Preparation device and method for environmentally-friendly composite membrane with preferential alcohol permeability performance

An alcohol-preferential and environmentally friendly technology, applied in the field of membrane separation, can solve problems such as pollution, explosiveness, and corrosion, and achieve the effect of improving the permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

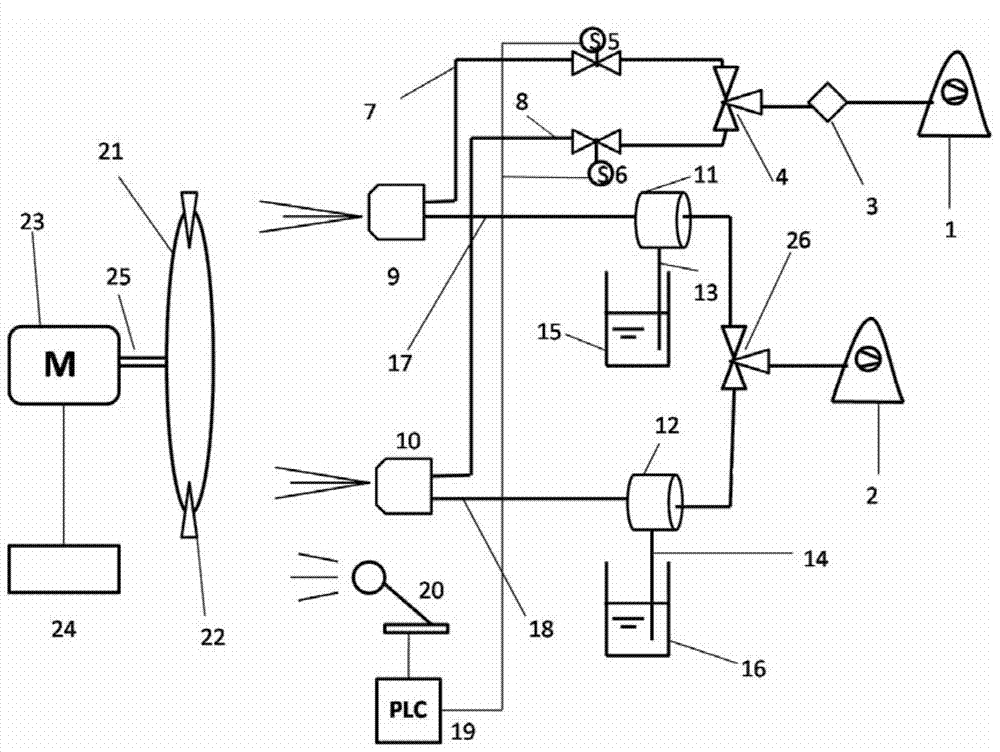

Method used

Image

Examples

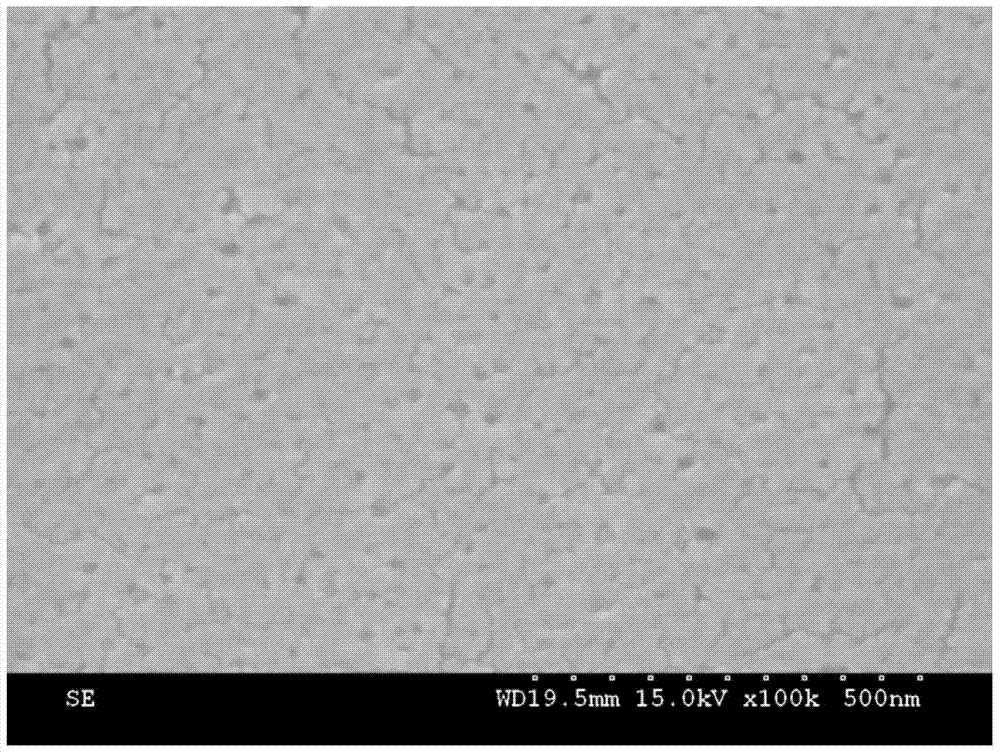

Embodiment 1

[0041] The support body is polysulfone (PS) material, flat ultrafiltration membrane, the pure water flux is 300LMH / bar, and the membrane area is 92cm 2 , the polymer material used is polydimethylsiloxane (PDMS, viscosity 100Pa·S), the crosslinking agent is tetraethyl orthosilicate (TEOS, molecular weight 208), and the catalyst is dibutyltin dilaurate ( Molecular weight is 631). Polydimethylsiloxane is insoluble in the solvent, and the solvent of ethyl orthosilicate and dibutyltin dilaurate is ethanol. The experiments were carried out in a constant temperature and humidity laboratory, the temperature was kept at 20°C, and the humidity was kept at 20%. Crosslinking temperature 100°C, 15h.

[0042] Assembly conditions and methods:

[0043] (1) Let the polydimethylsiloxane stand and defoam to form an alcohol-permeable material solution. Add 0.015wt% dibutyltin dilaurate to ethyl orthosilicate with ethanol to form 1000ml of a 20wt% solution, stir and ultrasonically defoam to be...

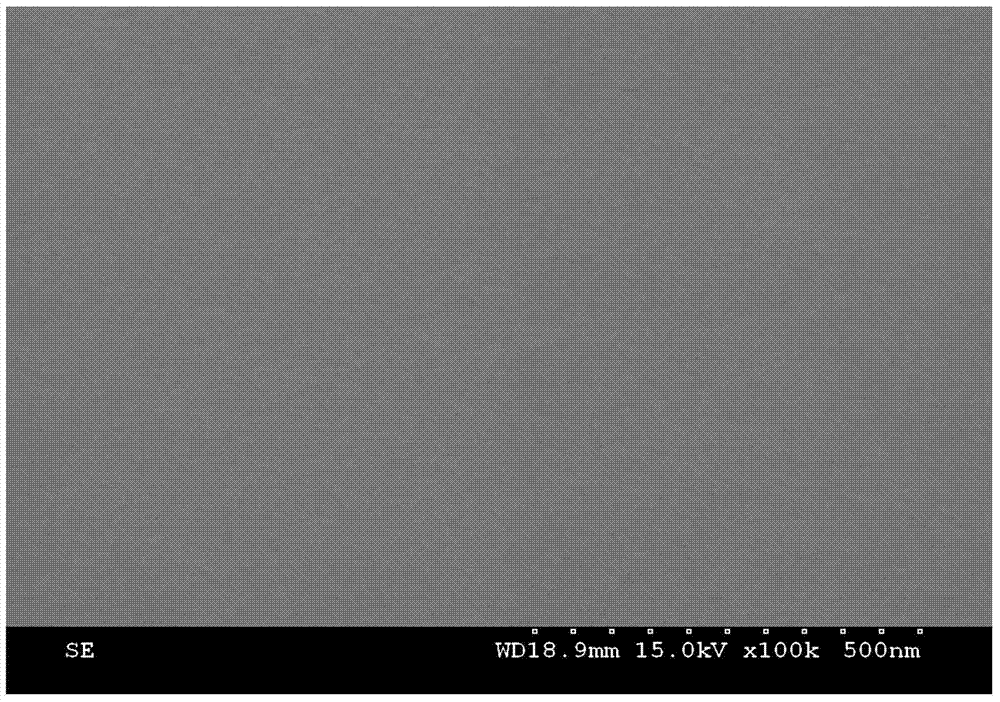

Embodiment 2

[0056] The support body is polysulfone (PS) material, flat ultrafiltration membrane, the pure water flux is 300LMH / bar, and the membrane area is 92cm 2 , the polymer material used is polydimethylsiloxane (PDMS, viscosity 100Pa·S), the crosslinking agent is tetraethyl orthosilicate (TEOS, molecular weight 208), and the catalyst is dibutyltin dilaurate ( Molecular weight is 631). Polydimethylsiloxane is insoluble in the solvent, and the solvent of ethyl orthosilicate and dibutyltin dilaurate is ethanol. The experiments were carried out in a constant temperature and humidity laboratory, the temperature was kept at 20°C, and the humidity was kept at 20%. Crosslinking temperature 100°C, 15h.

[0057] Assembly conditions and methods:

[0058] (1) Let the polydimethylsiloxane stand and defoam to form an alcohol-permeable material solution. Add 0.015wt% dibutyltin dilaurate to ethyl orthosilicate with ethanol to form 1000ml of a 20wt% solution, stir and ultrasonically defoam to be...

Embodiment 3

[0070] The support body is polysulfone (PS) material, flat ultrafiltration membrane, the pure water flux is 300LMH / bar, and the membrane area is 92cm 2 , the polymer material used is polydimethylsiloxane (PDMS, viscosity 100Pa·S), the crosslinking agent is tetraethyl orthosilicate (TEOS, molecular weight 208), and the catalyst is dibutyltin dilaurate ( Molecular weight is 631). Polydimethylsiloxane is insoluble in the solvent, and the solvent of ethyl orthosilicate and dibutyltin dilaurate is ethanol. The experiments were carried out in a constant temperature and humidity laboratory, the temperature was kept at 20°C, and the humidity was kept at 20%. Crosslinking temperature 100°C, 15h.

[0071] Assembly conditions and methods:

[0072] (1) Let the polydimethylsiloxane stand and defoam to form an alcohol-permeable material solution. Add 0.015wt% dibutyltin dilaurate to ethyl orthosilicate with ethanol to form 1000ml of a 20wt% solution, stir and ultrasonically defoam to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com