High Efficiency Water Purification System

a high-efficiency, water-purification technology, applied in water treatment multi-stage treatment, water/sewage multi-stage treatment, membranes, etc., can solve the problems of fouling of reverse osmosis membranes and limited recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

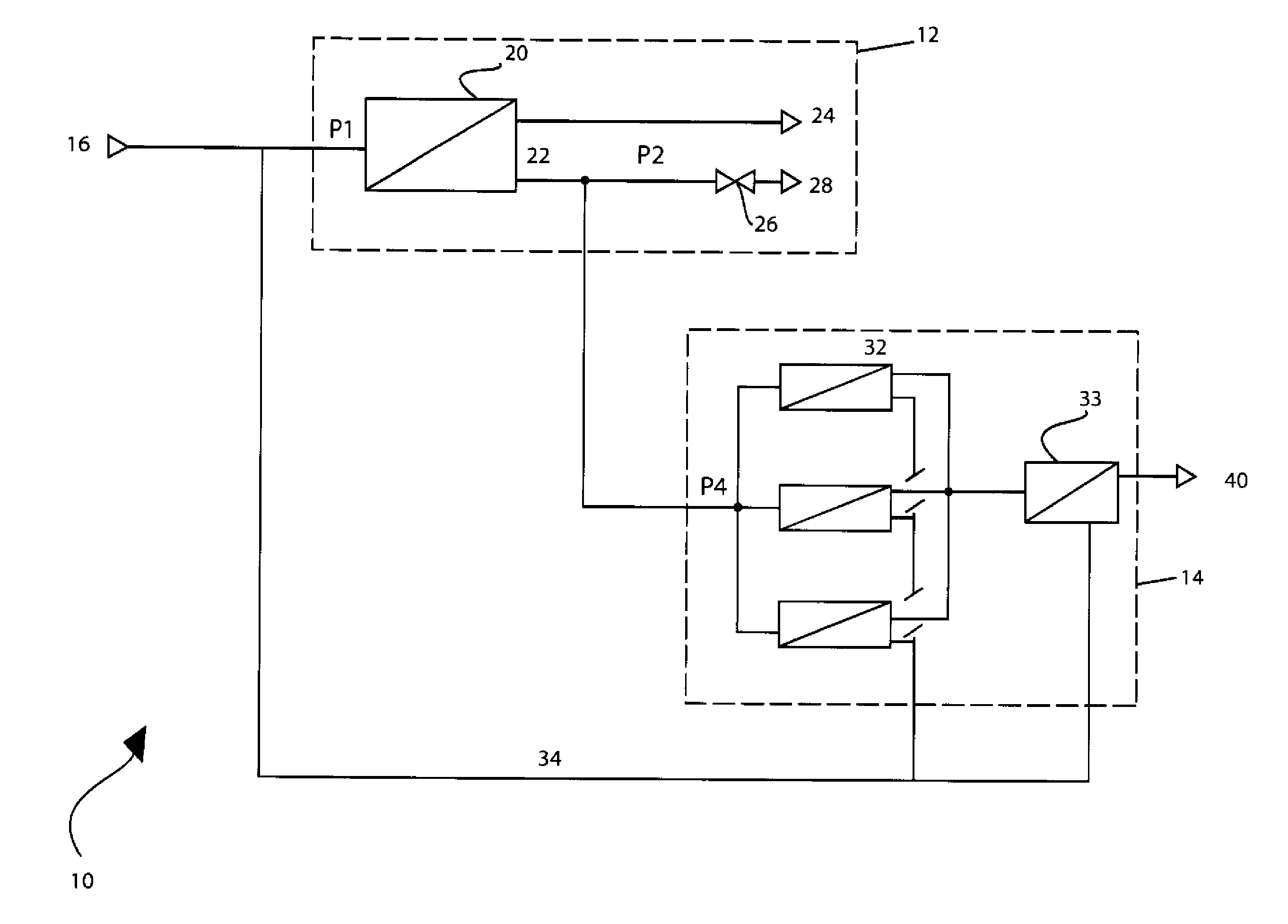

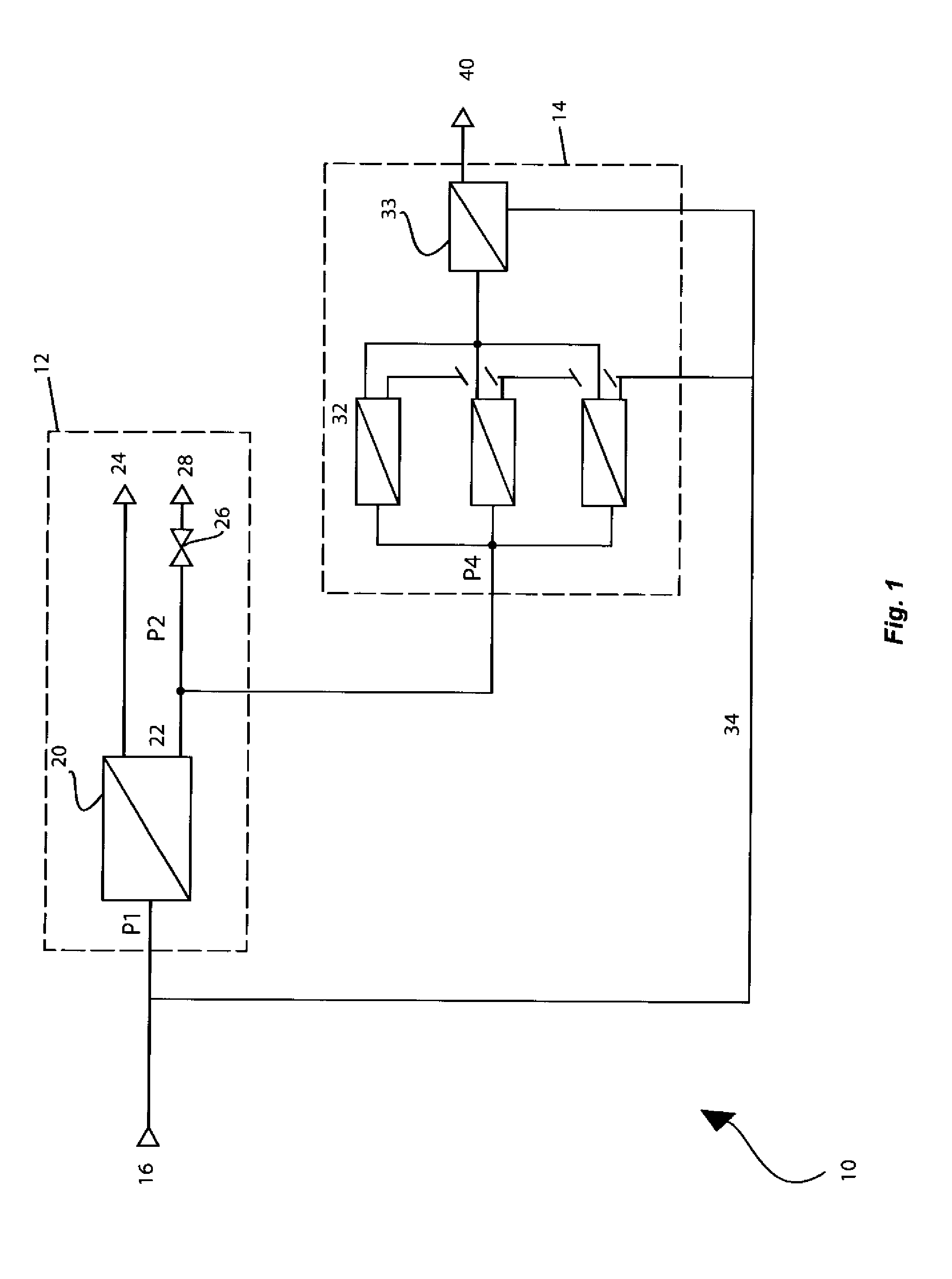

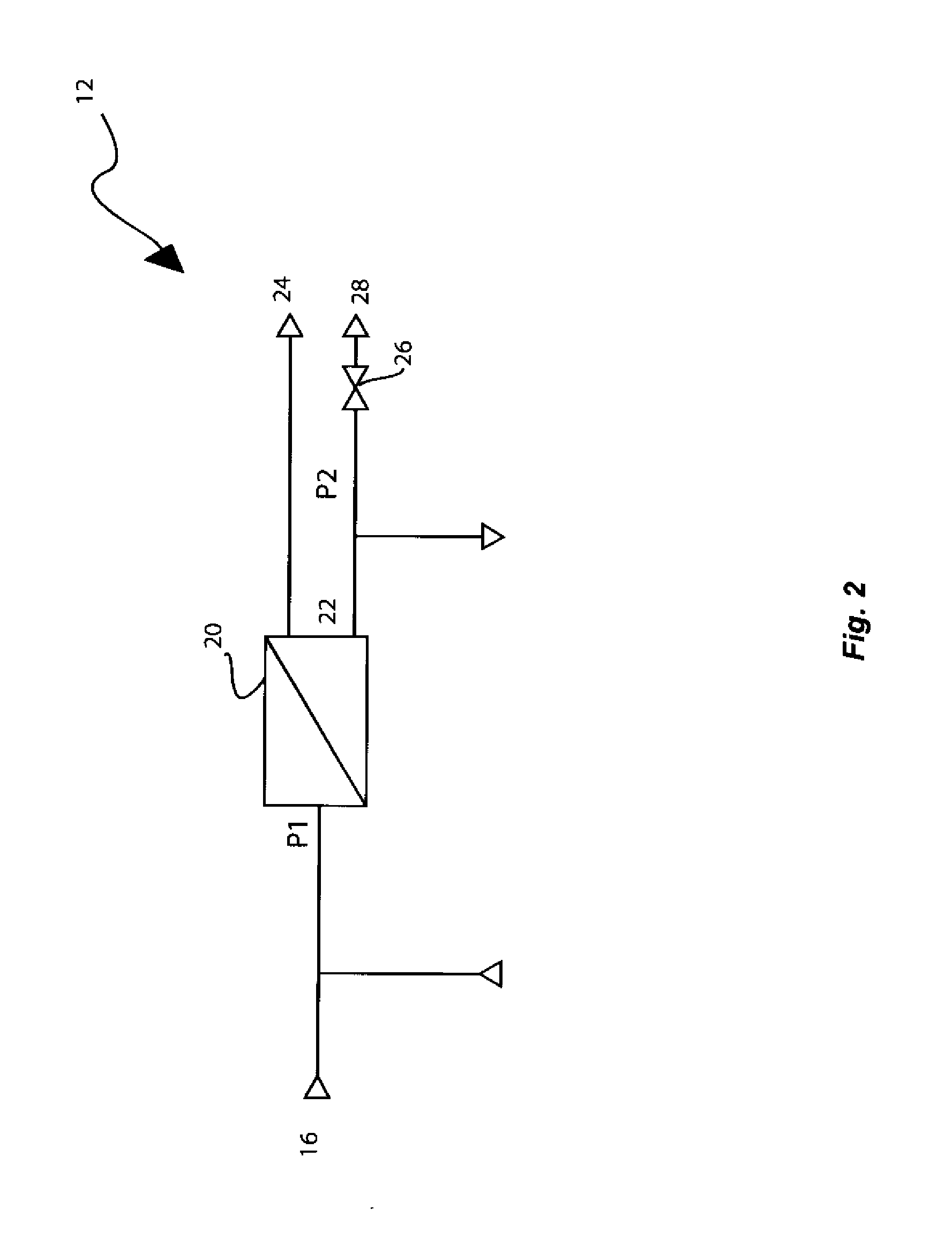

[0046]Example systems, methods, processes, and so on are now described. In the following description, for purposes of explanation, numerous specific details are set forth in order to facilitate thoroughly understanding the methods, systems, processes, and so on. It may be evident, however, that the methods, systems and so on can be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to simplify description.

[0047]As used in this application, the term “semi-permeable membrane” or “polyamide membrane” refers to thin film composite membranes such as reverse osmosis (RO) or nanofiltration (NF) membranes used to purify water, the soluble inorganic ions such as sodium, potassium, calcium, magnesium, iron, chloride, fluoride, carbonate, bicarbonate, sulfate and silica are separated by the membrane while the water is allowed to permeate or pass through the membrane. These thin film composite membranes genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com