Hydroprocessing method of inferior gasoline

A low-quality gasoline and hydrotreating technology, applied in hydrotreating process, treating hydrocarbon oil, petroleum industry, etc., can solve the problem that the device cannot be operated for a long time, avoid fouling and coking, easy to operate, and effectively utilize heat energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

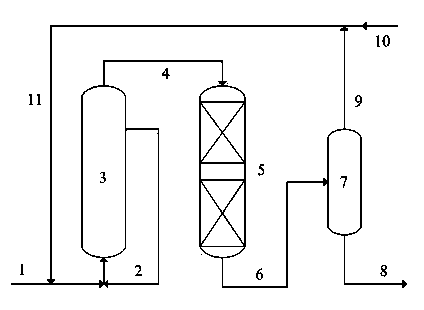

[0037] use figure 1 The process flow shown. The properties of the raw oil used are listed in Table 2, the properties of the catalyst are listed in Table 3, and the process conditions and test results are listed in Table 4 and Table 12, respectively.

[0038] Table 2 Raw oil properties.

[0039] Oil name FCC gasoline Density, g / cm 3 0.7300 Distillation range / ℃ 36~206 Sulfur content / μg·g -1 575 Nitrogen content / μg·g -1 39 Mercaptan sulfur, μg g -1 35.4 RON 93.5

[0040] Table 3 The main composition and properties of the catalysts.

[0041] catalyst pretreatment catalyst hydrogenation catalyst Catalyst composition MoO 3 +CoO / wt% 5% 20% carrier Aluminum oxide Aluminum oxide The main properties of the catalyst Particle size, mm 0.2 — Specific surface / m 2 g -1 180 226 Pore volume / mL·g -1 0.68 0.51

[0042] Table 4 Example 1 process conditions...

Embodiment 2

[0045] use figure 1 The process flow shown. The properties of the raw oil used are listed in Table 5, the properties of the catalyst are listed in Table 6, and the process conditions and test results are listed in Table 7 and Table 12, respectively.

[0046] Table 5 Raw oil properties.

[0047] Oil name Coking gasoline feedstock Density, g / cm 3 0.7413 Distillation range / ℃ 57~206 Sulfur content, μg / g 5656 Nitrogen content, μg / g 236

[0048] Table 6 Main composition and properties of catalysts.

[0049] catalyst pretreatment catalyst hydrogenation catalyst Catalyst composition MoO 3 +CoO / wt% 0 25% carrier Aluminum oxide Aluminum oxide The main properties of the catalyst Particle size, mm 0.3 — Specific surface / m 2 g -1 180 226 Pore volume / mL·g -1 0.68 0.51

[0050] Table 7 Example 2 process conditions.

[0051] Process conditions data ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com