Method of surface functionalization of aramatic polyamides reverse osmosis thin film composite membrane

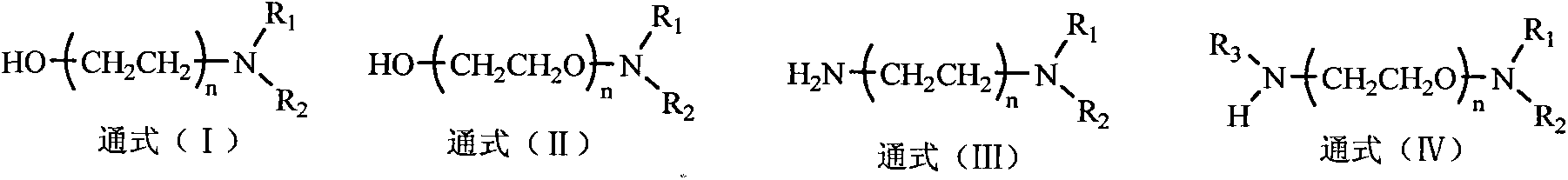

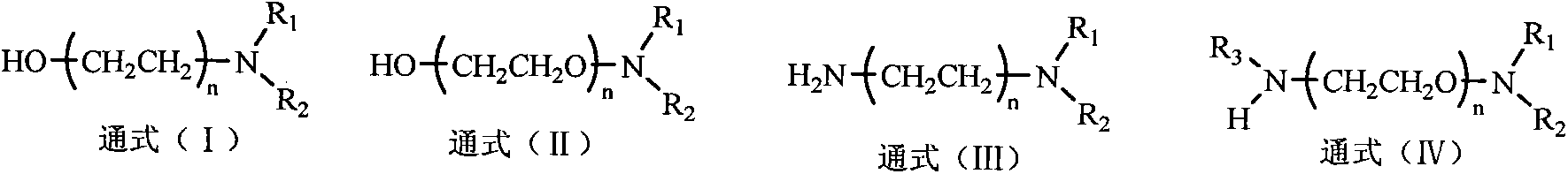

A technology of reverse osmosis composite membrane and aromatic polyamide, which is applied to the surface modification of quaternary ammonium salt and salicylaldehyde functional group of aromatic polyamide reverse osmosis composite membrane, and the field of surface functionalization of aromatic polyamide reverse osmosis composite membrane, which can solve the problem. Reduced permeability, poor modification uniformity, blockage of micropores of aromatic polyamide reverse osmosis composite membrane, etc., to achieve the effect of simple and easy method and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

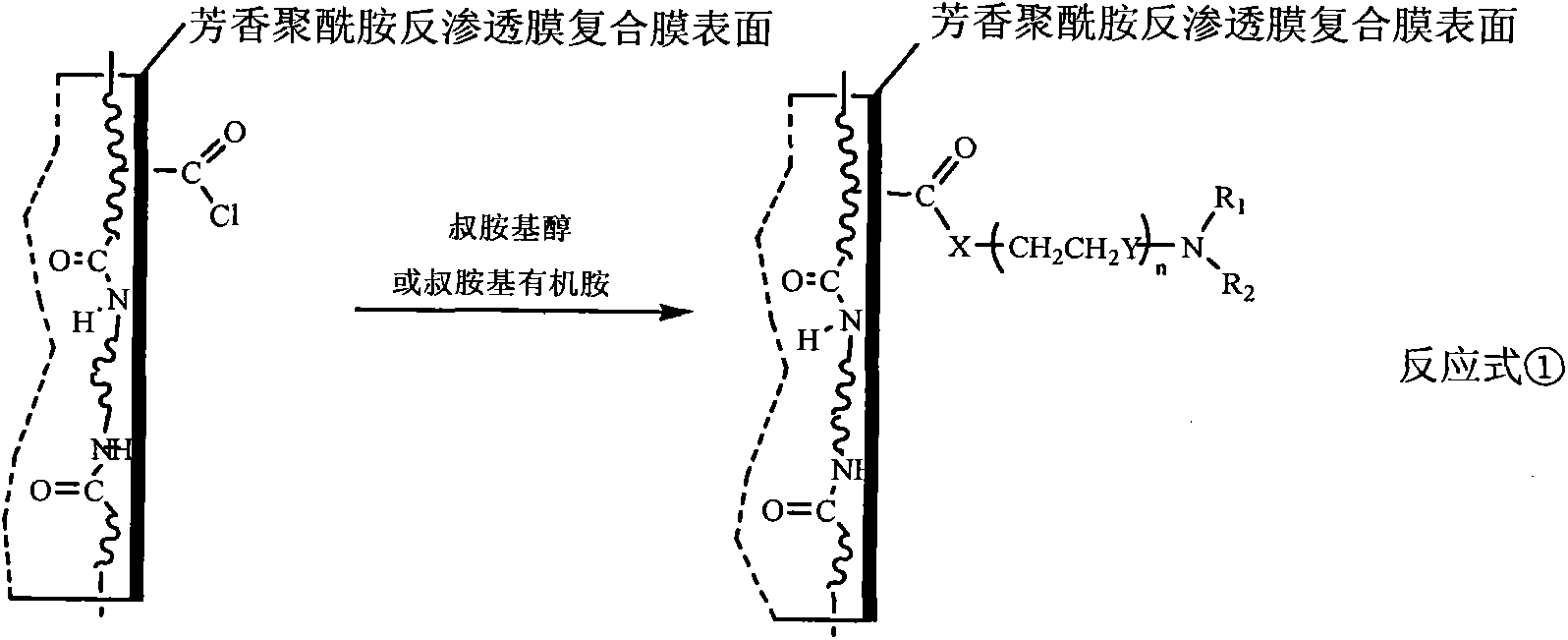

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Preparation of aromatic polyamide-polysulfone composite membrane containing quaternary ammonium salt and salicylaldehyde functional groups on the surface

[0047] Step 1 Preparation of aromatic polyamide-polysulfone composite membrane containing acid chloride groups on the surface

[0048] Take the purified and dried polysulfone support membrane with a molecular weight cut-off of 20,000-50,000 and immerse it in a dichloromethane solution with a mass percent concentration of 3-15% m-phenylenediamine, immerse it at room temperature for 24 hours, take it out and air-dry it, and spray it at room temperature A dichloromethane solution containing isophthaloyl chloride, trimesoyl chloride and triethylamine with a mass percent concentration of 3-15%, after reacting at room temperature for 0.2 hours, raise the temperature to 50-90°C and continue the reaction for 2 hours , washed with acetone, and vacuum-dried to prepare an aromatic polyamide-polysulfone composite membr...

Embodiment 2

[0053] Example 2 Preparation of aromatic polyamide-polypropylene fiber non-woven composite membrane containing quaternary ammonium salt and salicylaldehyde functional groups on the surface

[0054] According to the method and operation steps of Example 1, the polysulfone support membrane in Step 1 of Example 1 was replaced with polypropylene non-woven fabric, that is, the aromatic polyamide-polypropylene non-woven fabric with "planting" quaternary ammonium salt and salicylaldehyde on the surface was obtained. Spun composite membrane (abbreviated as QS-PEG-PA / PP composite membrane).

Embodiment 3

[0055] Example 3 Preparation of aromatic polyamide-cotton fiber filter paper composite membrane containing quaternary ammonium salt and salicylaldehyde functional groups on the surface

[0056] According to the method and operation steps of Example 1, the polysulfone support membrane in Step 1 of Example 1 was replaced with cotton fiber filter paper, and the monodiethylamino polyethylene glycol in Step 2 was replaced with 2-(dimethylamino)ethylene glycol. Amine, that is, the aromatic polyamide-cotton fiber filter paper composite membrane (referred to as QS-DMA-PA / FP composite membrane) that is "planted" with quaternary ammonium salt and salicylaldehyde on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com