Ultrathin polymer composite membrane for realization of five-prevention and oxygen enrichment functions of mask and application

An ultra-thin film and polymer technology, used in the medical and health field, can solve the problems of long-term use and prevention of PM2.5 particles that can enter the lungs.

Inactive Publication Date: 2013-12-25

武汉龙飞翔科技产品制造有限公司

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is currently no technology or product that can meet the functions of the five defenses (that is, dust prevention (including anti-PM2.5), anti-virus, anti-bacteria, anti-pollution, and anti-smoke) functions, and while meeting the five defense functions, it can also provide oxygen-enriched air. f

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Login to View More

Abstract

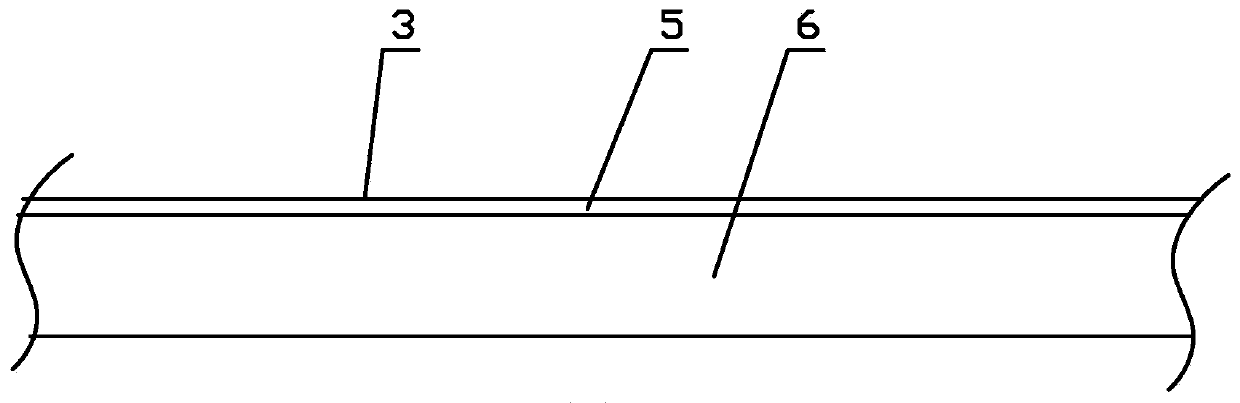

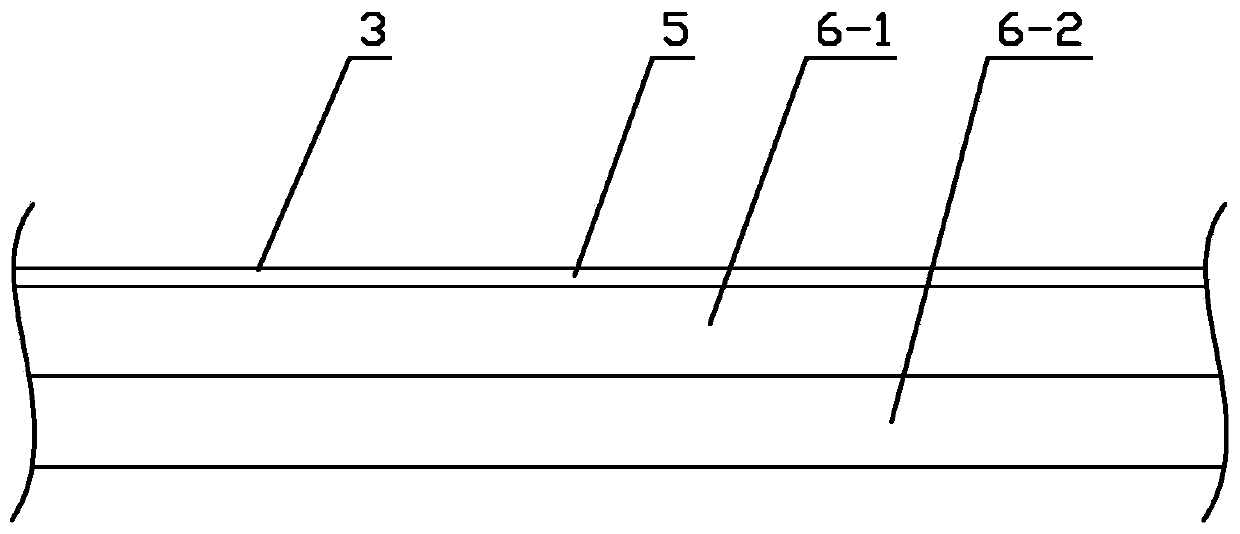

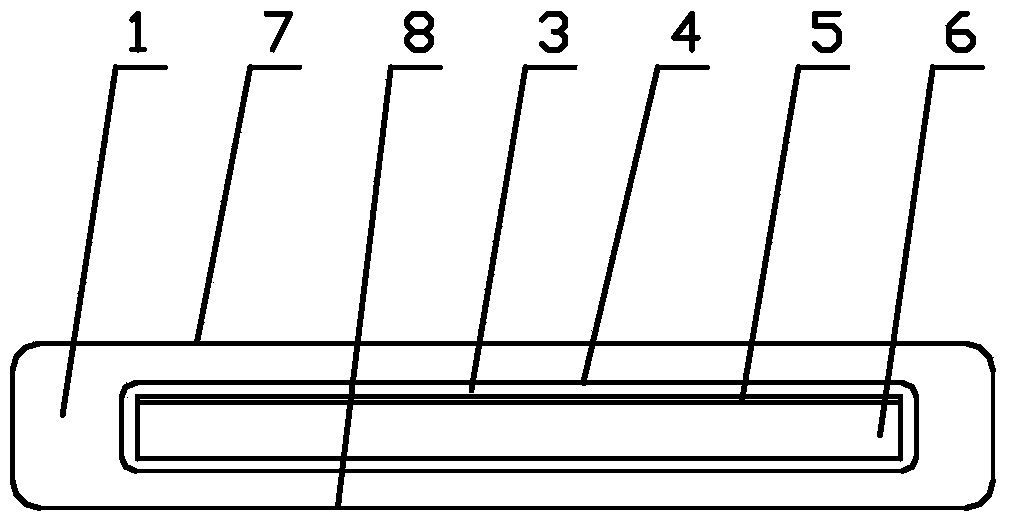

The invention belongs to the technical field of medical treatment and public health, and discloses an ultrathin polymer composite membrane for realization of five-prevention and oxygen enrichment functions of a mask. A supporting layer of the ultrathin polymer composite membrane is a porous ultrathin membrane carrier layer made of porous material; the surface of the porous ultrathin membrane carrier layer is covered with a homogeneous aporate ultrathin polymer membrane layer; the homogeneous aporate ultrathin polymer membrane layer is a homogeneous aporate compact layer made of a polymer which has high oxygen permeability or has high selectivity in the oxygen permeation process meeting the requirements of a solution-diffusion model; the rate of permeability coefficients of oxygen to nitrogen in the homogeneous aporate ultrathin polymer membrane layer is (1.5-6):1; the thickness of the homogeneous aporate ultrathin polymer membrane layer is 0.001-5 microns. The composite membrane provided by the invention enables the mask to have the functions of preventing dust particles (including PM2.5), virus, bacteria, pollutants and smoke dust, and to further achieve an oxygen enrichment function.

Description

technical field [0001] The invention belongs to the field of medical and health technology, and specifically relates to a mask that can be used to produce five defenses and oxygen-enriched functions, and is made of a polymer with a high oxygen permeability or a highly selective permeation of oxygen that complies with a dissolution-diffusion model composite film. Background technique [0002] In the prior art, polymer gas separation membranes are polymer membranes used to separate mixed gases, usually divided into porous membranes and non-porous membranes, and the main parameters are permeability coefficient and separation coefficient. Different polymer membranes have different permeability and selectivity to different types of gas molecules, so a certain gas can be selectively separated from the gas mixture, such as collecting oxygen from the air. General Electric Company of the United States uses polycarbonate and organosilicon copolymer as the separation membrane, and 40%...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D69/12B01D69/02A62B7/10A62B9/06

Inventor 黄河

Owner 武汉龙飞翔科技产品制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com