Thin film composite membranes for forward osmosis, and their preparation methods

A technology of forward osmosis membrane and composite membrane, applied in the field of forward osmosis membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

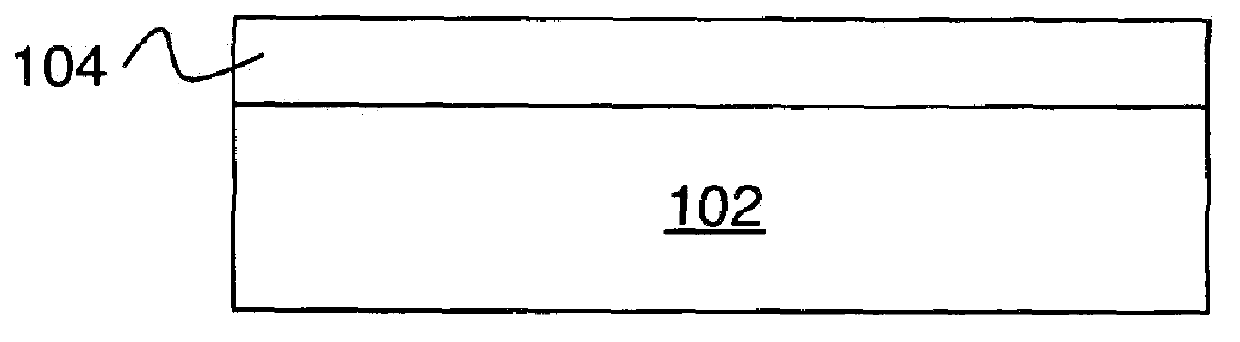

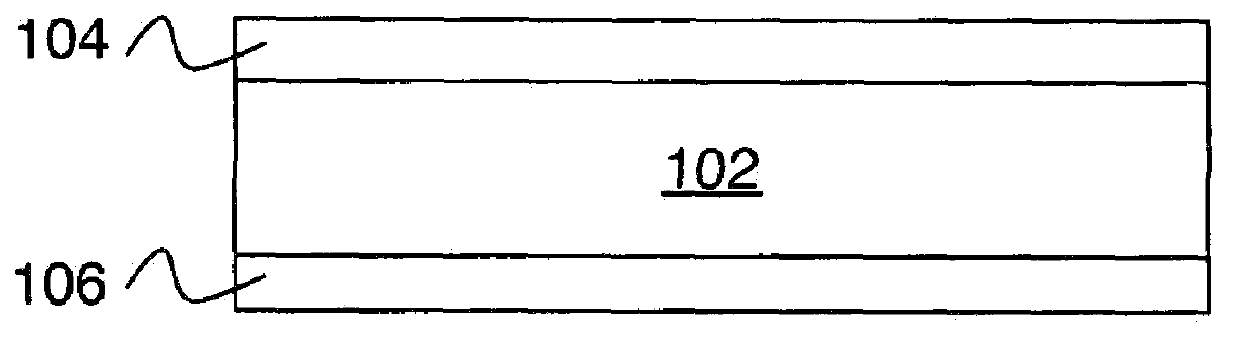

[0023] Example 1 concerns the fabrication of flat sheet membranes according to the method of the invention and the performance comparison of these membranes with commercially available FO membranes.

Embodiment 2

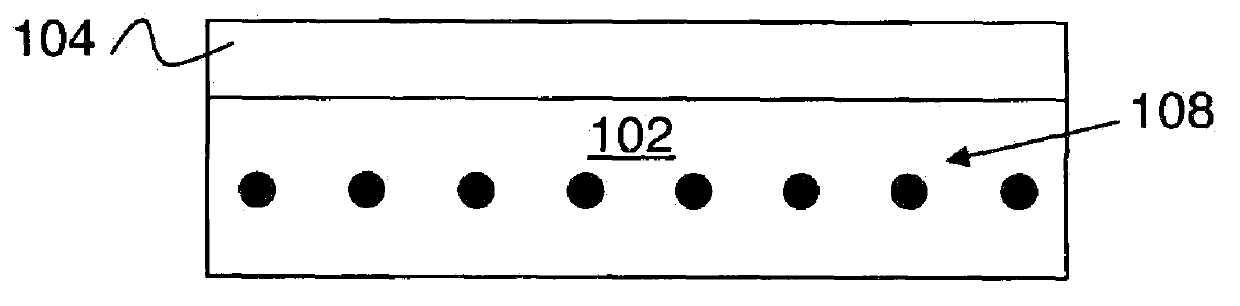

[0024] Example 2 concerns the configuration of incorporated carbon nanotubes in the support layer.

Embodiment 3

[0025] Example 3 involved an acrylate-modified poly(vinylidene fluoride) polymer support layer (other examples involved meta-aramid support layers).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com