Patents

Literature

43results about How to "Improve fouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

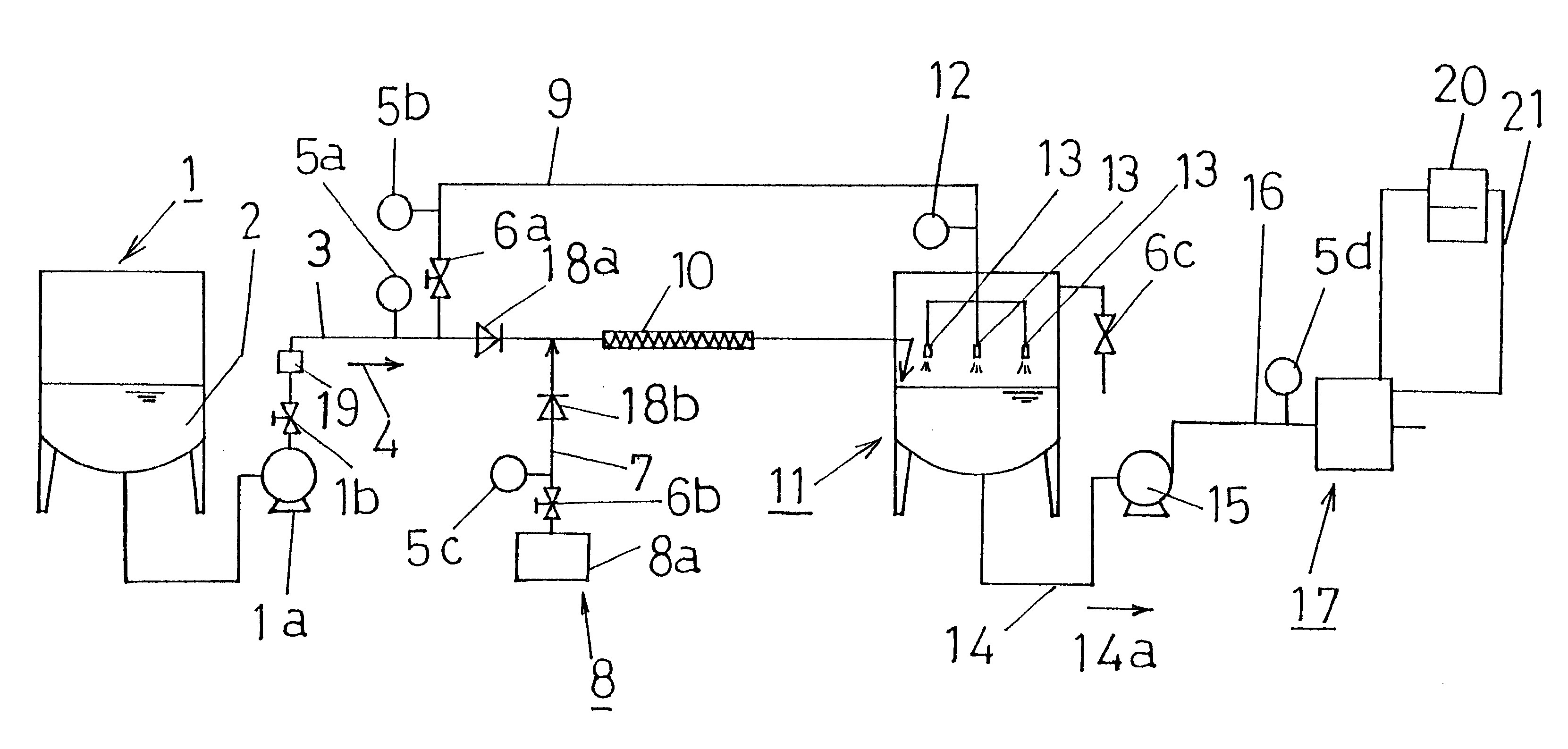

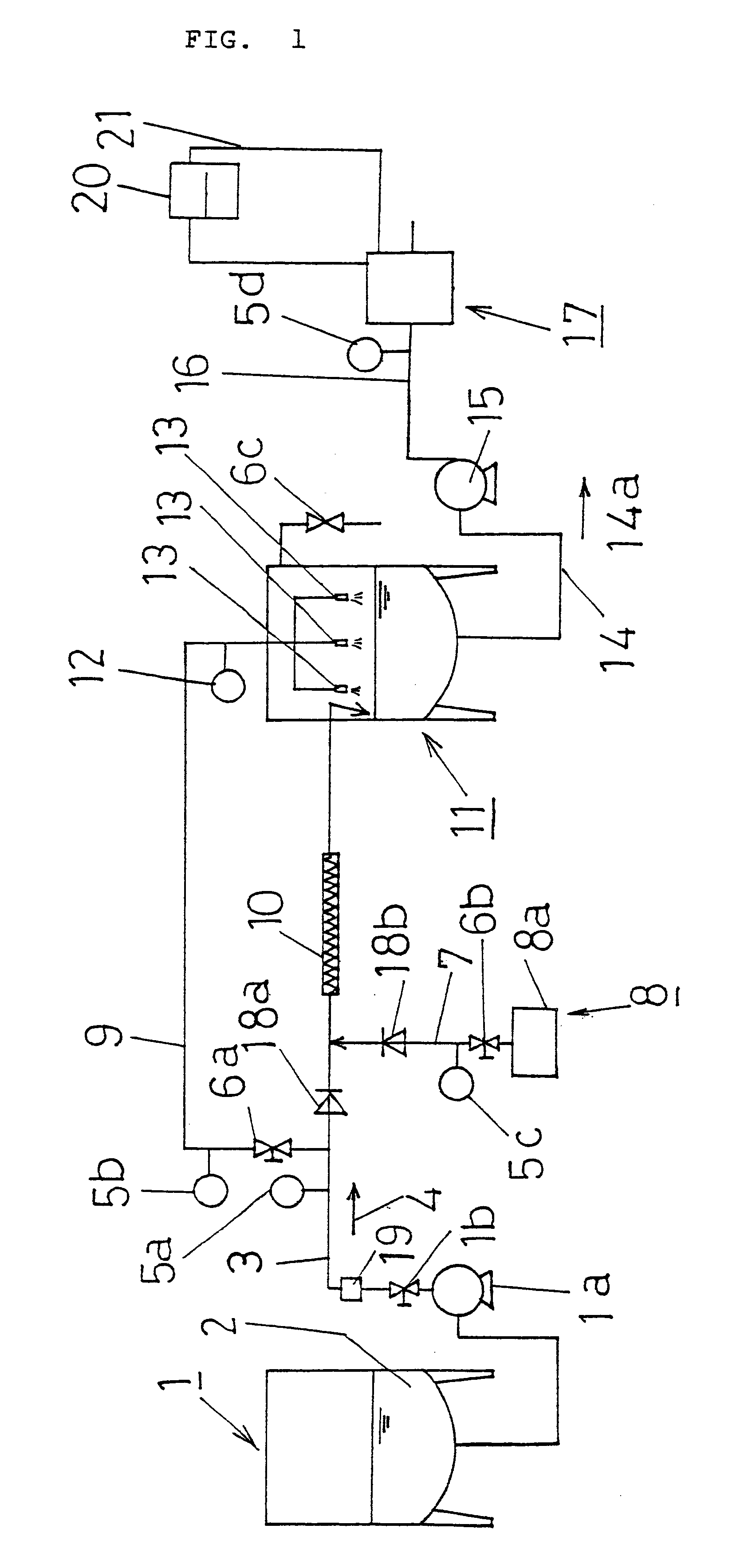

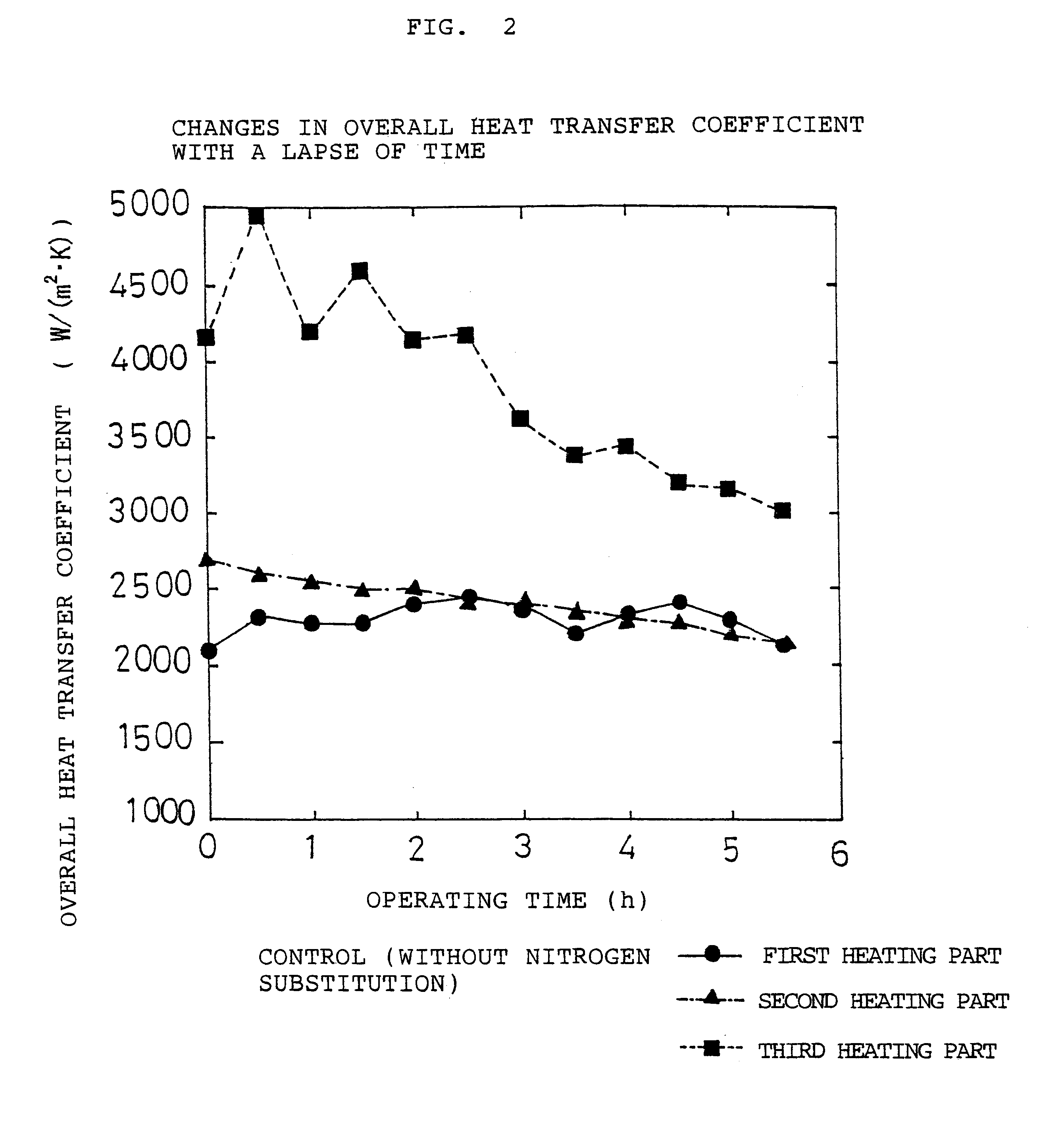

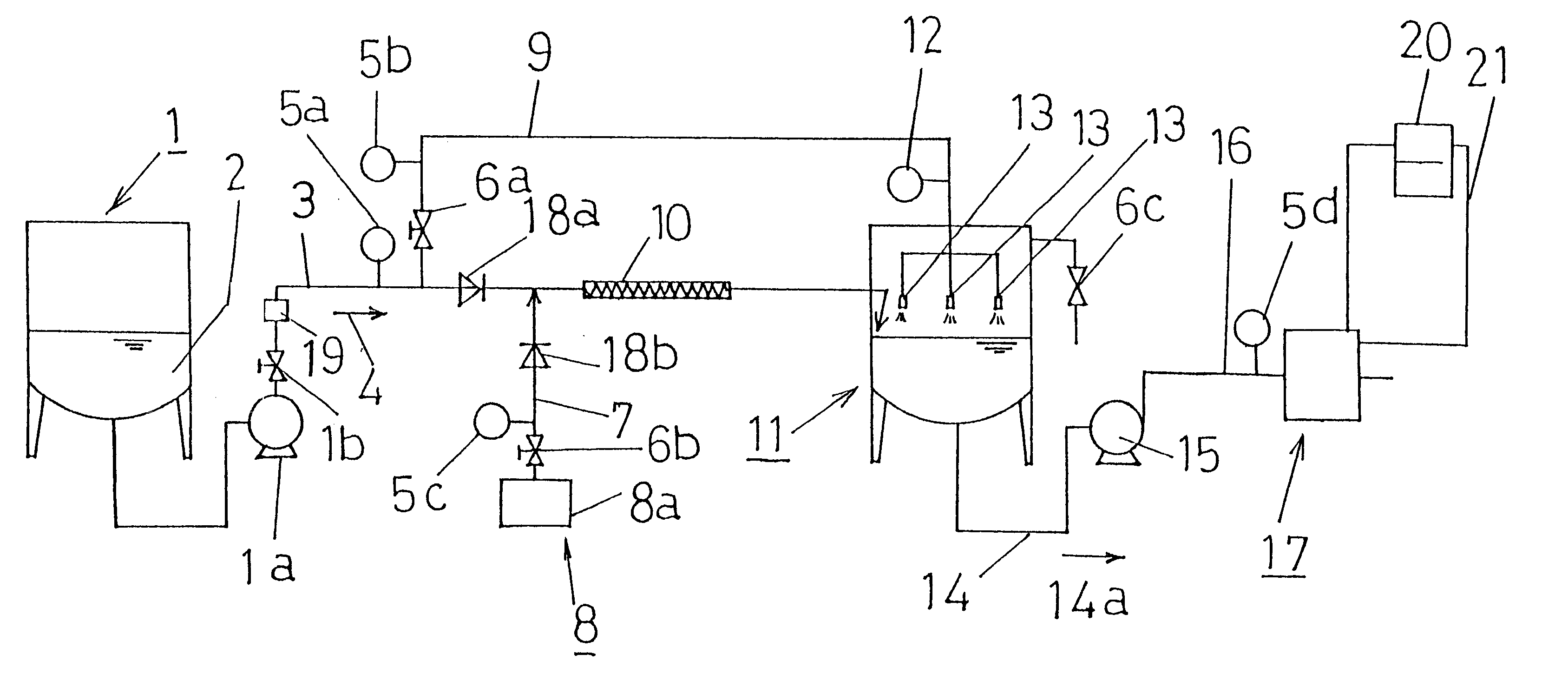

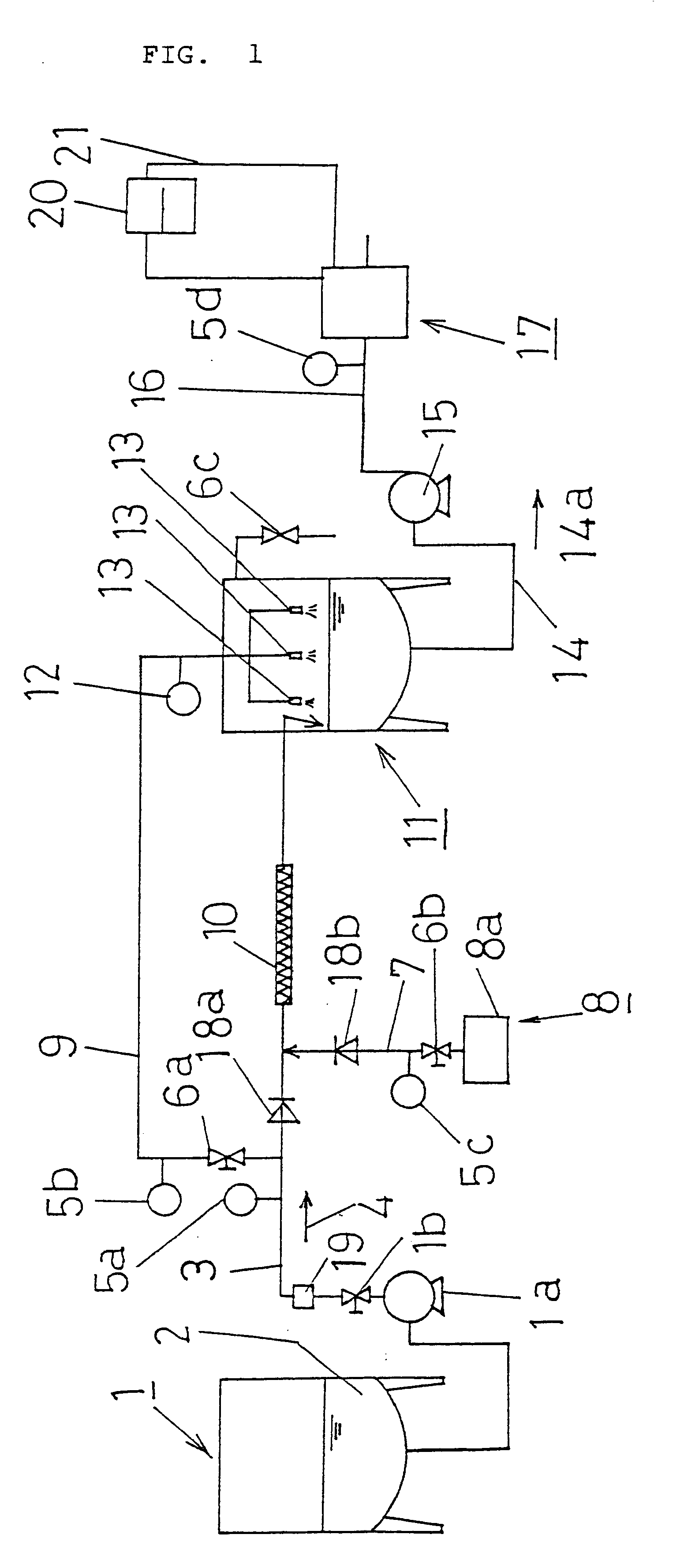

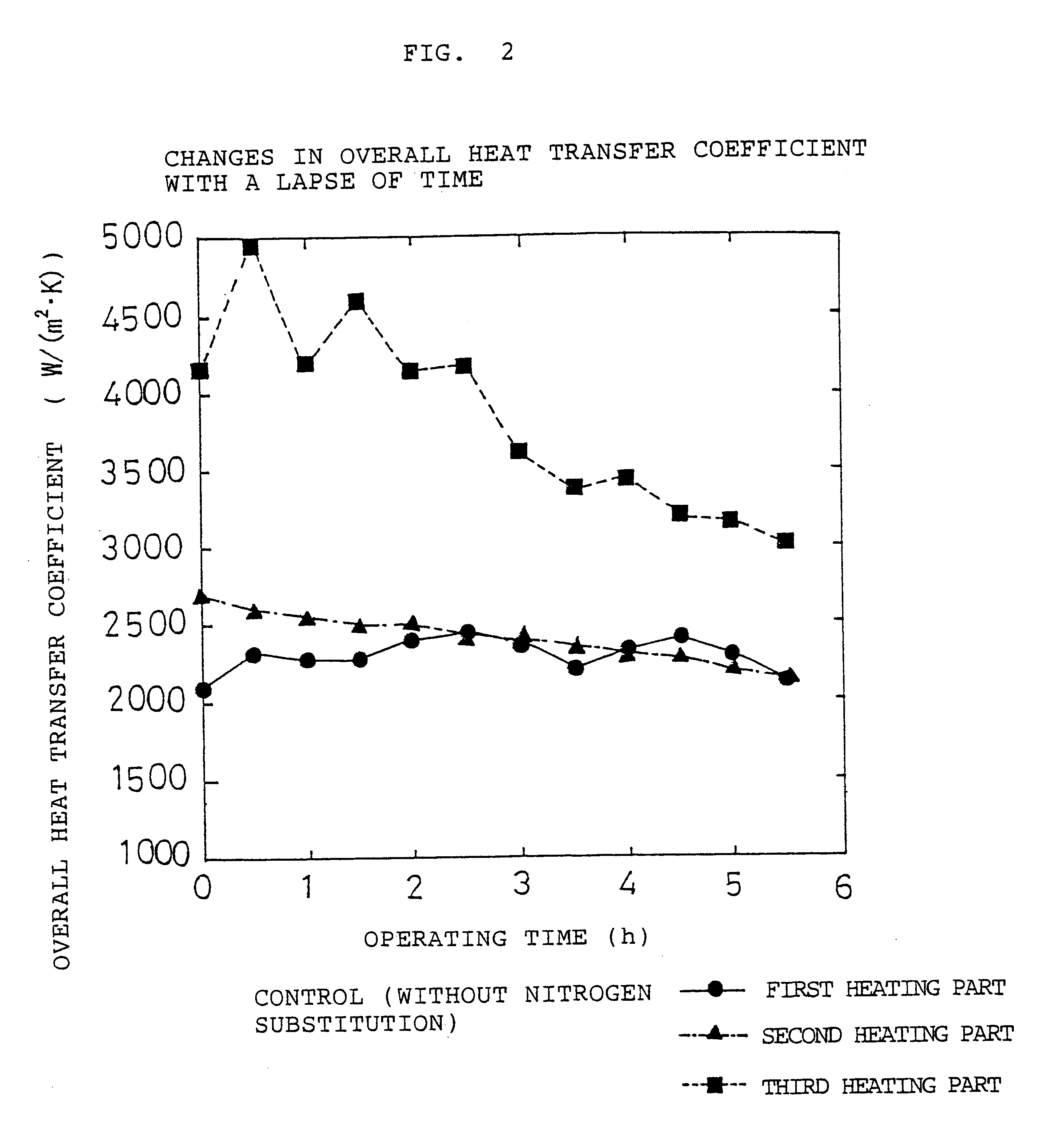

Sterilizing method by substituting the dissolved oxygen in milk or the like with nitrogen gas, a product thereof and an apparatus for nitrogen gas substitution

InactiveUS6447828B1Suppress generationEquipment is smallMilk preparationMilk preservationProduct gasNitrogen gas

An object of the present invention is to reduce the generation of smell by sterilization and to improve the taste in carrying out the sterilization of milk or the like, and the method of the present invention is a method where sterilization is carried out after the dissolved oxygen in milk or the like is substituted with nitrogen gas, and the method is characterized in that a step in which nitrogen gas is directly mixed with and dispersed in milk or the like and a step in which milk or the like with which nitrogen gas is not mixed is sprayed from a nozzle(s) to the top of milk or the like, with and in which nitrogen gas has been mixed and dispersed, stored in a nitrogen gas substituting tank under a nitrogen gas atmosphere, are jointly used whereby the dissolved oxygen amount in the milk or the like is reduced by substitution of the dissolved oxygen with nitrogen gas, followed by subjecting to sterilization.

Owner:MEIJI CO LTD

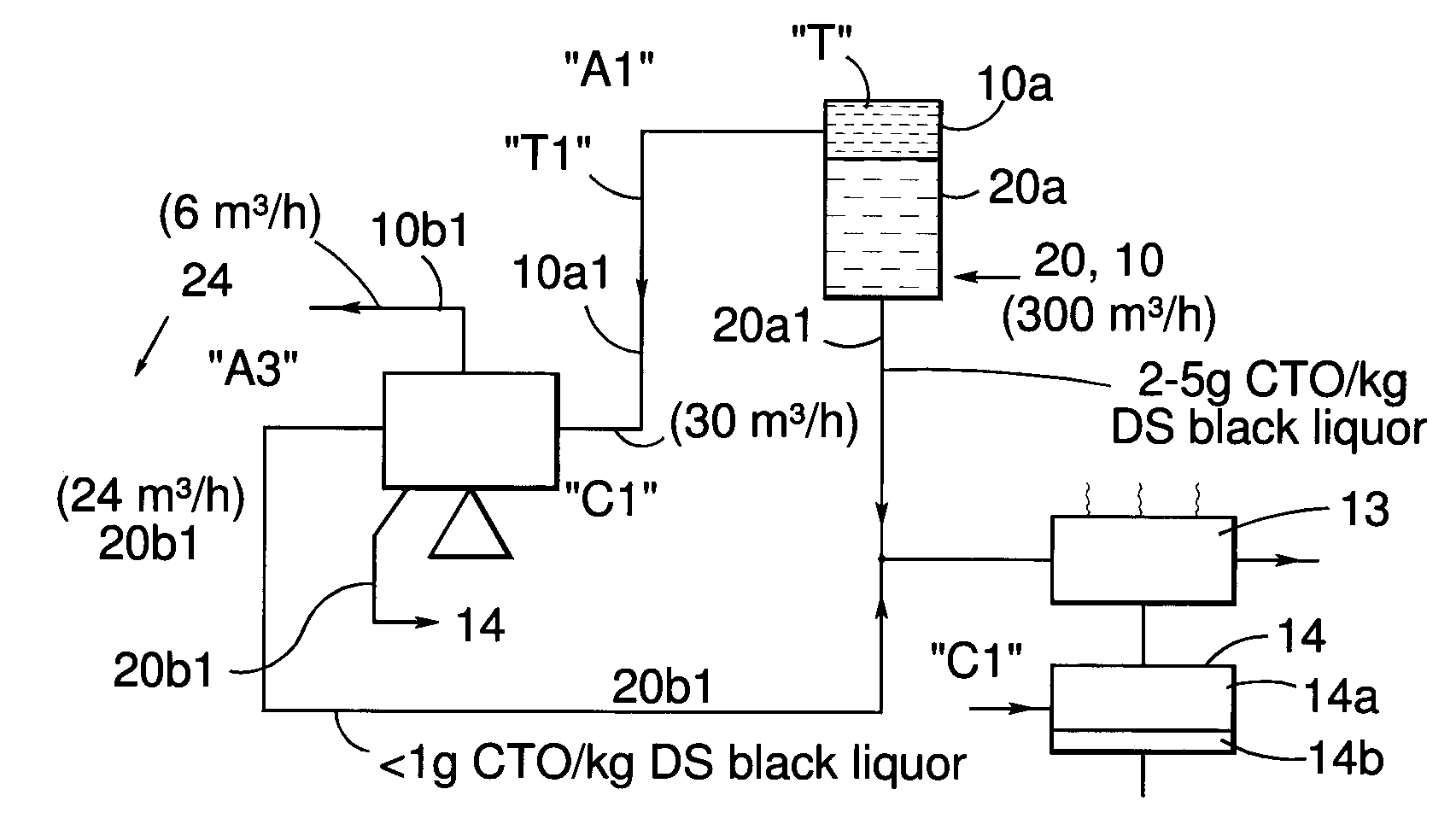

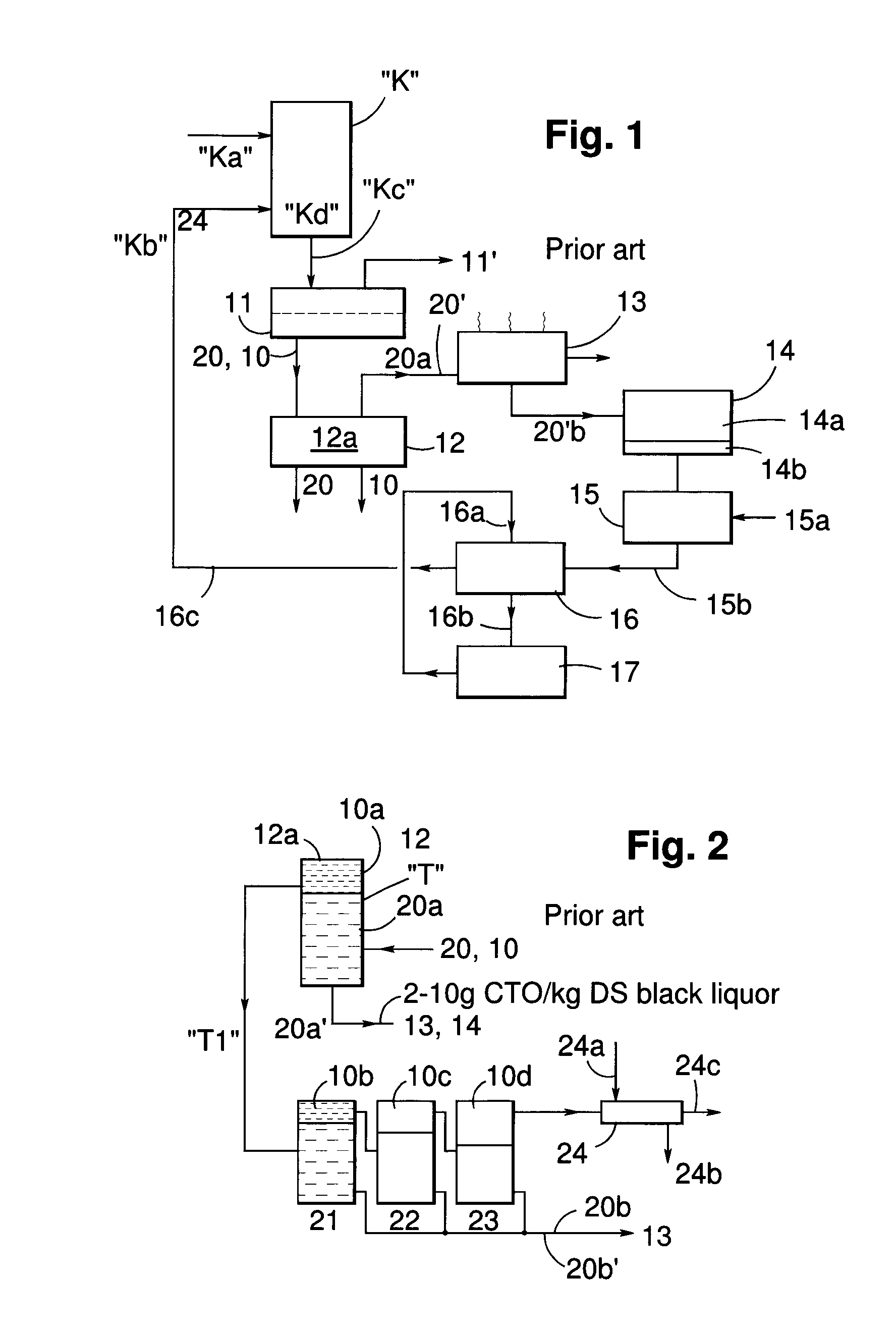

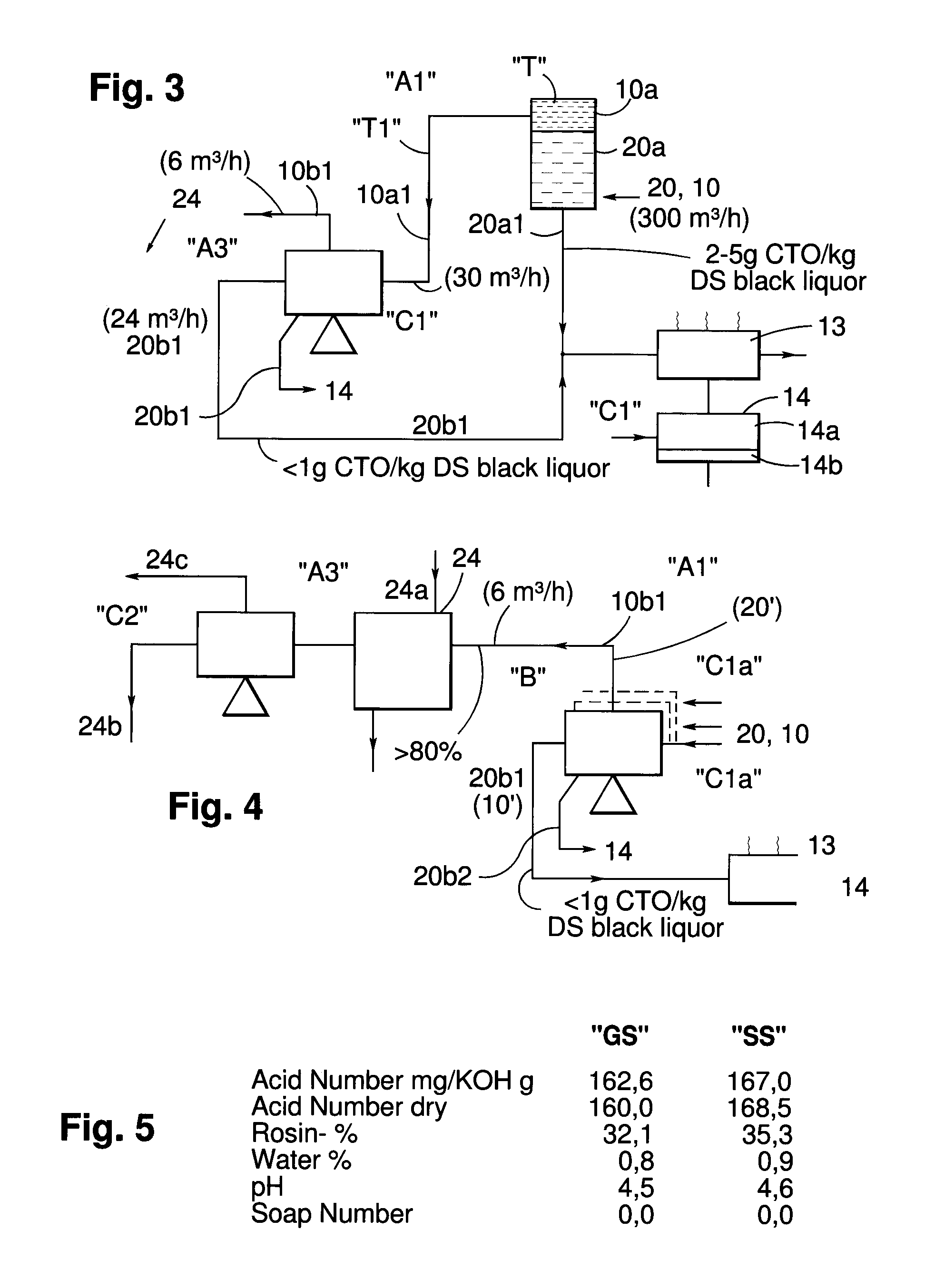

Method Of Separating, From A Mixture Of Black Liquor And Tall Oil Soap Product, Concentrated Portions Of Tall Oil Soap Product And Arrangements For Said Concentrated Tall Oil Soap Product And/Or Separated Black Liquor

InactiveUS20120296066A1Quality improvementReduce energy lossFatty oils/acids recovery from wastePulp liquors combustionRecovery boilerCentrifugal separator

A continuous method and an arrangement for separation of crude tall oil (CTO) from black liquor. The method involves an initial separation within a tank and / or within a centrifugal separator, and processing of the thus separated tall oil soap product by acidulation and / or splitting, followed by further separation, e.g. by centrifugation. The black liquor fraction may be processed for further CTO retrieval, before evaporation and feeding to a recovery boiler.

Owner:HOFSTEDT ANDERS GORAN

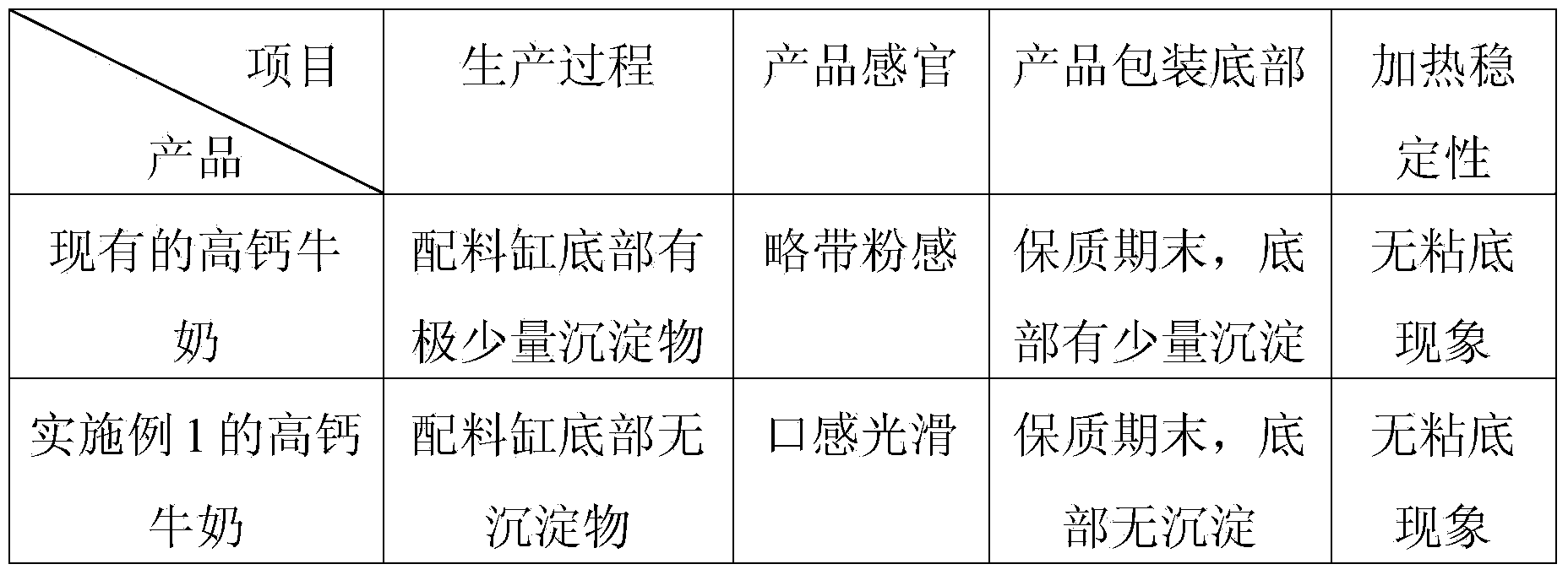

High-calcium milk as well as raw material composition and preparation method thereof

The invention discloses high-calcium milk as well as a raw material composition and a preparation method thereof. The preparation method comprises the following steps of (1) dissolving an annion calcic compound, emulsifying salt and an emulsifier into drinking water so as to obtain a reaction liquid, wherein the temperature of the reaction liquid is 40-55 DEG C; (2) raising the temperature of the milk to be 40-55 DEG C, uniformly adding the reaction liquid prepared in the step (1) into the milk, and stirring for 5-15 minutes; (3) evaporating the moisture, wherein the mass of the moisture is equal to the amount of the drinking water in the step (1); and (4) homogenizing, sterilizing and cooling so as to obtain the high-calcium milk. The high-calcium milk disclosed by the invention is good in stability, free of protein flocculation and free of protein scaling phenomenon after being produced and boiled.

Owner:BRIGHT DAIRY & FOOD

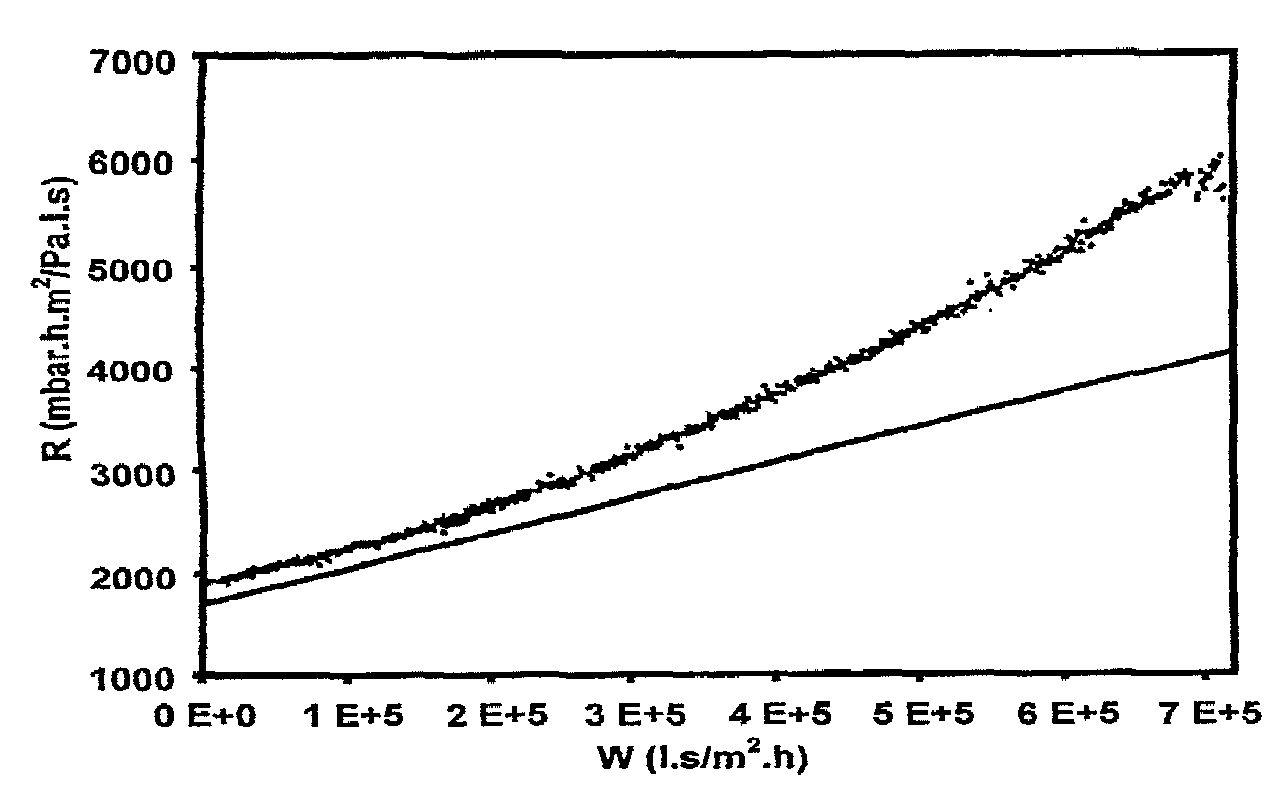

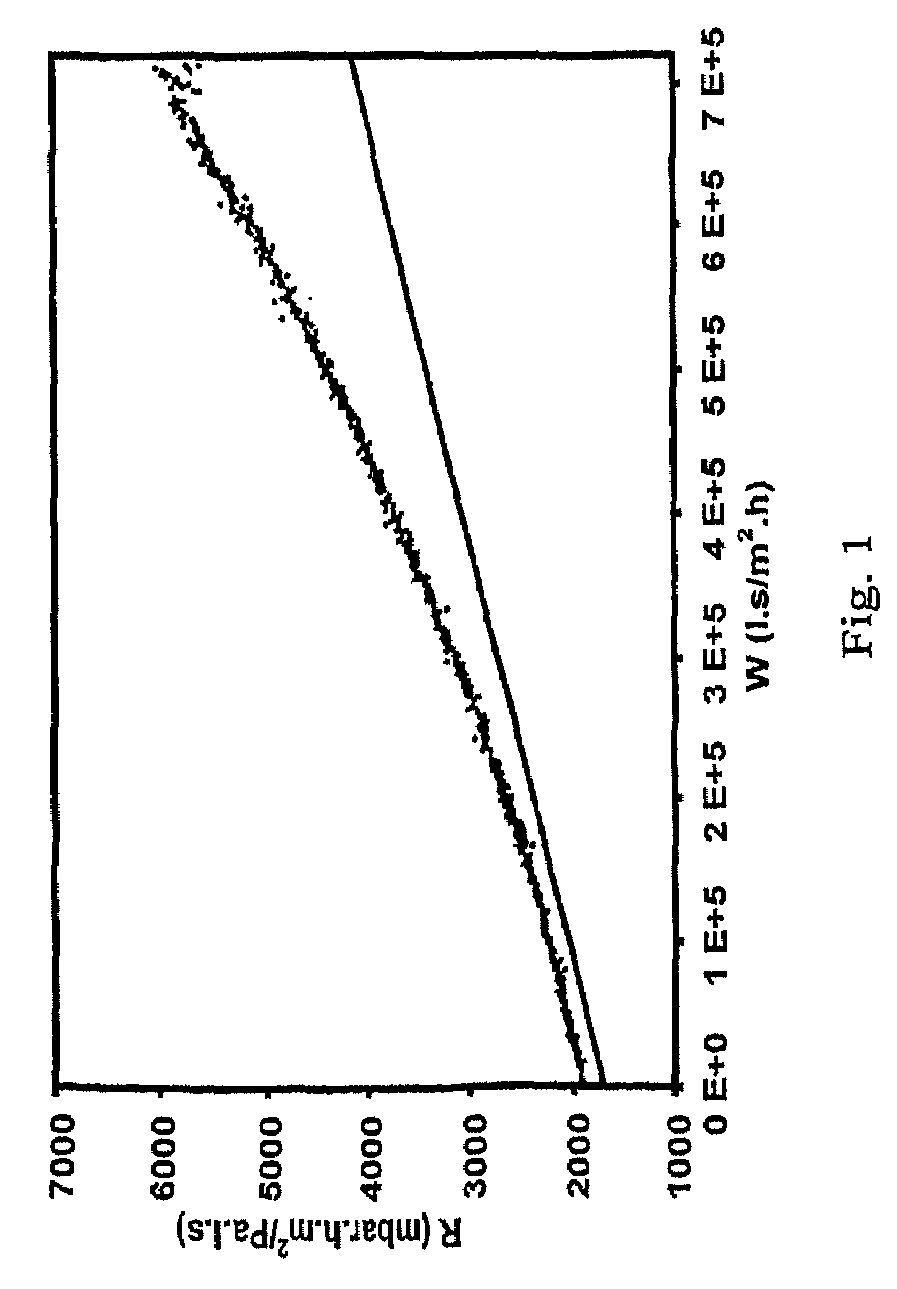

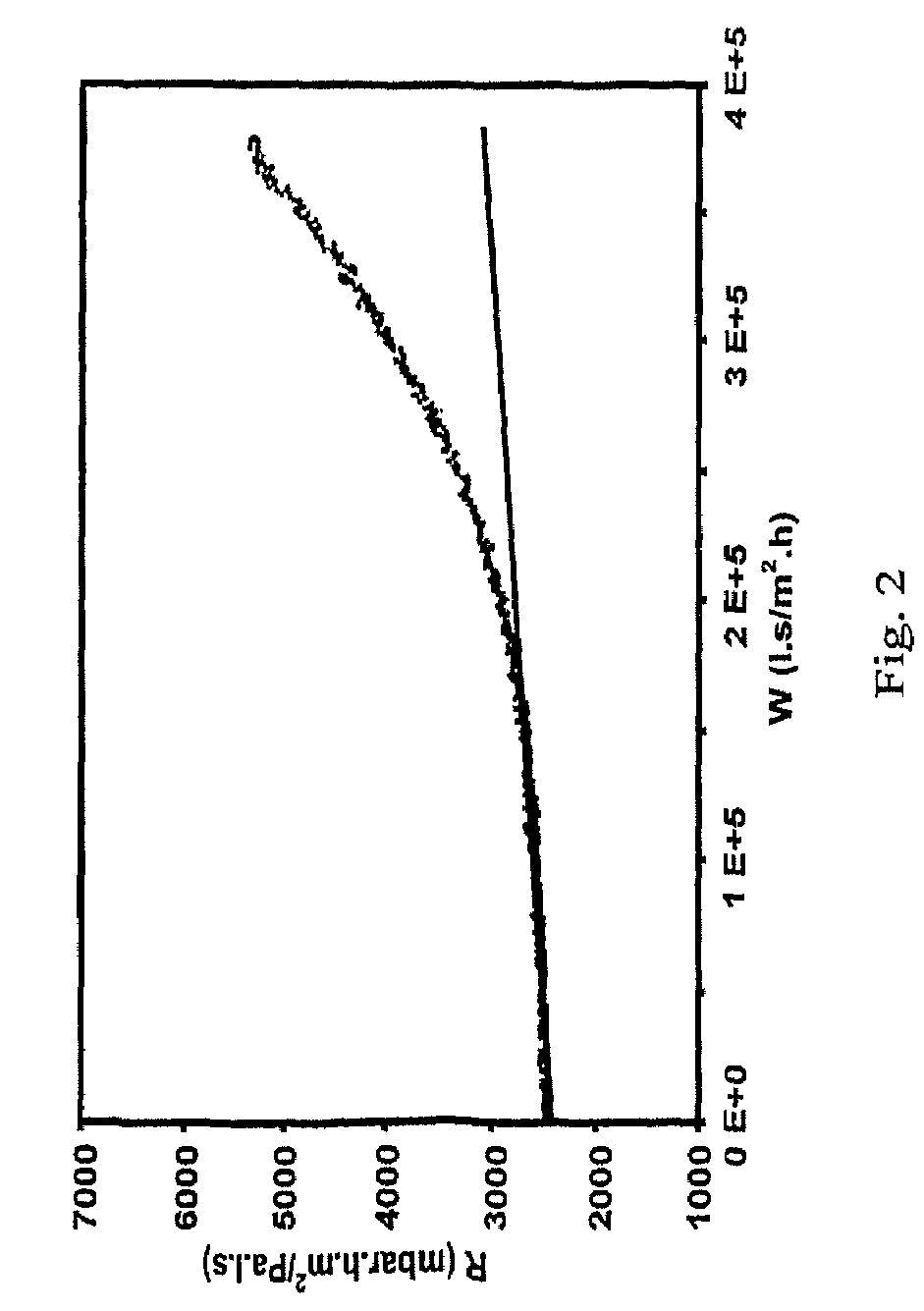

Method for monitoring the degree of fouling of a filter

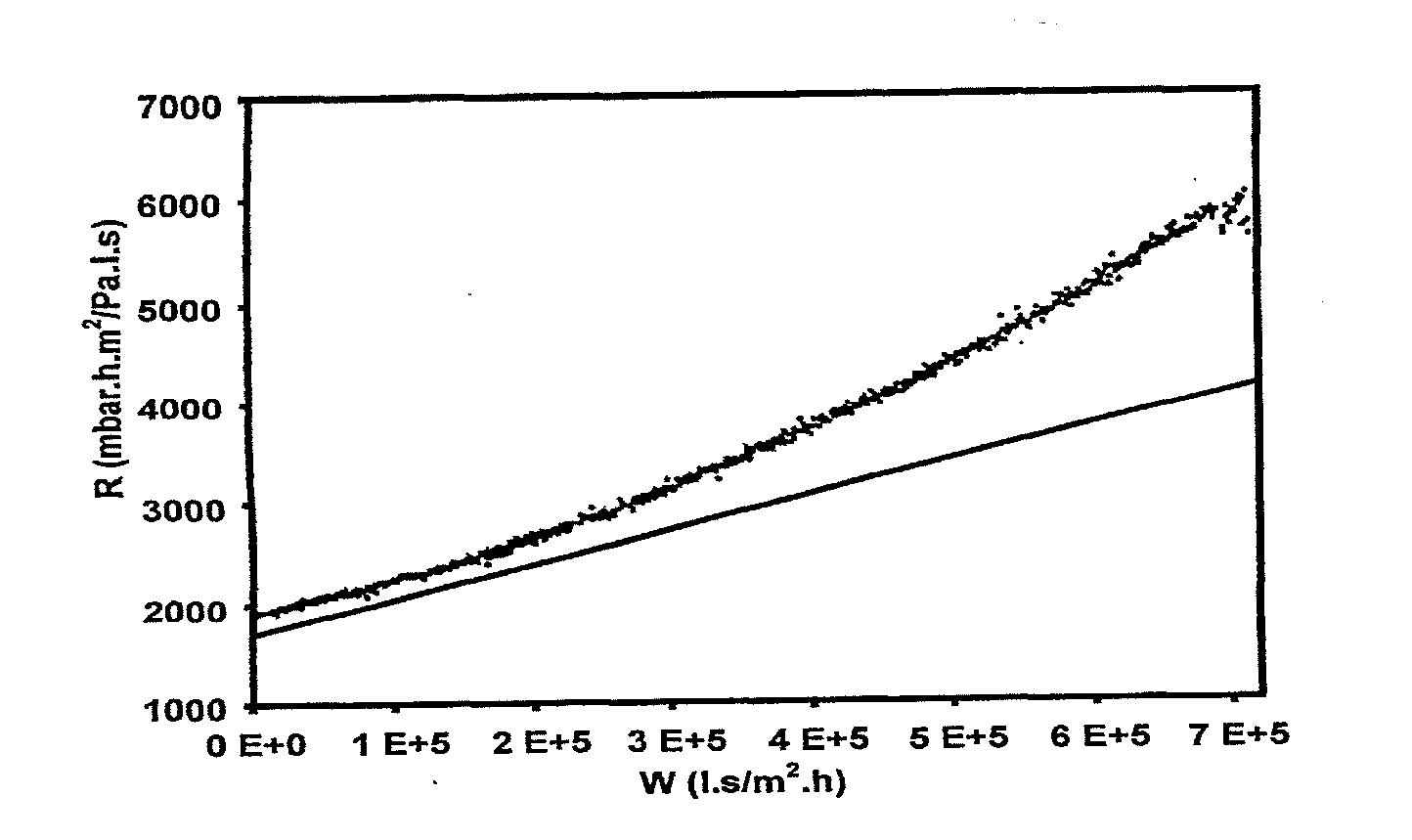

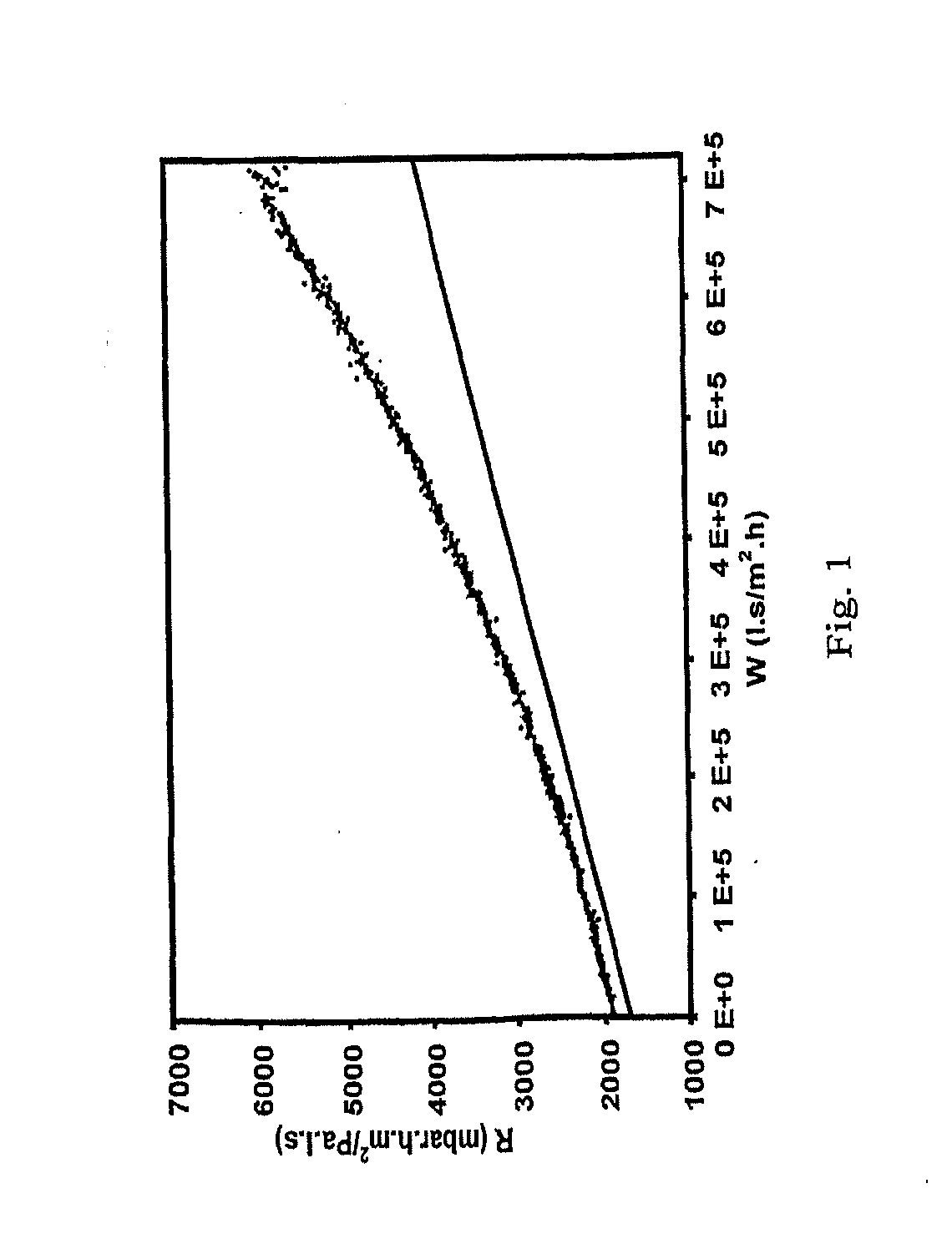

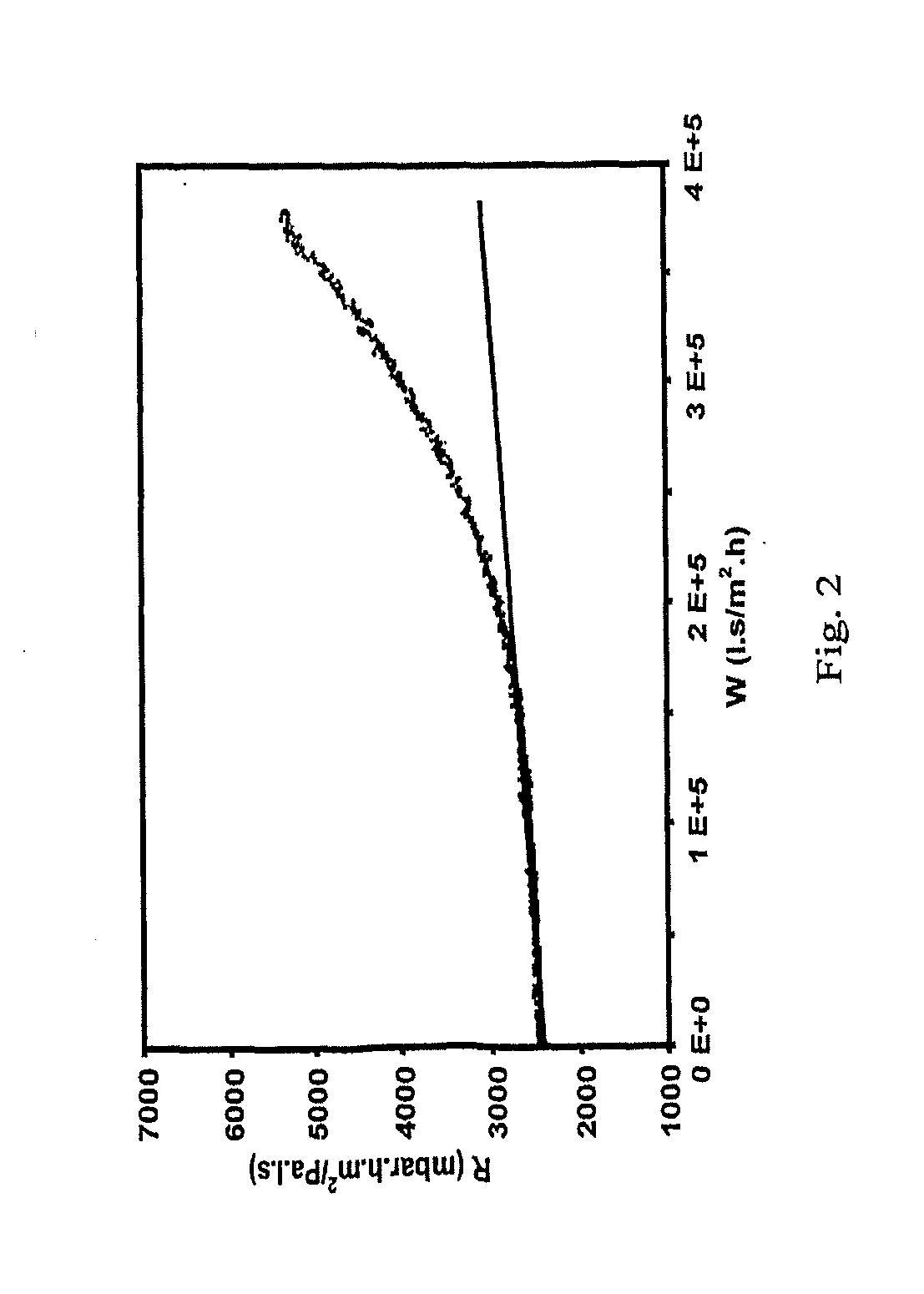

InactiveUS7611634B2Quick changeImprove foulingDispersed particle filtrationDifferential sedimentationEngineeringStreamflow

A method of filtering a fluid wherein after filtering a contaminated fluid, which causes the formation of a filter cake, a substantially non-contaminated fluid is fed through the filter cake and filter at varying flux or at varying driving force. At the same time the necessary driving force or the obtained flux, respectively, are measured. The measured value and the respective value setting are compared with at least one standard set of data and on the basis of this comparison the fouling status of the fluid to be filtered, the filter and the filter cake is determined. The method makes it possible to accurately determine characteristics of a fluid to be filtered. This may be realized by simply varying the flux and measuring the driving force at different flux values, or vice versa.

Owner:NORIT MEMBRAAN TECH

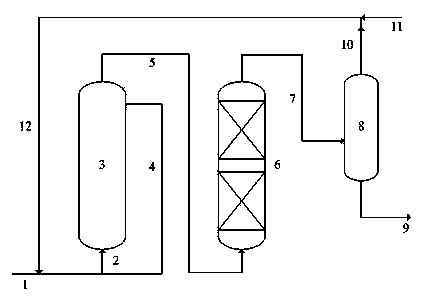

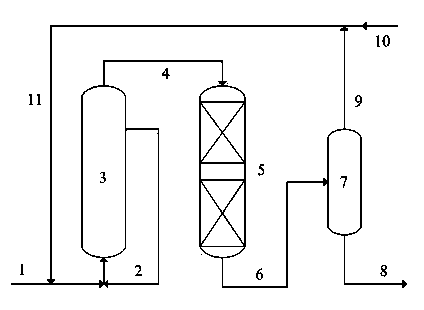

Hydrotreating method of inferior gasoline raw material

ActiveCN103805264AEfficient use ofAvoid abnormal downtimeTreatment with hydrotreatment processesHydrogenFluidized bed

The invention discloses a hydrotreating method of an inferior gasoline raw material. The method comprises the following steps: mixing inferior gasoline with thermal loaded oil and circulating hydrogen, allowing the mixture to enter a fluidized bed hydrogenation pretreatment reactor; separating the effluent of the hydrogenation pretreatment to obtain gas and liquid; returning the liquid as thermal loaded oil to the pretreatment reactor, allowing the gas to pass through a gasoline hydrotreating reactor in an upward flow manner; performing gas-liquid separation of the gasoline hydrogenation effluent in a low temperature low pressure separator, purifying the obtained hydrogen-rich gas for recycle, and performing gas stripping of the obtained liquid so as to be used as a gasoline blending component or a chemical raw material. The method of the invention greatly prolongs the running period of the inferior gasoline hydrotreating device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing ash blocking of rotor of heating surface rotary air preheater

ActiveCN108870432AReduce heat lossReduce cloggingCombustion processIndirect carbon-dioxide mitigationAir preheaterElectrical control

The invention discloses a method for reducing ash blocking of a rotor of a heating surface rotary air preheater. When temperature sensors detect that the lowest temperature of surfaces of heat transfer elements in chambers which are located at one side of a rotor cold end is lower than 100 DEG C, an electric signal is sent to an electrical control system through the temperature sensors, the rotating speed of a rotor driven by a variable-speed motor is improved through the electrical control system, and the rotating speed of the variable-speed motor is kept until the lowest temperature of the cold end of the rotor exceeds 100 DEG C. The invention aims to provide the method for reducing the ash blocking of the rotor of the heating surface rotary air preheater, the ash accumulation and the scale accumulation on the surfaces of the heat transfer elements and the inner walls of the chambers can be reduced or avoided, cleaning of the accumulating ash on the surfaces of the heat transfer elements and the inner walls of the chambers is more convenient, the heat exchange efficiency is high, and the service life is long.

Owner:宁夏华能达环保科技开发有限公司

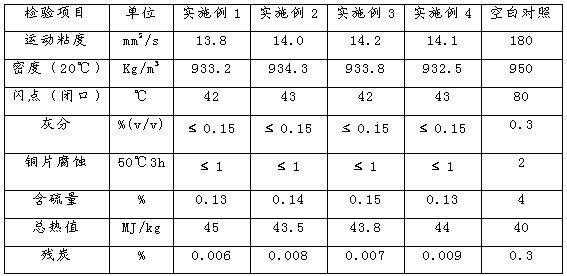

Environment-friendly composite fuel oil additive and preparation method thereof

ActiveCN103627456AInhibition of lysisThe catalytic effect of combustion is remarkableLiquid carbonaceous fuelsEnvironmental chemistryCarbon black

The invention provides an environment-friendly composite fuel oil additive and a preparation method thereof. The environment-friendly composite fuel oil additive comprises 120# solvent oil, calcium sulfonate, isooctyl nitrate, barium naphthanate, ferrocene / manganese complex and sodium diisooctyl sulfosuccinate. The additive solves the problems of high pollutant content and harm to the human body after combustion of heavy oil; and the heavy fuel oil catalytic combustion additive added into the heavy oil can greatly lower the concentration of carbon black in fume, thereby alleviating the environmental problem caused by combustion of heavy oil.

Owner:SHANDONG TAIDE NEW ENERGY

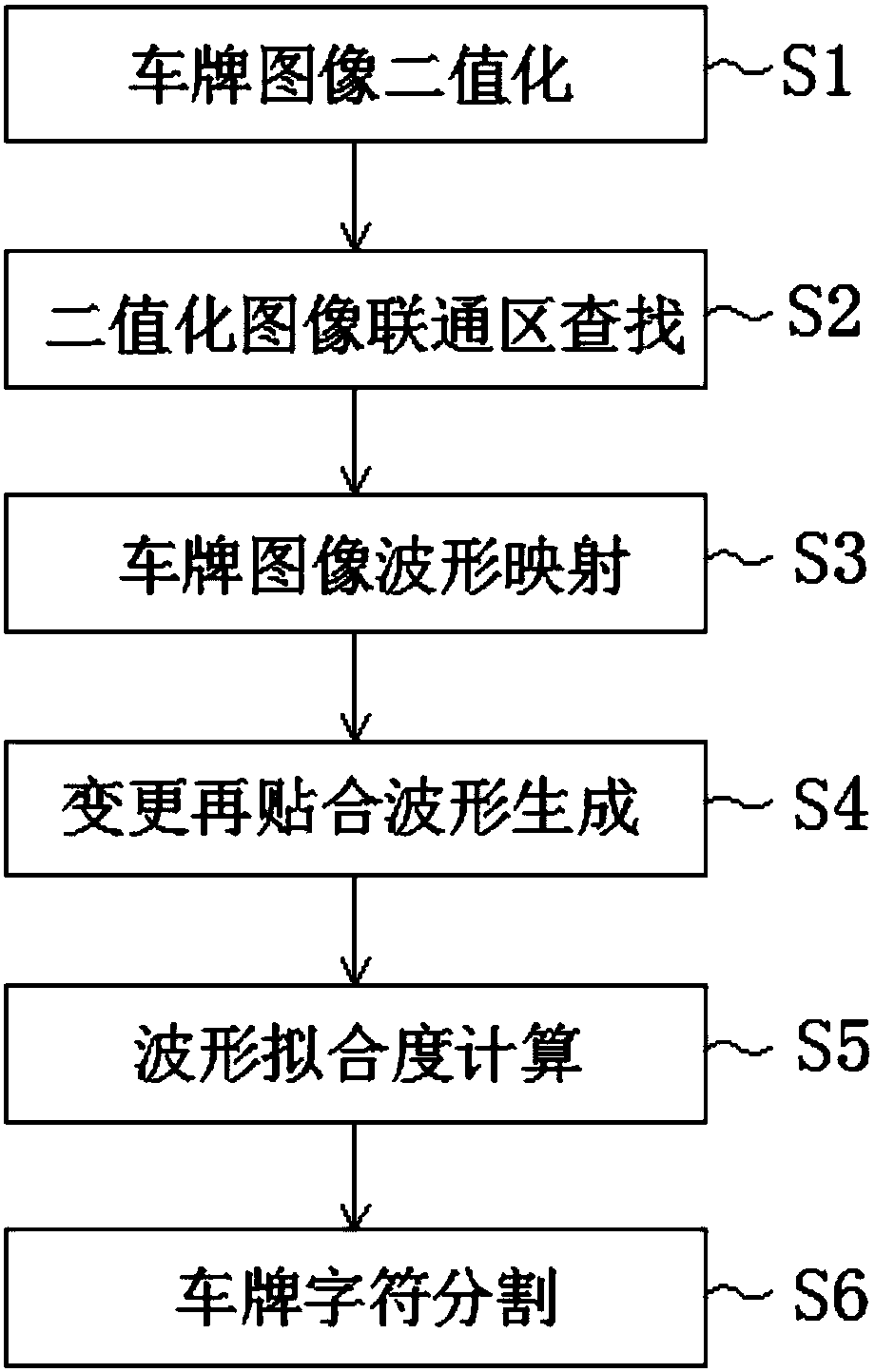

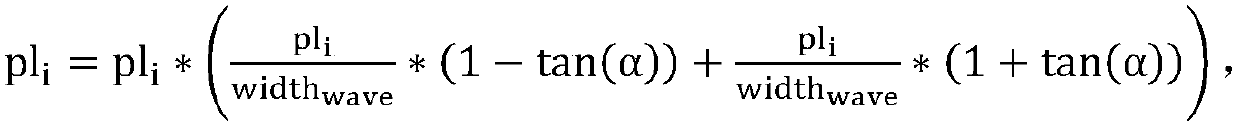

A license plate character segmentation method

ActiveCN109800760AExcellent adhesionImprove foulingCharacter and pattern recognitionPattern recognitionLength wave

The invention relates to the technical field of license plate recognition, in particular to a license plate character segmentation method, which comprises the following steps of S1, binarizing a license plate image; S2, searching a binary image connection region; S3, license plate image waveform mapping; S4, generating a changed re-fitting waveform; S5, calculating a waveform fitting degree; S6, license plate character segmentation. After the method is adopted. The waveform of the given license plate image is fitted by using the prefabricated waves with different amplitudes, wavelengths, phases and rotation; and finding the optimal fitting wave, and segmenting the image through the wave crest position in the wave. Therefore, the segmentation accuracy can be obviously improved when licenseplate character adhesion, stain, inclination, partial bending and license plate integral positioning are inaccurate.

Owner:北京筑梦园科技有限公司

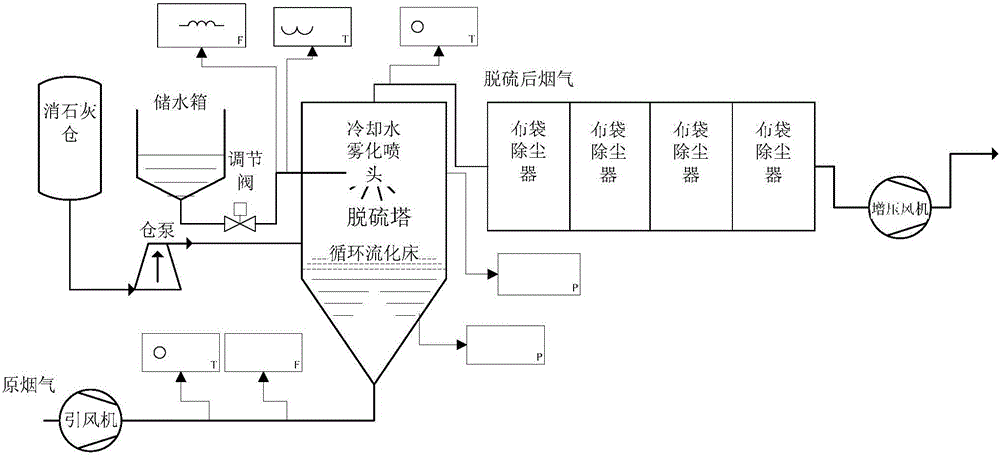

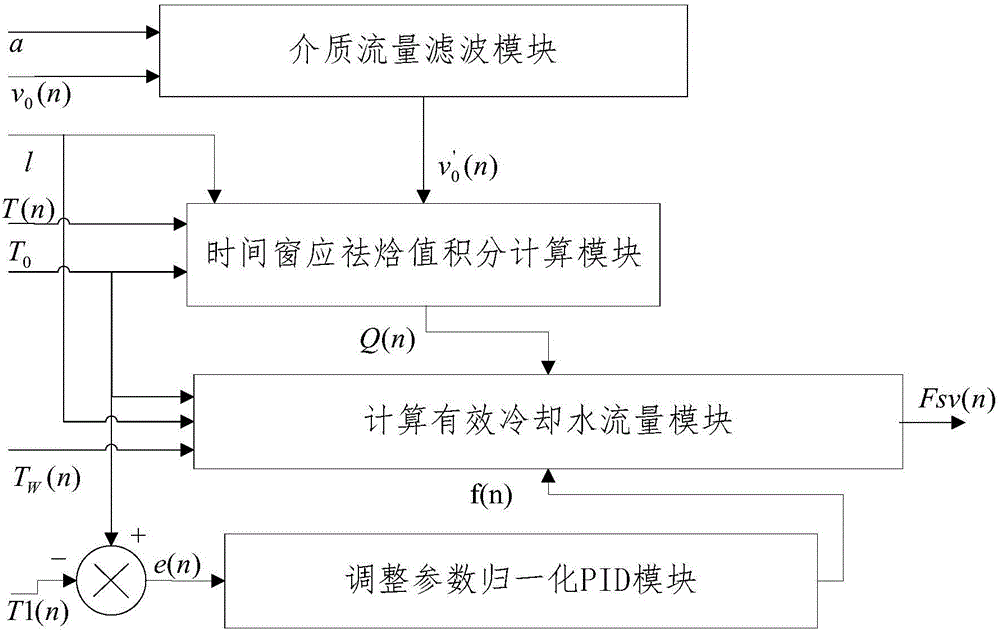

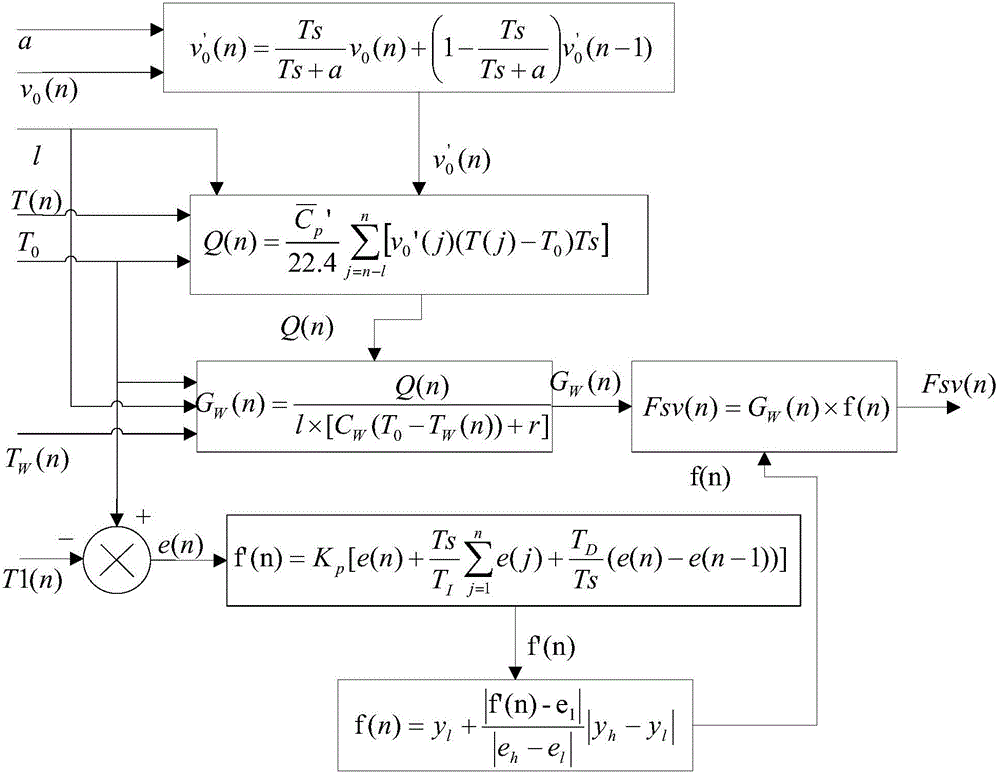

Time-window-enthalpy-value-integral-based smoke cooling control method and system

The invention discloses a time-window-enthalpy-value-integral-based smoke cooling control method and system. The method comprises: obtaining a smoke flow at an entrance of a smoke processing system; calculating an integral value of a smoke removing enthalpy; dividing the integral value by a time window length; establishing a static function relation model between the removing enthalpy value and cooling water flows in unit time in the time window; and controlling the flow of cooling water according to the integral of removing enthalpy needed by the smoke. Therefore, the cooling water flow during the smoke cooling process can be effectively controlled.

Owner:HUATIAN ENG & TECH CORP MCC

Composite fuel oil and preparation method thereof

ActiveCN102676245AHigh calorific valueEasy to transportLiquid carbonaceous fuelsFuel additivesFuel oilSolvent

The invention provides composite fuel oil and a preparation method thereof. The composite fuel oil comprises the following components of heavy oil, solvent oil and an additive, wherein the heavy oil is a substance diluted by a diluent, naturally settled and filtered; and the additive comprises a combustion-supporting agent, an atomizing agent and an anticorrosive agent. The preparation method comprises the following steps of: adding the diluent into the heavy oil; naturally settling and filtering the heavy oil added with the diluent, and removing impurities from the heavy oil; adding the solvent oil and the additive into the heavy oil after the impurities are removed, and stirring to obtain the composite fuel oil. The composite fuel oil provided by the invention has the characteristics of high efficiency, energy conservation, environmental friendliness, safety, no toxicity, no smoke or corrosion, no remained liquid, cleanness, sanitation, easy transportation, easy storage and low price; the oil saving amount can reach more than 15% averately; the composite fuel oil is the preferred fuel for replacing liquefied gas and diesel; when the composite fuel oil is applied in burning of a boiler, the content of components such as CO and SO2 of the flue gas is obviously reduced, and the heat efficiency of the boiler is increased; and the scaling condition in the boiler is obviously improved.

Owner:浙江同凯石油化工有限公司

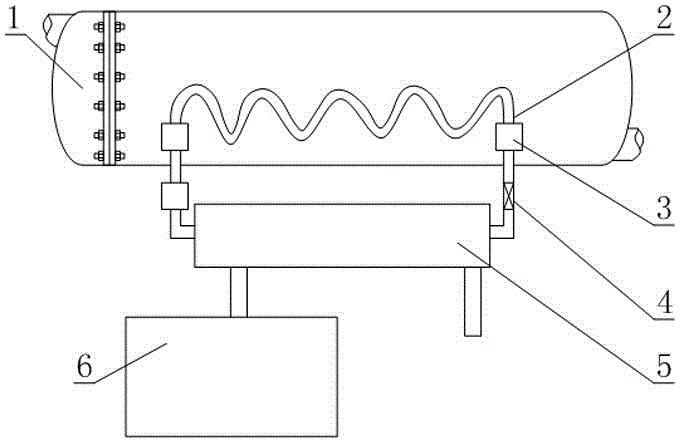

Sterilizing method by substituting the dissolved oxygen in milk or the like with nitrogen gas, a product thereof and an apparatus for nitrogen gas substitution

InactiveUS6637318B2Suppress generationEquipment is smallGrain huskingMilk preparationProduct gasNitrogen gas

An object of the present invention is to reduce the generation of smell by sterilization and to improve the taste in carrying out the sterilization of milk or the like, and the method of the present invention is a method where sterilization is carried out after the dissolved oxygen in milk or the like is substituted with nitrogen gas, and the method is characterized in that a means in which nitrogen gas is directly mixed with and dispersed in milk or the like and a means in which milk or the like with which nitrogen gas is not mixed is sprayed from a nozzle(s) to the top of milk or the like, with and in which nitrogen gas has been mixed and dispersed, stored in a nitrogen gas substituting tank under a nitrogen gas atmosphere, are jointly used whereby the dissolved oxygen amount in the milk or the like is reduced by means of substitution of the dissolved oxygen with nitrogen gas, followed by subjecting to sterilization.

Owner:MEIJI CO LTD

compound fuel oil

ActiveCN102676245BHigh calorific valueEasy to transportLiquid carbonaceous fuelsFuel additivesFuel oilSolvent

The invention provides composite fuel oil and a preparation method thereof. The composite fuel oil comprises the following components of heavy oil, solvent oil and an additive, wherein the heavy oil is a substance diluted by a diluent, naturally settled and filtered; and the additive comprises a combustion-supporting agent, an atomizing agent and an anticorrosive agent. The preparation method comprises the following steps of: adding the diluent into the heavy oil; naturally settling and filtering the heavy oil added with the diluent, and removing impurities from the heavy oil; adding the solvent oil and the additive into the heavy oil after the impurities are removed, and stirring to obtain the composite fuel oil. The composite fuel oil provided by the invention has the characteristics of high efficiency, energy conservation, environmental friendliness, safety, no toxicity, no smoke or corrosion, no remained liquid, cleanness, sanitation, easy transportation, easy storage and low price; the oil saving amount can reach more than 15% averately; the composite fuel oil is the preferred fuel for replacing liquefied gas and diesel; when the composite fuel oil is applied in burning of a boiler, the content of components such as CO and SO2 of the flue gas is obviously reduced, and the heat efficiency of the boiler is increased; and the scaling condition in the boiler is obviously improved.

Owner:浙江同凯石油化工有限公司

Device using smoke for heating

InactiveCN106196608AGuaranteed heat transfer efficiencyImprove foulingStorage heatersCombustionFuel tank

The invention discloses a device using smoke for heating. The device using smoke for heating comprises a hot water tank, a combustion stove and a smoke pipe used for smoke discharging of the combustion stove. The device using smoke for heating further comprises a conduction oil pipe used for containing conduction oil. The conduction oil pipe is an annular pipeline and passes through the hot water tank and the smoke pipe. The conduction oil pipe is connected with the wall surface of the hot water tank through nuts. The device using smoke for heating further comprises a circulating pump used for driving the conduction oil in the conduction oil pipe to flow circularly. The device using smoke for heating further comprises an oil storage tank connected with the conduction oil pipe through a pipeline. By the adoption of the device, the problem that when straw is used as a heat source to heat water, the heated surface of water is prone to scaling can be solved; and meanwhile, the device is long in service life and high in heat transfer efficiency.

Owner:成都沸鼎环保设备有限公司

Method for delaying calcium sulfate scaling in pretreatment and hardness removal processes of desulfurization wastewater

PendingCN114772793AReduce dosageIncrease profitWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSodium acid carbonateChemistry

The embodiment of the invention provides a method for delaying calcium sulfate scaling in pretreatment and hardness removal processes of desulfurization wastewater, and relates to the field of wastewater treatment. The method comprises the steps that the high-COD and high-salt flue gas washing desulfurization wastewater is subjected to neutralization magnesium removal treatment to obtain a neutralization solution, the pH value of the neutralization solution is larger than or equal to 11, and lime milk is contained in the neutralization solution; adding quantitative sodium carbonate into the neutralization solution for pre-softening treatment until 1g / L to 2g / L of calcium ions are precipitated, so as to obtain a pre-softened treatment solution; carrying out primary solid-liquid separation on the pre-softening treatment liquid to obtain a separation liquid; sodium carbonate is added into the separation liquid for softening treatment, and softening treatment liquid is obtained; and carrying out flocculation treatment and secondary solid-liquid separation on the softening treatment liquid. After the method provided by the invention is used, the calcium sulfate scaling condition of a plate-and-frame filter press or filter cloth for carrying out first-time solid-liquid separation is well improved, and the calcium sulfate scaling condition is effectively delayed.

Owner:ZHAOQING FEINAN METAL

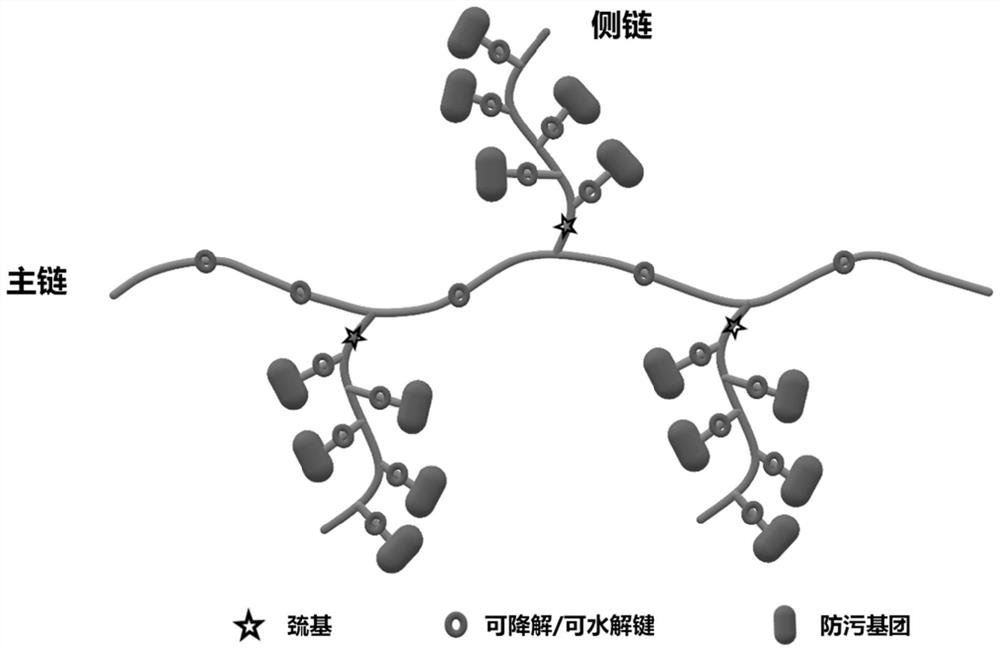

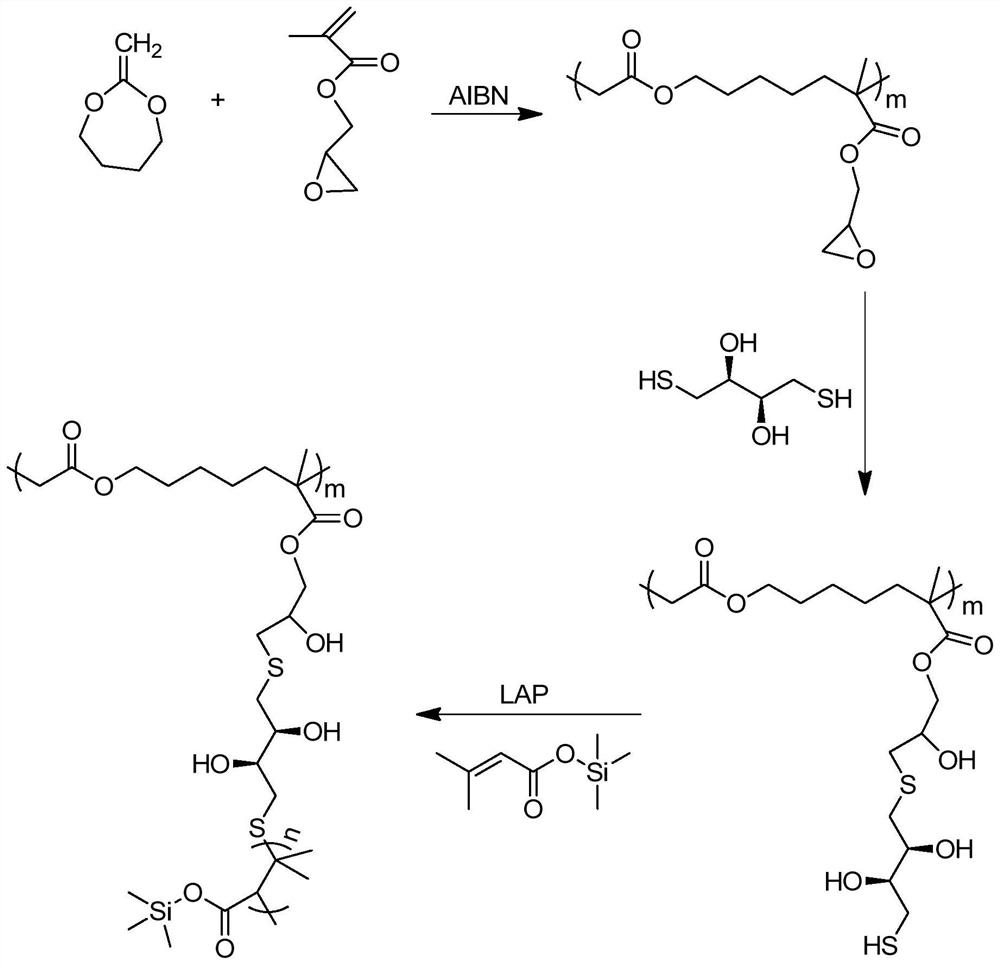

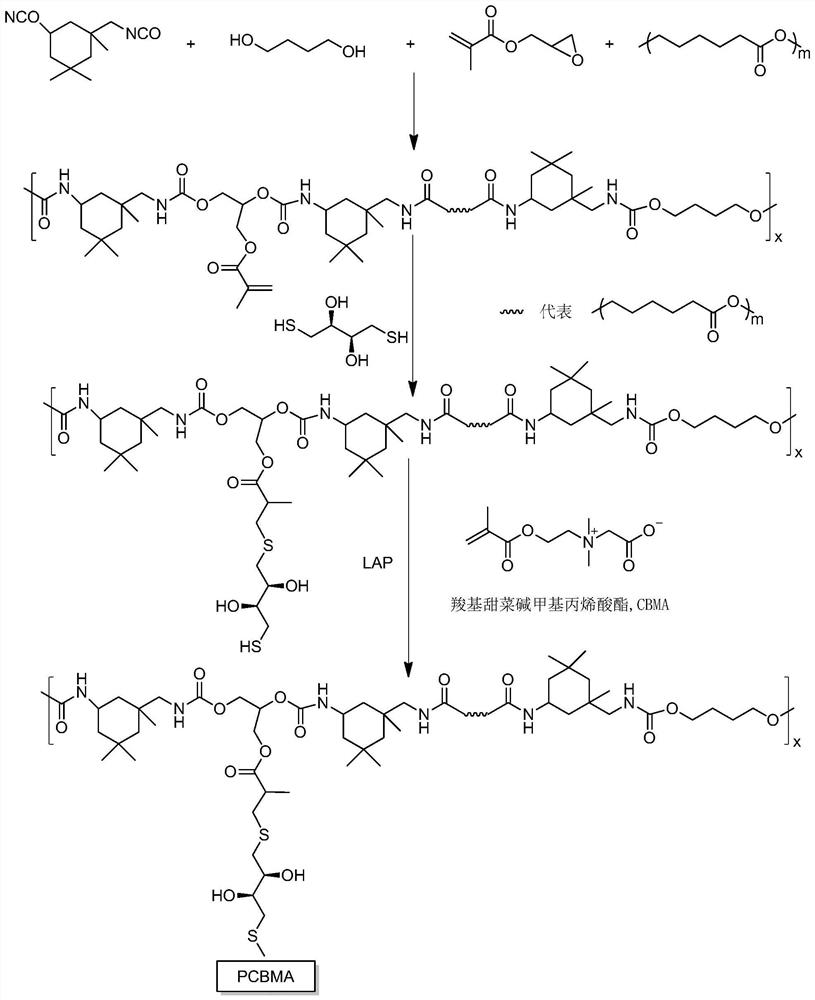

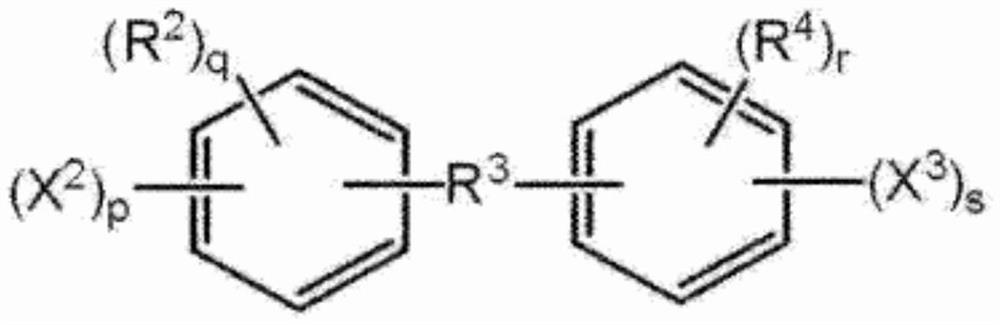

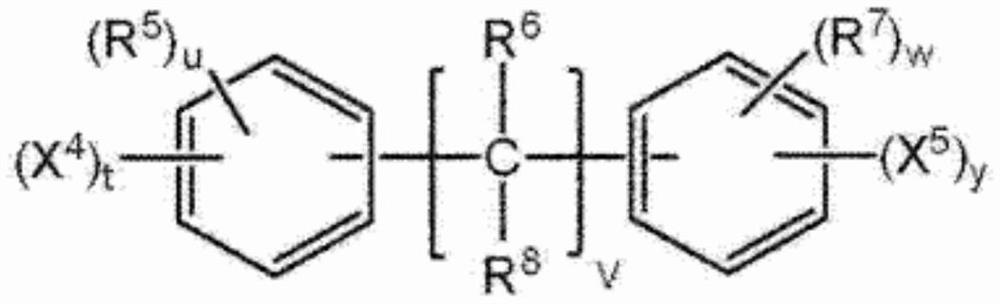

Degradable polymer as well as preparation method and application thereof

ActiveCN114702627ASimple structureSimple manufacturing methodAntifouling/underwater paintsPaints with biocidesPolymer scienceFunctional monomer

The invention discloses a degradable polymer as well as a preparation method and application thereof. The degradable polymer is simple in structure, the side chain of the degradable polymer contains a large number of antifouling functional groups, and the number of the antifouling functional groups can be adjusted through the polymerization degree of the antifouling functional monomer; meanwhile, continuous and stable release of antifouling functional groups can be realized through degradable bonds. The preparation method of the degradable polymer is simple, efficient and easy to realize, has strong universality and practicability, and can realize industrial production. The coating prepared from the degradable polymer has excellent water fouling prevention and treatment effects and antibacterial effects, and does not need to be compounded with an antifouling agent, and the degradable polymer and the prepared coating can be widely applied to the field of water fouling prevention and treatment.

Owner:GUANGDONG ZHANJIANG PROVINCIAL LAB OF SOUTHERN MARINE SCI & ENG

Anti-coking agent for distillation of benzaldehyde

The invention provides an anti-coking agent for distillation of benzaldehyde, which is composed of following raw materials, by weight: 3-5% of pyridine, 15-20% of imidazole, 5-10% of thiazole, 15-30% of quinoline, 10-20% of furan and the balanced being pryimidine. The anti-coking agent is added into a benzaldehyde distillation still during a purification and rectification process of the benzaldehyde with addition concentration being not more than 100 ppm. The anti-coking agent can effectively prevent a coking problem during the distillation of the benzaldehyde. During the purification and rectification process of the benzaldehyde, by-products generated in distillation can be reduced and polymerization of the benzaldehyde at the bottom of the distillation still can be inhibited, thereby improving scaling problem in the distillation still, preventing generation of coking products and improving the yield of benzaldehyde by about 20%.

Owner:武汉工商学院

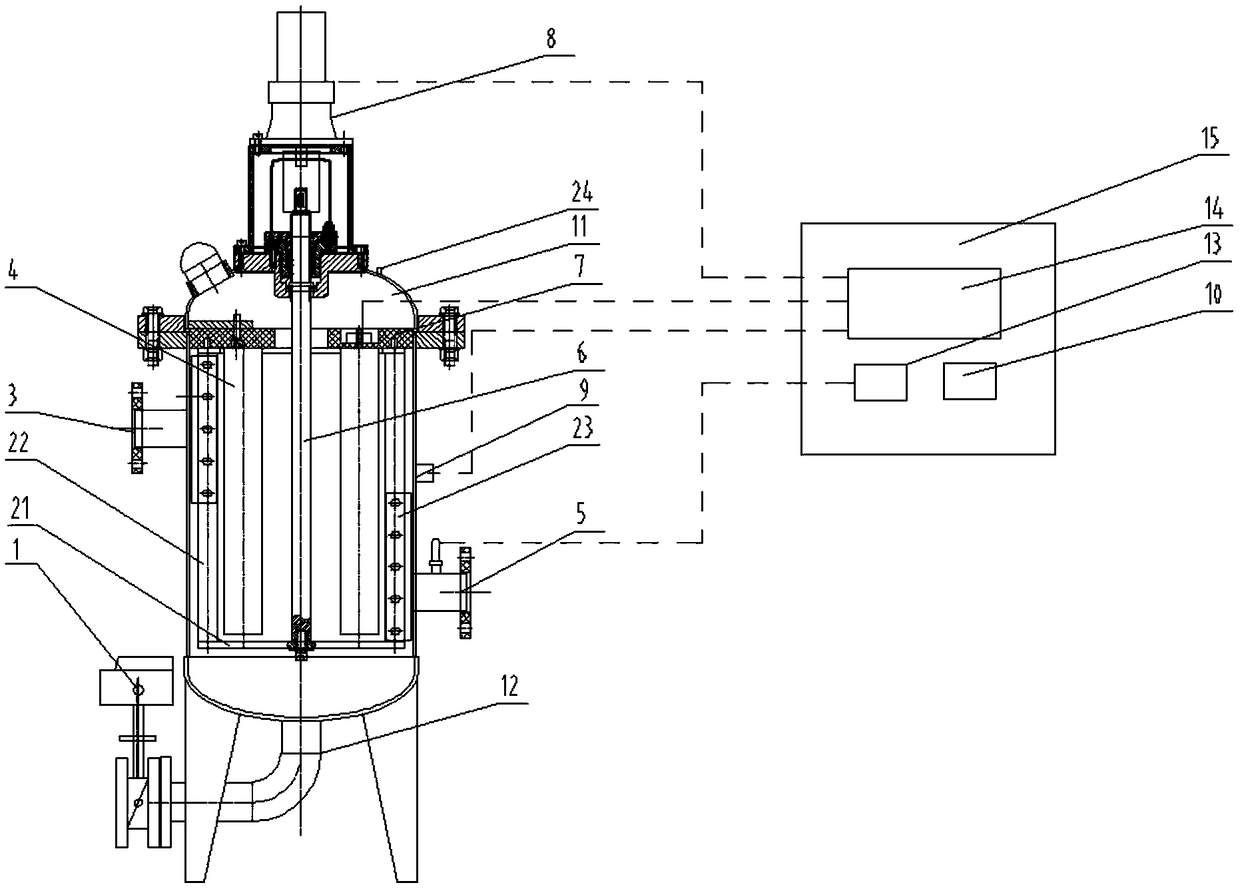

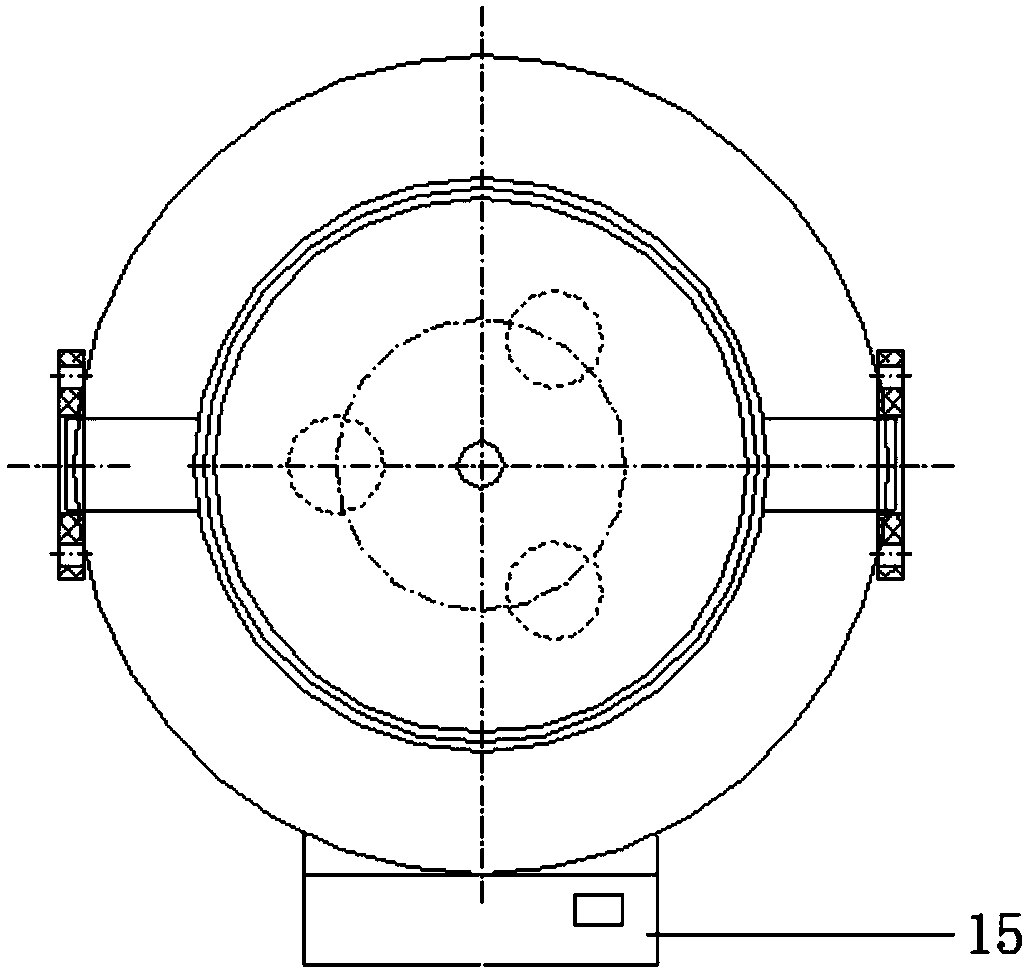

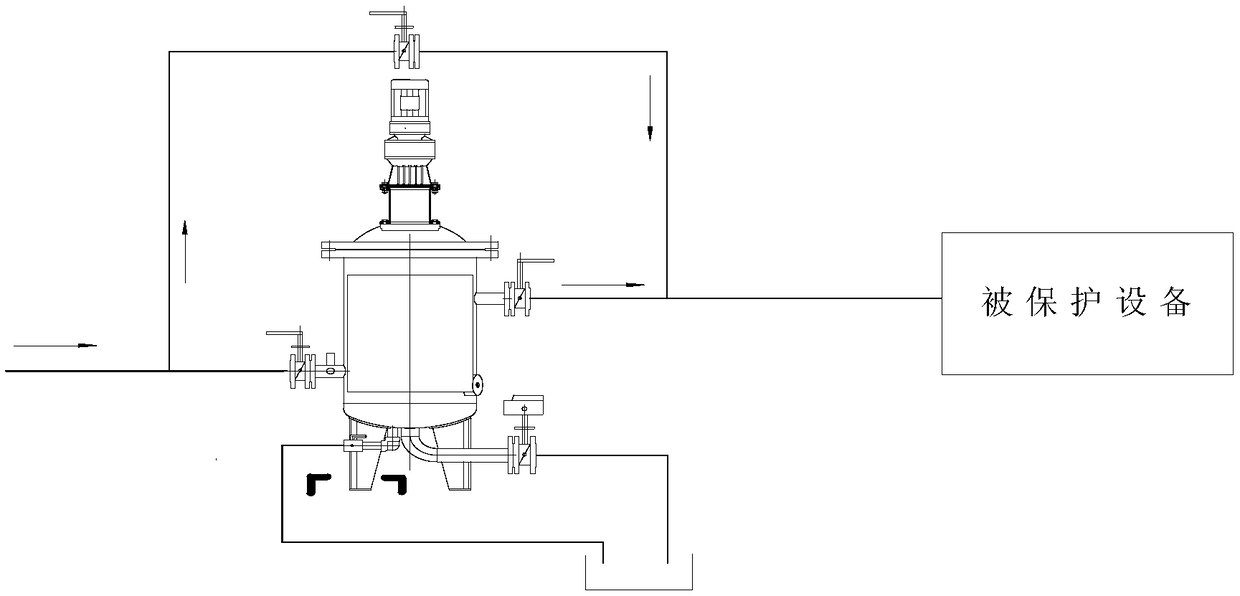

Pressure-bearing type intelligent scale analysis device

The invention discloses a pressure-bearing type intelligent scale analysis device which comprises a metallic scale analysis device main body, a titanium alloy anode, a water inlet, a water outlet, a scale cleaning mechanism, a draining port, a current detector, a PH online monitor, a processor and an electrolysis power supply control cabinet. The scale analysis device is arranged on the front endof a protected device; the PH online monitor is used for monitoring a PH value of water flowing in a chamber of the scale analysis device main body in real time at the water inlet and sending the PH value to the processor; after overproof water quality is detected by the processor, the scale cleaning mechanism is controlled to clean the scales around the cathode and the sewage is drained from thedraining port; the current detector is used for monitoring the current at the joint of the scale analysis device main body and the cathode in real time and sending the current to the processor; if thecurrent change reaches or exceeds a preset safety value, the scale analysis device is controlled by the electrolysis power supply control cabinet to cut off power. The pressure-bearing type intelligent scale analysis device is capable of realizing automatic scale cleaning and automatic scale discharging, is endowed with a scale absorbing capacity and is capable of reducing the later maintenance cost of the device.

Owner:BEIJING JIEYUTONG ENVIRONMENTAL PROTECTION SCI & TECH

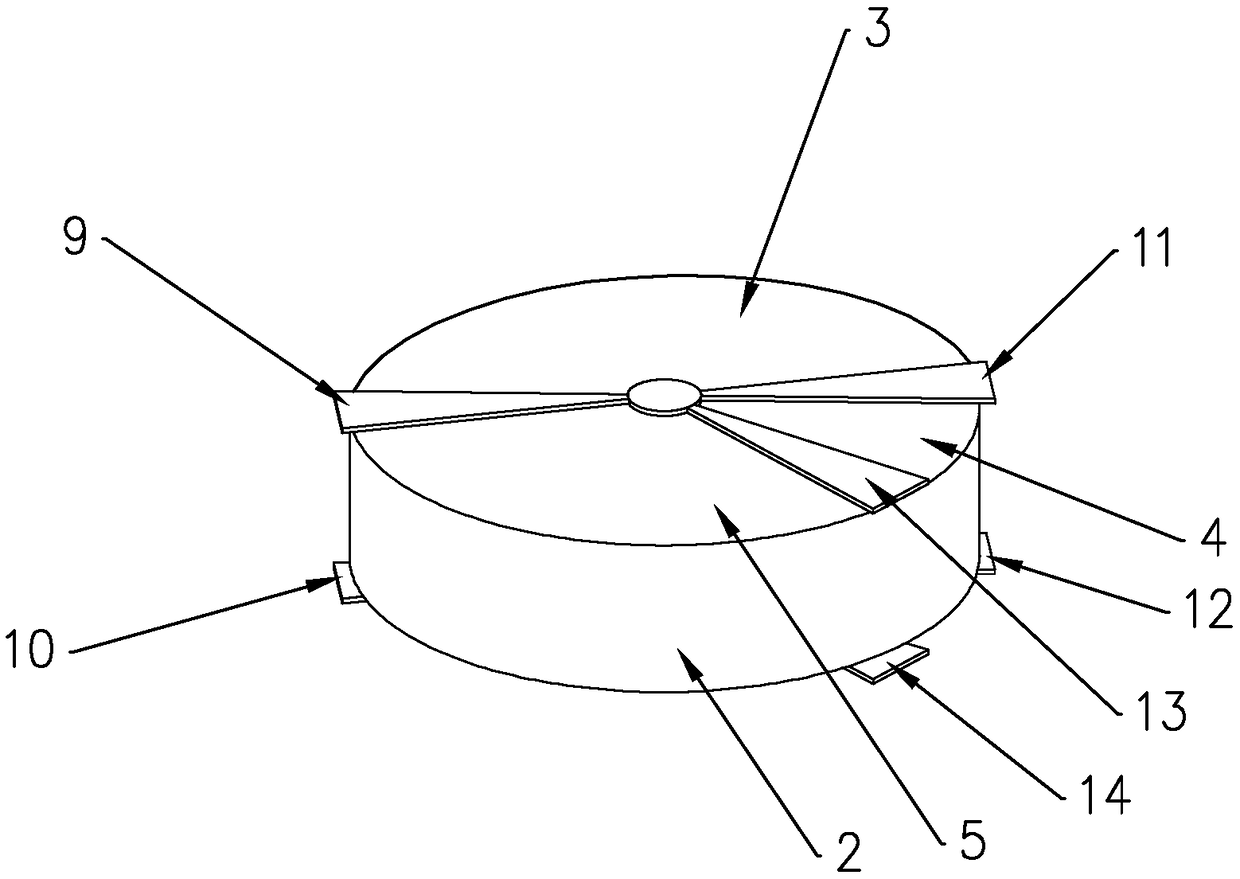

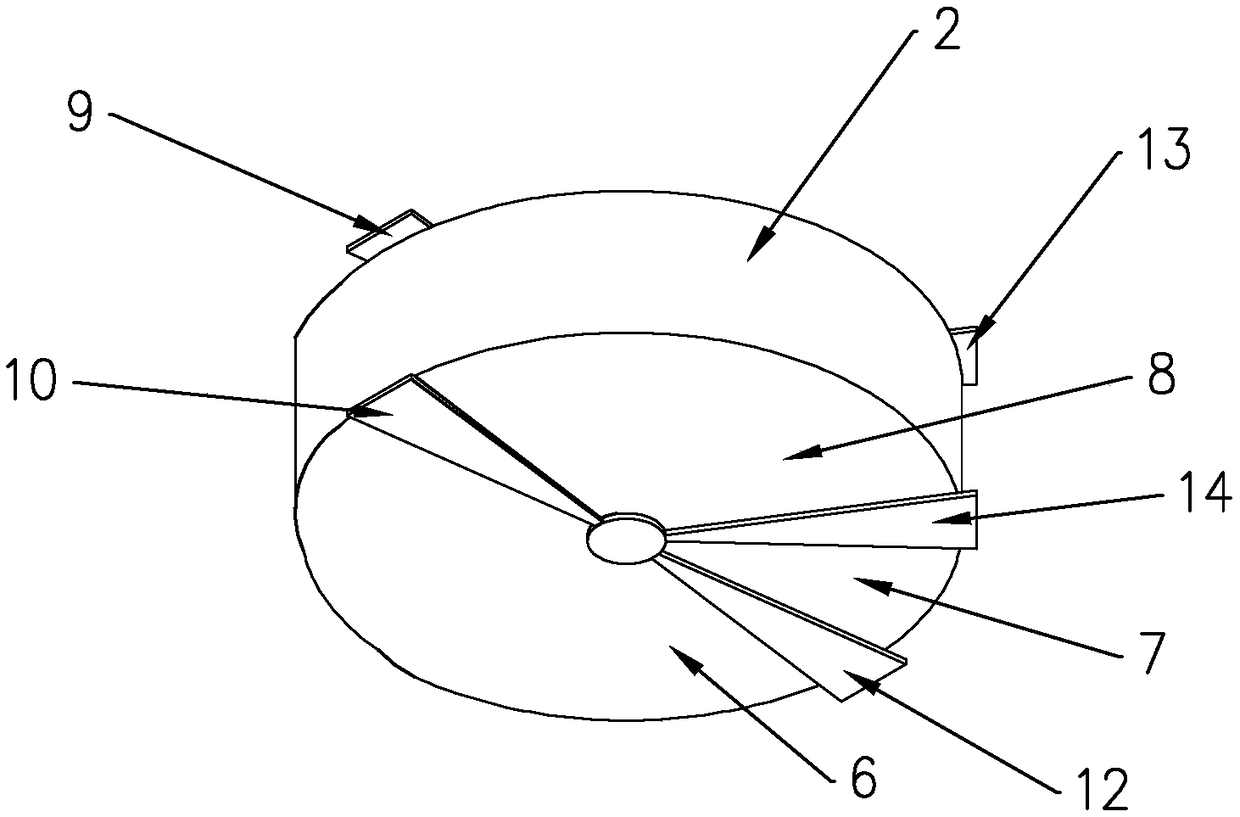

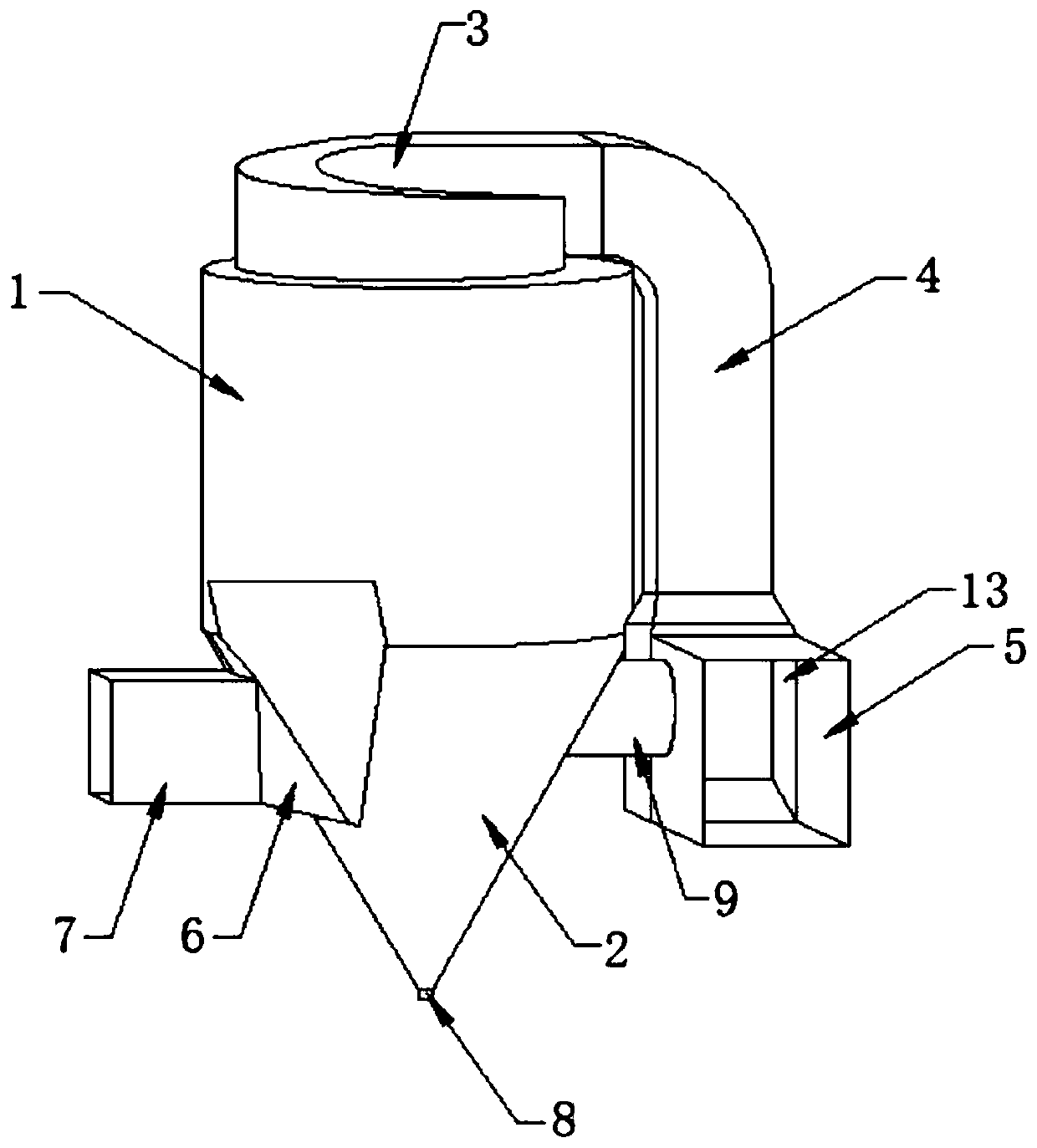

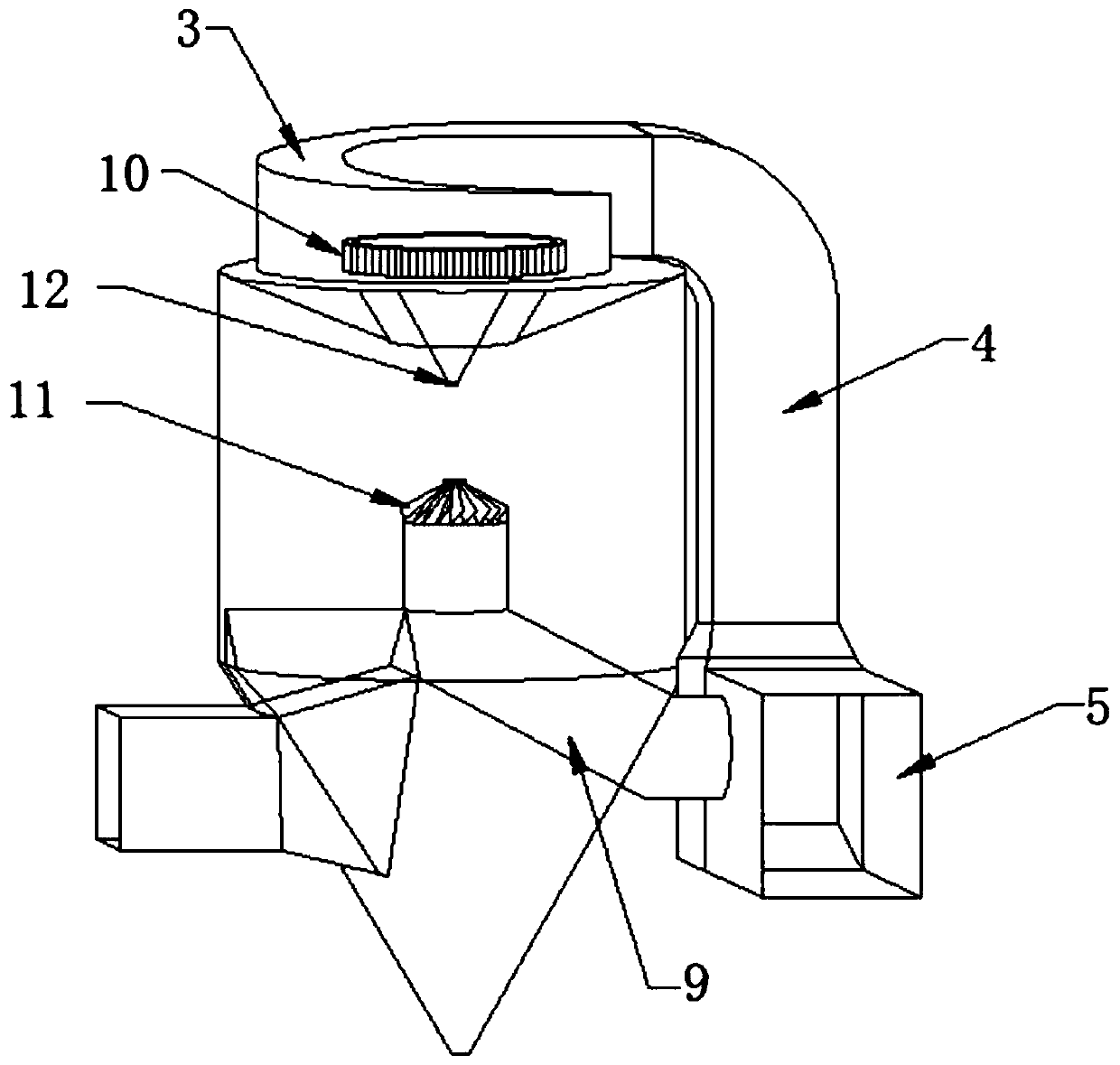

Annular inlet blade of SDA desulfurization column

InactiveCN110124502AChanging the smoke flow fieldImprove foulingGas treatmentDispersed particle separationEngineeringFlue gas

The invention discloses an annular inlet blade of an SDA desulfurization column. The SDA desulfurizing column comprises a desulfurizing column main body. A gas inlet pipe is arranged at the top end ofthe desulfurizing column body. A plurality of air inlet blades are installed in the air inlet pipe, the bottoms of the air inlet blades are in a conical funnel shape, and the total number of the airinlet blades is 120. Each blade has a folding structure with an included angle of 135 degrees; an atomizing wheel is mounted at the bottoms of the air inlet blades; a flue gas distributor is mounted at the bottom of the atomizing wheel; a conical column is arranged at the bottom end of the desulfurizing column main body. The annular gas inlet blades change the speed and pressure of the original flue gas entering the desulfurizing column, so that the flue gas flow field is changed, and the problem of scaling of a product is improved. By arranging the baffle and the flue structure, the flue gasdistribution ratio of the upper flue and the lower flue is adjusted, and the desulfurization reaction is more sufficient.

Owner:WUHAN UNIV OF SCI & TECH

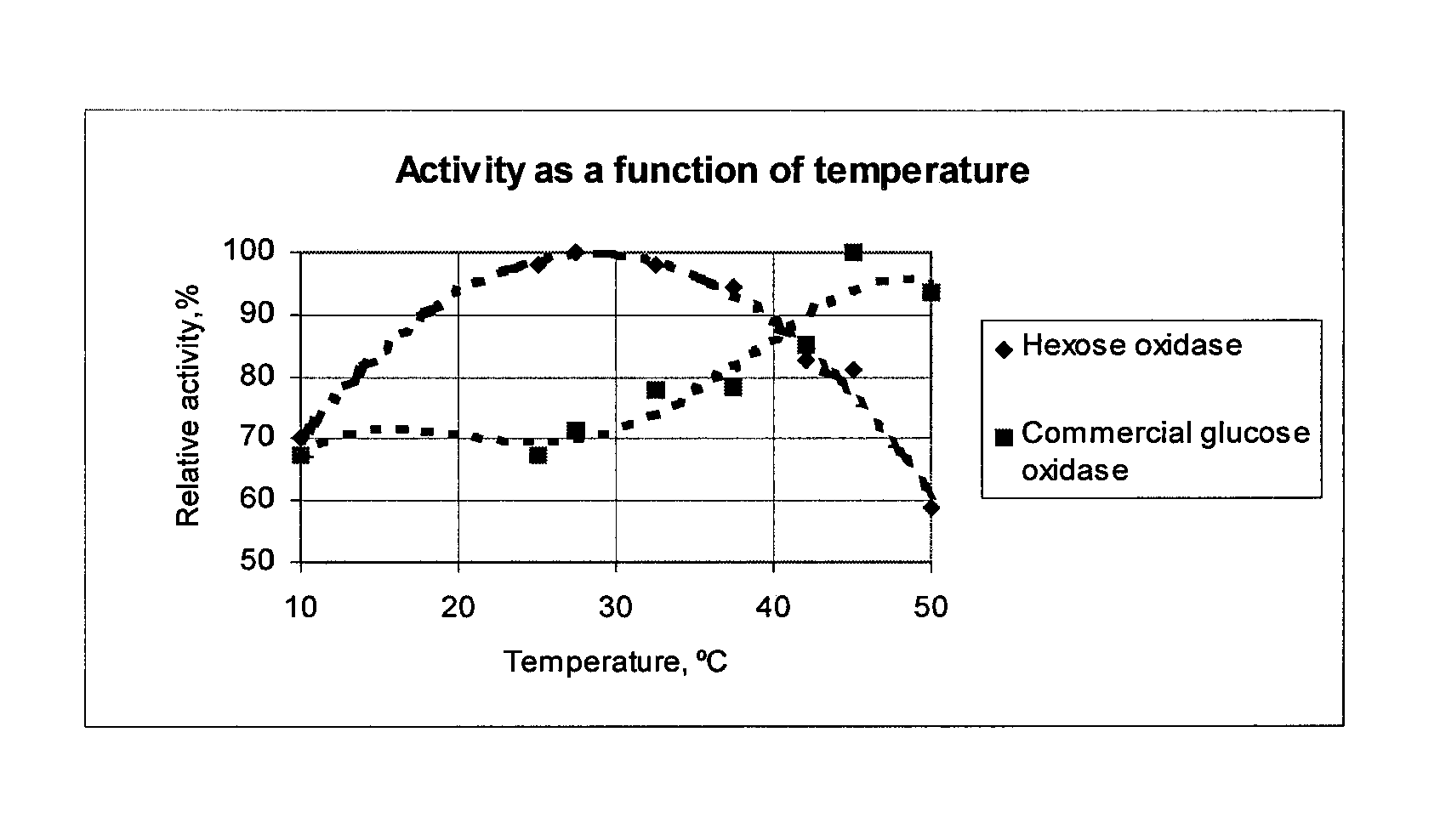

Composition

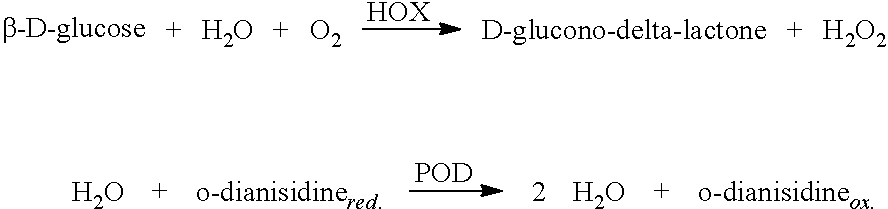

InactiveUS20130224820A1High affinityIncrease valueBiocideAntifouling/underwater paintsEnzymeSurface coating

There is provided an anti-fouling composition comprising (i) a surface coating material; (ii) an enzyme obtained or obtainable from a marine organism; and (iii)(a) a substrate for the enzyme; and / or (b) a precursor enzyme and a precursor substrate, wherein the precursor enzyme and the precursor substrate are selected such that a substrate for the enzyme is generatable by action of the precursor enzyme on the precursor substrate; wherein the enzyme and the substrate are selected such that an anti-foulant compound is generatable by action of the enzyme on the substrate.

Owner:AS DE DANSKE SUKKERFABRIKKER

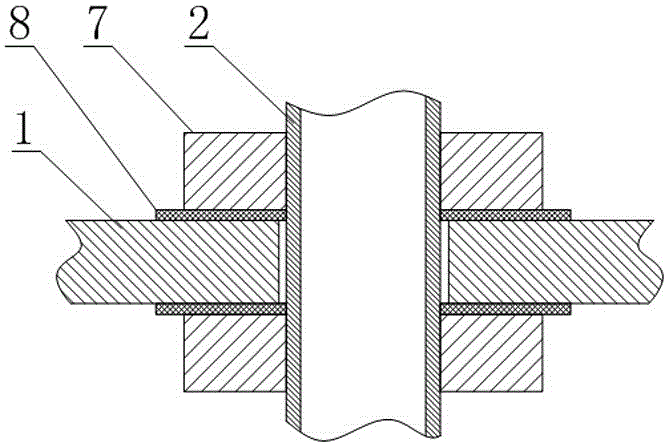

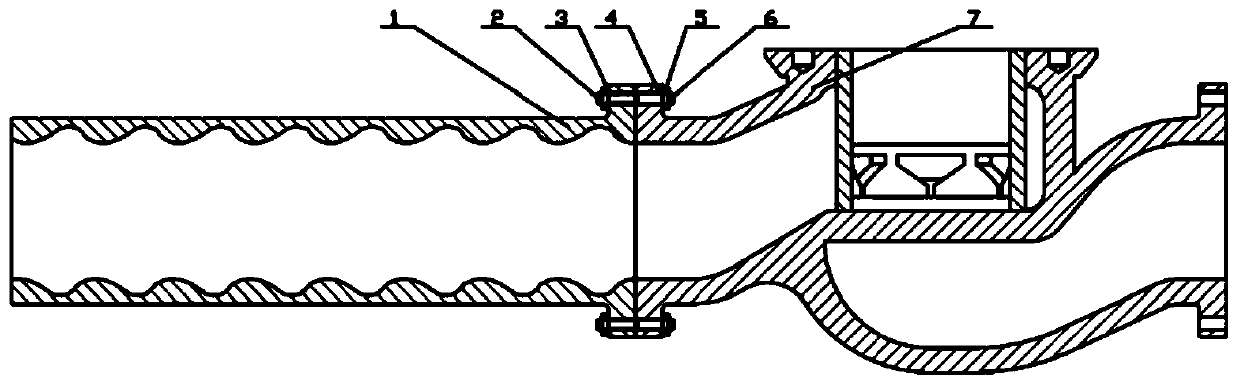

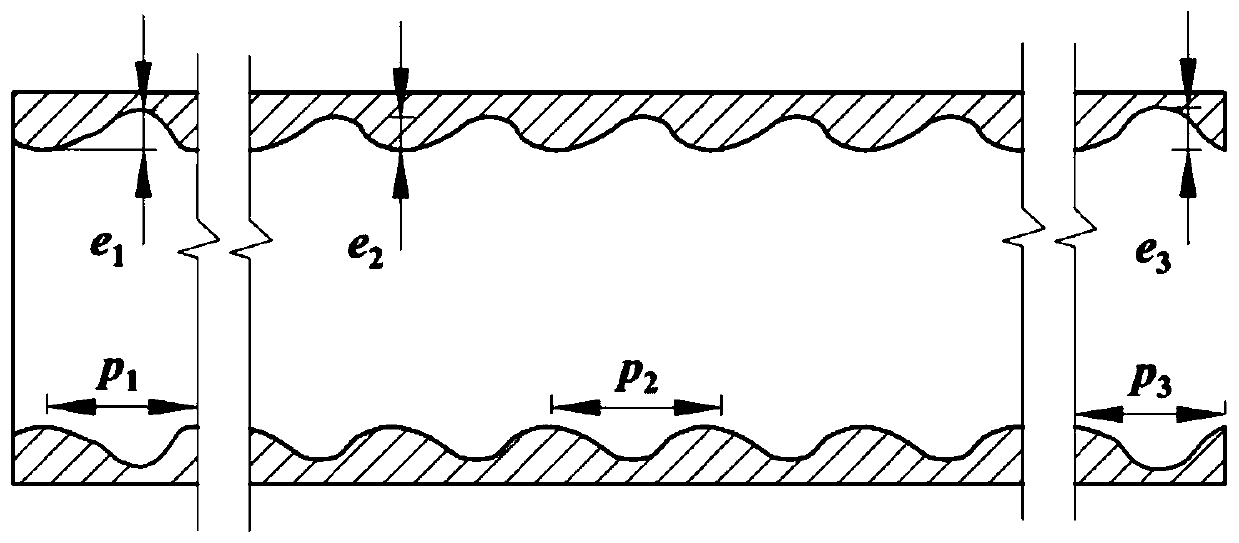

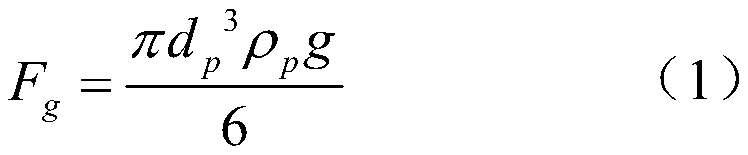

Internal thread pipe for improving anti-scaling performance of valve and design optimization method

The invention discloses an internal thread pipe for improving the anti-scaling performance of a valve and a design optimization method. The internal thread pipe is composed of an inlet strengthening section, an outlet buffering section and a normal flowing section, and the lengths and the shapes of the three sections are different. The length of the inlet strengthening section is 150mm, the pitchratio p1 / D is 2.02, and the groove depth ratio e1 / D is 0.07; the length of the outlet buffer section is 100mm, the pitch ratio p3 / D is equal to 2.43, and the groove depth ratio e3 / D is equal to 0.09;the pitch ratio p2 / D of the normal flow section is equal to 1.82, and the groove depth ratio e2 / D is equal to 0.06. After a solid-liquid mixed phase passes through the internal threaded pipe, most solid particles are thrown to the pipe wall of the internal threaded pipe under the action of centrifugal force, and fluid continuously flows into the valve, so that the dirt resistance of the valve is improved.

Owner:ZHEJIANG UNIV

Marine organism fouling prevention method of active-service underwater structure for marine facility

ActiveCN111364428AGood effectEasy constructionArtificial islandsAntifouling/underwater paintsMarine engineeringUnderwater

The invention discloses a marine organism fouling prevention method of an active-service underwater structure for a marine facility. The method is characterized by comprising the following implementation steps of (1), clearing marine organisms and other unstable attachments on the underwater structure, and polishing to be smooth by using a pneumatic polisher; (2), wrapping a wrapping tape, into which solvent-free underwater antifouling paint infiltrates, around the surface of the well treated underwater structure, and fixing the upper end and the lower end by using strapping tapes after wrapping is completed; (3), before the underwater antifouling paint is subjected to surface drying, wrapping a foamed copper alloy thin tape around the external surface, and fixing the upper end and the lower end by using the strapping tapes after wrapping is completed; and (4), removing the strapping tapes after 24 hours to complete the marine organism fouling prevention construction of the underwaterstructure. Compared with other marine organism elimination or marine organism fouling prevention methods, the marine organism fouling prevention method of the active-service underwater structure for the marine facility, which is provided in the invention, has the advantages of being lasting in effect, being economical and safe, and being convenient to construct.

Owner:深圳市百安百科技有限公司

Method for monitoring the degree of fouling of a filter

InactiveUS20070241058A1Avoid cloggingAvoid adsorptionDispersed particle filtrationLoose filtering material filtersEngineeringFilter cake

A method of filtering a fluid wherein after filtering a contaminated fluid, which causes the formation of a filter cake, a substantially non-contaminated fluid is fed through the filter cake and filter at varying flux or at varying driving force. At the same time the necessary driving force or the obtained flux, respectively, are measured. The measured value and the respective value setting are compared with at least one standard set of data and on the basis of this comparison the fouling status of the fluid to be filtered, the filter and the filter cake is determined. The method makes it possible to accurately determine characteristics of a fluid to be filtered. This may be realized by simply varying the flux and measuring the driving force at different flux values, or vice versa.

Owner:NORIT MEMBRAAN TECH

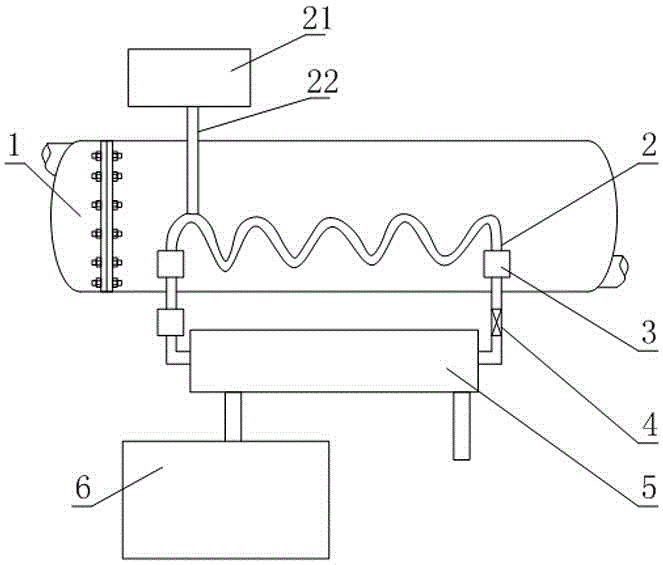

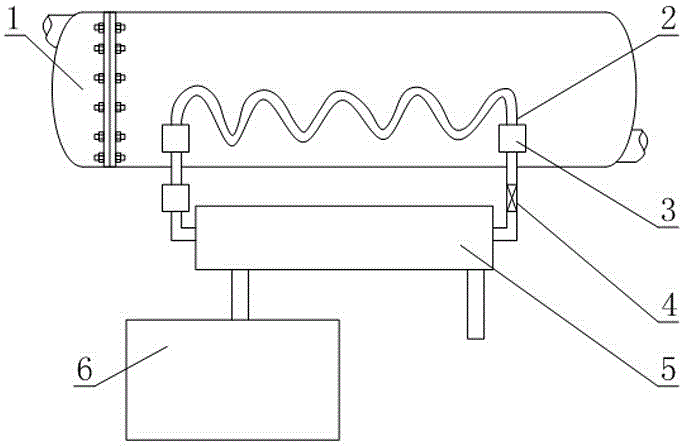

Water heating system

InactiveCN106288389AReduce thermal stressGuaranteed heat transfer efficiencyStorage heatersCombustionFlue gas

The invention discloses a water heating system. The water heating system comprises a hot water tank, a combustion stove and a flue gas pipe for flue gas exhaust of the combustion stove. The water heating system further comprises a heat conducting oil pipe for containing heat conducting oil. The heat conducting oil pipe is an annular pipe, and the heat conducting oil pipe passes through the hot water tank and the flue gas pipe. The water heating system further comprises at least two expansion joints, the expansion joints are connected to the heat conducting oil pipe in series, and the portions, inside and outside the hot water tank, of the heat conducting oil pipe are both provided with at least one expansion joint. The water heating system further comprises a circulating pump for driving the heat conducting oil in the heat conducting oil pipe to cyclically flow. By means of the system, the problem that when straw serves as a heat source to heat water, the heated face of the water easily scales can be solved.

Owner:成都沸鼎环保设备有限公司

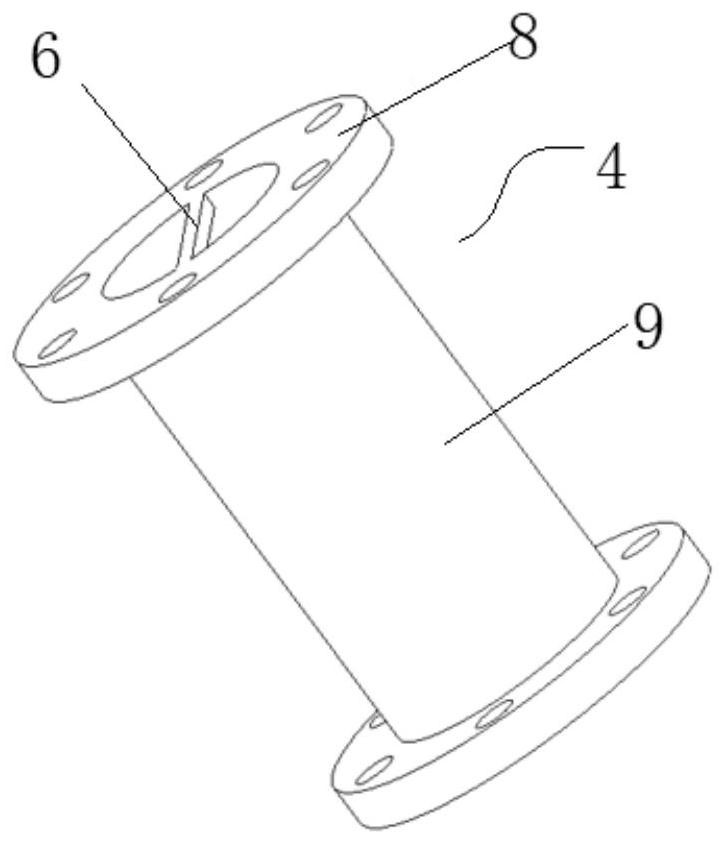

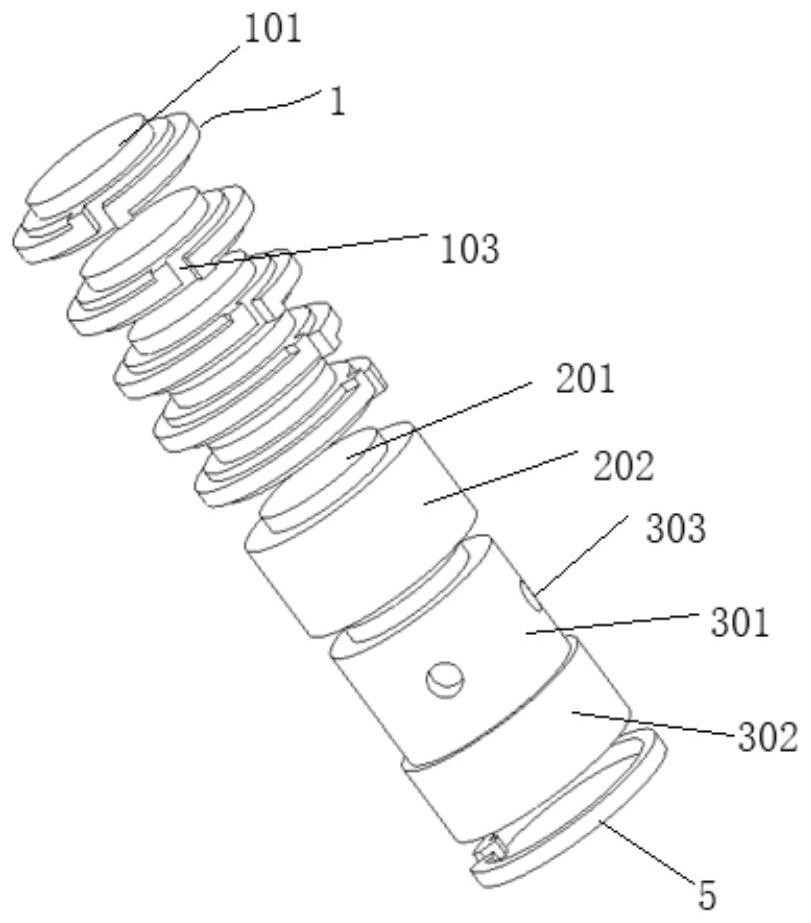

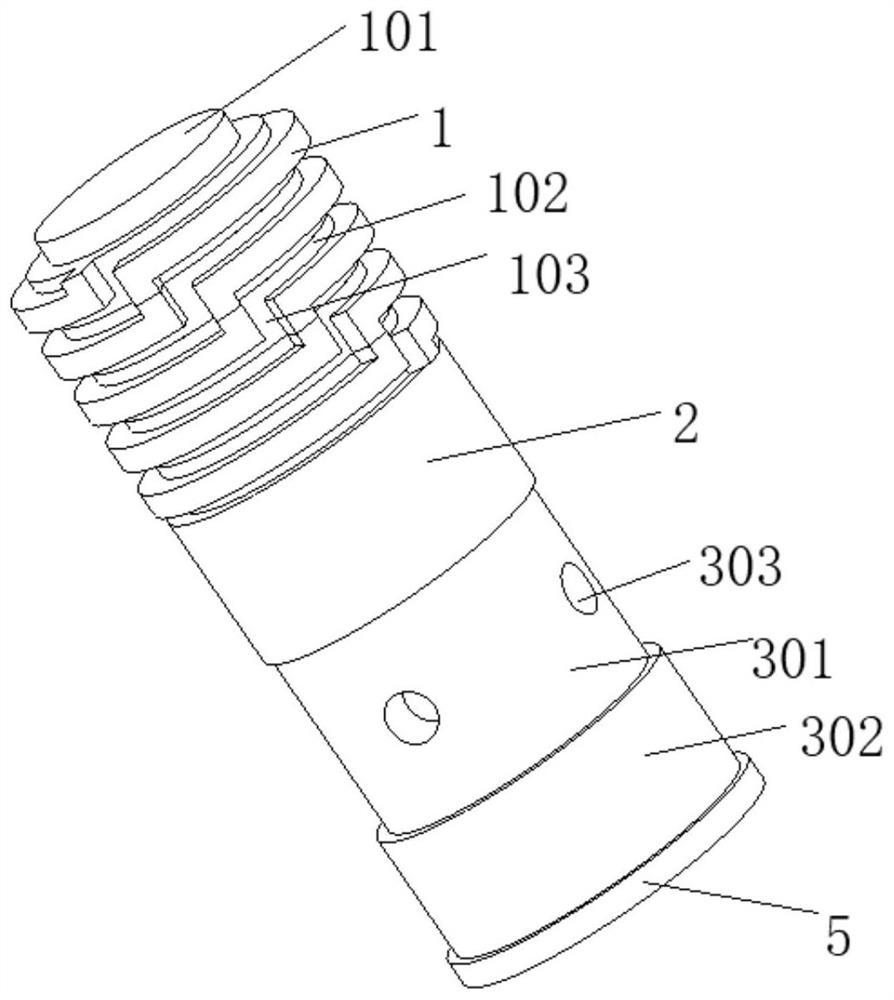

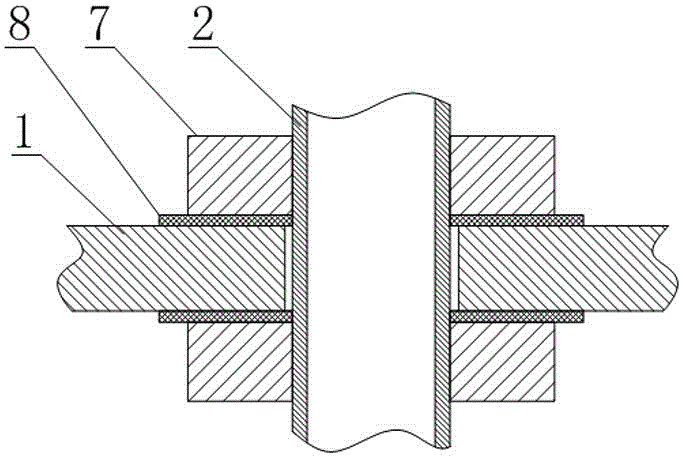

Adjustable throttling device

PendingCN112815174AReach the purpose of reuseAvoid Step Pressure DropsPipe elementsPressure decreaseEngineering

The invention relates to an adjustable throttling device which comprises an outer sleeve, a plurality of first inner core columns, a second inner core column, a third inner core column, a limiting clamping ring, a limiting rib and a limiting clamping ring. The first inner core columns, the second inner core columns and the third inner core columns are sequentially and fixedly connected in the axial direction through positioning bosses and positioning grooves and then are axially positioned through the outer sleeve, the limiting ribs on the outer sleeve and the limiting clamping ring. The outer diameter of the second inner core column is smaller than that of the first inner core column, the third inner core column comprises an open cylinder part and a hollow cylinder part, and the outer diameter of the hollow cylinder part is larger than that of the open cylinder part. When the pressure reduction requirement is changed, redesign is not needed, the number of the first inner core columns, the diameter of the outer cylinder of the second inner core column and the number and hole diameter of the throttling holes in the third inner core column are determined and selected only through simple calculation, and the purpose that one set of device is reused is achieved.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

Hot water device with long service life

The invention discloses a hot water device with long service life. The hot water device comprises a hot water tank, a combustion cooker, a flue gas pipe used for exhausting smoke of the combustion cooker, a heat conducting oil pipe used for containing heat conducting oil and a circulating pump used for driving the heat conducting oil in the heat conducting oil pipe to flow in a circulation manner, wherein the heat conducting oil pipe is an annular pipeline, passes through the hot water tank and the flue gas pipe and is connected with the wall surface of the hot water tank through screw caps. With adoption of the hot water device, the problem that when straws are adopted as a heat source to heat water, the heating surface of the water is liable to scale can be solved, and meanwhile, the service life is long.

Owner:成都沸鼎环保设备有限公司

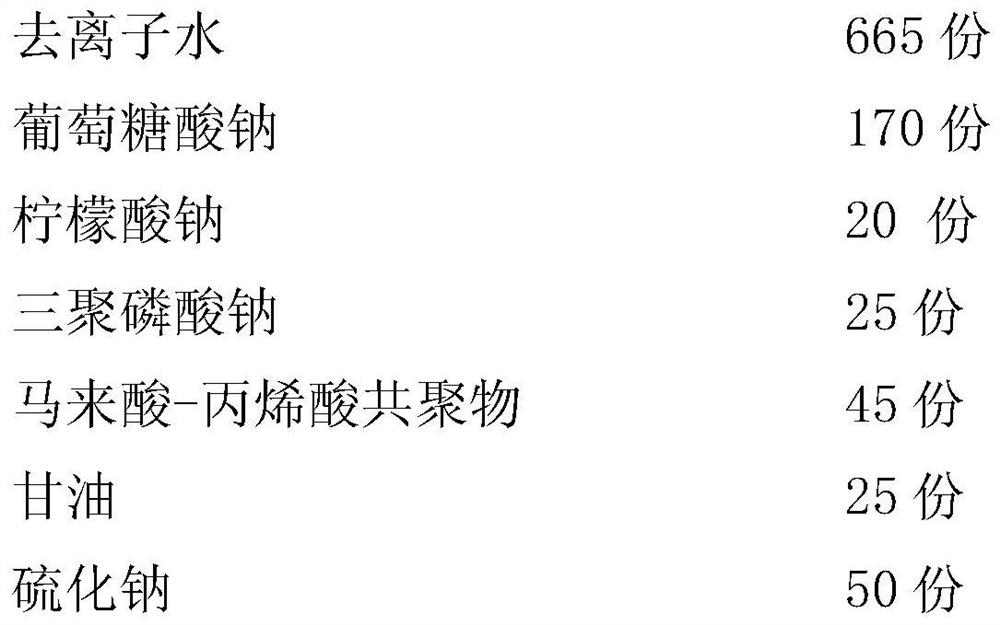

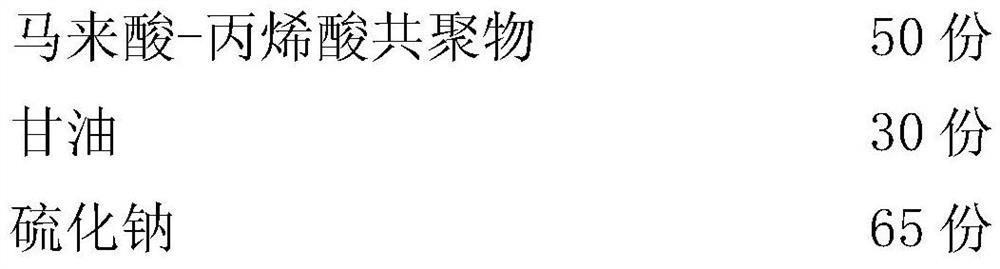

Aluminum material alkaline etching additive and preparation method thereof

PendingCN114262895ALess sedimentLess foulingSurface reaction electrolytic coatingPhysical chemistrySulfide compound

The invention relates to an aluminum material alkali corrosion additive and a preparation method thereof, and the aluminum material alkali corrosion additive comprises the following components in parts by mass: 170-230 parts of an organic complexing agent, 25-50 parts of an inorganic complexing agent, 40-70 parts of a scale inhibitor, 20-30 parts of glycerol, 40-80 parts of sulfide and 540-705 parts of deionized water. The preparation method comprises the following steps: step 1, weighing materials; step 2, mixing and stirring; according to the aluminum material alkali corrosion additive and the preparation method thereof, the obtained product is used for aluminum material alkali corrosion and has a good auxiliary effect during aluminum material alkali corrosion, the phenomena of non-uniform corrosion and excessive corrosion cannot occur when oil stains and an oxide layer on the surface of an aluminum material are removed through alkali corrosion, a uniform and consistent matrix surface layer can be obtained, and the corrosion resistance of the aluminum material is improved. And smooth anodic oxidation is ensured.

Owner:佛山市顺德区美硕金属表面技术有限公司

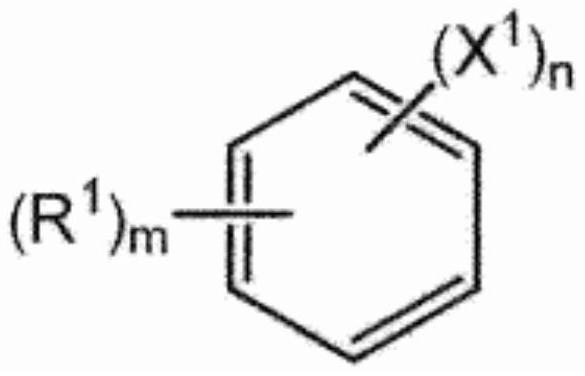

Supported catalyst for olefin polymerization, and method for preparing polyolefin by using same

The present invention relates to a supported catalyst for olefin polymerization, and a method for preparing a polyolefin by using same, the supported catalyst comprising: a main catalyst comprising a metallocene-based compound; a cocatalyst comprising an organoaluminum-based compound; an aromatic compound in which two or more polar groups selected from a hydroxyl group (-OH), an amine group (-NH2), a thiol group (-SH), a carboxyl group (-COOH) and an amide group (-CONH2) are bonded, and one or more halogen groups are bonded; and a support for supporting the main catalyst, the cocatalyst and the aromatic compound. When olefins are polymerized by using the supported catalyst of the present invention, the catalyst exhibits excellent activity and fouling can be reduced by inhibiting the generation of polyolefin fine powder.

Owner:LOTTE CHEM CORP

A method for preventing marine biofouling of underwater structures of active marine facilities

ActiveCN111364428BGood effectEasy constructionArtificial islandsAntifouling/underwater paintsBiological stainFishery

The invention discloses a method for preventing marine biofouling of the underwater structure of active marine facilities, which is characterized in that the implementation steps of the method are: (1) cleaning the marine organisms and other loose attachments on the underwater structure, and using Grinding with a pneumatic grinder until smooth; (2) Winding a wrapping tape soaked in solvent-free underwater antifouling paint on the surface of the treated underwater structure, and fixing the upper and lower ends with cable ties after winding; (3) Underwater antifouling Before the surface of the damaged paint dries, wrap a foamed copper alloy thin strip on the outer surface. After the winding is completed, fix the upper and lower ends with cable ties; (4) Remove the cable ties after 24 hours to complete the anti-marine biofouling construction of the underwater structure. Compared with other methods for removing or preventing marine biofouling, the method for preventing marine biofouling of underwater structures of active marine facilities has the advantages of lasting effect, economy, safety, and convenient construction.

Owner:深圳市百安百科技有限公司

Hydroprocessing method of inferior gasoline

ActiveCN103805246AAvoid local overheatingEfficient use ofTreatment with hydrotreatment processesHeating oilHydrodesulfurization

The invention discloses a hydroprocessing method of inferior gasoline. The hydroprocessing method comprises following steps: (1) inferior gasoline raw material is mixed with heating oil and hydrogen so as to obtain a mixture, and the mixture is delivered into a boiling bed reactor for hydrogenation pretreatment; (2) a reaction effluent obtained via hydrogenation pretreatment is subjected to gas-liquid separation; (3) a gas material obtained via pretreatment is delivered into a gasoline hydrodesulfurization reactor for hydrodesulfurization, an obtained hydrogenation reaction effluent is delivered into a separator for gas-liquid separation, an obtained liquid is subjected to gas stripping, and then is taken as a gasoline product or a gasoline blending component; and (4) a liquid material obtained via pretreatment is taken as the heating oil for recycling. The hydroprocessing method is capable of prolonging running period of inferior gasoline equipment greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com