Nano-silver solution and preparation method thereof

A nano-silver, nano-silver oxide technology, applied in the directions of botanical equipment and methods, chemical instruments and methods, silver compounds, etc., can solve the problems of insufficient safety and antibacterial activity, and achieve the effect of high antibacterial performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] More specifically, the preparation method of nano-silver solution of the present invention mainly comprises the following steps:

[0040] (1) Put the dispersant in a certain amount of deionized water, stir continuously until it is completely dissolved to prepare a dispersant solution, then add a certain amount of silver nitrate, and stir to dissolve the silver nitrate to obtain a solution (I);

[0041] (2) Take a certain amount of reducing agent solution, add it to solution (I), and stir to mix evenly to obtain solution (II);

[0042] (3) The solution (II) is irradiated under ultraviolet light, stirred rapidly with an electromagnetic stirrer, and reacted for a period of time to prepare the nano-silver solution (III).

[0043] If it is necessary to form nano-silver oxide particles in the solution, the step (4) is further included: passing oxygen into the solution (III) for a certain period of time to prepare a nano-silver oxide solution.

[0044] Wherein in the first st...

example 1

[0050] In this example, the concrete steps of preparing nano-silver solution include:

[0051] (1) Dissolve 3.5 grams of PEG in 96.6 grams of deionized water, stir continuously until completely dissolved to prepare a dispersant solution, then add 60 mg of silver nitrate, stir to dissolve the silver nitrate to obtain a solution (I);

[0052] (2) Take 3.4 ml of 1% ascorbic acid solution, add it to solution (I), and stir and mix evenly to obtain solution (II);

[0053] (3) Put the solution (II) under the ultraviolet lamp and irradiate it quickly with an electromagnetic stirrer, and react for 2 hours to prepare the nano-silver solution (III). The wattage of the ultraviolet lamp used in this step is 5 watts, and the stirring speed is 600 rpm.

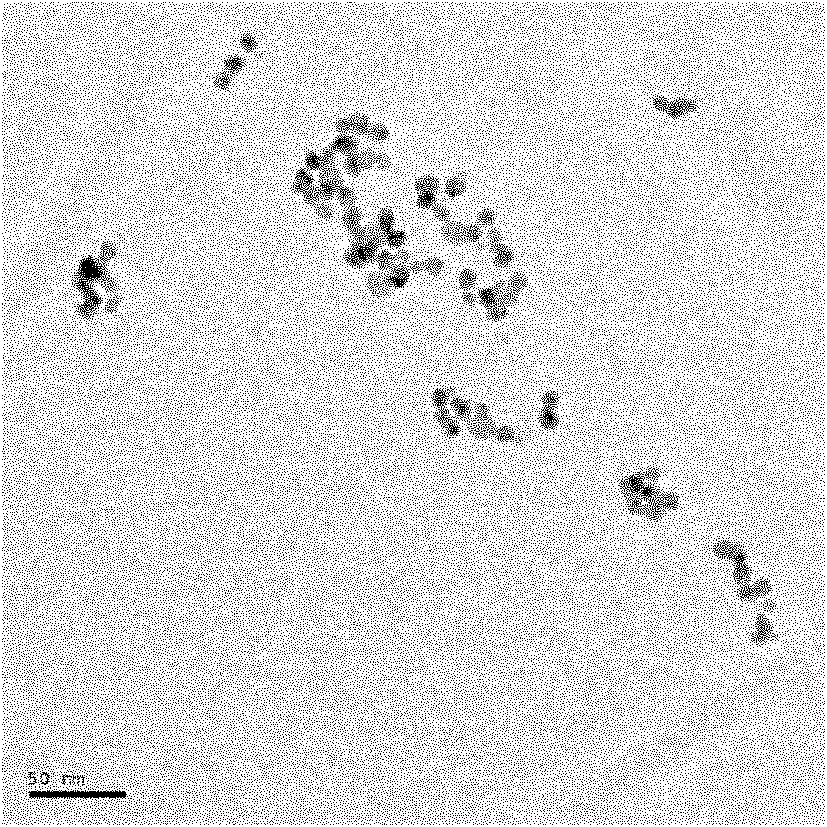

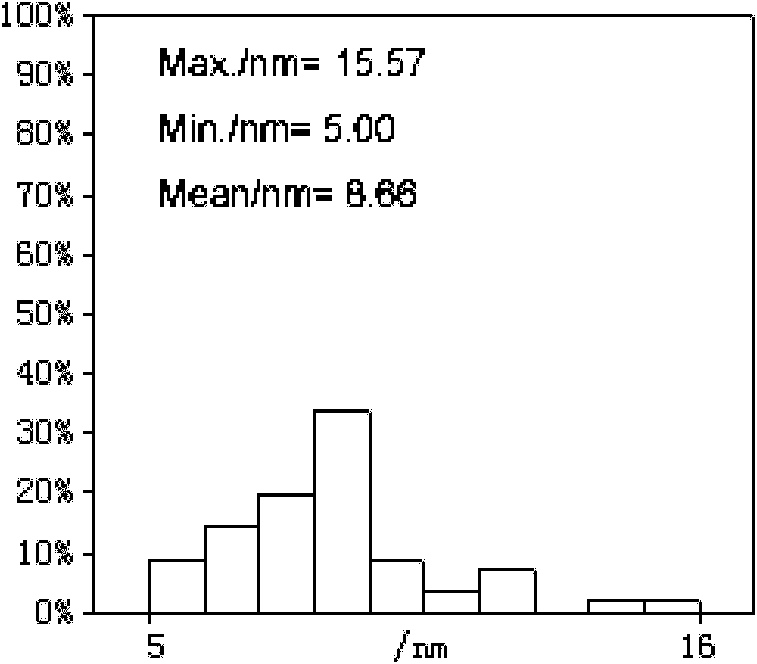

[0054] The concentration of the prepared nano-silver solution is 390ppm. Use the nano measure 1.2.5 method for particle size statistics, see figure 2 , the maximum diameter in the field of view is 15.57nm, the minimum is 5nm, and the ave...

example 2

[0057] In this example, the concrete steps of preparing nano-silver solution include:

[0058] (1) Dissolve 3.5 grams of MC in 96.6 grams of deionized water, stir continuously until completely dissolved to prepare a dispersant solution, then add 40 mg of silver nitrate, and stir to dissolve the silver nitrate to obtain a solution (I);

[0059] (2) Take 3.4 ml of 1% citric acid solution, add it to solution (I), and stir to mix evenly to obtain solution (II);

[0060] (3) Put the solution (II) under the ultraviolet lamp and irradiate it quickly with an electromagnetic stirrer, and react for 2 hours to prepare the nano-silver solution (III). The wattage of the ultraviolet lamp used in this step is 5 watts, and the stirring speed is 600 rpm.

[0061] The prepared nano-silver solution has a concentration of 260 ppm and an average particle diameter of about 9.2 nanometers.

[0062] Furthermore, the above nano-silver solution (III) is passed through step (4) into the solution (III)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com