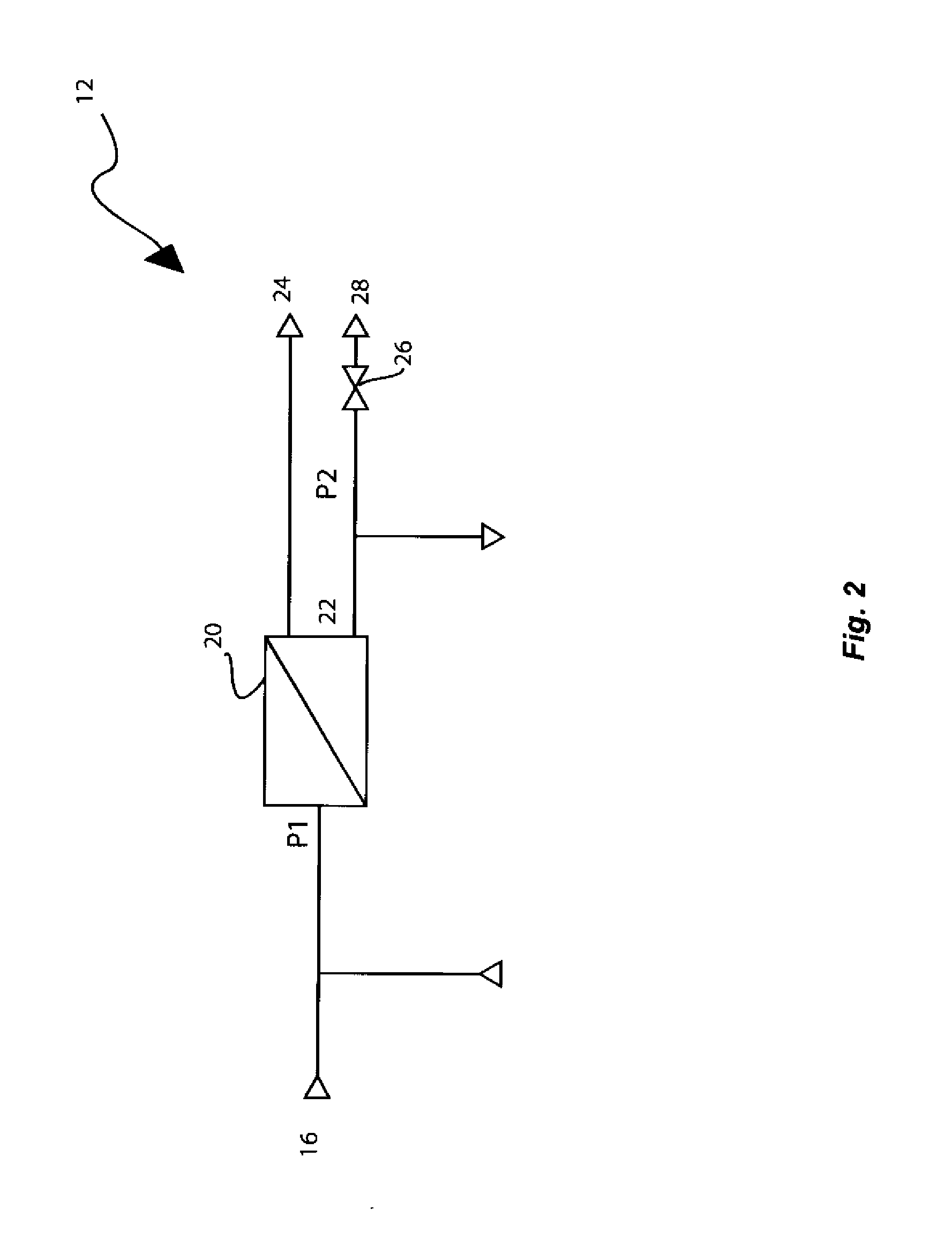

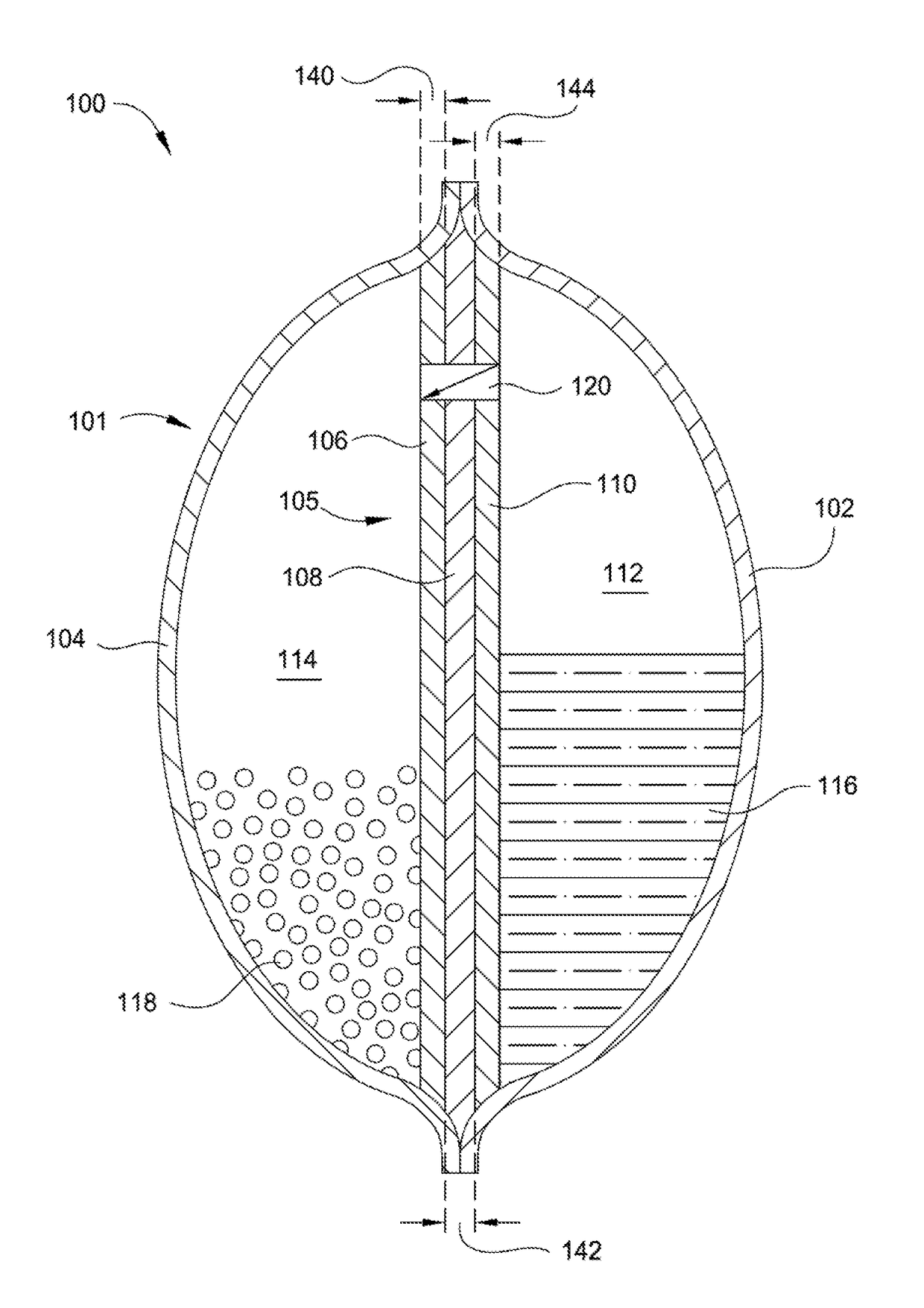

High Efficiency Water Purification System

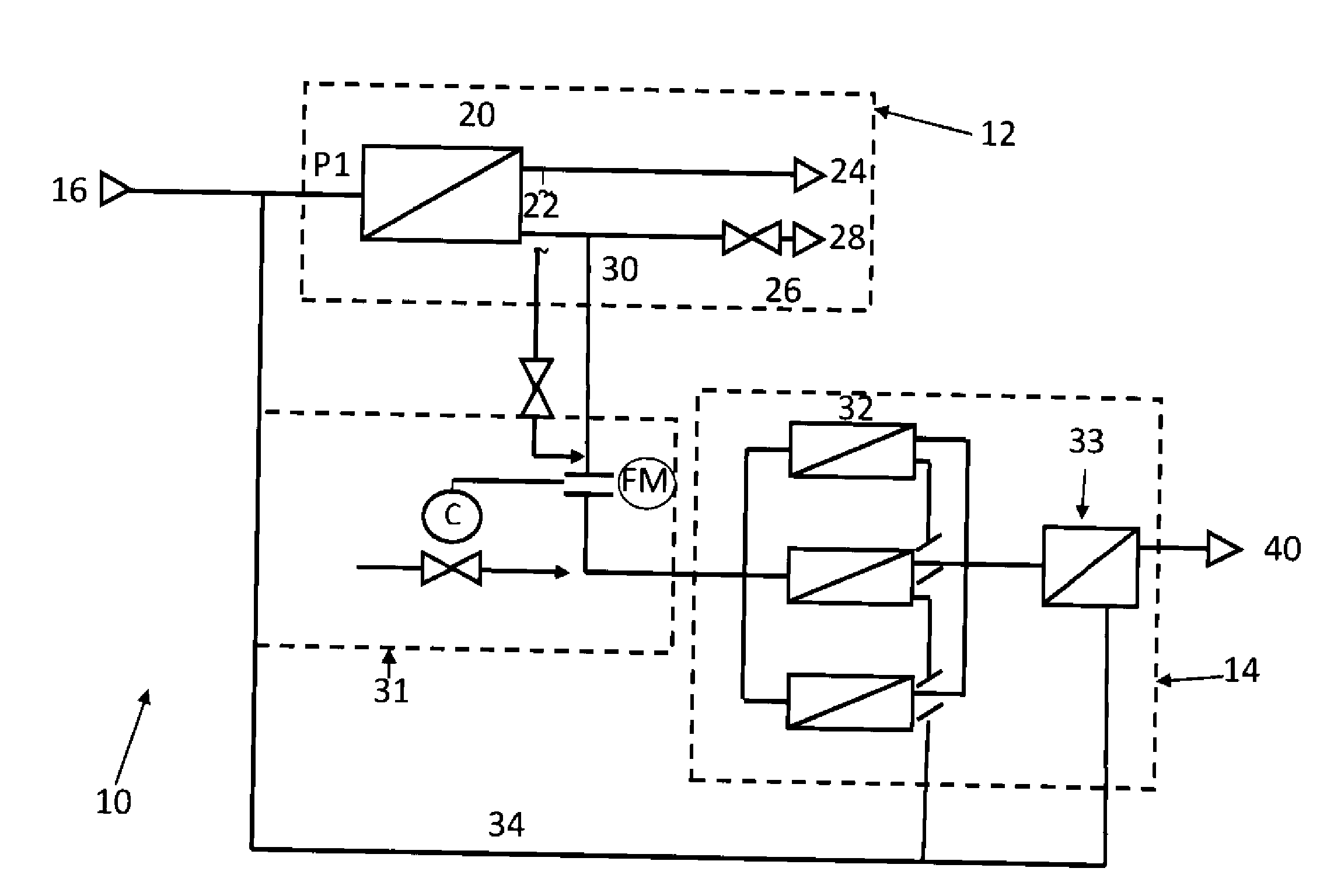

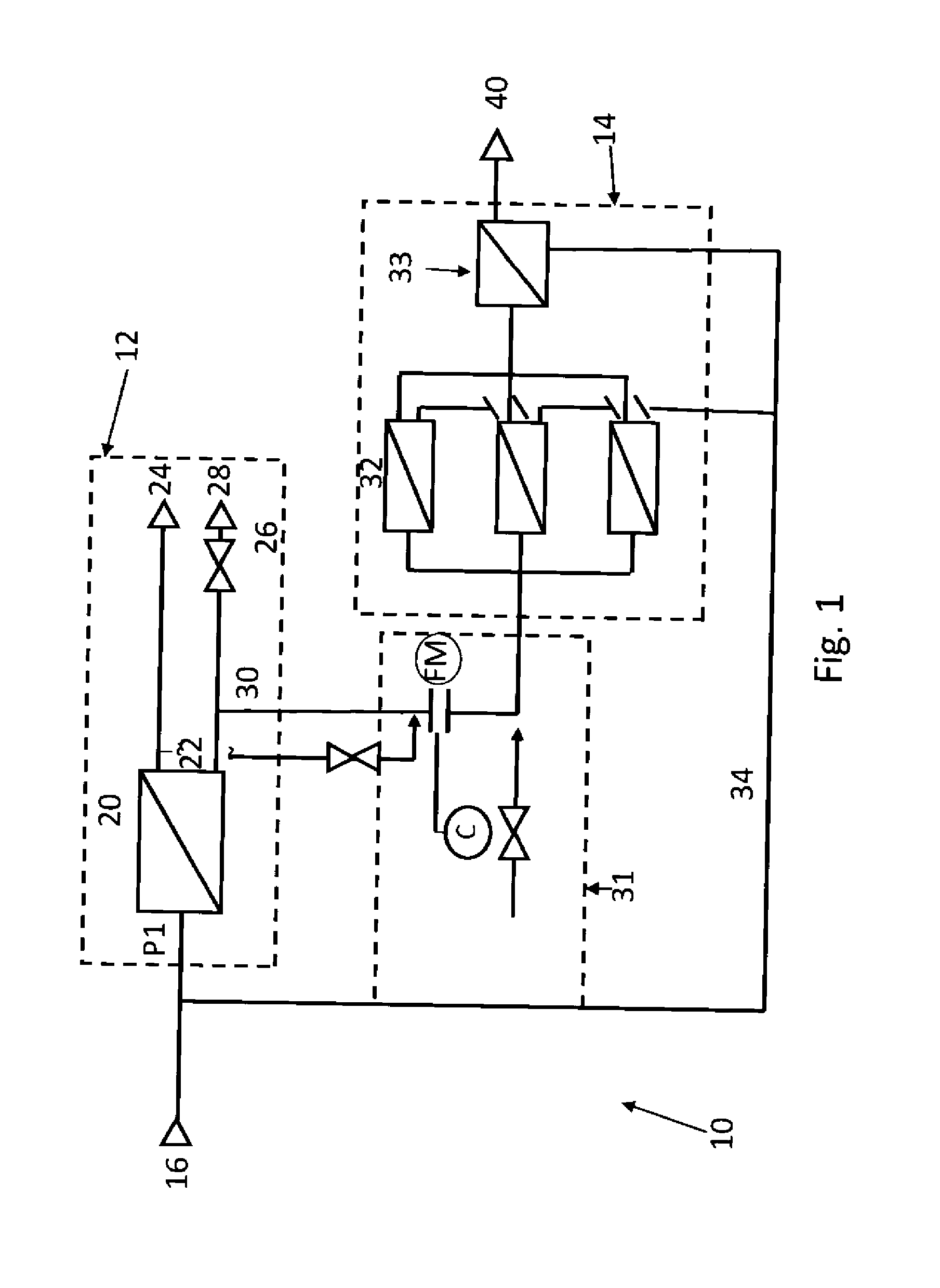

A high efficiency water purification system is provided incorporating a process to recover a portion of the concentrate wastewater associated with the reverse osmosis unit to reduce the overall volume of concentrate wastewater requiring discharge / disposal by reusing the purified concentrate of a concentrate recovery units as RO feed water. The initial municipal feedwater is pressurized and passed through an RO membrane, and separated into a permeate flow and a concentrate flow. After passing through the membrane, a portion of the higher pressure concentrate is then directed to an additional set of thin film composite membranes (concentrate recovery membranes). The concentrate is drawn from the primary RO unit upstream of a concentrate flow control valve where the pressure is typically 100-600 psig. The concentrate recovery membranes are arranged in an array such that the concentrate pressure is adequate to provide the force required to drive the concentrate through the recovery system membranes. The permeate produced by the concentrate recovery system is directed back to the feed of the primary RO unit; thereby, reducing the volume of raw feed water required for system operation. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:WATER INTPROP

Methods of enhancing water flux of a tfc membrane using oxidizing and reducing agents

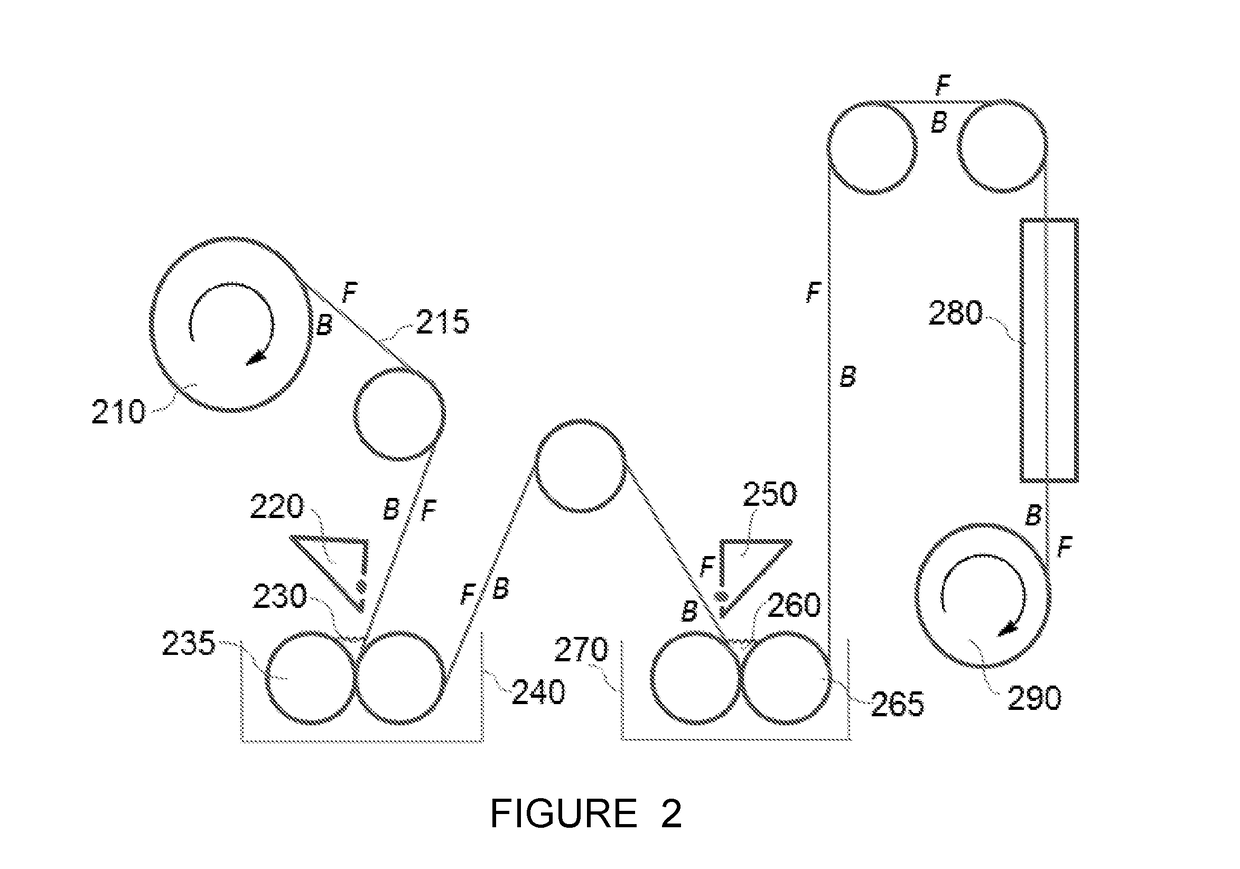

ActiveUS20170252705A1Improve water fluxMembranesGeneral water supply conservationWater useBrackish water

Provided is a post-formation process for preparation of a highly permeable thin film composite membranes for reverse osmosis, particularly for use with brackish water at low energy conditions. The process includes contacting a polyamide discrimination layer of a TFC membrane with a solution containing an oxidizing agent to form a treated membrane, followed by contacting the treated membrane with a solution containing a reducing agent. The resulting membrane exhibits enhanced water flux while maintaining salt rejection. Also provided are reverse osmosis membranes prepared in accord with the method, and modules containing the highly permeable thin film composite membranes, and methods of purifying water using the membranes or modules.

Owner:LG NANOH2O +1

Process for improved water flux through a tfc membrane

ActiveUS20170197182A1Preserve TFC membrane performance propertyWater flux performanceGeneral water supply conservationSeawater treatmentBrackish waterThin-film composite membrane

Provided is a process for preparation of a highly permeable thin film composite membranes for nanofiltration, reverse osmosis, and forward osmosis, particularly for reverse osmosis of brackish water. The process includes treating a prepared TFC membrane containing a discrimination layer on a frontside, a support layer, and a felt layer on the backside by contacting the backside of TFC membrane with a solution containing a pore protection agent that includes a tertiary amine salt of camphorsulfonic acid prior to or at the same time as contacting the frontside of the membrane with a solution containing a coating agent and drying the membrane. Also provided are reverse osmosis membranes prepared in accord with the method, and modules containing the highly permeable thin film composite membranes.

Owner:LG NANOH2O +1

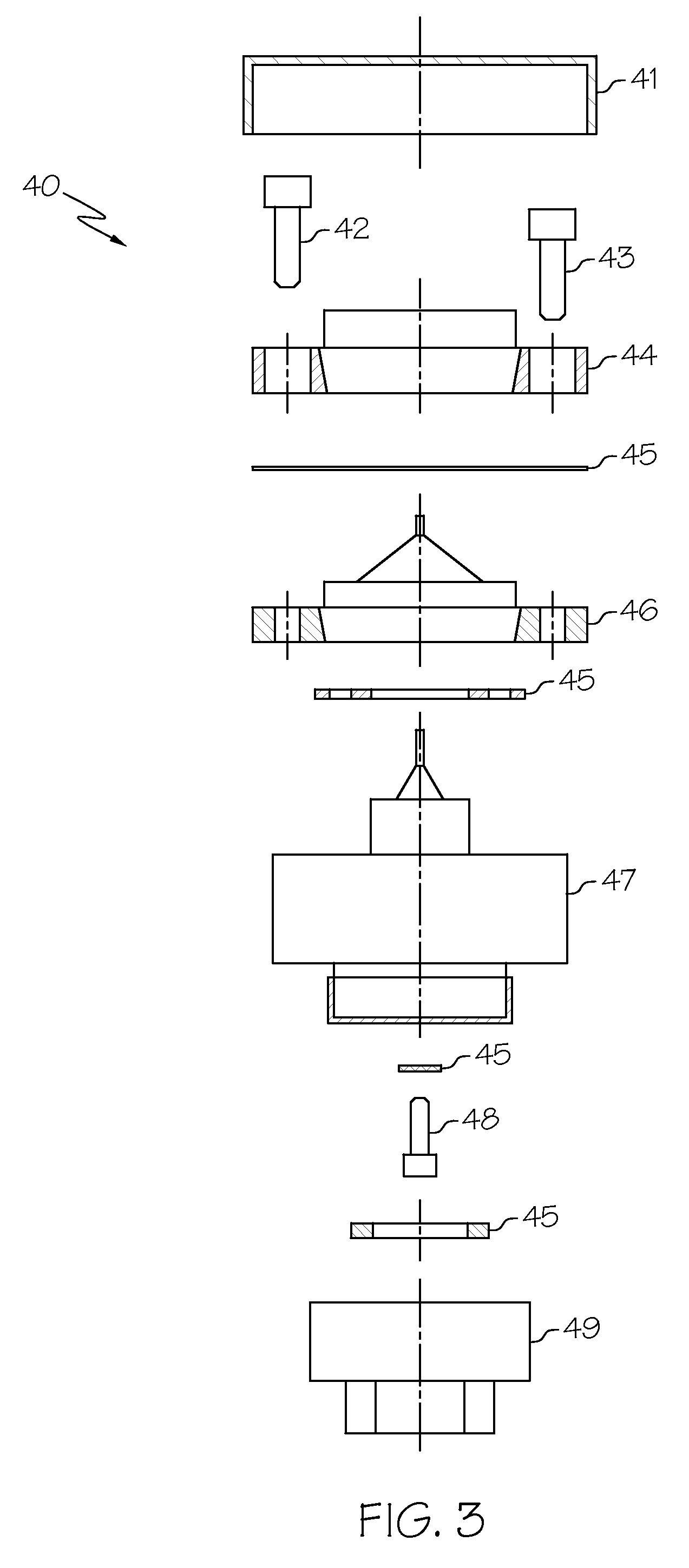

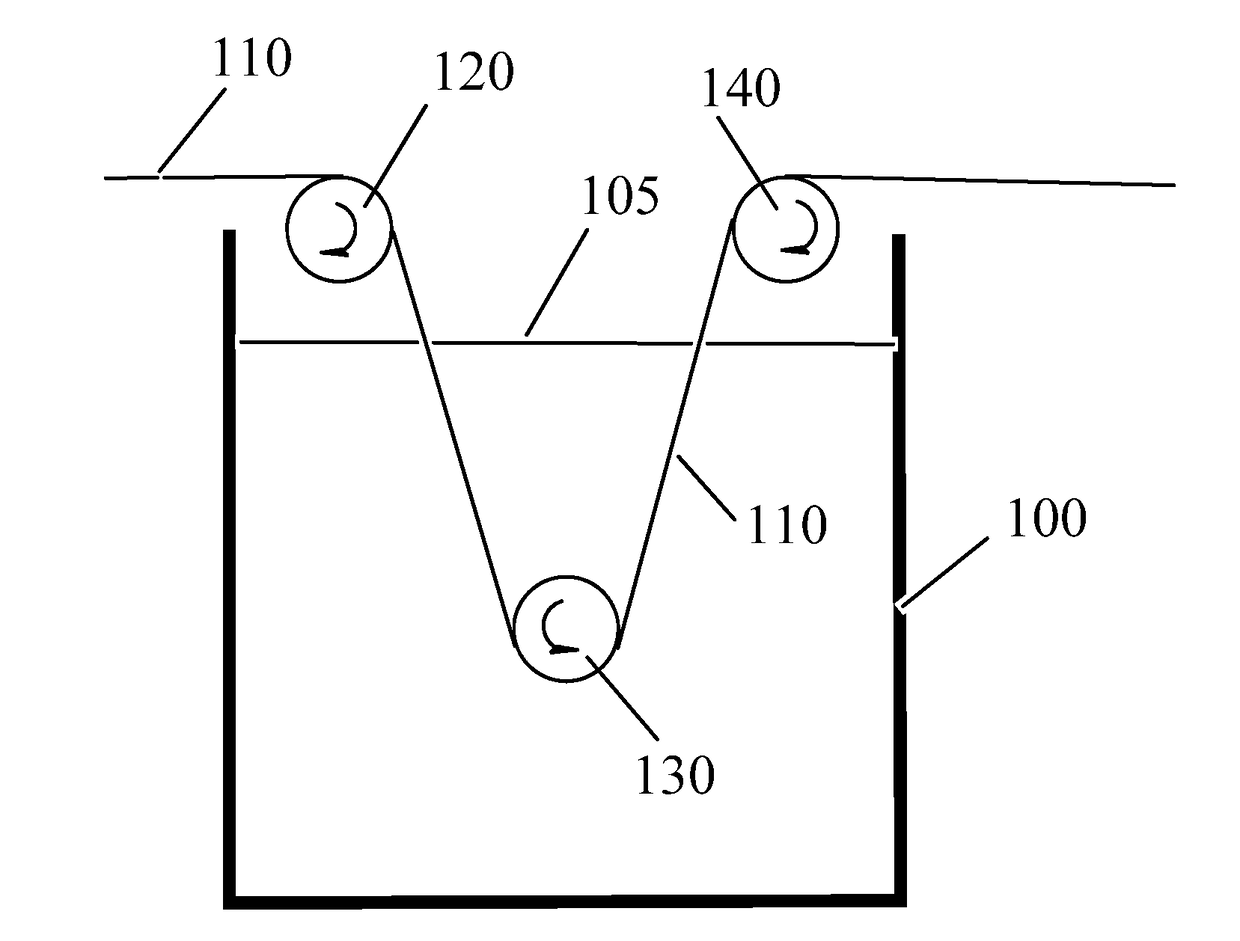

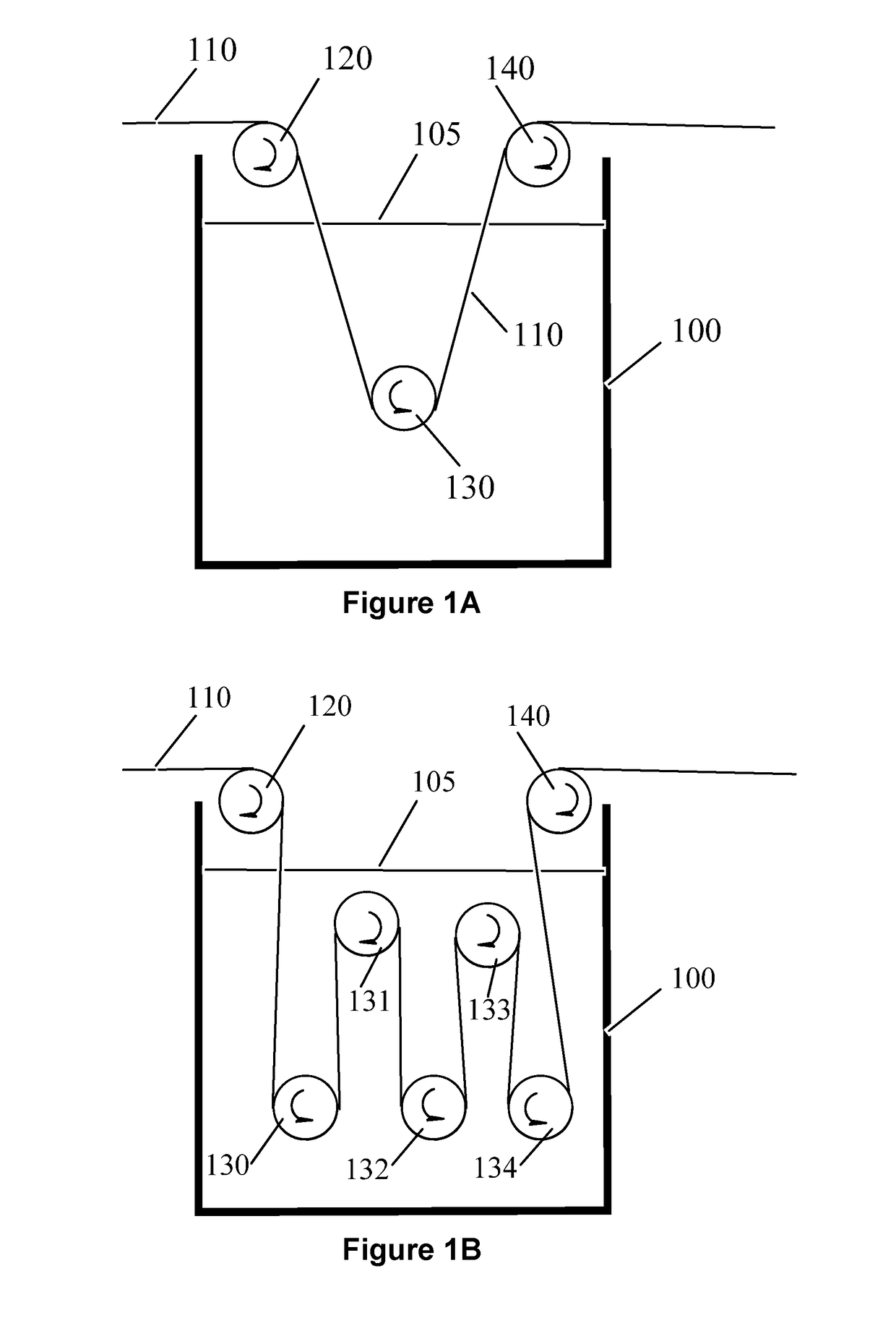

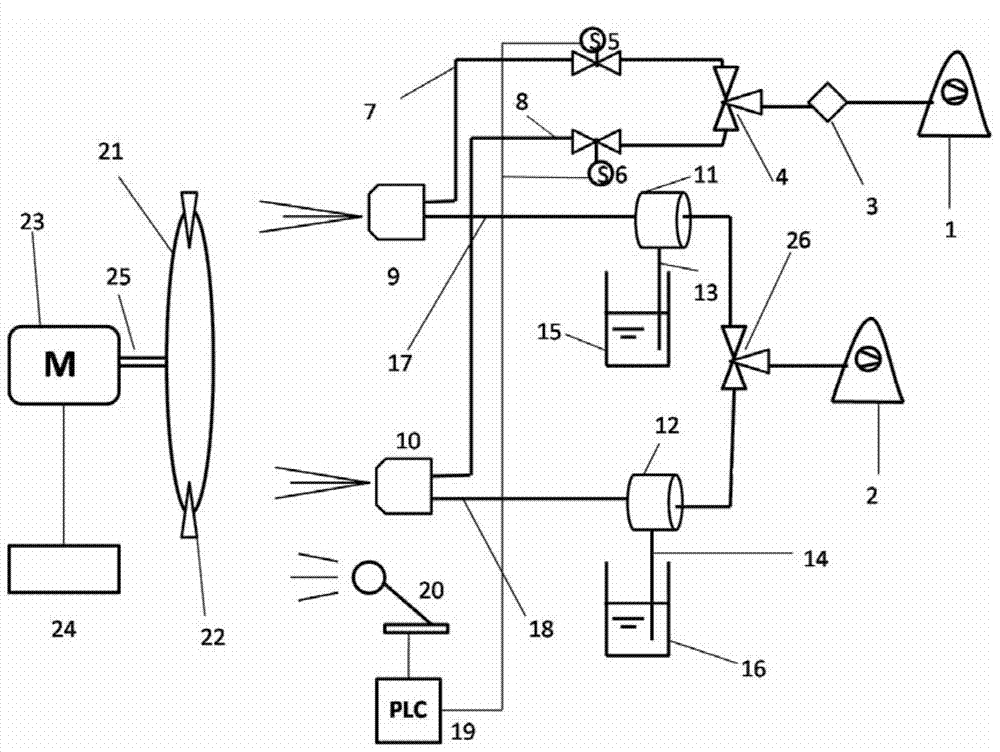

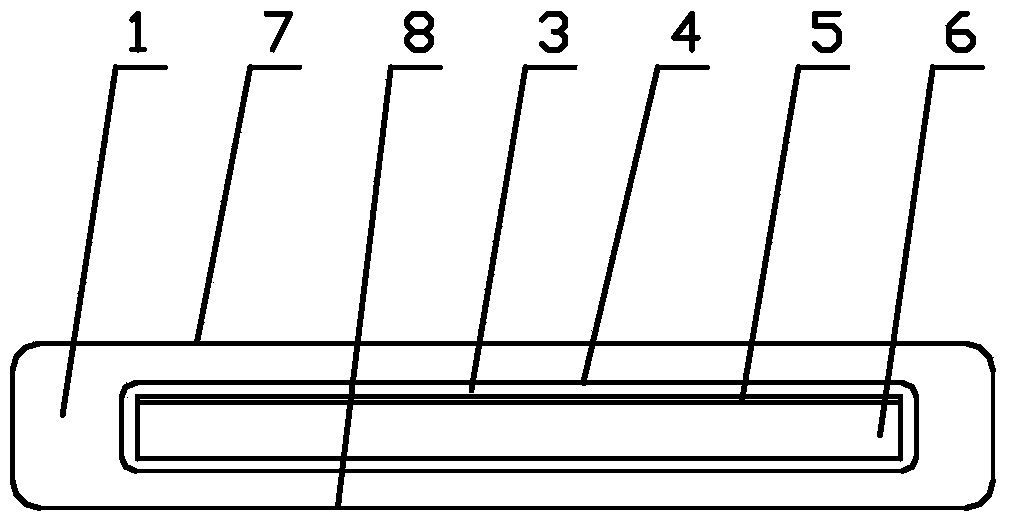

Preparation device and method for environmentally-friendly composite membrane with preferential alcohol permeability performance

ActiveCN103706262AEvenly dispersedThickness can be controlledSemi-permeable membranesCross-linkLow speed

The invention provides a preparation device and a method for an environmentally-friendly composite membrane with preferential alcohol permeability performance, and belongs to the membrane separation technology field. The preparation device comprises an air compressor, a filtration pressure-reducing valve, a triple valve, an atomizing nozzle, a solenoid valve, a loading tray, a baking lamp, a PLC controller, a low speed motor and a diaphragm pump. The solenoid valve control opening and closing of the atomizing nozzle. Polymers with a low viscosity are assembled on a basic membrane surface directly through pressure spraying in a solvent-free state, and furthermore, cross-linking agents and catalysts are sprayed in environmentally-friendly solvents, and therefore a composite separation membrane with a preferential alcohol permeability performance. The technology is simple and the composite membrane is environmentally friendly.

Owner:BEIJING UNIV OF TECH

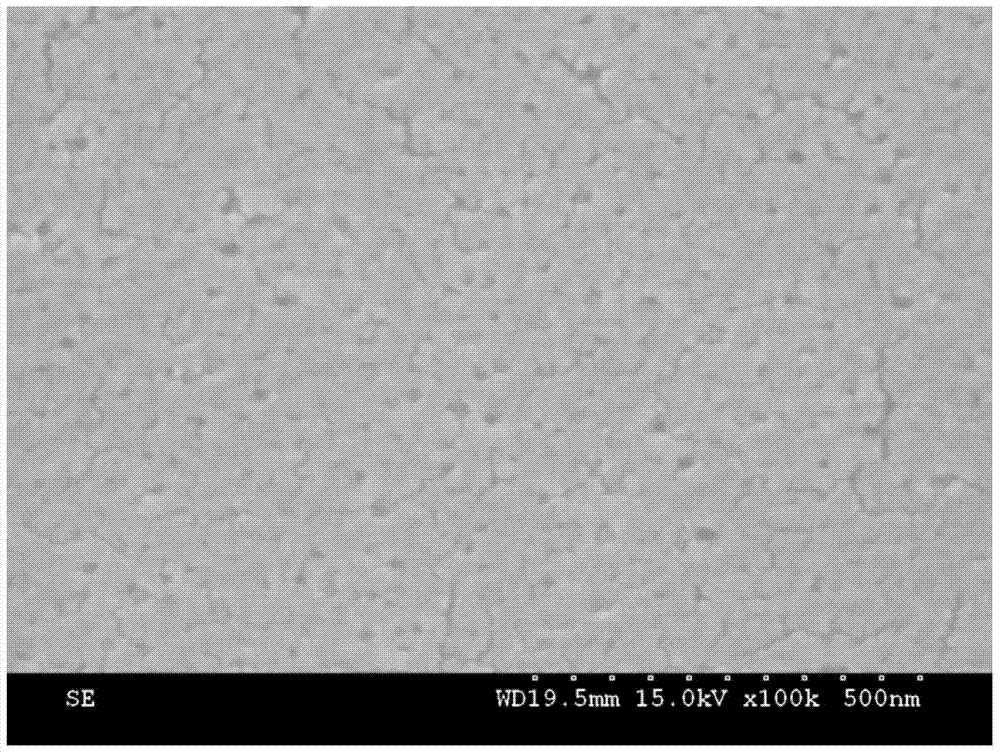

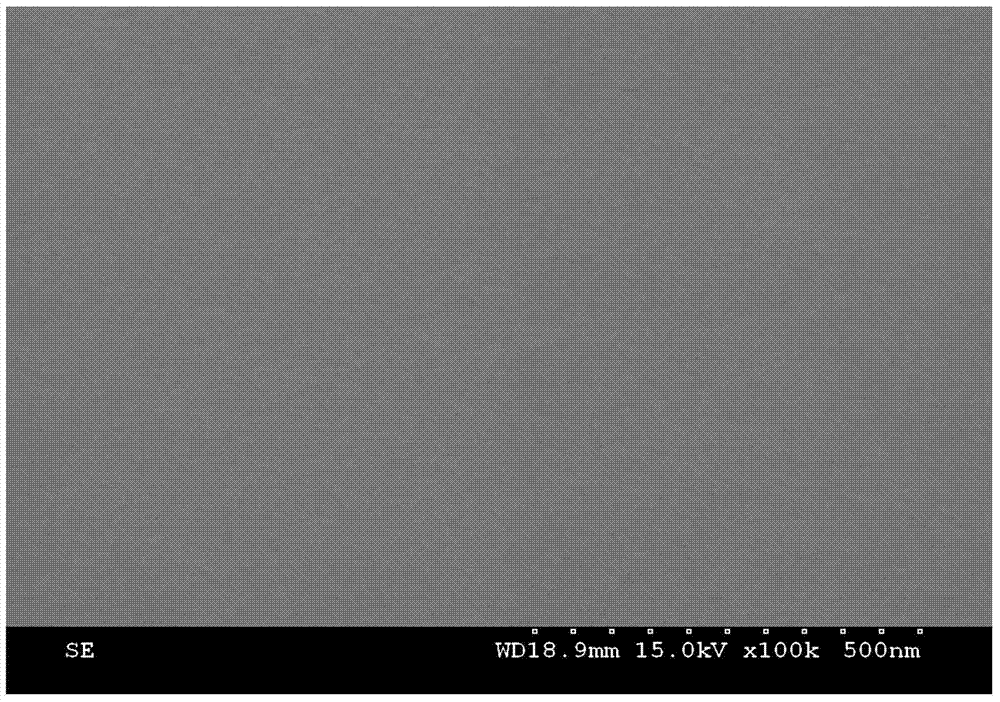

Thin film composite film taking metal organic framework as functional layer, preparation method thereof and preparation method of metal organic framework

ActiveCN111346525AAddress uneven distributionGood repeatabilitySemi-permeable membranesComposite filmPolyamide

The invention provides a preparation method of a thin film composite film taking a metal organic framework as a functional layer, which comprises the following steps: 1) mixing a metal organic framework mixed solution containing a polyamine with an alcohol to obtain a dispersion solution; (2) spraying the dispersion liquid obtained in the step (1) on a base film by utilizing a spraying technology,so that a uniform metal organic framework layer is formed on the surface of the base film; and 3) spraying a polybasic acyl chloride solution on the surface of the metal organic framework layer prepared in the step 2) by using a spraying technology, and generating a polyamide layer by using an interfacial polymerization reaction to fix the metal organic framework, thereby obtaining the thin filmcomposite film. According to the invention, the spraying technology is applied to the construction of the metal organic framework film composite film; the problems that large-scale preparation of themetal organic framework film composite film is difficult and repeatability is poor are solved, the metal organic framework film composite film with a thin functional layer and excellent dye interception performance can be prepared, and the prepared MOF film composite film has a very high industrial application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

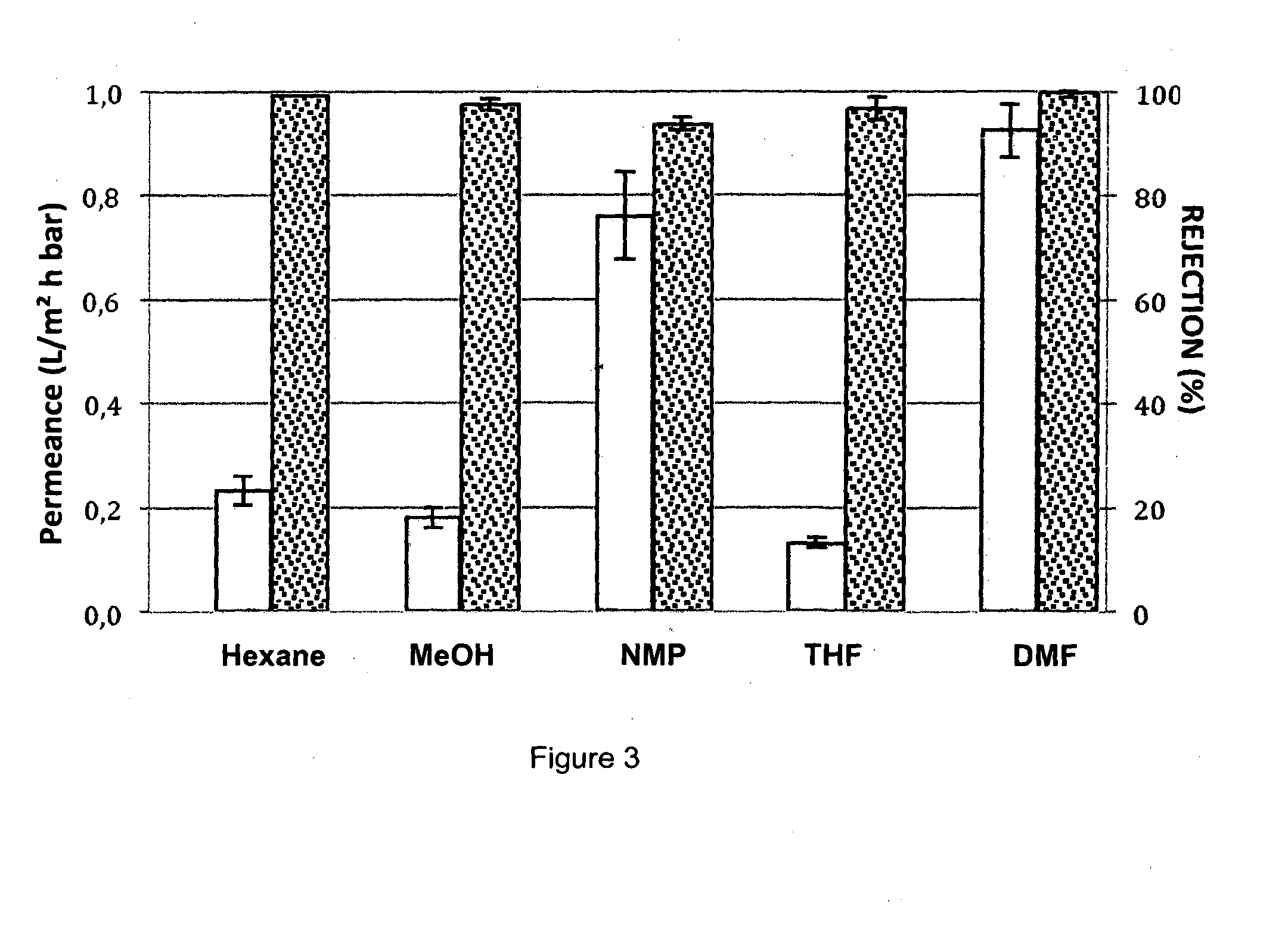

Solvent resistant thin film composite membrane and its preparation

InactiveUS20170065937A1Improve efficiencyImprove stabilityMembranesReverse osmosisUltrafiltrationSolvent

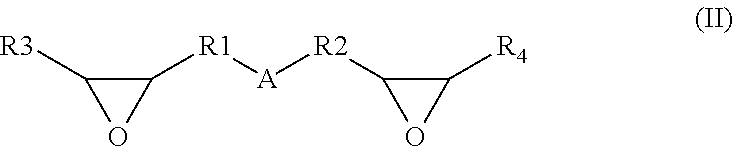

The present invention relates to improved methods for synthesis of thin film composite membranes by interfacial polymerization. More in particular, the method of the present invention comprises the impregnation of an ultrafiltration porous support membrane with an aqueous solution containing a polyfunctional nucleophilic monomer, and contacting the impregnated support membrane with a second largely water-immiscible solvent containing a polyfunctional epoxide monomer.

Owner:KATHOLIEKE UNIV LEUVEN

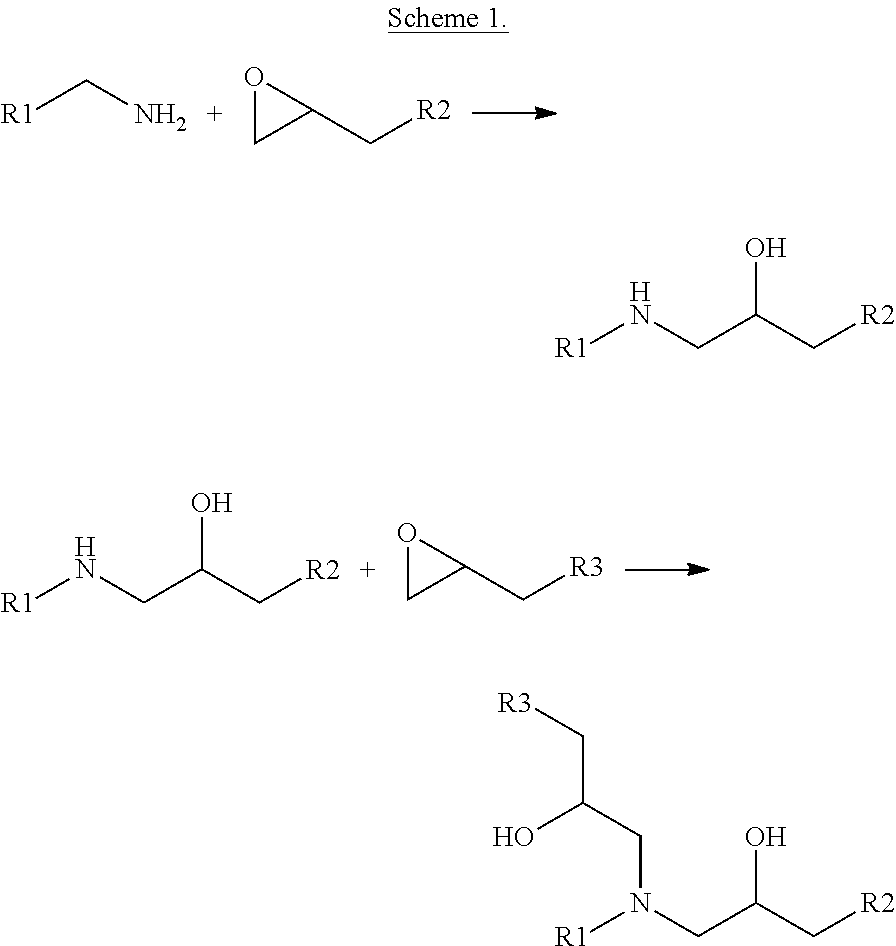

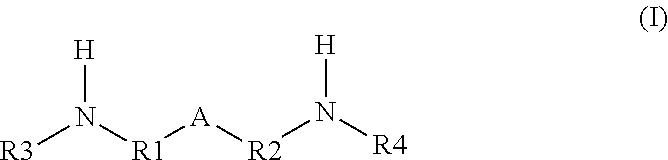

Combination of chemical additives for enhancement of water flux of a membrane

ActiveUS20160355416A1Low costReduces initial capital costMembranesGeneral water supply conservationMetal chelatePolyamine

Provided is an interfacial polymerization process for preparation of a highly permeable thin film composite membrane, which can be used for nanofiltration, or forward or reverse osmosis, for use with tap water, seawater and brackish water, particularly for use with brackish water at low energy conditions. The process includes contacting a porous support membrane with an aqueous phase containing a polyamine and a flux enhancing combination, which includes a metal chelate additive containing a bidentate ligand and a metal atom or metal ion and a dialkyl sulfoxide, to form a coated support membrane, and applying an organic phase containing a polyfunctional acid halide to the coated support membrane to interfacially polymerize the polyamine and the polyfunctional acid halide to form a discrimination layer of the thin film composite membrane. Also provided are the membranes prepared by the methods and reverse osmosis modules containing the membranes.

Owner:LG NANOH2O

Thin film composite membranes and their method of preparation and use

InactiveUS8617395B2Adhesive processesSolid sorbent liquid separationMass transfer resistanceThin-film composite membrane

The present invention is a technique to fabricate thin-film composite perm-selective membranes by a transfer method. The composite membranes are useful in separating liquid, vapor or gaseous mixtures by selective permeation and reduce mass transfer resistance of the support layer. Selectivity and flux are improved by reduction of the mass transfer resistance of the support layer.

Owner:US SEC AGRI

Thin film composite membranes incorporating carbon nanotubes

ActiveUS8591741B2Material nanotechnologyWater treatment compoundsCarbon nanotubeThin-film composite membrane

Processes for manufacturing a thin film composite membrane comprising multi-walled carbon nanotubes include contacting under interfacial polymerization conditions an organic solution comprising a polyacid halide with an aqueous solution comprising a polyamine to form a thin film composite membrane on a surface of a porous base membrane; at least one of the organic solution and the aqueous solution further including multi-walled carbon nanotubes having an outside diameter of less than about 30 nm.

Owner:BL TECH INC

Reusable cold pack

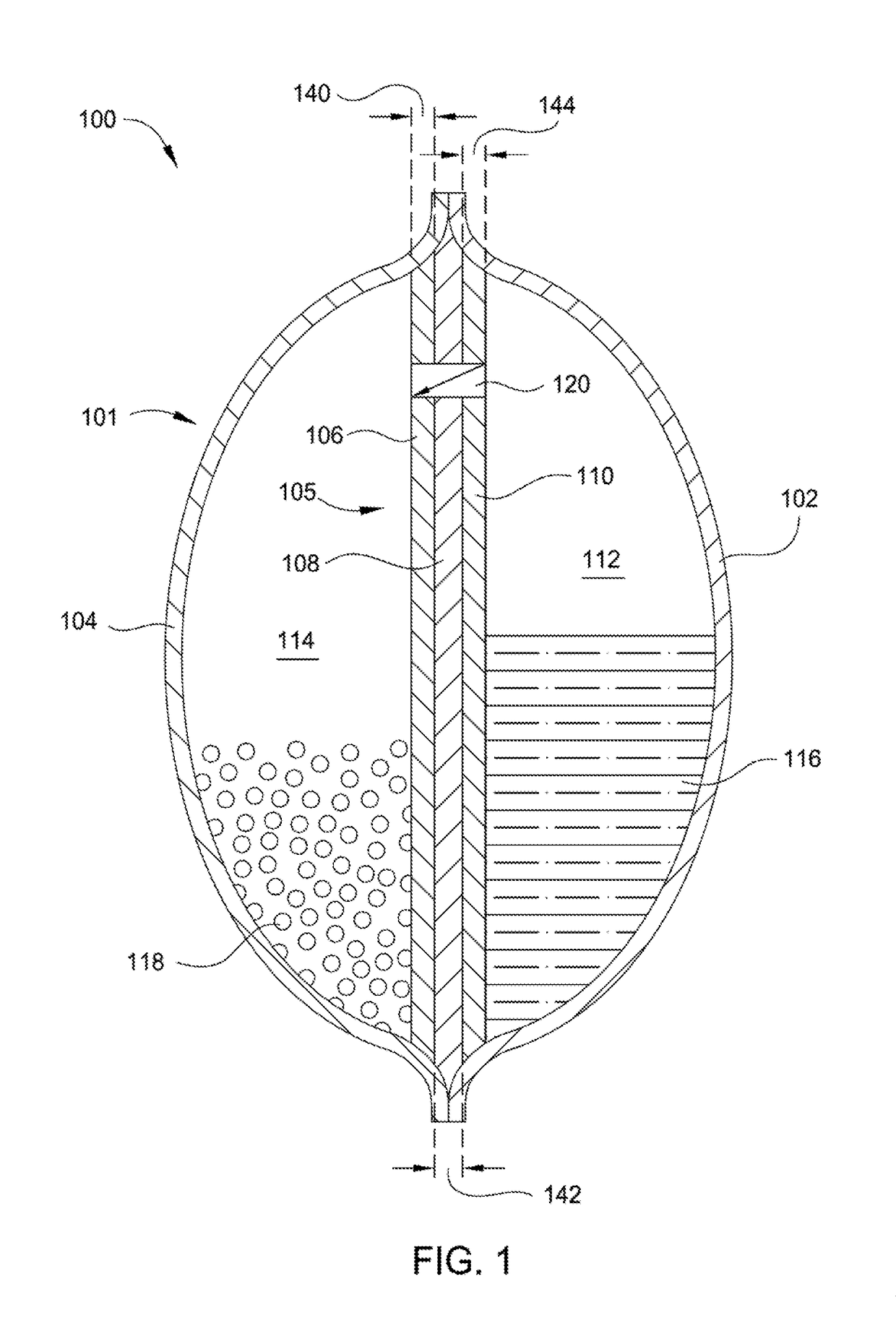

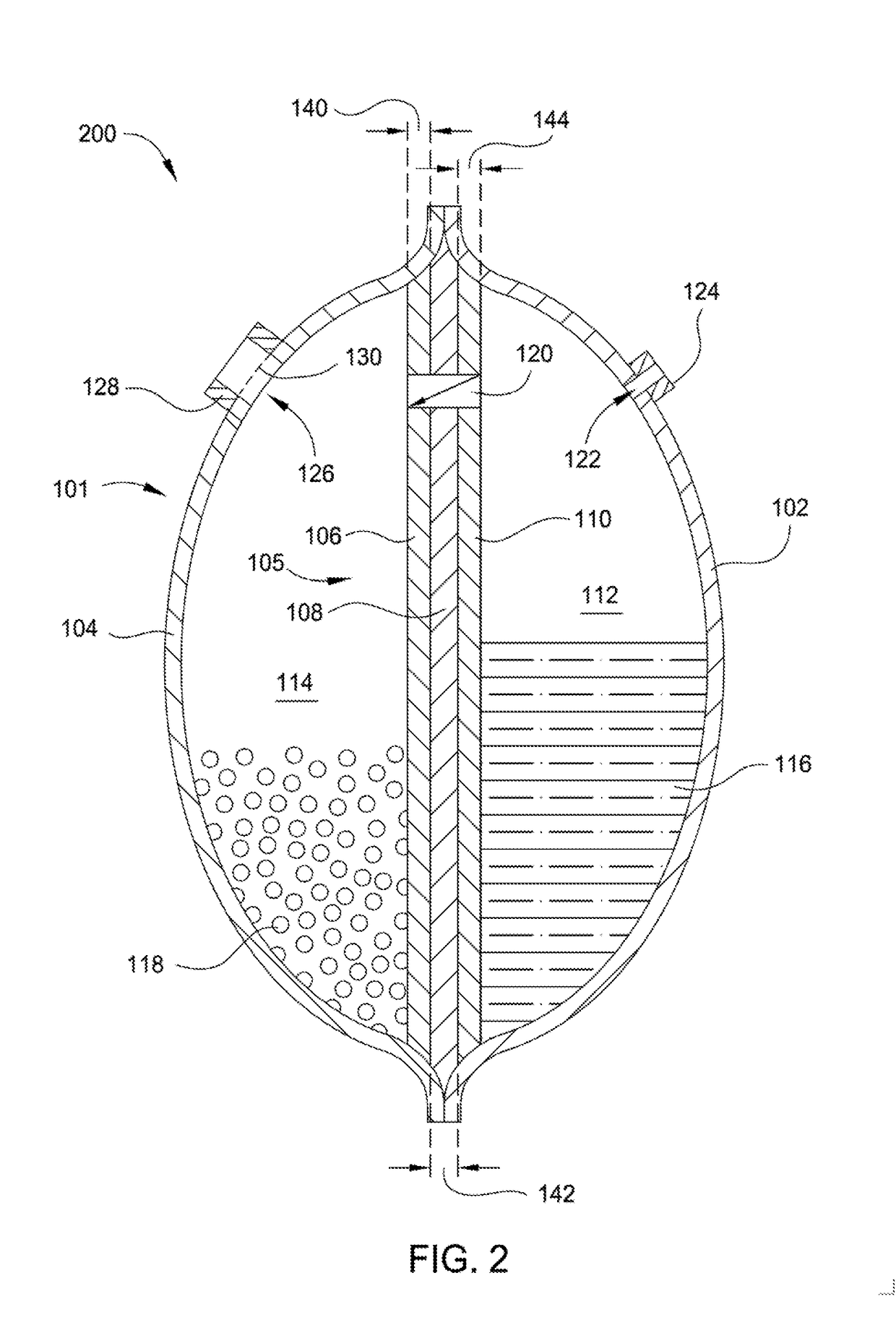

Embodiments described herein relate to a reusable chemical cold pack. The apparatus includes a body which defines a chamber having two volumes separated by a thin film composite membrane. The thin film composite membrane includes a fabric material sheet, a thermoplastic polymer material sheet, and a polyamide material sheet. A first volume disposed on one side of the thin film composite membrane contains a solvent and a second volume disposed on an opposite side of the thin film composite membrane contains a solute. A check valve is disposed through the thin film composite membrane and enables mixing of the solvent and the solute. The solvent and the solute may also be separated after mixing by diffusion of the solvent through the thin film composite membrane.

Owner:IBM CORP

Composite polyamide membrane including dissolvable polymer coating

ActiveUS20150367288A1Broaden applicationMaintain performanceSemi-permeable membranesMembranesPolyamidePolymer coatings

A thin film composite membrane including a thin film polyamide layer positioned between a porous support and an outer coating, and a humectant; wherein the membrane has an A-value of at least 8 l / m2 hr / bar when tested at 25 l / m2 hr with pure water at 25° C. for one hour, and wherein the outer coating comprises a dissolvable cellulose polymer provided at coverage of at least 10 mg / m2 that substantially dissolves from the membrane after one hour of continuous cross-flow of water at 25 l / m2 hr and 25° C.

Owner:DOW GLOBAL TECH LLC

Improved method for synthesis of polyamide composite membranes

The present invention provides a method for the preparation of thin film composite (TFC) membranes, preferably solvent resistant TFC membranes, by interracial polymerization (IFP), more in particular solvent resistant TFC membranes wherein a thin PA-layer is deposited on a porous support membrane. Said method comprises the replacement of the aqueous and / or the organic solvent in the IFP method by an ionic liquid (IL) as solvent for the monomers which form said TFC membranes, to alter the top layer morphology, thickness and crosslinking degree.

Owner:KATHOLIEKE UNIV LEUVEN

High Efficiency Water Purification System

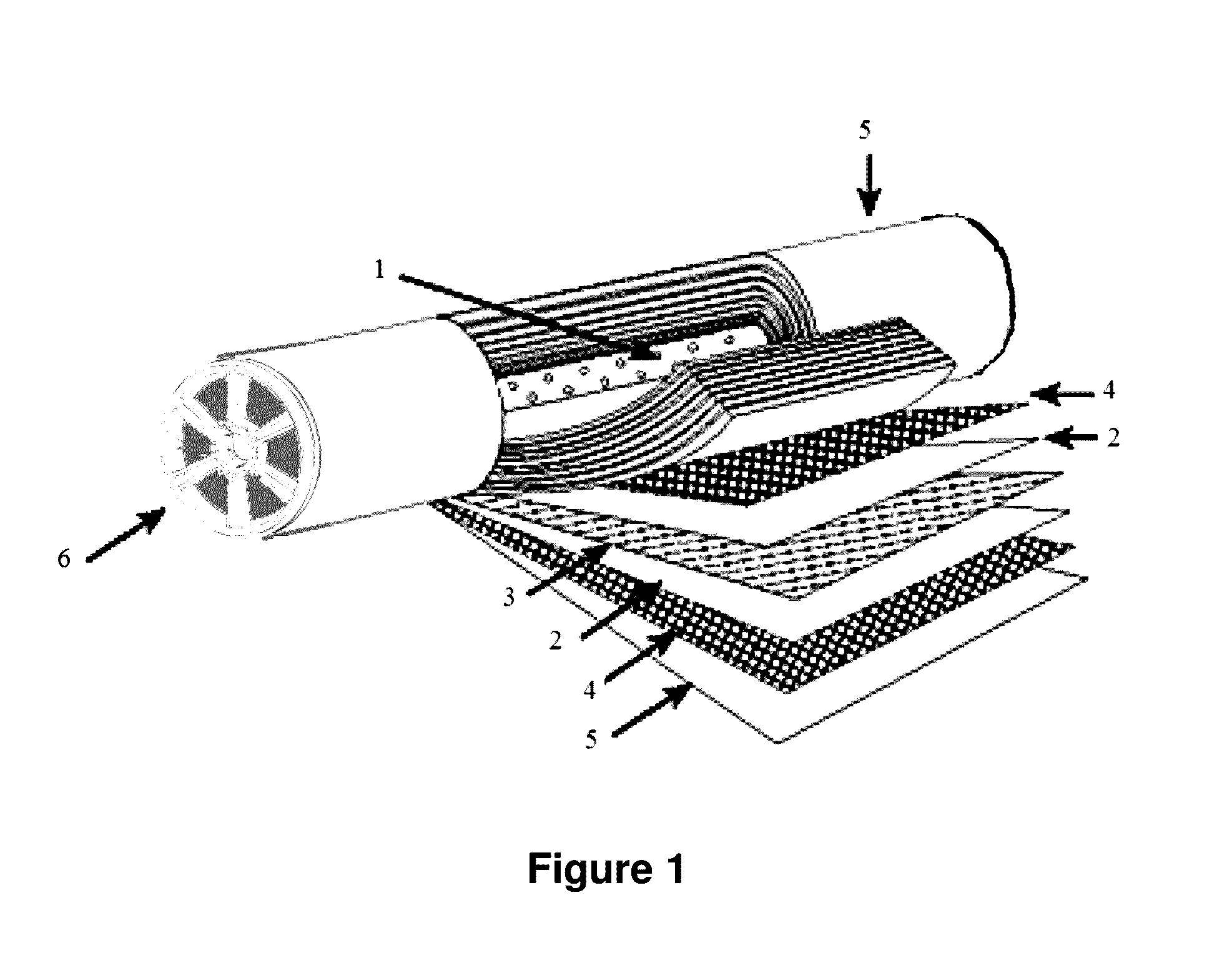

InactiveUS20120145636A1MembranesWater treatment parameter controlHigh pressureThin-film composite membrane

A high efficiency water purification system is provided incorporating recovery of a portion concentrate wastewater associated with the reverse osmosis unit. This reduces the overall volume of concentrate wastewater requiring discharge / disposal by reusing the purified concentrate of a concentrate recovery units as RO feed water. Initial feedwater is pressurized and passed through an RO membrane, and separated into a permeate flow and a concentrate flow. A portion of the higher pressure concentrate is then directed to an additional set of thin film composite membranes (concentrate recovery membranes). The concentrate recovery membranes are arranged in an array such that the concentrate pressure is adequate to provide the force required to drive the concentrate through the recovery system membranes. The permeate produced by the concentrate recovery system is directed back to the feed of the primary RO unit; thereby, reducing the volume of raw feed water required for system operation.

Owner:WATER INTPROP

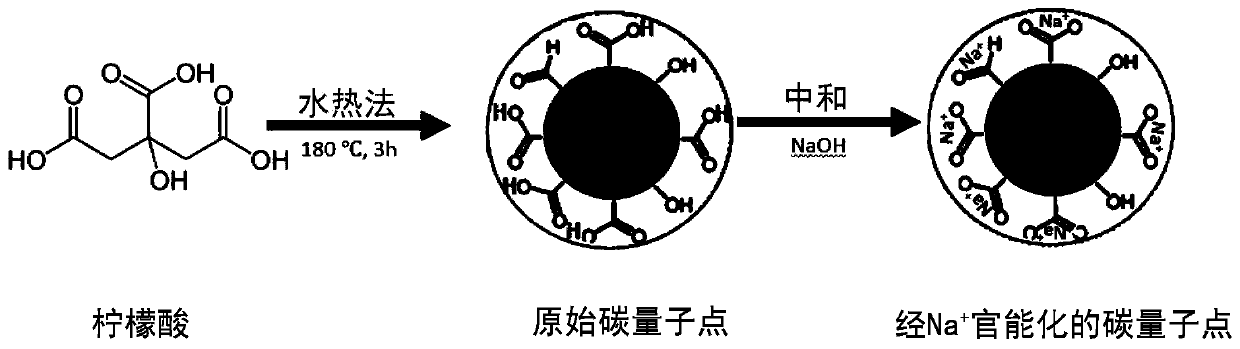

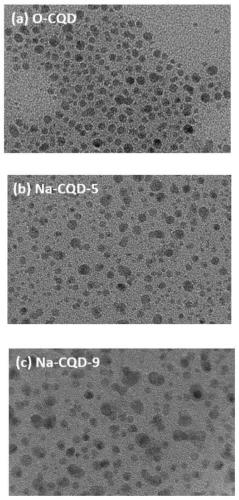

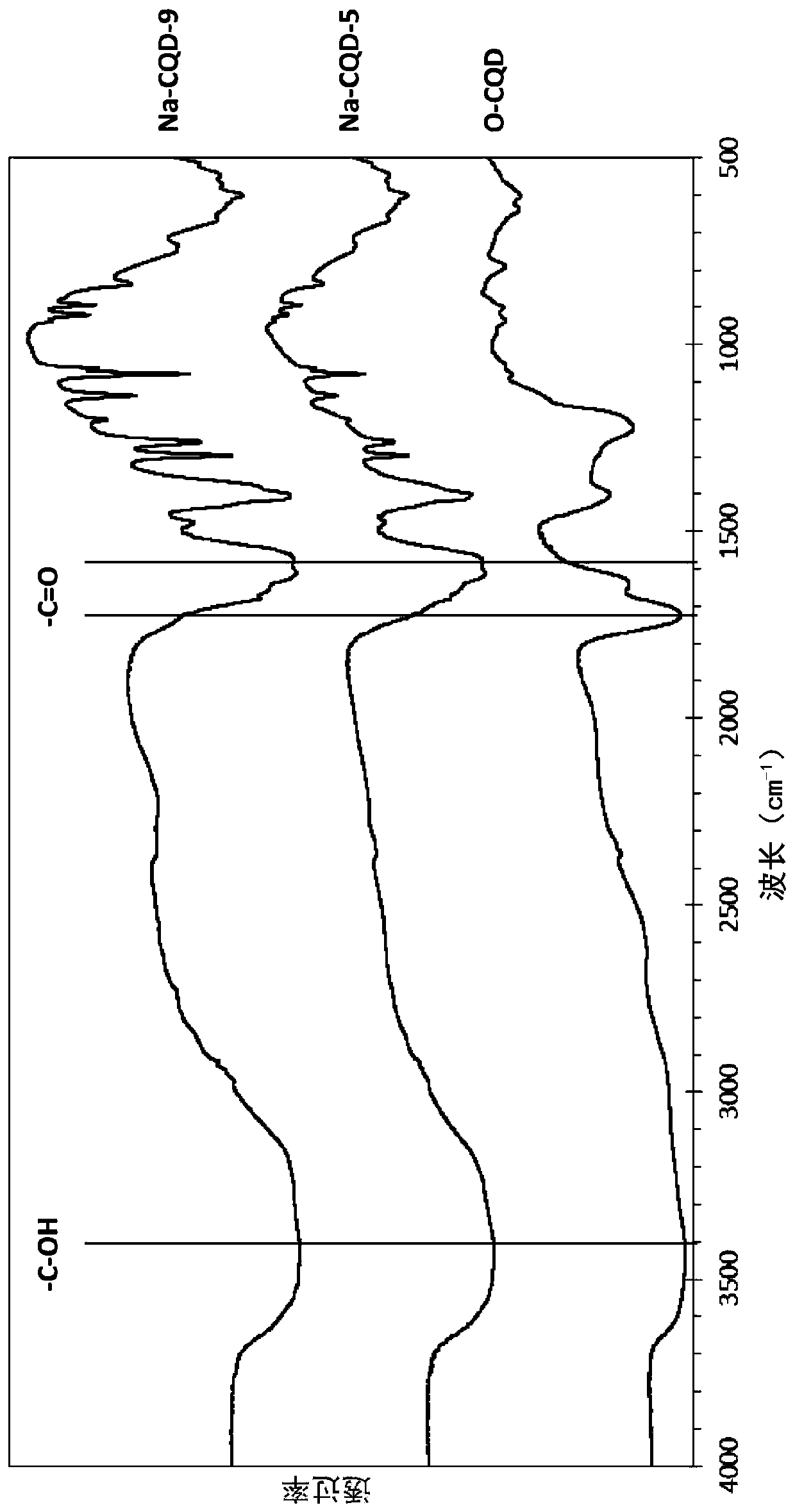

A thin film composite membrane

There is provided a thin film composite (TFC) membrane comprising a support layer and a selective layer, formed of a cross-linked polyamide comprising Na+-functionalised carbon quantum dots (NaCQD), on a surface of the support layer. There is also provided a method of forming the TFC membrane.

Owner:NAT UNIV OF SINGAPORE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com