Method for delaying calcium sulfate scaling in pretreatment and hardness removal processes of desulfurization wastewater

A desulfurization wastewater and pretreatment technology, which is applied in gaseous discharge wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and difficulty, and achieve high utilization rate, The effect of less dosage and improved calcium sulfate scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The present embodiment provides a method for delaying the scaling of calcium sulfate in desulfurization wastewater during pretreatment and dehardening, which includes the following steps:

[0068] S1. Oil removal and impurity removal treatment: The high COD and high salt flue gas scrubbing and desulfurization wastewater is passed into a grease trap to remove oil slicks. Enter the second-stage oil separator, add liquid caustic soda (NaOH) to the oil removal waste liquid to adjust the pH of the oil removal waste liquid to 7.5, and then enter the nano air flotation tank to continue to scrape the floating oil, and the waste liquid after the secondary oil separation enters the Neutralize the reaction tank.

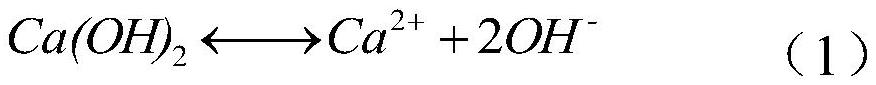

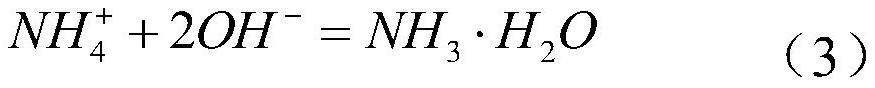

[0069] S2. Neutralization, precipitation and magnesium removal treatment: Add lime milk as a neutralizing agent to the neutralization reaction tank for neutralization, precipitation and magnesium removal for 2 hours to obtain a neutralization solution with a pH value of ...

Embodiment 2

[0076] The present embodiment provides a method for delaying the scaling of calcium sulfate in desulfurization wastewater during pretreatment and dehardening, which includes the following steps:

[0077] S1. Oil removal and impurity removal treatment: The high COD and high salt flue gas scrubbing and desulfurization wastewater is passed into a grease trap to remove oil slicks. Enter the second-stage oil separator, add liquid caustic soda (NaOH) to the oil removal waste liquid to adjust the pH of the oil removal waste liquid to 8, and then enter the nano air flotation tank to continue scraping the floating oil, and the waste liquid after the secondary oil separation enters the Neutralize the reaction tank.

[0078] S2. Neutralization precipitation and magnesium removal treatment: Add lime milk as a neutralizing agent to the neutralization reaction tank for neutralization, precipitation and magnesium removal treatment for 1 h to obtain a neutralization solution with a pH value o...

Embodiment 3

[0085] The present embodiment provides a method for delaying the scaling of calcium sulfate in desulfurization wastewater during pretreatment and dehardening, which includes the following steps:

[0086] S1. Oil removal and impurity removal treatment: The high COD and high salt flue gas scrubbing and desulfurization wastewater is passed into a grease trap to remove oil slicks. Enter the second-stage oil separation tank, add liquid alkali (NaOH) to the oil removal waste liquid to adjust the pH of the oil removal waste liquid to 7, and then enter the nano air flotation tank to continue to scrape the floating oil, and the waste liquid after the secondary oil separation enters the Neutralize the reaction tank.

[0087] S2. Neutralization, precipitation and magnesium removal treatment: Add lime milk as a neutralizing agent to the neutralization reaction tank for neutralization, precipitation and magnesium removal for 1.5 hours to obtain a neutralization solution with a pH value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com