Time-window-enthalpy-value-integral-based smoke cooling control method and system

A technology of flue gas cooling and control method, applied in general control system, control/adjustment system, adaptive control, etc., can solve the problems of frequent action, tower body wall, adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

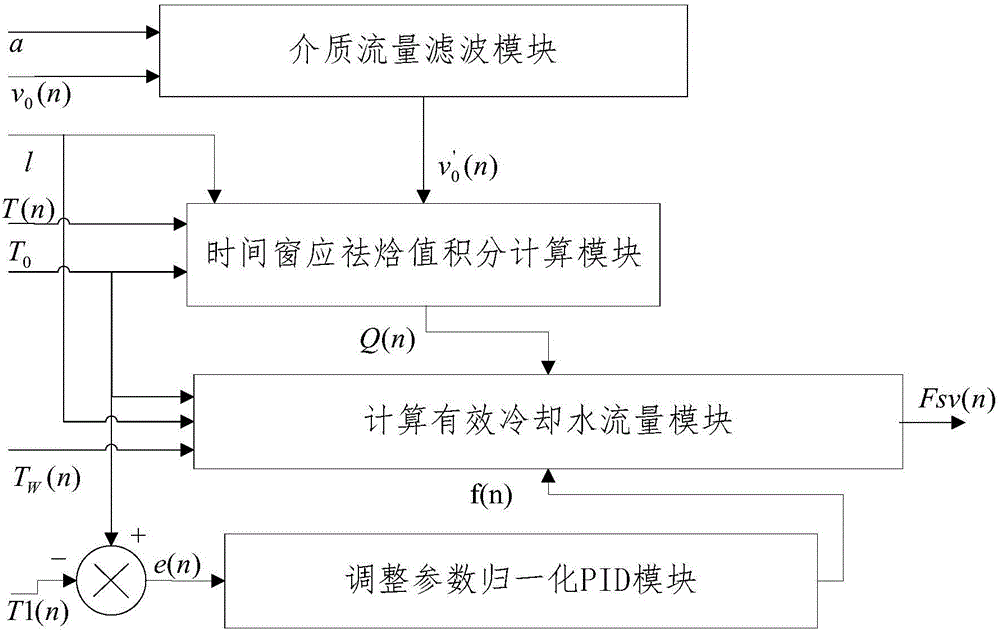

[0117] In this embodiment, the flue gas cooling control system based on time window enthalpy integration includes 4 program modules:

[0118] (1) Medium flow filter module

[0119] (2) Time window response enthalpy integral calculation module

[0120] (3) Calculate effective cooling water flow module

[0121] (4) Adjust the parameters to normalize the PID module

[0122] Such as figure 2 As shown, the combined structure diagram of the temperature control model based on the time window enthalpy value integration of the four program modules, in the figure,

[0123] a: Indicates the parameters used to adjust the filtering effect

[0124] v 0 (n): Indicates the measured value of flue gas flow entering the tower body, in m 3 / s

[0125] v 0 '(n): Indicates the filtered flue gas flow measurement value, the unit is m 3 / s

[0126] Q(n): Indicates the integral value of the enthalpy that should be removed within the time window, and the unit is kJ / s

[0127] f(n): Indicates...

Embodiment 2

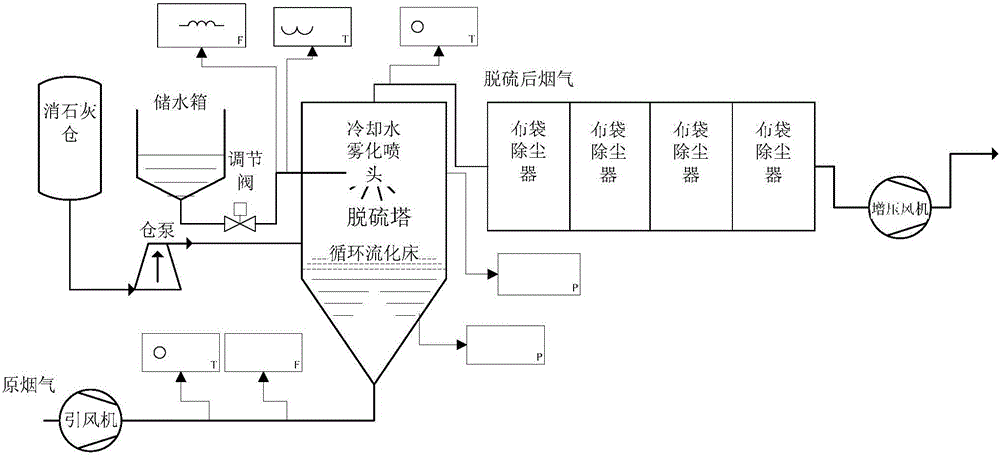

[0198] This embodiment is based on the flue gas cooling control method of time window enthalpy integration, obtains the flue gas flow rate at the inlet of the flue gas treatment system, calculates the integral value of the flue gas enthalpy that should be removed, divides the integral value by the length of the time window, and establishes the time window. The static functional relationship model between the enthalpy value to be removed per unit time and the cooling water flow rate controls the flow rate of the cooling water according to the integral of the enthalpy removal required by the flue gas.

[0199] The cooling water capacity is calculated based on the enthalpy of flue gas contained between the cooling water nozzle and the temperature detection point in the piping system, and the time taken by the flue gas in the piping system from the cooling water nozzle to the temperature detection point as the time window length .

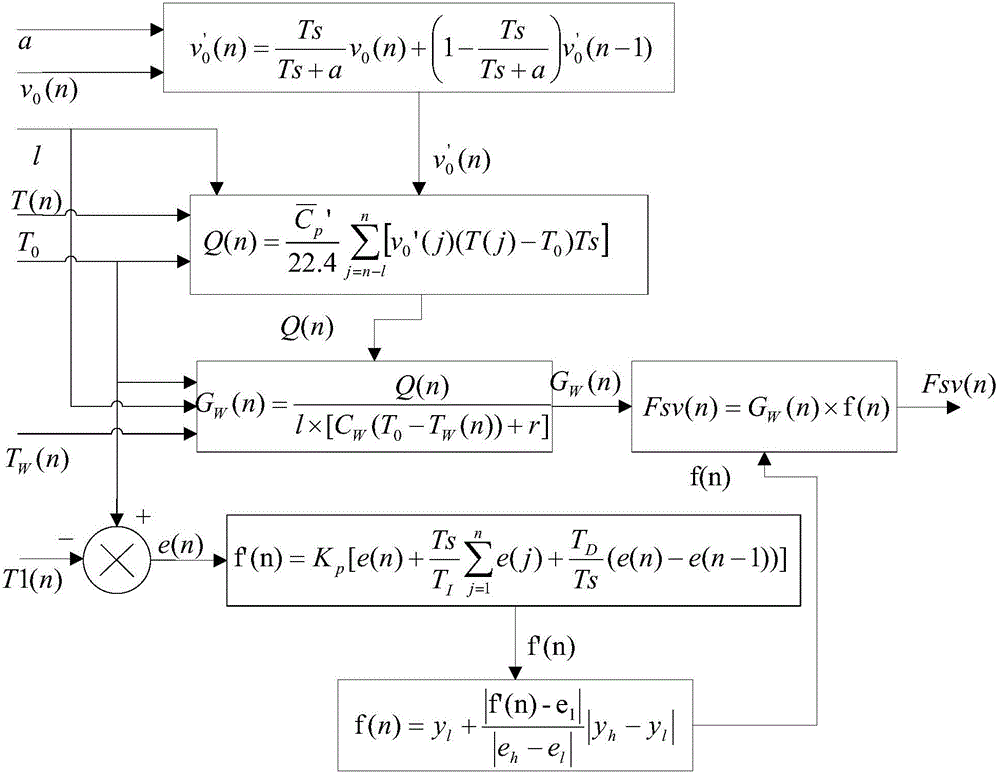

[0200] Such as image 3 As shown, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com