Patents

Literature

60results about How to "Solve local overheating problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

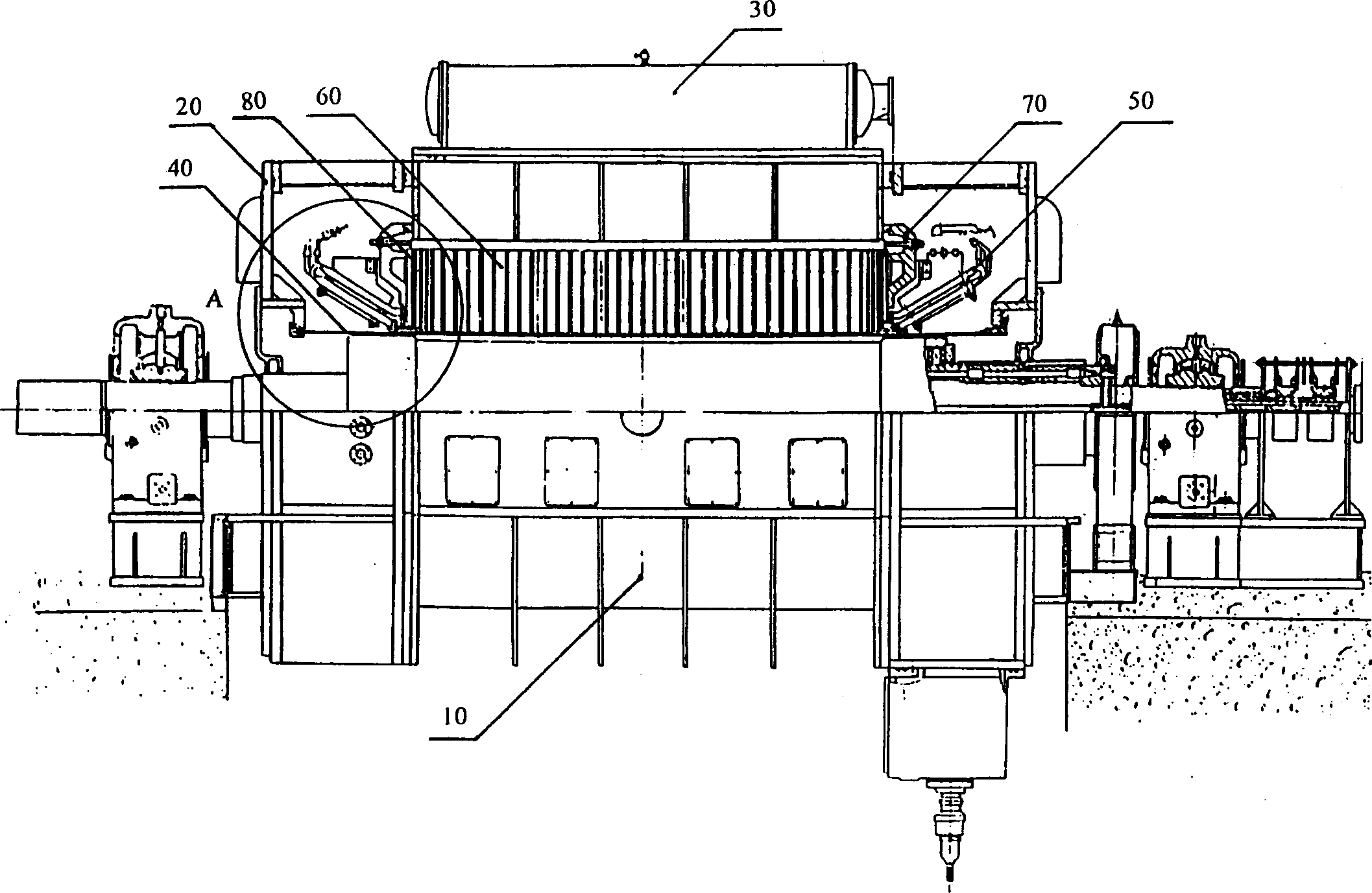

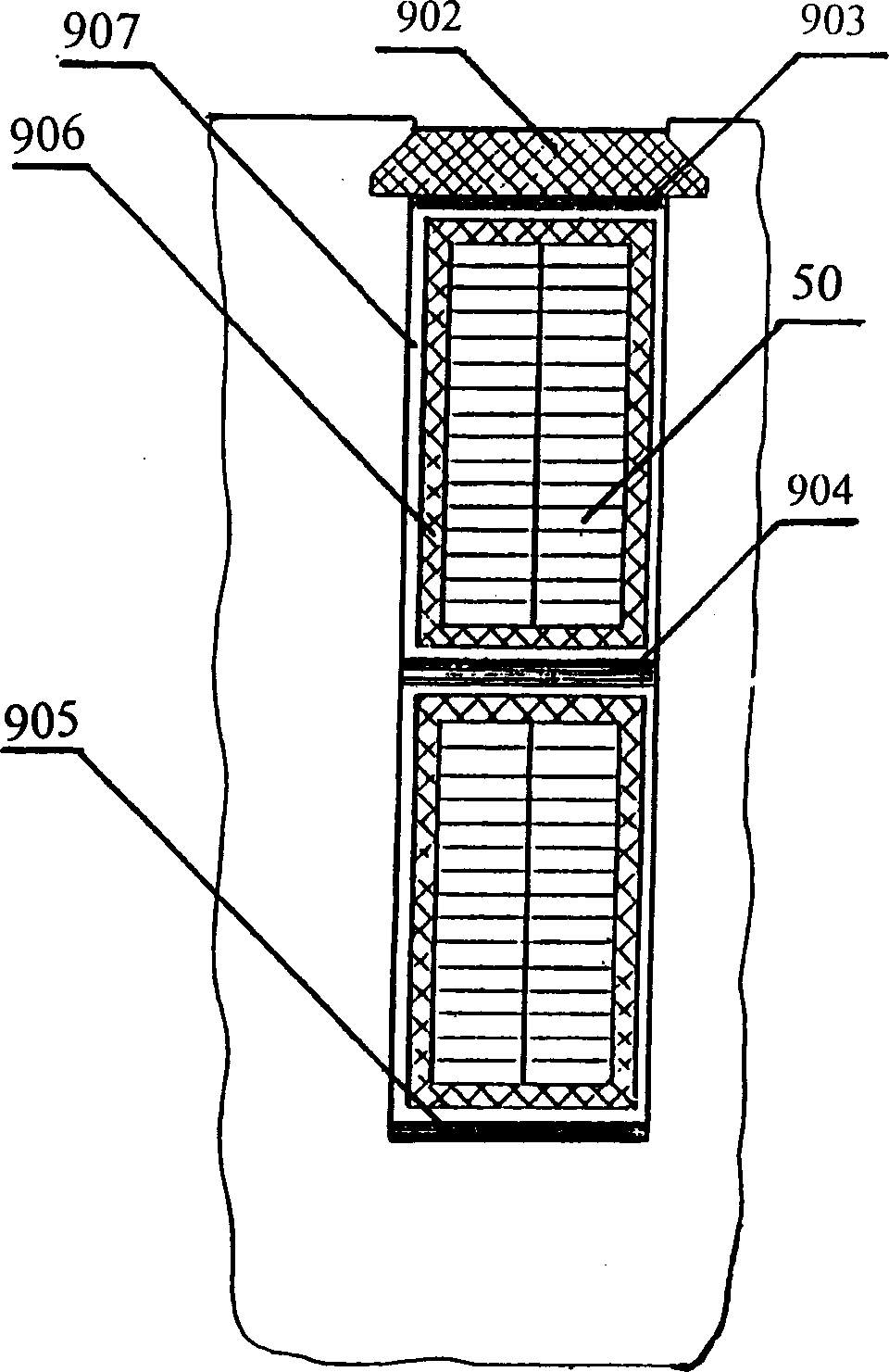

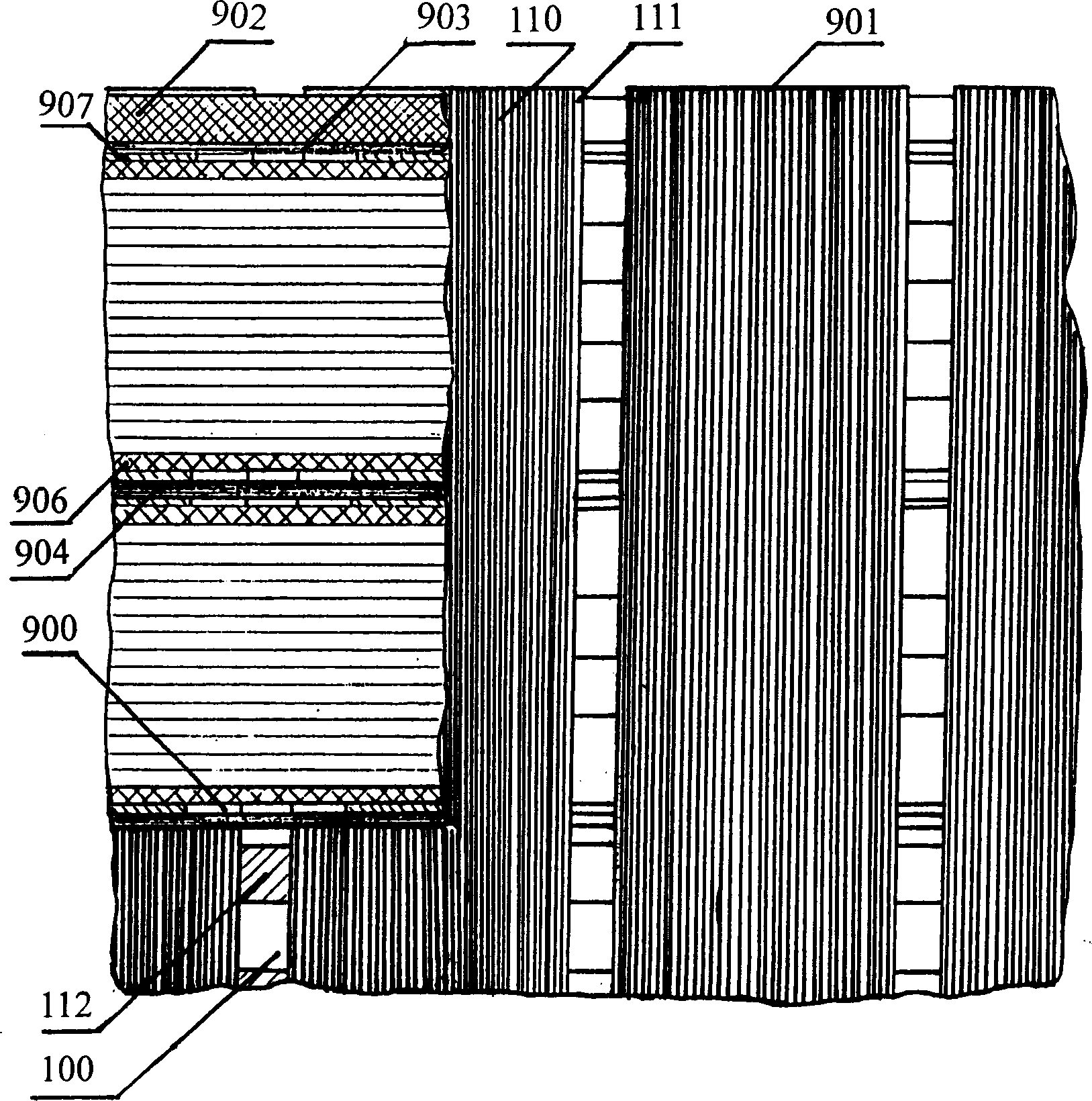

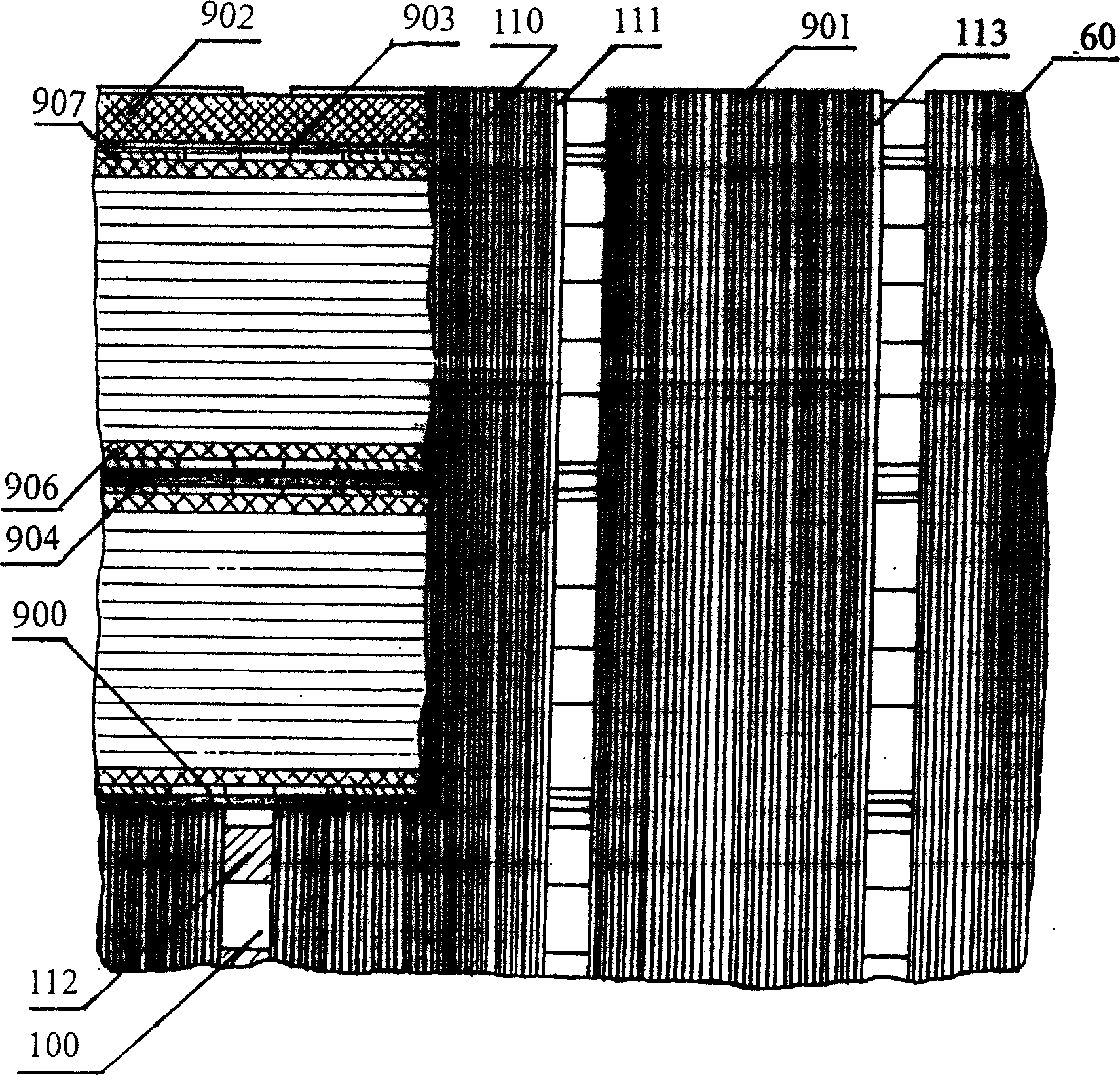

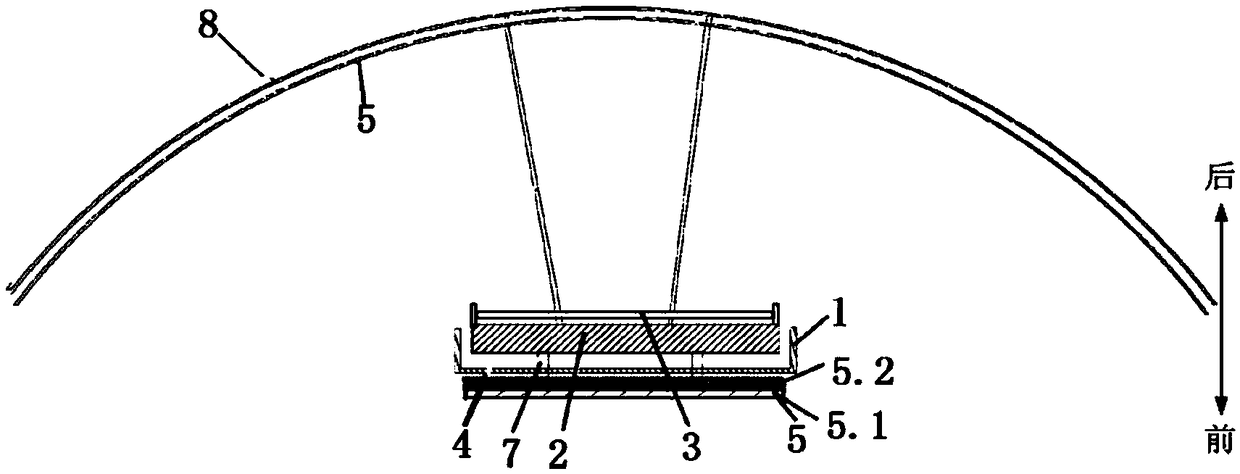

Full immersed type self circular loop of evaporative cooling stator of steam turbine generator

InactiveCN1416201AAdequate infiltrationImprove cooling effectCooling/ventillation arrangementHydrogenNuclear engineering

The cooling circulation loop includes the cooling circulation sub-loop in the slot part of the stator core, the sub-loop between the sections of the iron core and the sub-loop between the pressing rings at the end parts of the stator core and the tooth pressure plates. The liquid cooling medium with high insulation and low boiling point of good physical and chemical properties is injected into the cavity of the stator. Each sub-loop is connected to the cavity of the stator. The cooling liquid absorbs the heat so as to be boiled and gasified, flowing in the circulation loop freely getting earth part of the stator cooled. The said cooling circulation loop possesses the advantages of the water, hydrogen and air-cooling and prevents the insulatiom damage and explosion caused by the leakage of water and hdyrogen.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

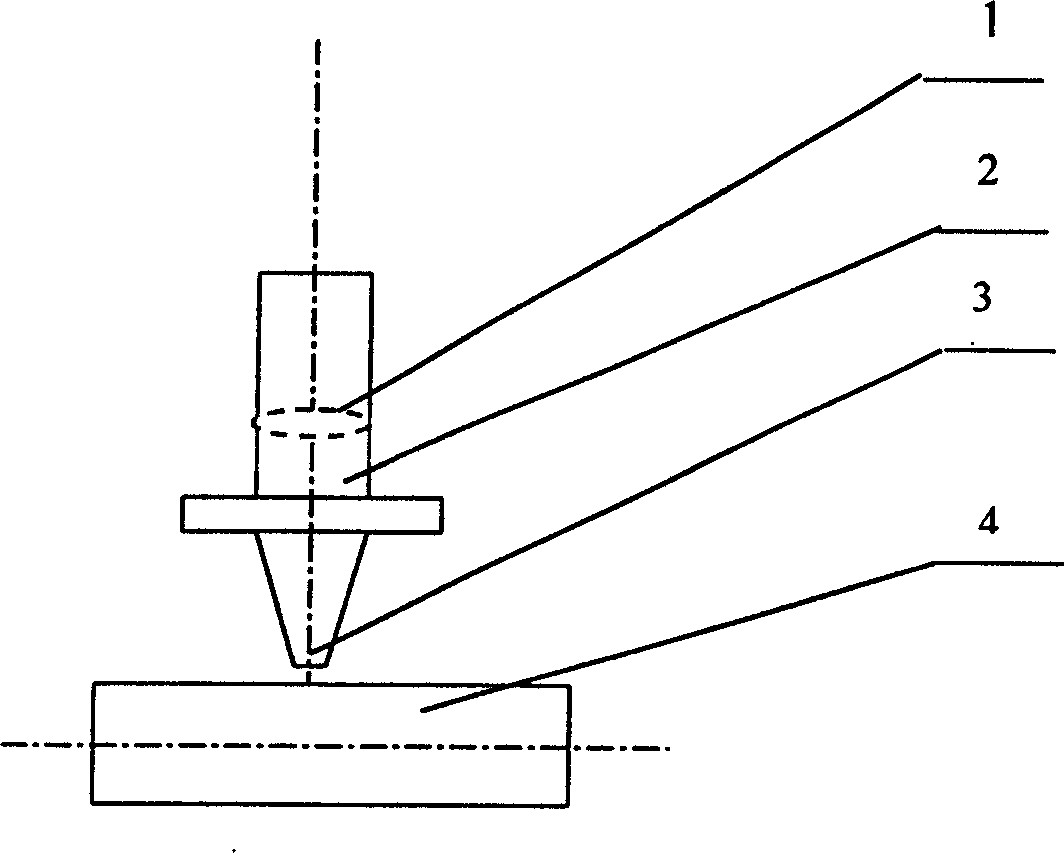

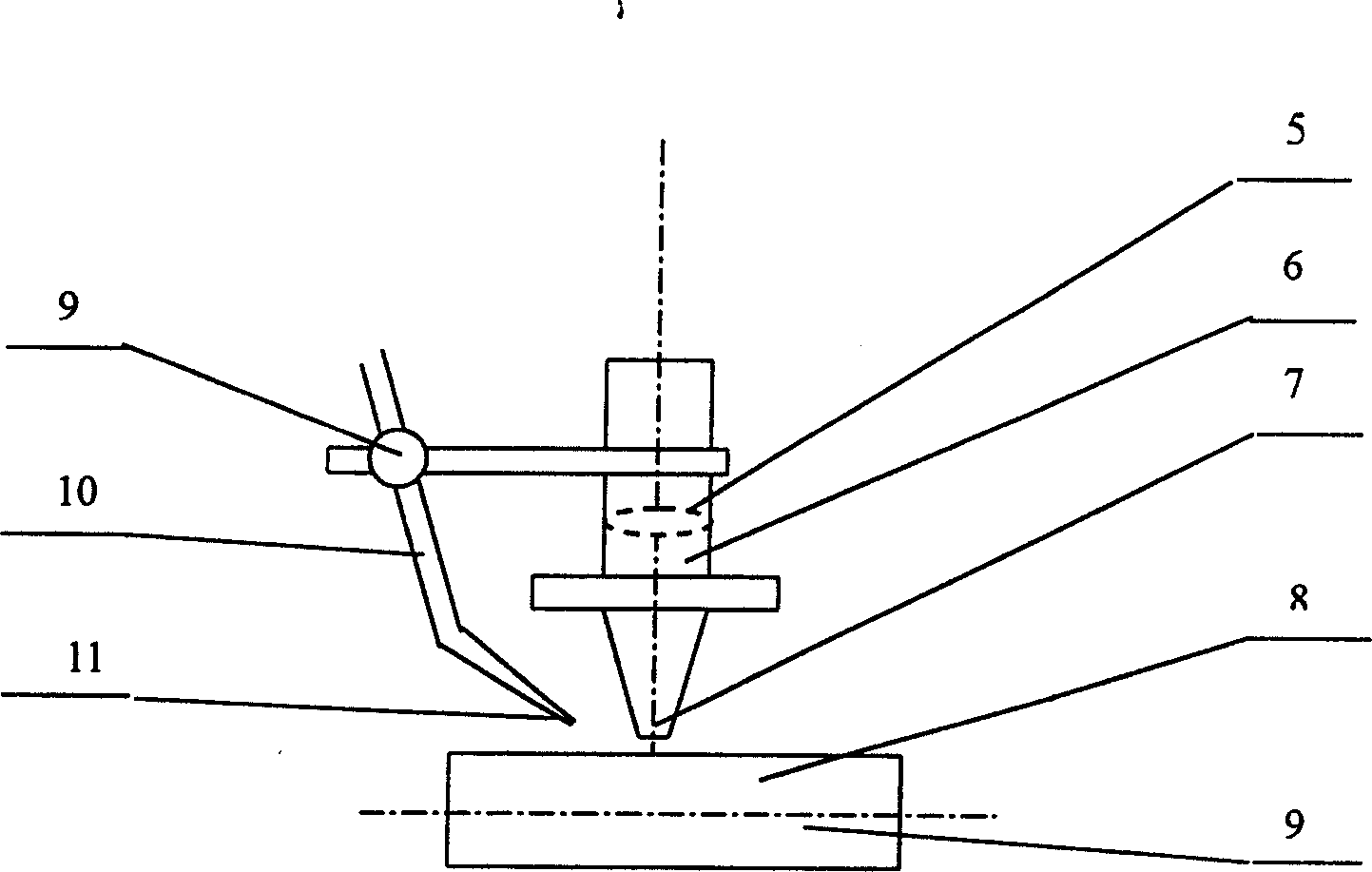

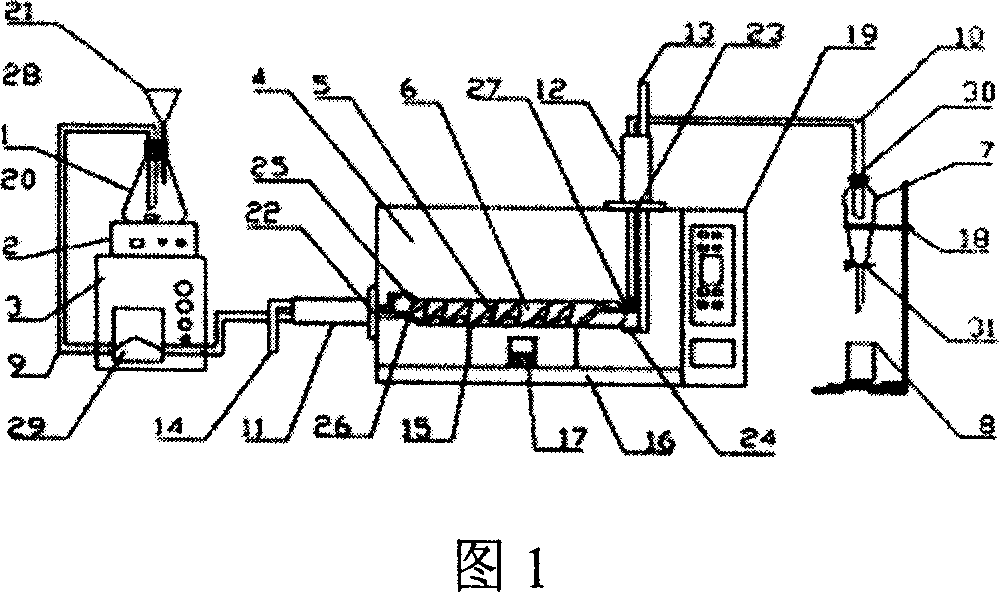

Technique for laser cutting metal tube utilizing compressed air and apparatus thereof

InactiveCN1541801ASolve local overheating problemsSave oxygen consumptionLaser beam welding apparatusLaser cuttingEngineering

The present invention belongs to the field of laser cutting apparatus and the technological scheme is that the laser cutting apparatus consists of focus lens, cutting laser head, oxygen nozzle, nozzle regulating support and compressed air nozzle. One regulating support is installed for the cutting laser head to regulate the angle between the compressed air nozzle and the oxygen nozzle within 40-50 deg, the distance between the compressed air nozzle and the oxygen nozzle within 15-25 mm, the distance between the compressed air nozzle and the cut workpiece within 6-10 mm and pressure of compressed air in 1.5-2.5 times that of oxygen. The method and apparatus of the present invention can avoid overheat during cutting process.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

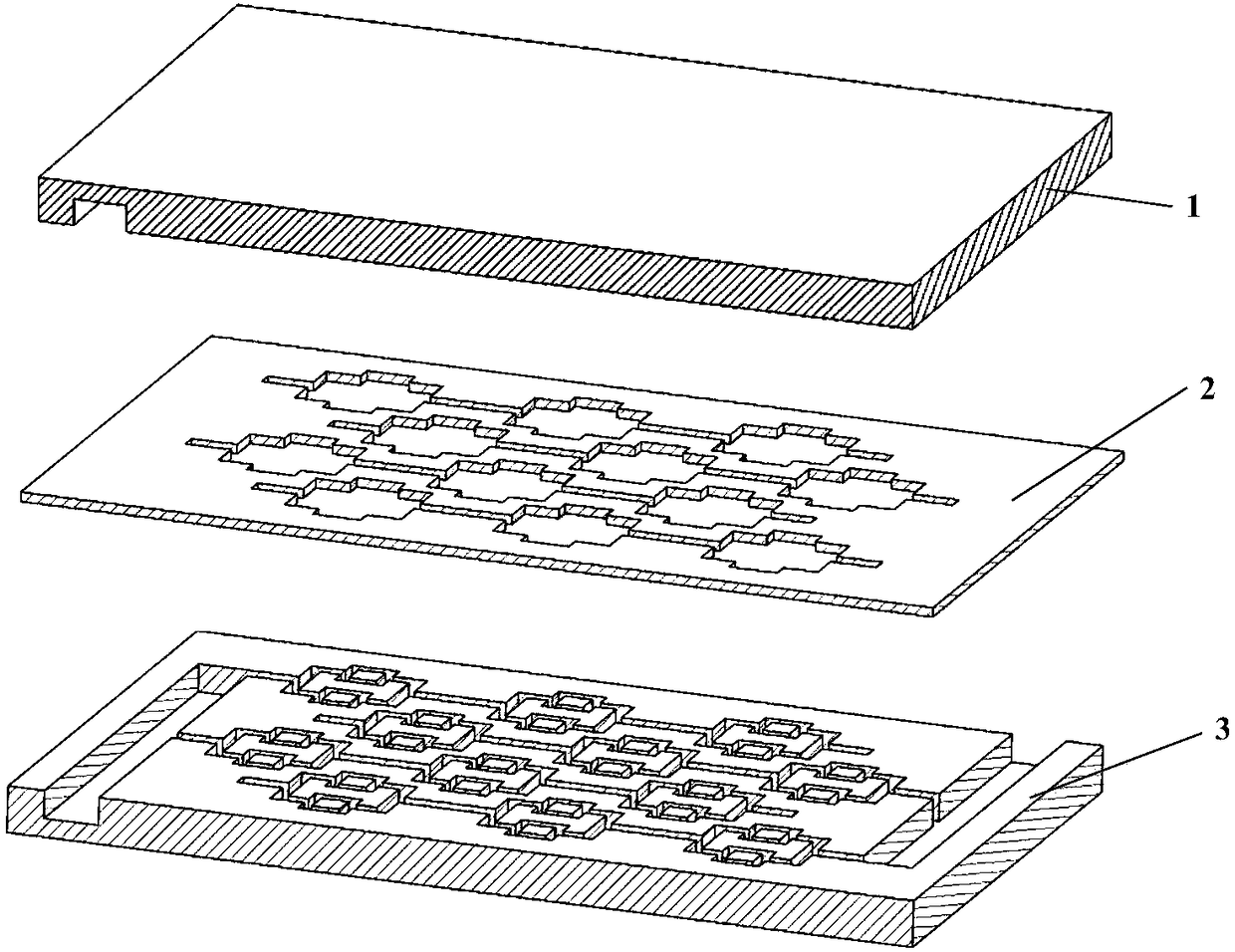

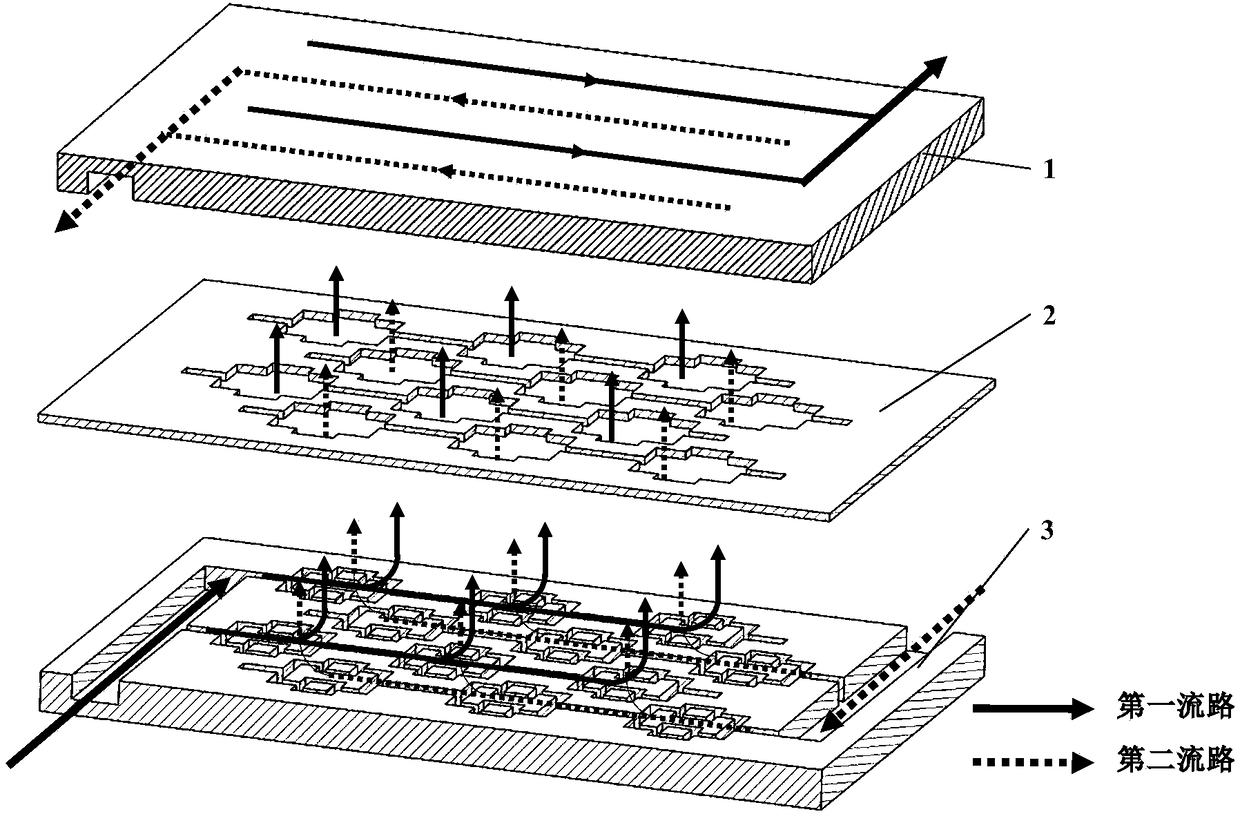

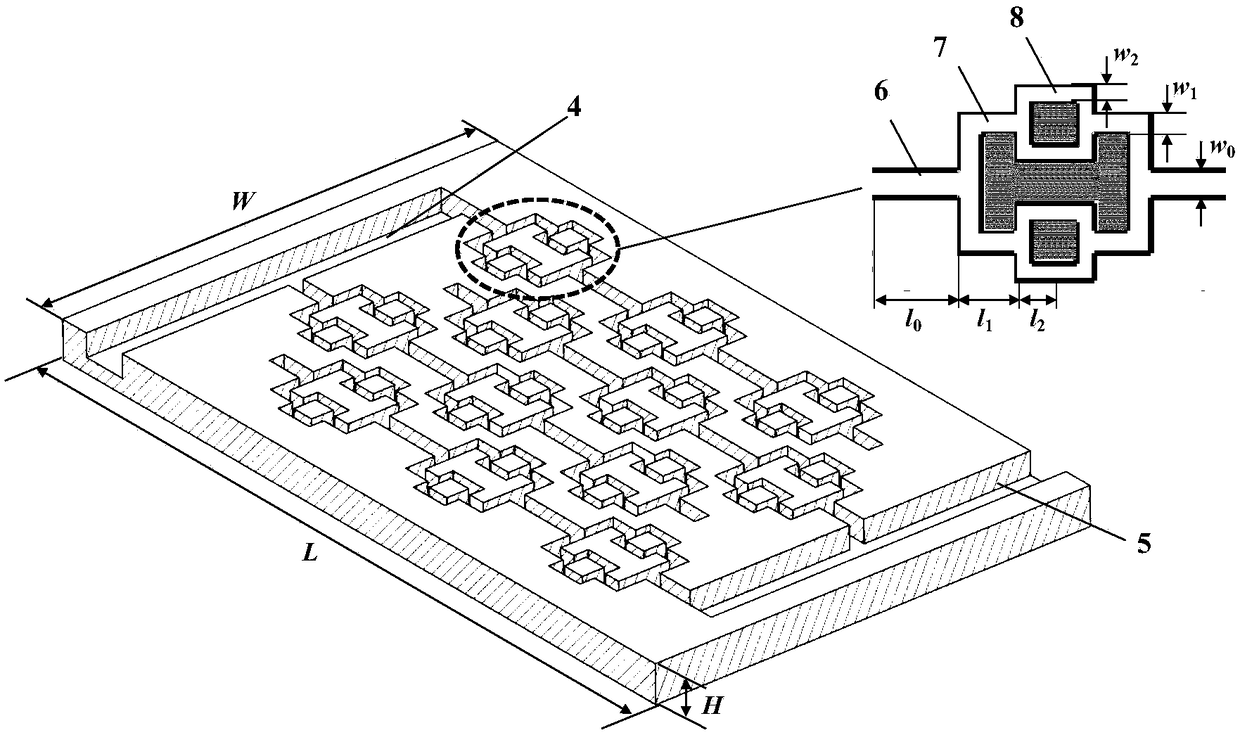

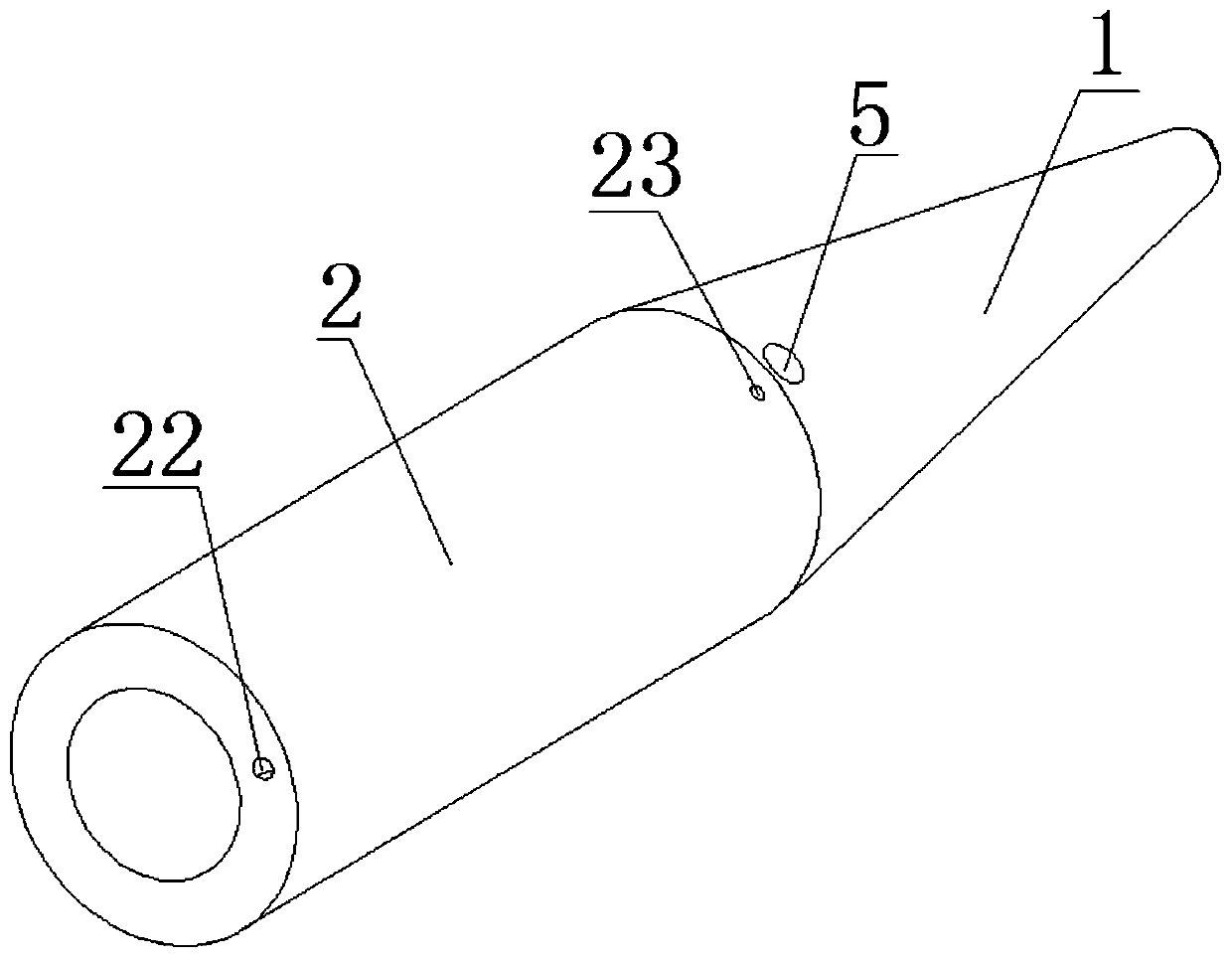

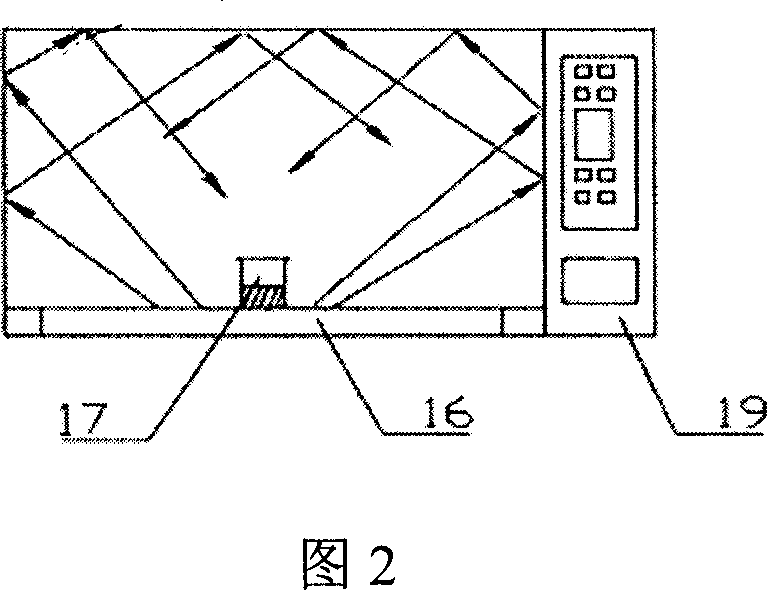

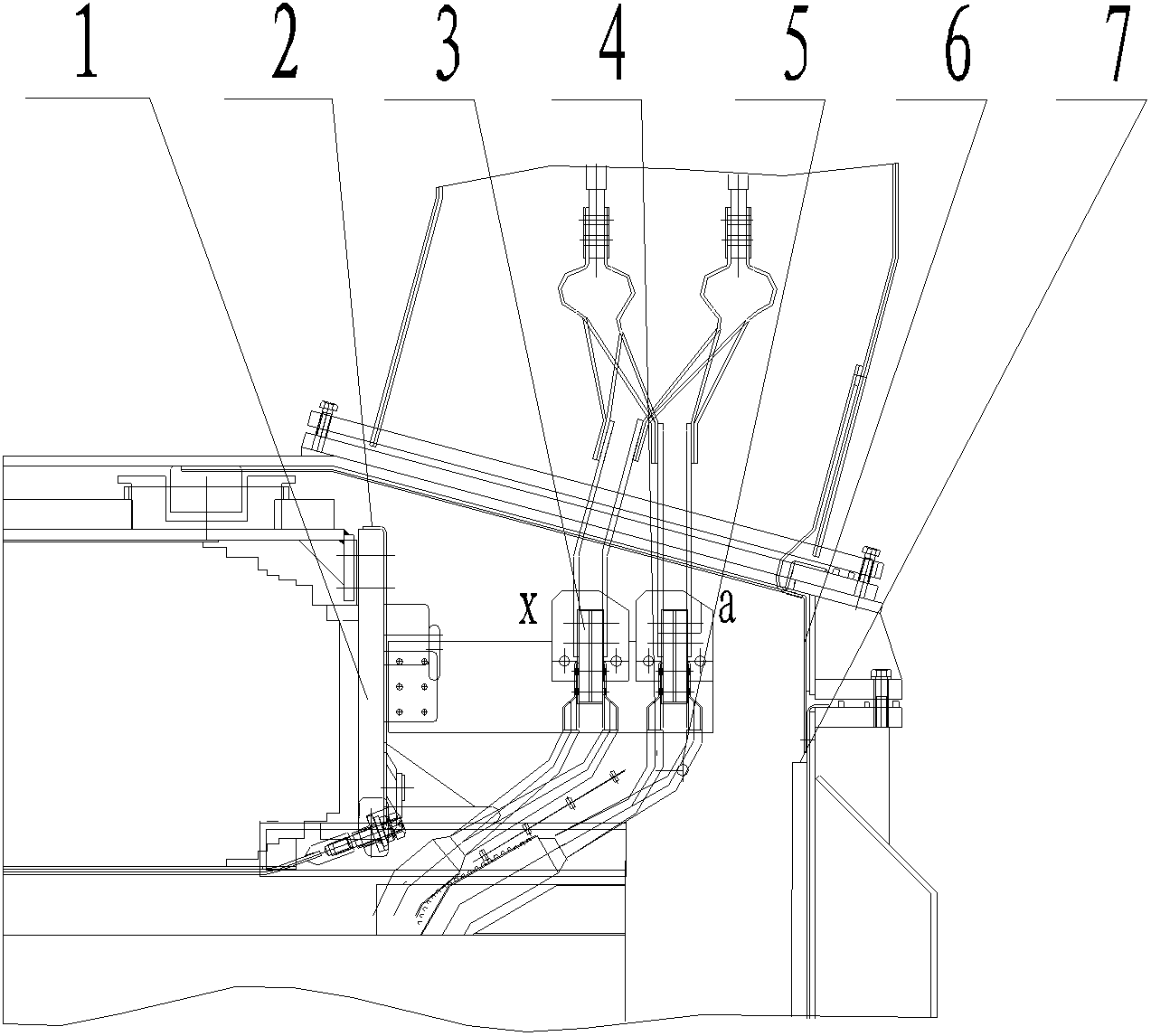

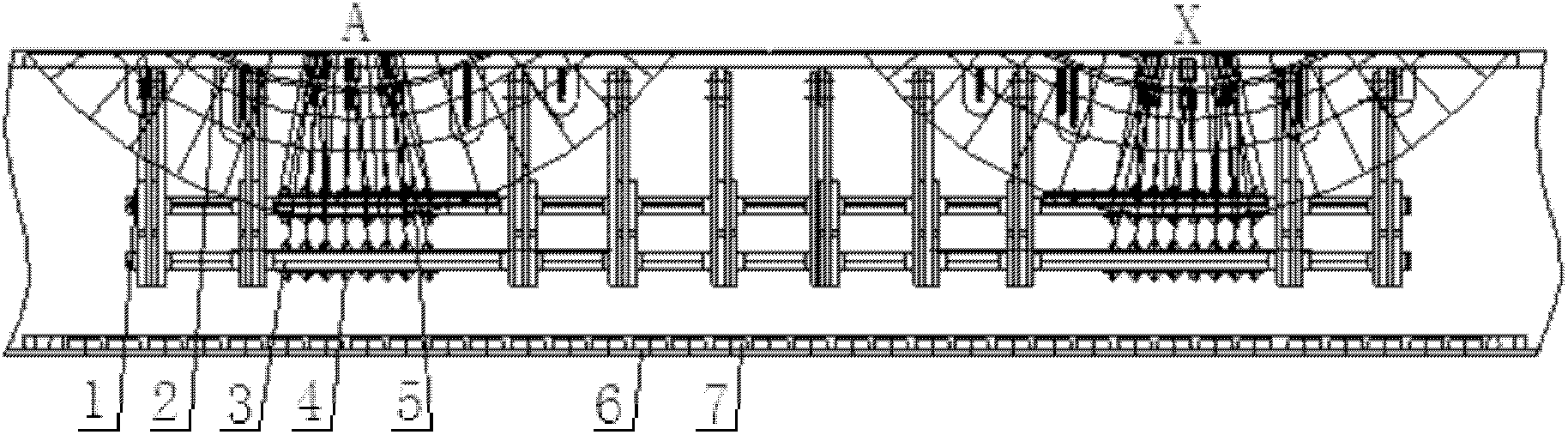

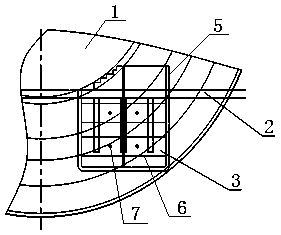

Fractal micro-channel cold plate with bidirectional flow path

ActiveCN108112218ASolve local overheating problemsIncrease the heat exchange areaCooling/ventilation/heating modificationsCold plateElectrical and Electronics engineering

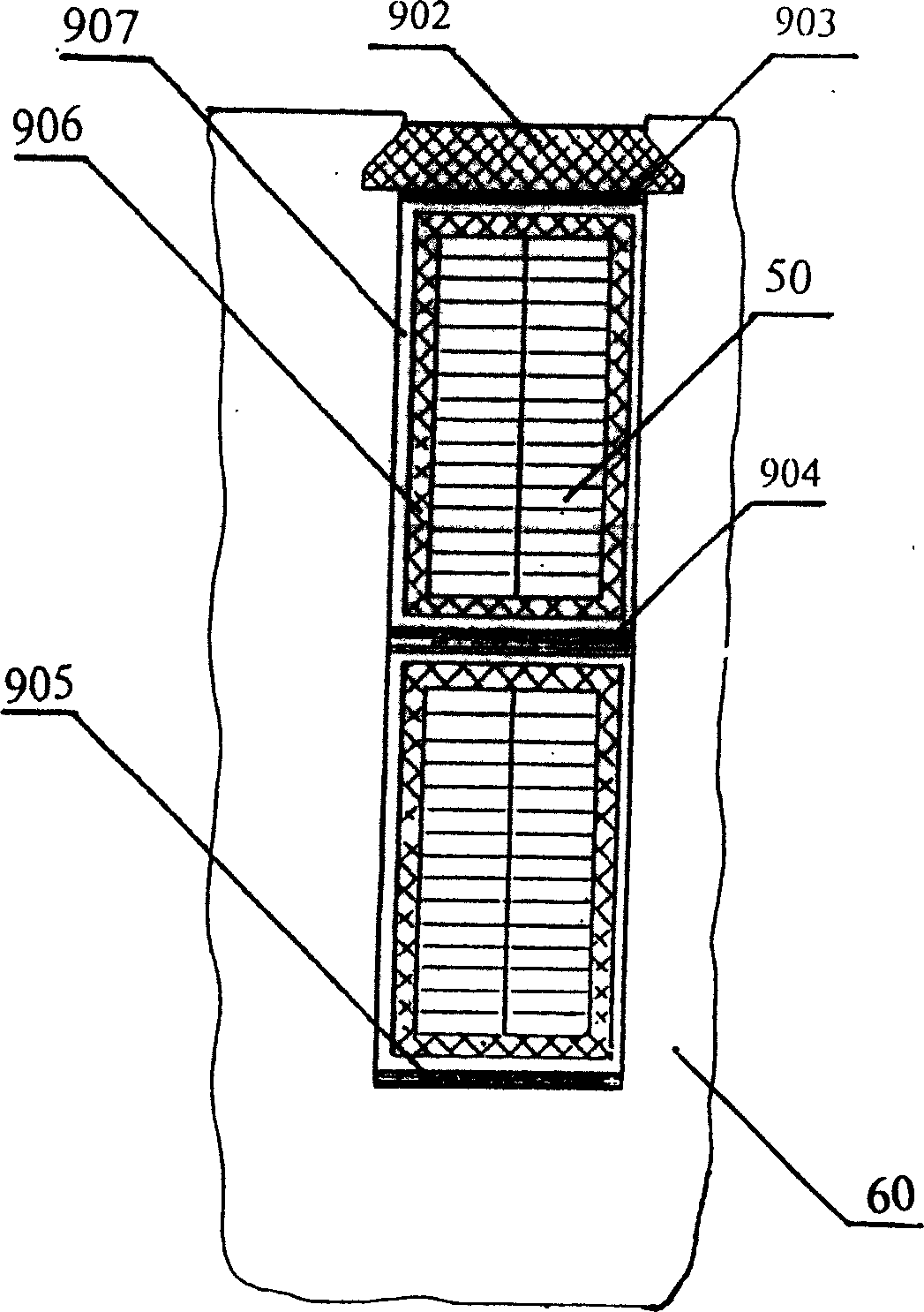

The invention discloses a fractal micro-channel cold plate with a bidirectional flow path. The cold plate comprises a liquid inlet plate, a middle plate and a liquid returning plate, wherein the liquid returning plate comprises a first inlet liquid dividing channel, a second inlet liquid dividing channel and liquid inlet zero-grade branch channels. The first inlet liquid dividing channel is connected with the liquid inlet zero-grade branch channels in the odd-number rows. The second inlet liquid dividing channel is connected with the liquid inlet zero-grade branch channels in the even-number rows. The middle plate comprises hollowed holes which are set in correspondence with the liquid inlet zero-grade branch channels. The liquid returning plate comprises a first outlet liquid collecting channel, a second outlet liquid collecting channel and liquid collecting zero-grade branch channels. The first outlet liquid collecting channel is connected with the liquid collecting zero-grade branchchannels in the even-number rows, and the second outlet liquid collecting channel is connected with the liquid collecting zero-grade branch channels in the odd-number rows. The fractal micro-channelcold plate with the bidirectional flow path has advantages of improving duty ratio and heat exchange area of the micro-channels on the cold plate, and improving temperature homogeneity and heat radiation performance on the surface of the cold plate.

Owner:SHANGHAI JIAO TONG UNIV

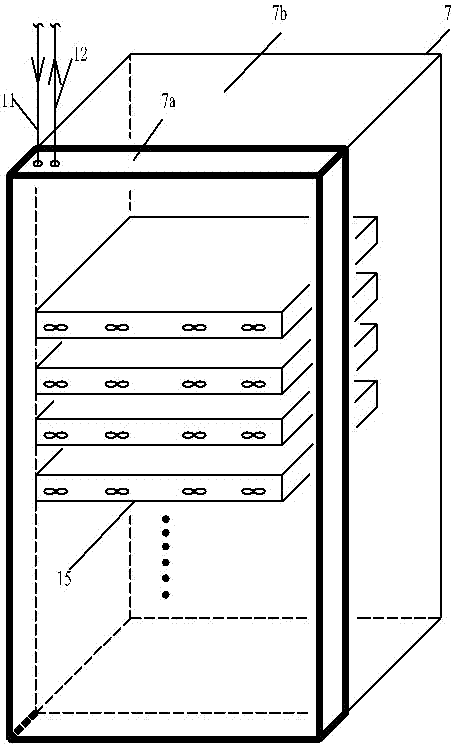

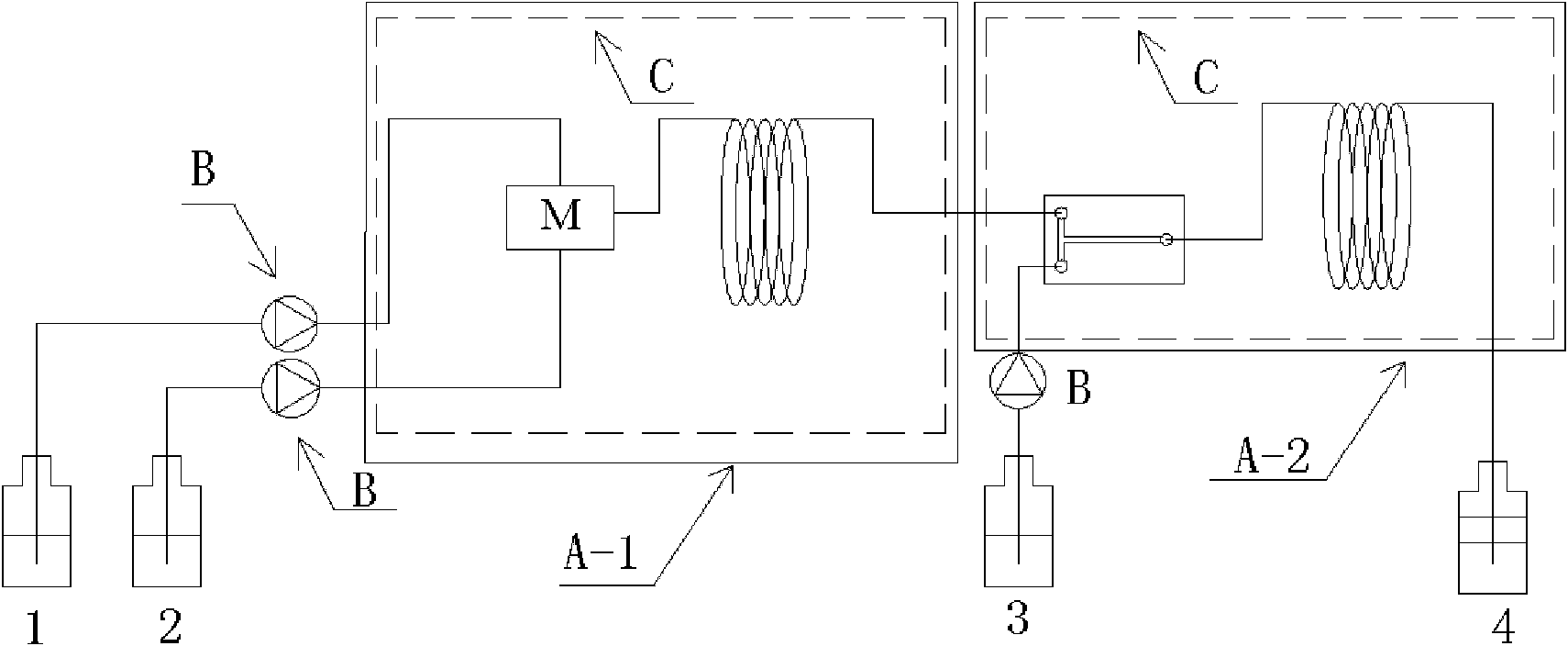

Double-drive heat pipe heat radiation cabinet

InactiveCN102869241ASolve the cooling problemSolve local overheating problemsCompression machines with non-reversible cycleFluid circulation arrangementVapor–liquid separatorFreon

The invention discloses a double-drive heat pipe heat radiation cabinet comprising a cabinet body and a heat radiator connected with the cabinet body. The cabinet body comprises a body and a back box on the back of the body, a Freon input pipe and a Freon output pipe are communicated on the back box, and a heat radiation pipe communicating the Freon input pipe with the Freon output pipe are arranged in the back box. The heat radiator comprises a gas and liquid separator, a compressor, a heat exchanger, a liquid storage device and a drying filter which are sequentially communicated, the drying filter is communicated with a fluorine pump and a throttling mechanism, the gas and liquid separator is communicated with the Freon output pipe, and the fluorine pump and the throttling mechanism are communicated with the Freon input pipe simultaneously. An inlet pipe and an outlet pipe of the compressor are respectively provided with an electromagnetic valve and communicated with a bypass pipe which is provided with an electromagnetic valve. A pressure sensor is arranged in the heat exchanger.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD

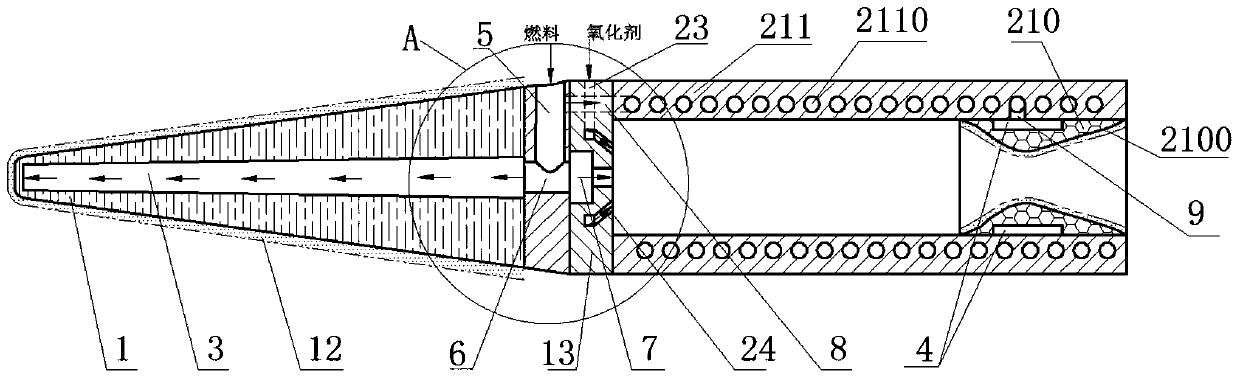

Rocket ejector and thermal protection structure and method thereof

PendingCN109812352ATroubleshooting Insufficient CoolingSolve local overheating problemsRocket engine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a thermal protection structure and method of utilizing emission and transpiration combined cooling for a TRRE (turbo-aided rocket-augmented ramjet combined cycle engine) rocketejector. The rocket ejector is divided into a front edge head cone and a thrust chamber, and the front edge head cone and the thrust chamber are cooled respectively. Laminate transpiration cooling isadopted by the front edge head cone portion to conduct thermal protection. The mode of combined cooling of emission cooling and transpiration cooling is adopted by the thrust chamber portion, and a spiral cooling channel structure is adopted by the emission cooling. The outer surface and the inner surface of a combustion chamber are cooled through emission cooling at the same time, the cooling effect of a spray pipe portion is poor, and then porous transpiration cooling is conducted on the spray pipe portion. The thermal protection structure and method are good in cooling effect, small in quantity of cooling agents and high in reliability, and can achieve the purpose of being reusable.

Owner:CENT SOUTH UNIV

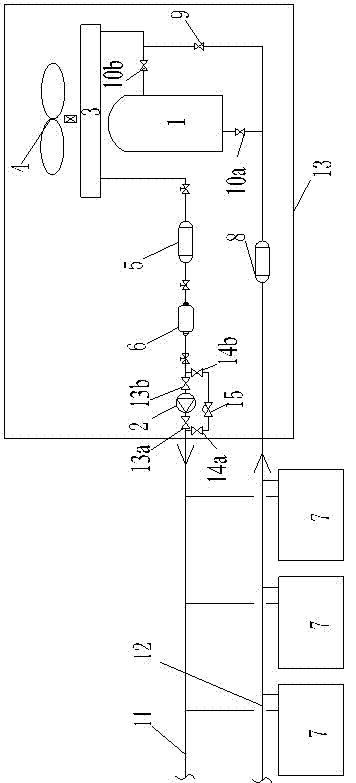

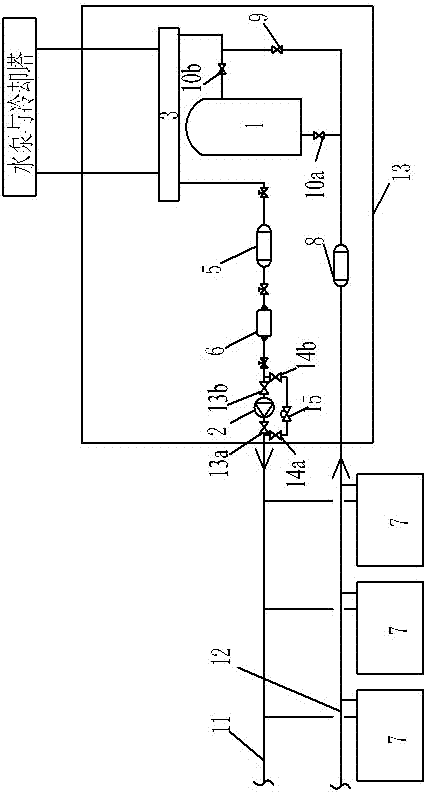

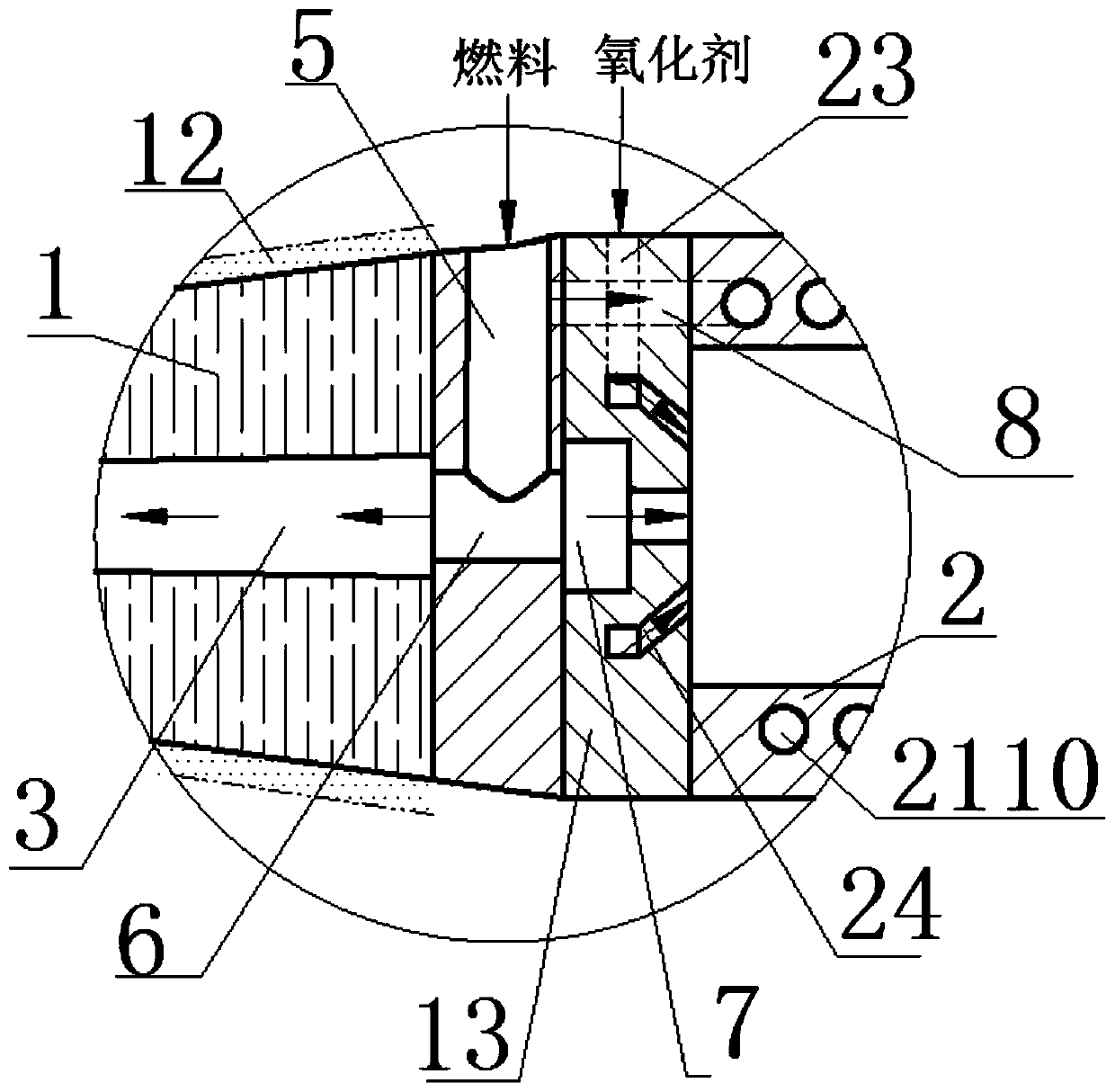

Flood irrigation type air conditioner adaptability energy-saving control system and method for machine room or base station

ActiveCN108507115ARealize energy-saving operation transformationAvoid hotspotsMechanical apparatusSpace heating and ventilation safety systemsIrrigationFixed frequency

The invention provides a flood irrigation type air conditioner adaptability energy-saving control system and method for a machine room or a base station. Energy-saving operation transformation for anair conditioner system of the machine room or the base station is effectively achieved by adopting an adaptability energy-saving control module, and the problem of a hot point existing in IT heating equipment is effectively solved. By monitoring the temperature / humidity in the machine room or the base station and fully utilizing the design redundancy of a fixed-frequency compressor, a fixed-frequency fan or a fixed frequency water pump of an air conditioner, the operation frequency of the compressor, the fan or the water pump is adjusted between the upper limit and the lower limit of the acceptable frequency of the compressor, the fan or the water pump, thus the system operation energy consumption of the machine room or the base station is effectively decreased under the situation withoutreplacing an air conditioner unit and system equipment, and the energy-saving operation and transformation costs of the air conditioner system of the machine room or the base station are greatly saved; and a new idea is provided for energy-saving transformation of the air conditioner of the machine room or the base station, and the energy saving and hot-point eliminating transformation costs are greatly reduced.

Owner:HEFEI GENERAL MACHINERY RES INST +1

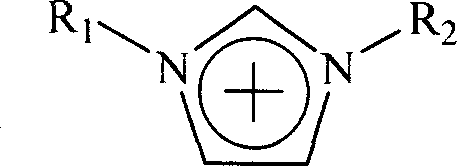

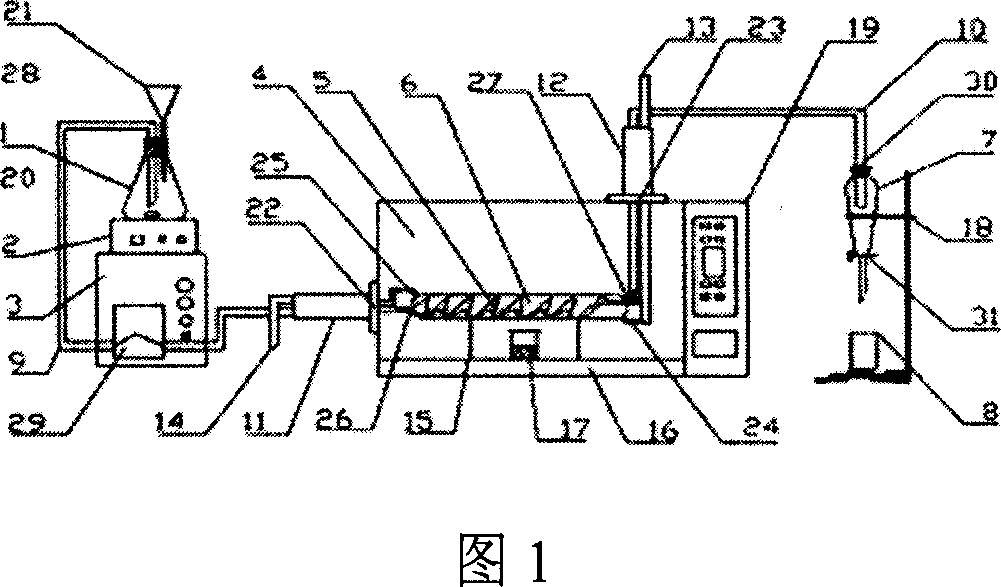

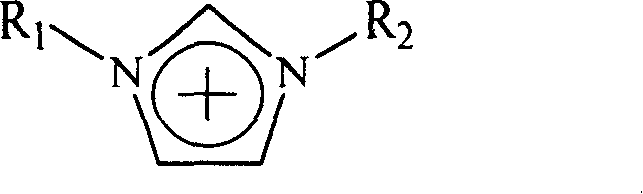

Method for preparing ion liquor

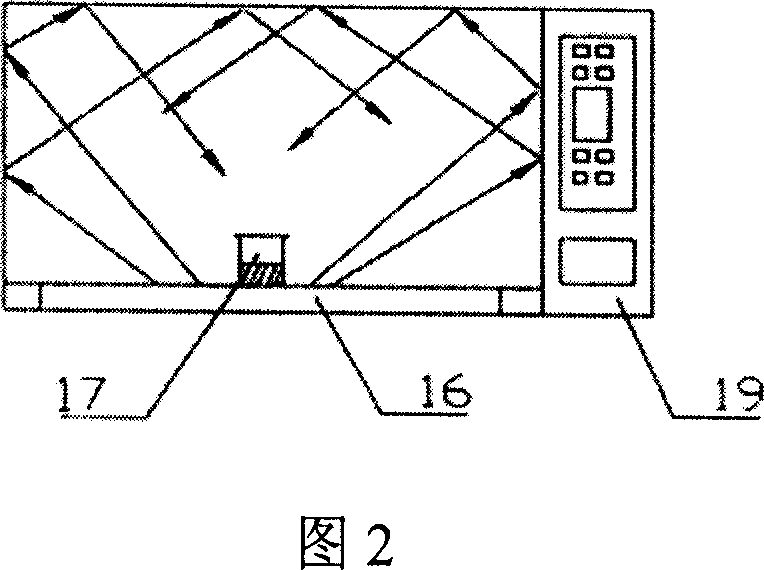

InactiveCN1958574ALow priceReduce volumeOrganic chemistryChemical recyclingMicrowave ovenReaction rate

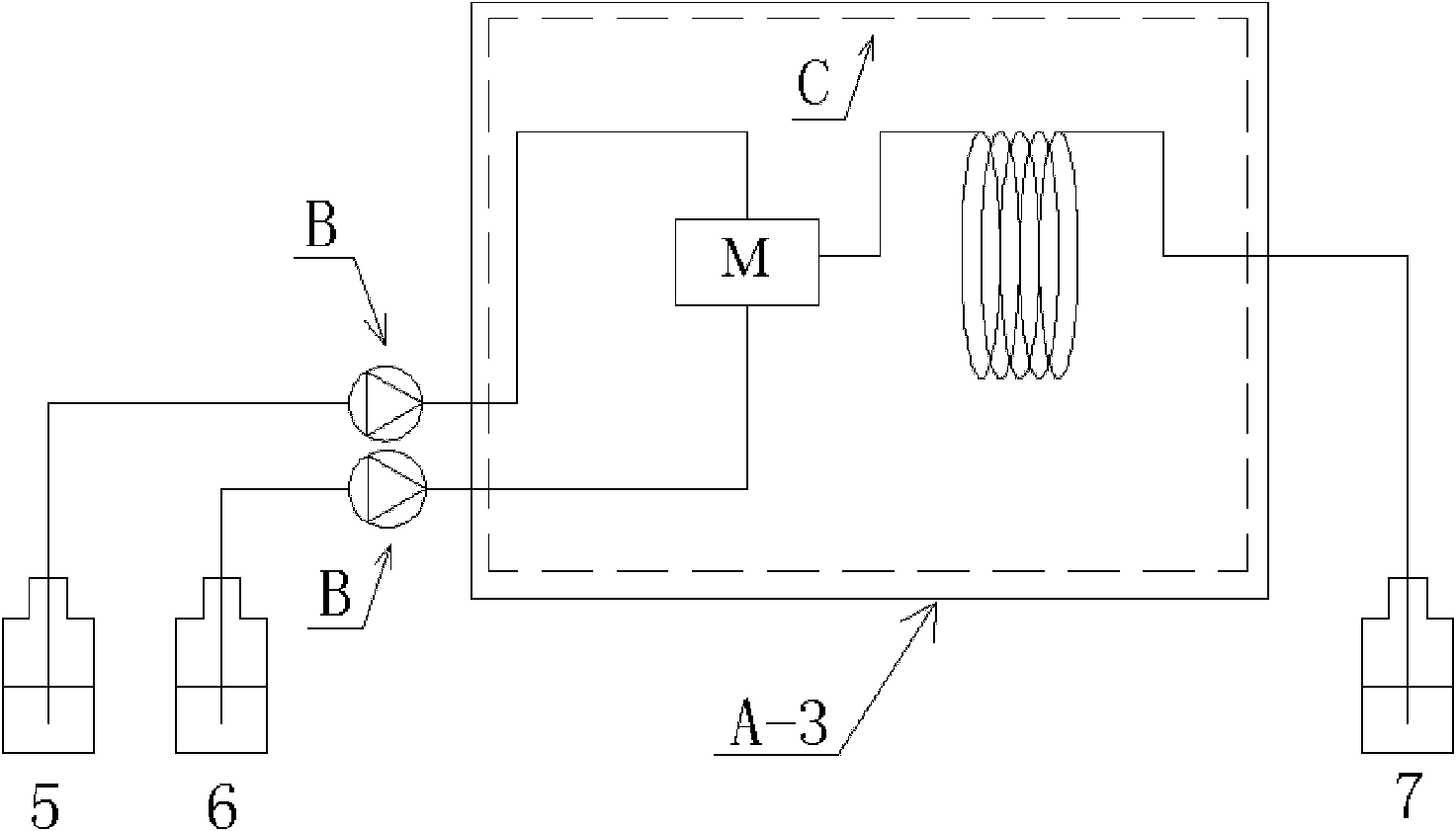

This invention relates to a method for preparing ionic liquid. The continuous microwave reaction equipment used is designed, modified and assembled on the basis of domestic microwave oven. The general chemical formula of the ionic liquid is A+B-, where A+ is organic cation, and B- is inorganic anion. The melting point of the ionic liquid is lower than 100 deg.C under an atmosphere (101.325 kPa). The method can increase the reaction rate by 10-1000 times, thus can shorten the time of ionic liquid synthesis from a week to within an hour. Besides, the process is continuous.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

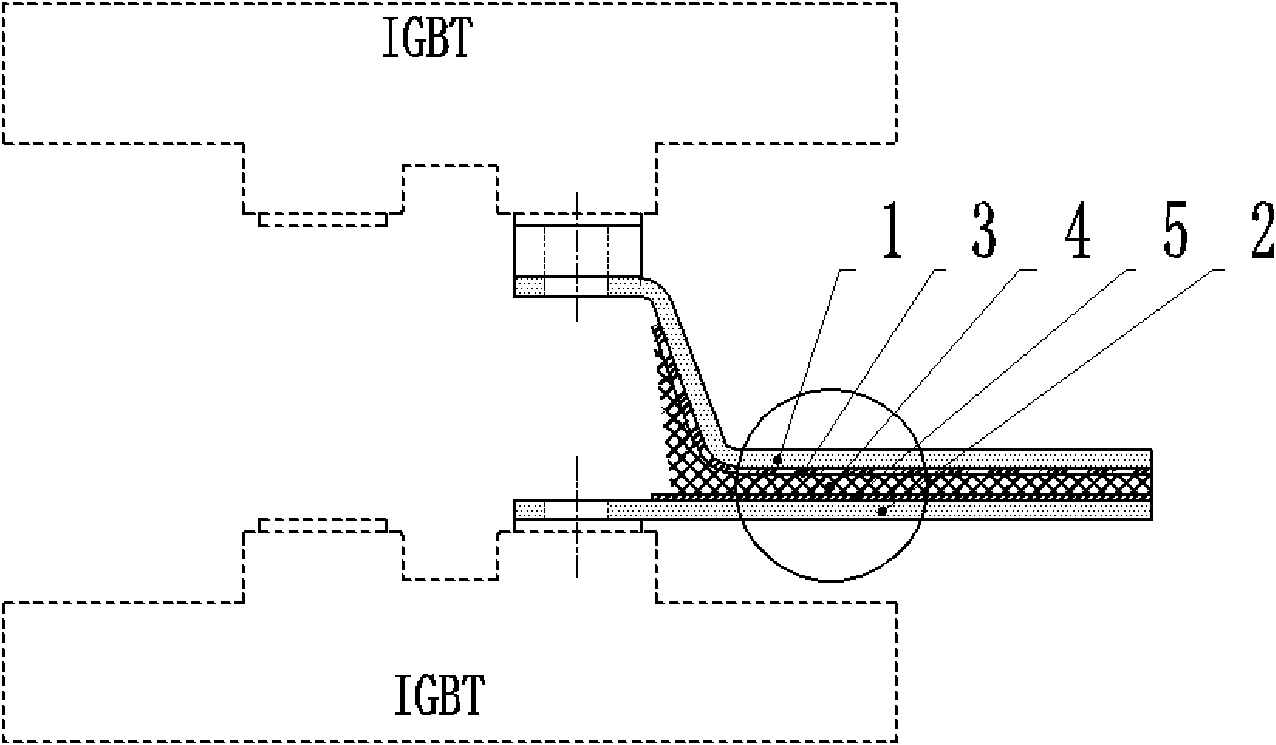

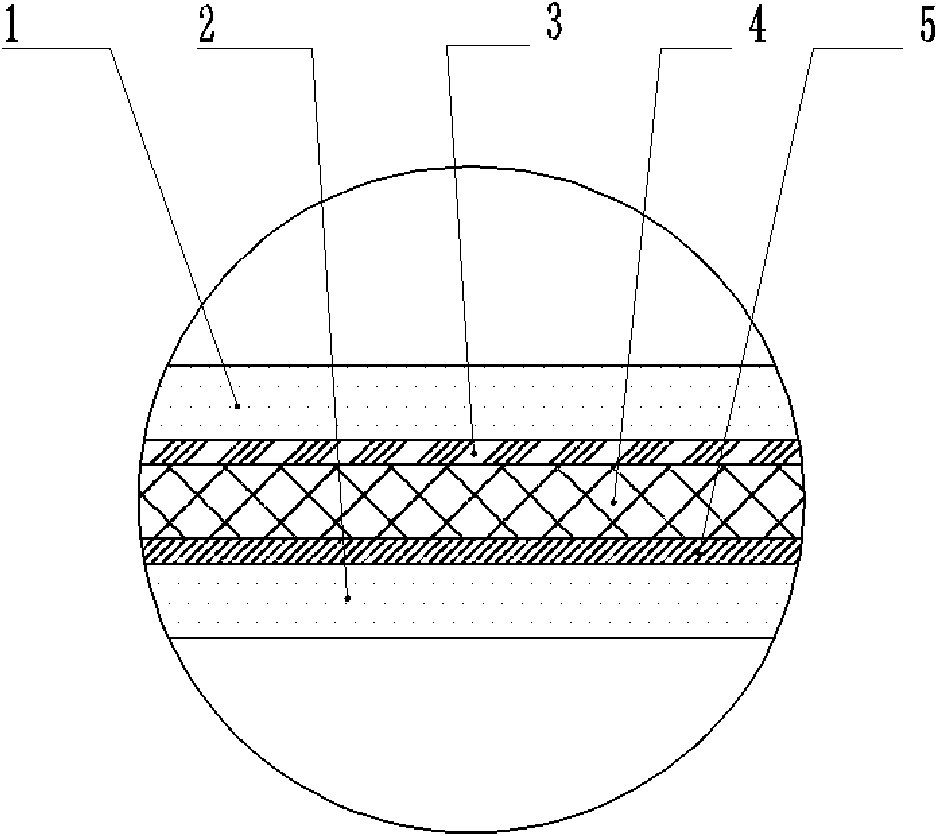

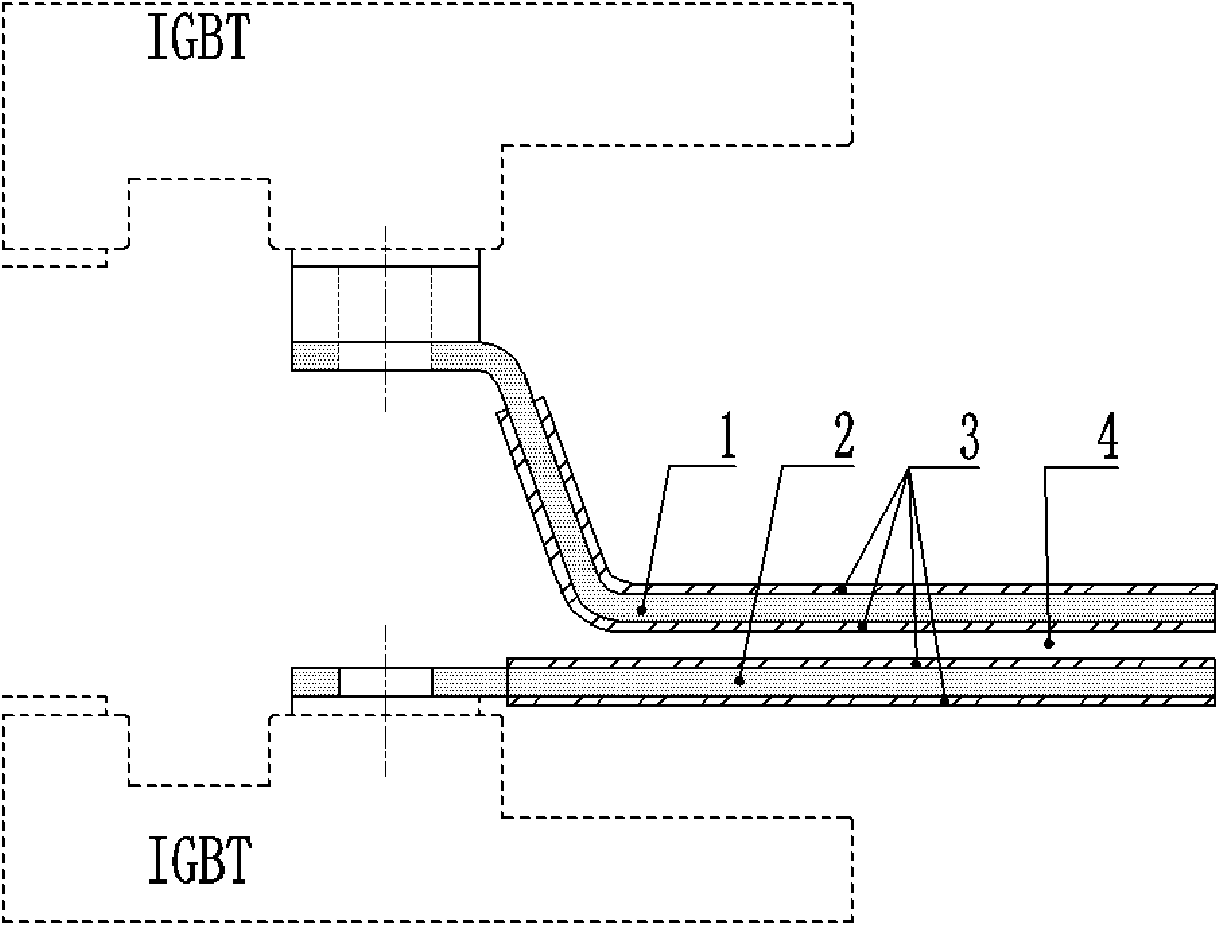

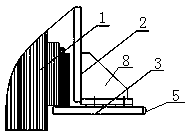

Compound insulation-based low-sense busbar

InactiveCN102129893ASolve the cooling problemSmall partial dischargeCoupling contact membersInsulated cablesBusbarEngineering

The invention relates to a compound insulation-based low-sense busbar. The compound insulation-based low-sense busbar is characterized by comprising a multi-layer structure which is formed by laminating and arranging a copper bar (1), a copper bar (2), an insulating layer (3), an insulating layer (4) and an insulating layer (5) sequentially. The structure greatly reduces the local release amount between the copper bars, effectively solves the radiating problem of the busbar, and has the characteristics of convenience for processing and manufacturing, low cost, high flexibility and high adaptability.

Owner:CHINA ELECTRIC POWER RES INST +1

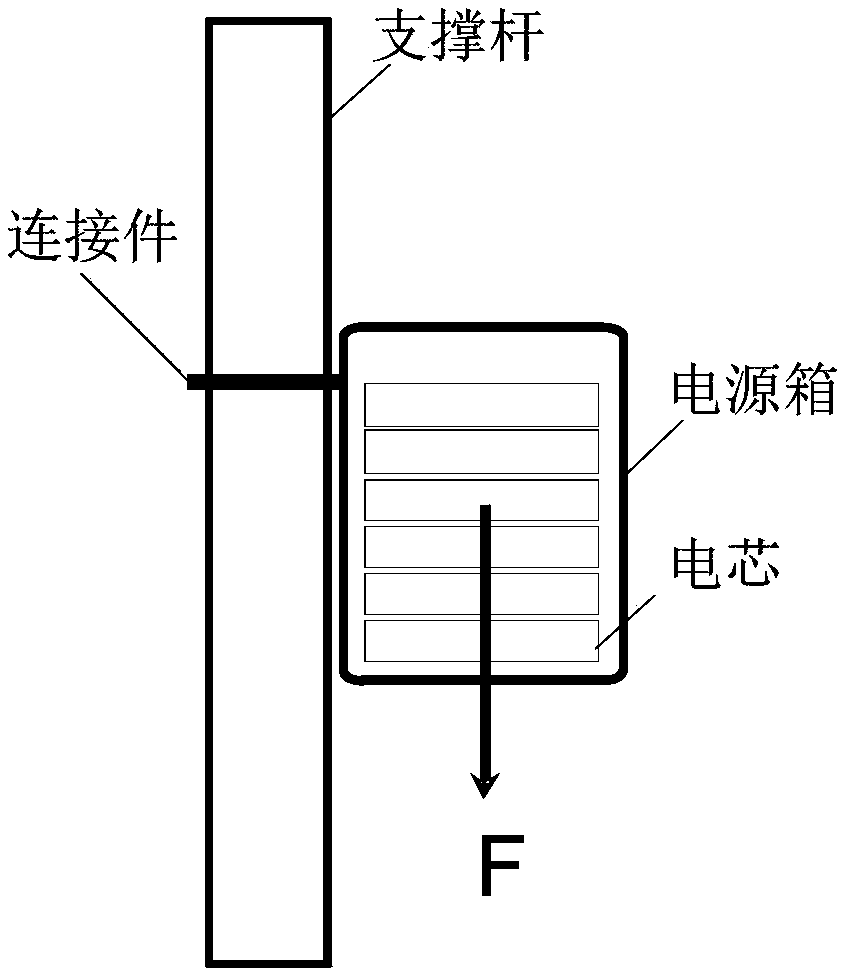

Holding pole power supply

InactiveCN108417746AImprove stabilityExtended service lifeMachine supportsCells structural combinationEngineeringBattery cell

Owner:HUAWEI TECH CO LTD

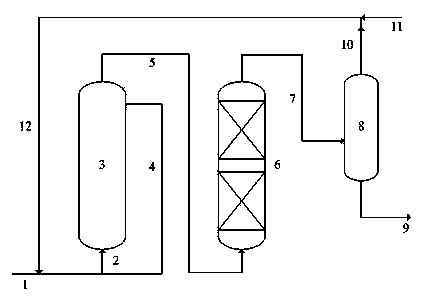

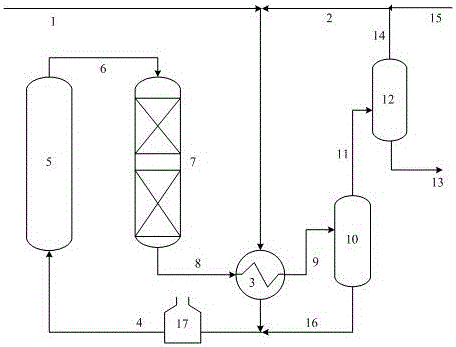

Hydrotreating method of inferior gasoline raw material

ActiveCN103805264AEfficient use ofAvoid abnormal downtimeTreatment with hydrotreatment processesHydrogenFluidized bed

The invention discloses a hydrotreating method of an inferior gasoline raw material. The method comprises the following steps: mixing inferior gasoline with thermal loaded oil and circulating hydrogen, allowing the mixture to enter a fluidized bed hydrogenation pretreatment reactor; separating the effluent of the hydrogenation pretreatment to obtain gas and liquid; returning the liquid as thermal loaded oil to the pretreatment reactor, allowing the gas to pass through a gasoline hydrotreating reactor in an upward flow manner; performing gas-liquid separation of the gasoline hydrogenation effluent in a low temperature low pressure separator, purifying the obtained hydrogen-rich gas for recycle, and performing gas stripping of the obtained liquid so as to be used as a gasoline blending component or a chemical raw material. The method of the invention greatly prolongs the running period of the inferior gasoline hydrotreating device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application of continuous microwave reactor

InactiveCN1973992ALow priceReduce volumeEnergy based chemical/physical/physico-chemical processesMicrowave ovenReaction rate

The present invention is the application of continuous microwave reactor in preparing ionic liquid. The continuous microwave reactor developed based on household microwave oven is applied in preparing ionic liquid in the general expression of A+B-, where, A+ is organic cation, B- is inorganic anion. The ionic liquid has smelting point at 1 atm (101.325kPa) lower than 100 deg.c. The continuous microwave reactor has high reaction rate of preparing ionic liquid, 10-1000 times higher than conventional process, and the continuous process results in effectively lowered cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

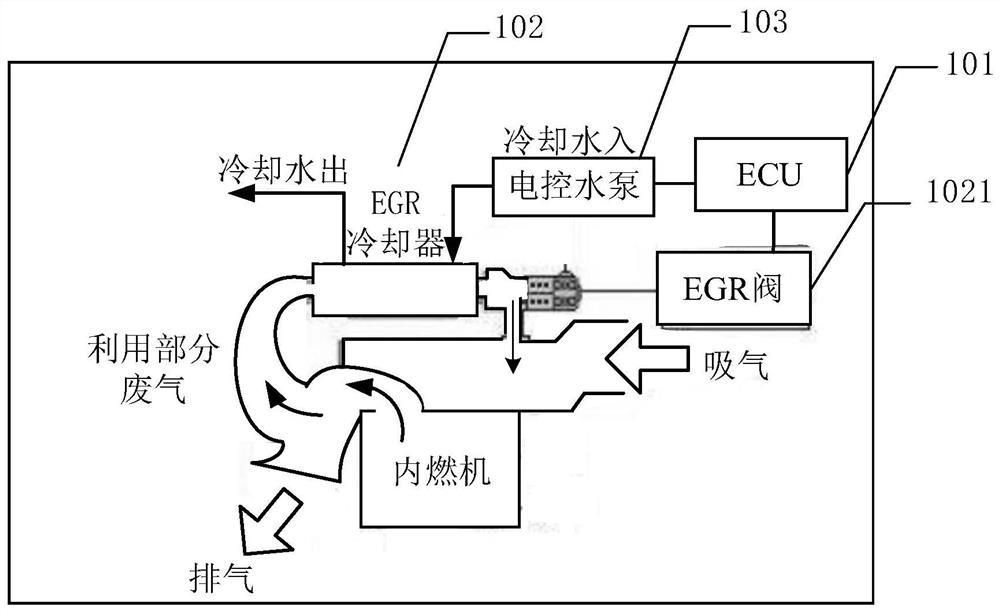

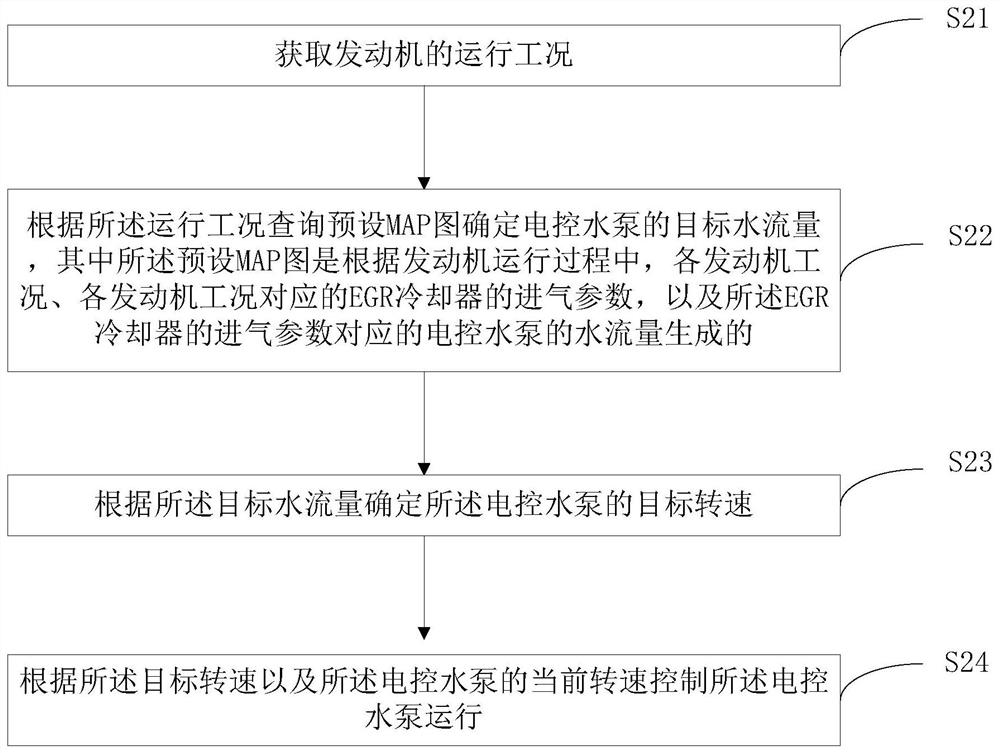

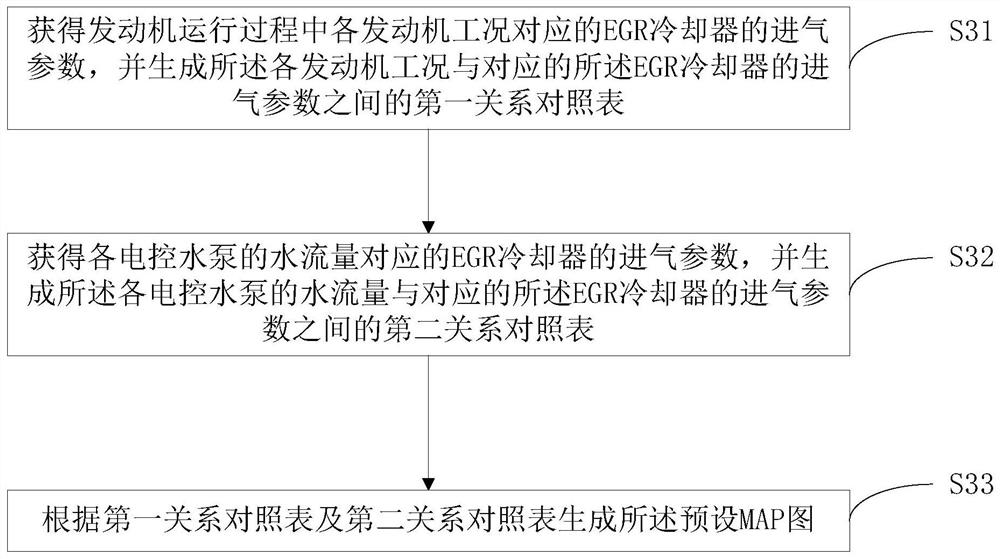

Electric control water pump control method and ECU

ActiveCN111734616AAvoid local overheatingSolve local overheating problemsExhaust gas recirculationPump controlThermodynamicsWater flow

The invention provides an electric control water pump control method and an ECU. The method comprises the steps of obtaining the operating condition of an engine, inquiring a preset MAP according to the operating condition to determine the target water flow of an electric control water pump, determining the target rotating speed of the electric control water pump according to the target water flow, and controlling the electric control water pump to operate according to the target rotating speed and the current rotating speed of the electric control water pump. The minimum water flow corresponding to the operating condition of the engine is determined according to the preset MAP, the rotating speed of the electric control water pump corresponding to the minimum water flow is determined, andthe operation of the electric control water pump is controlled according to the target rotating speed and the current rotating speed of the electric control water pump, so that the problem of local overheating in an EGR cooler in a cooling process is avoided.

Owner:WEICHAI POWER CO LTD

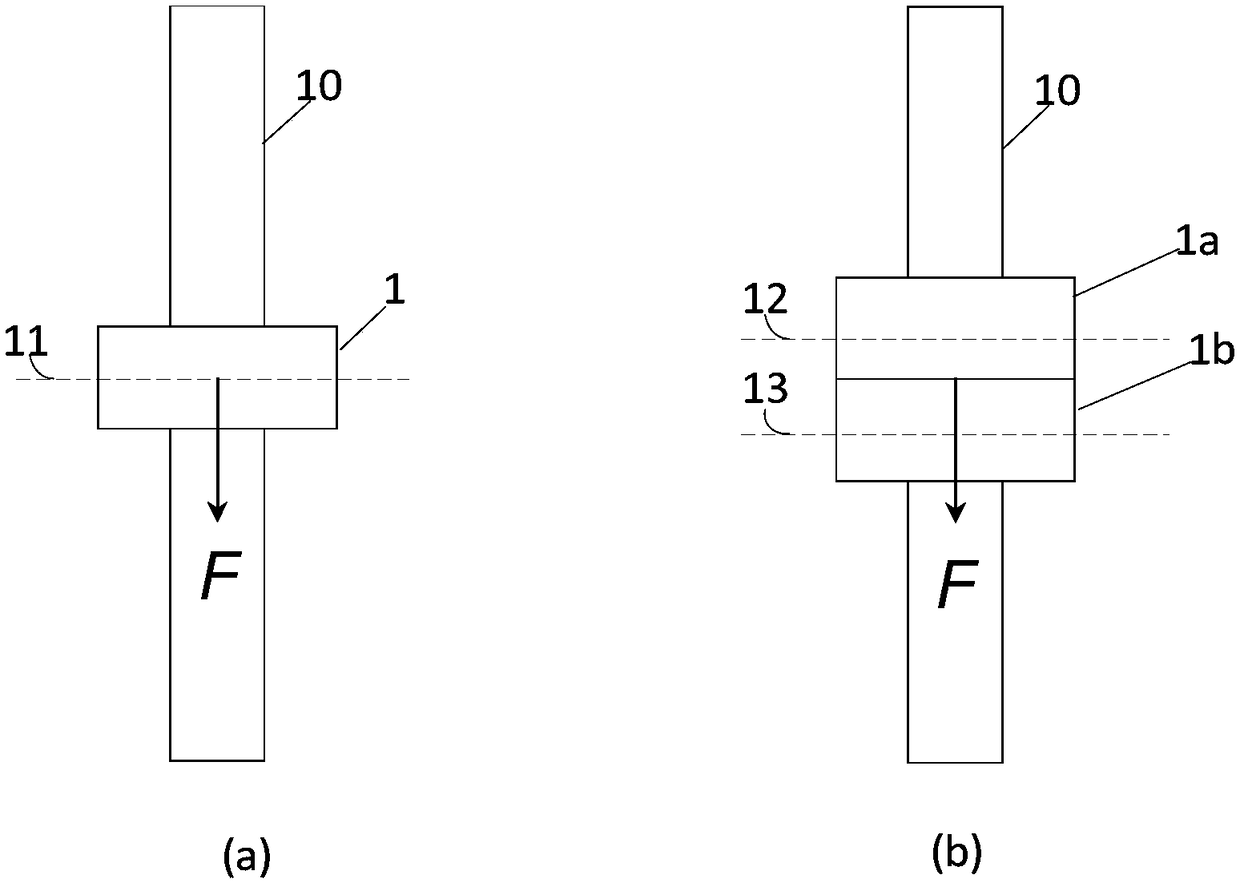

Overheating preventing structure for super-large current lead of transformer

InactiveCN102856056ASolve local overheating problemsSimple structureTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionLow voltageTransformer

The invention relates to an overheating preventing structure for a super-large current lead of a transformer. The overheating preventing structure is arranged on a low-voltage side of the transformer, and a shielding method combining a magnetic shield and a copper shield is adopted around a large-current lead on the low-voltage side. The shielding method combining the magnetic shield and the copper shield includes that a clamping piece copper shield is arranged on a core clamp piece on the upper portion of the low-voltage side, an oil tank copper shield is arranged on the inner surface of a tank cover on the low-voltage side and on a low-voltage tank wall, and simultaneously the oil tank magnetic shield in the vertical direction is arranged on the low-voltage tank wall. A low-voltage coil of the transformer adopts a two-column parallel connection structure, and a leading-out head of each column of coil is arranged on the upper portion, and two lead copper bars are arranged parallelly in juxtaposed mode. The overheating preventing structure solves the problem of overheating of a local portion of a structural member around the large-current lead. A copper plate is directly welded on a steel structural member, the structure is simple, and the manufacturability is good.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

A method for hydrogenation of benzene to prepare cyclohexane in a magnetically stabilized bed

ActiveCN103232315AExtended service lifeReduce churnHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneHydrogen

The present invention discloses a method for hydrogenation of benzene to prepare cyclohexane in a magnetically stabilized bed. The method comprises steps of: first loading sodium borohydride reduced Ni2 + and metal cation additive on a magnetic catalyst, and then loading the magnetic catalyst into the reaction unit of the magnetically stabilized bed, and controlling reaction conditions of a ratio of hydrogen to benzene, a space velocity, and a magnetic field strength to enable a bed layer to form a magnetically stabilized state for hydrogenation of benzene to prepare cyclohexane. By using the magnetically stabilized bed to control the bed layer fluidization state for hydrogenation of benzene to prepare cyclohexane, the method of the present invention prevents local hot spots from emerging in the bed layer, reduces catalyst deactivation, maintains a relatively high benzene conversion rate and cyclohexane selectivity, and substantially increases the service life of the catalyst; and the magnetic field can be used to separate and recover the catalyst, thus reduce production costs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

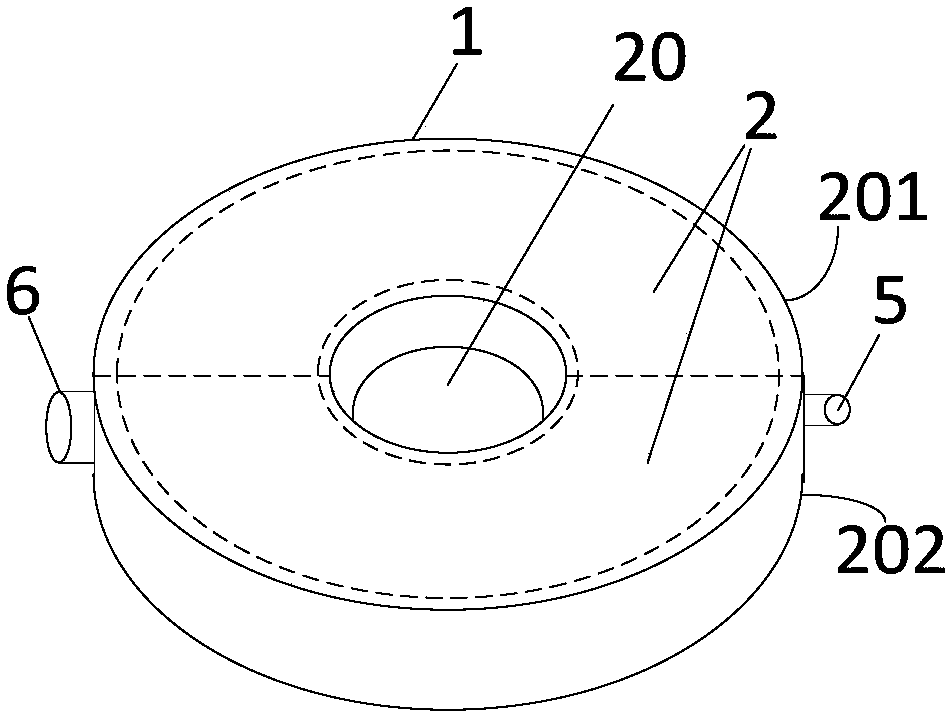

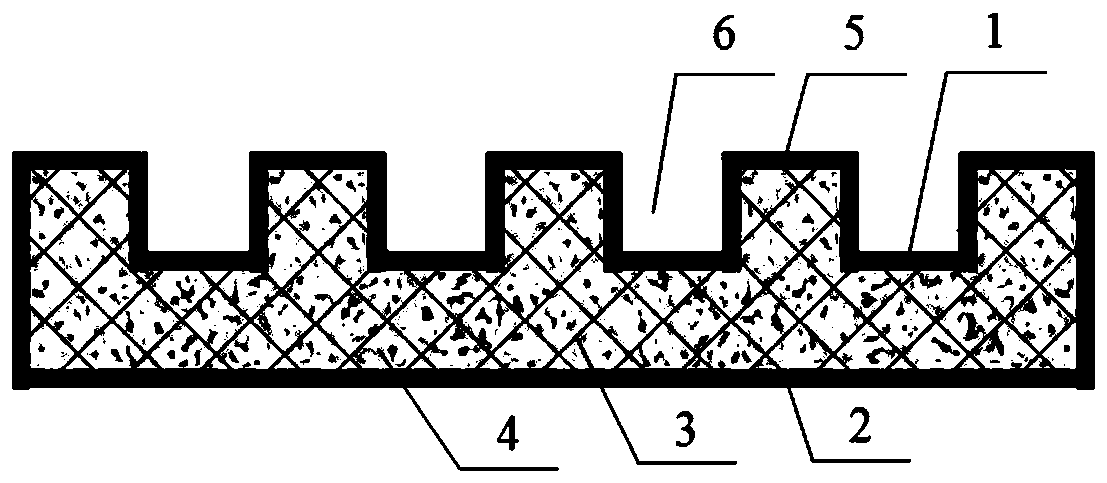

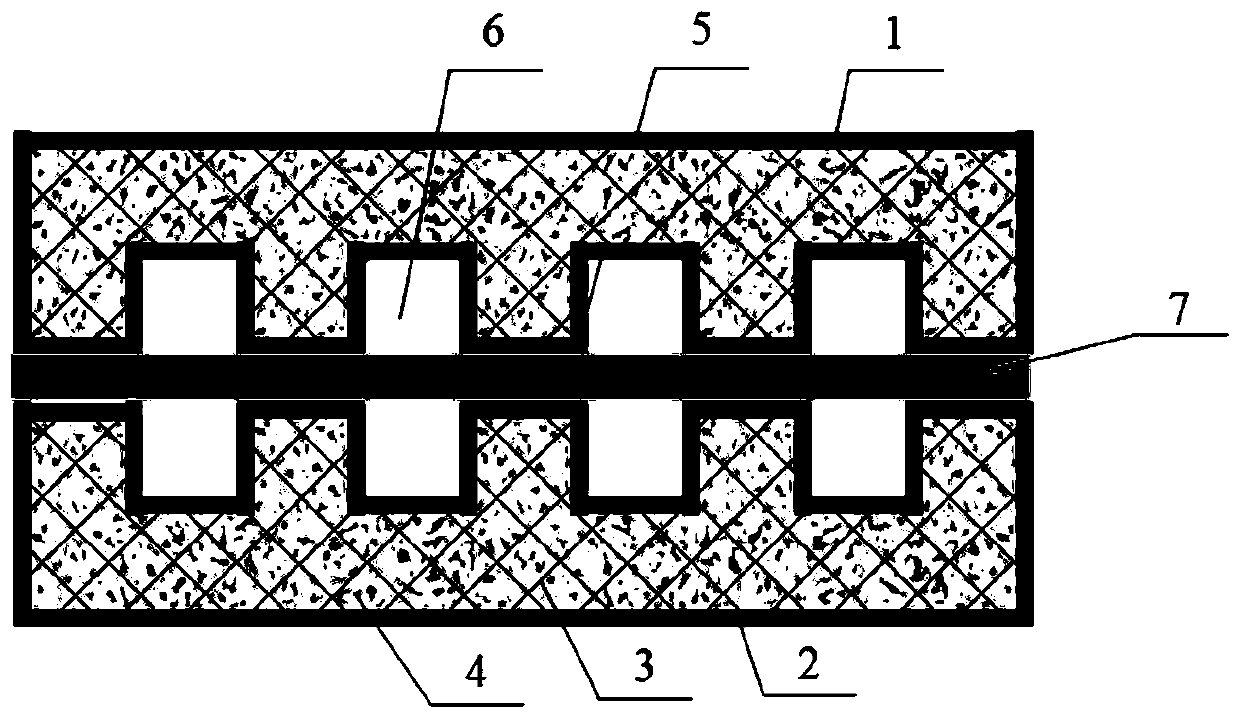

Light self-temperature-equalizing bipolar plate based on foam metal and preparation method thereof

ActiveCN110797547ASolve local overheating problemsShort response timeFinal product manufactureFuel cellsManufacturing technologyFuel cells

The invention discloses a light self-temperature-equalizing bipolar plate based on foam metal and a preparation method thereof. The bipolar plate structure comprises a plate body, a shell and the foammetal, wherein the shell is arranged to be of an outer layer structure of the plate body, the foam metal is arranged to be of an inner layer structure of the plate body, a cavity of the foam metal isfilled with a phase change material, heat generated by an overheating area is stored through the phase change material, the heat transfer process is enhanced through the foam metal, and problems thatthe phase change material is small in heat conductivity coefficient and long in heat charging time are solved. The bipolar plate structure is advantaged in that heat stored in the phase change material can provide heat for the process of battery restart to reduce the corresponding time, the foam metal material is adopted as a raw material for manufacturing the bipolar plate of the fuel cell, moreover, a shell is formed through laser sintering, and manufacturing process difficulty of the bipolar plate is reduced through the laser sintering technology.

Owner:西安交通大学深圳研究院 +1

High-capacity transformer magnetic shielding device

PendingCN111029114ASimple structurePrevent closureUnwanted magnetic/electric effect reduction/preventionStray lossEngineering

The invention relates to a local component of a transformer, in particular to a high-capacity transformer magnetic shielding device. The high-capacity transformer magnetic shielding device comprises an iron yoke and a clamping piece which are arranged on the transformer, and is characterized in that a magnetic shielding block matched with the iron yoke is arranged on the clamping piece, the magnetic shielding block is formed by superposing a plurality of layers of silicon steel sheets, and a frame is fixed on the outer sides of the silicon steel sheets. The high-capacity transformer magnetic shielding device has the advantages that leakage flux is prevented from passing through the structural part to be closed, the purposes of reducing stray loss and solving the problem of local overheating of the structural part are achieved, the structure is simple, the shielding effect is good, and the manufacturing and using cost of the transformer is greatly reduced.

Owner:SHANDONG TAIKAI TRANSFORMER CO LTD

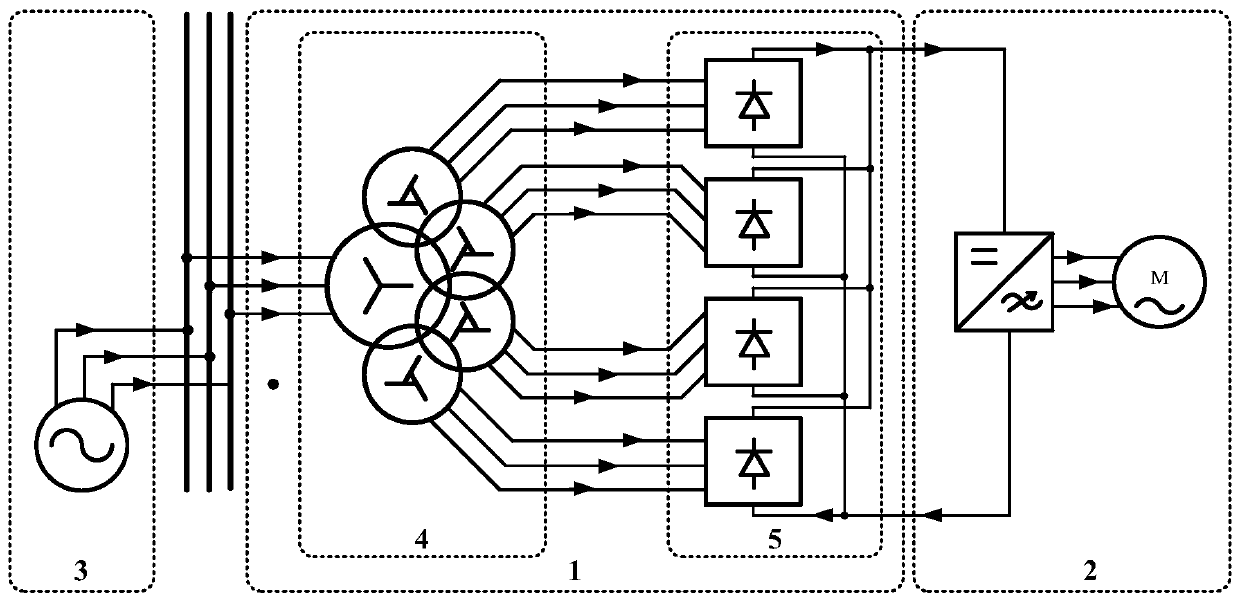

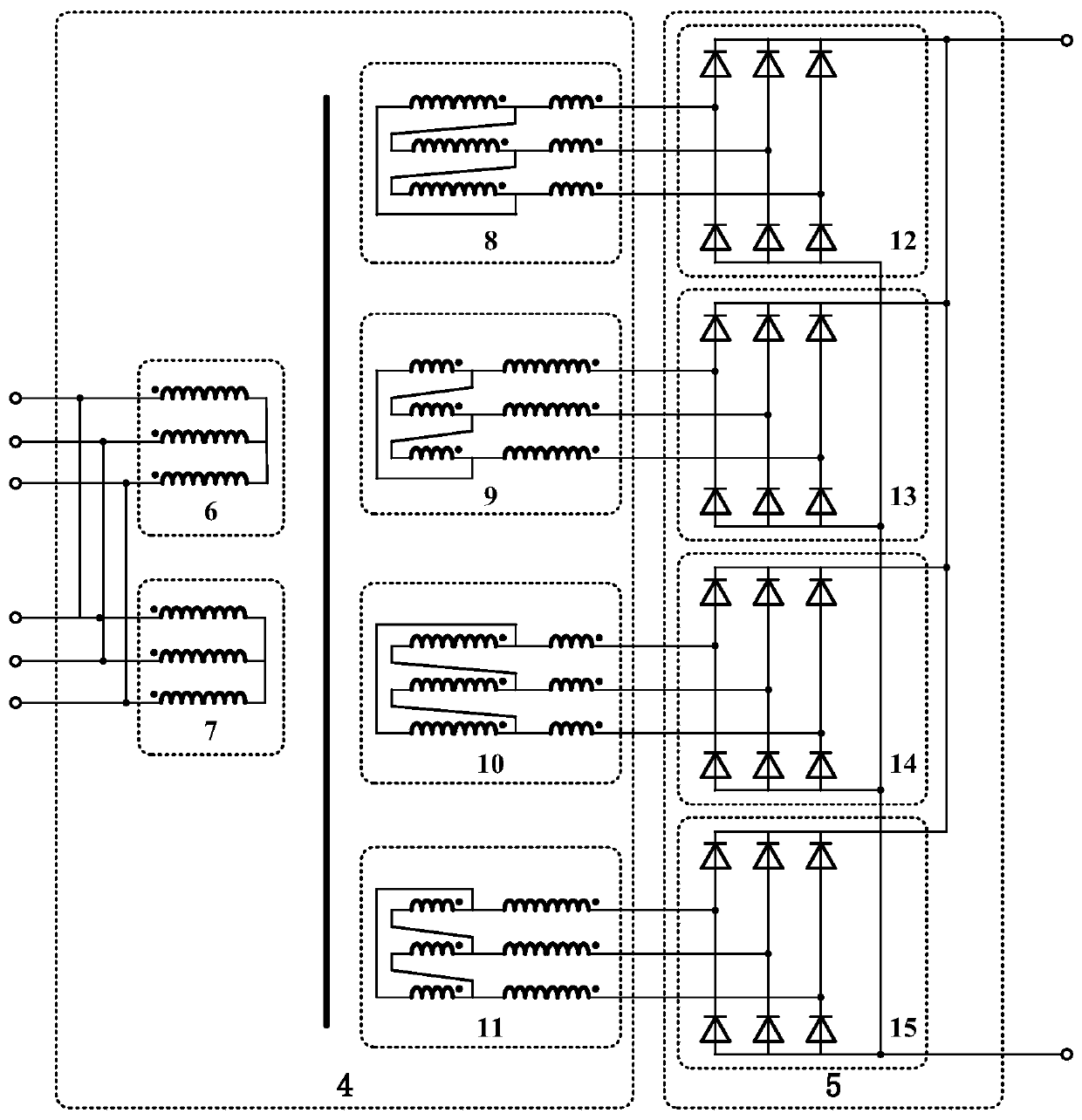

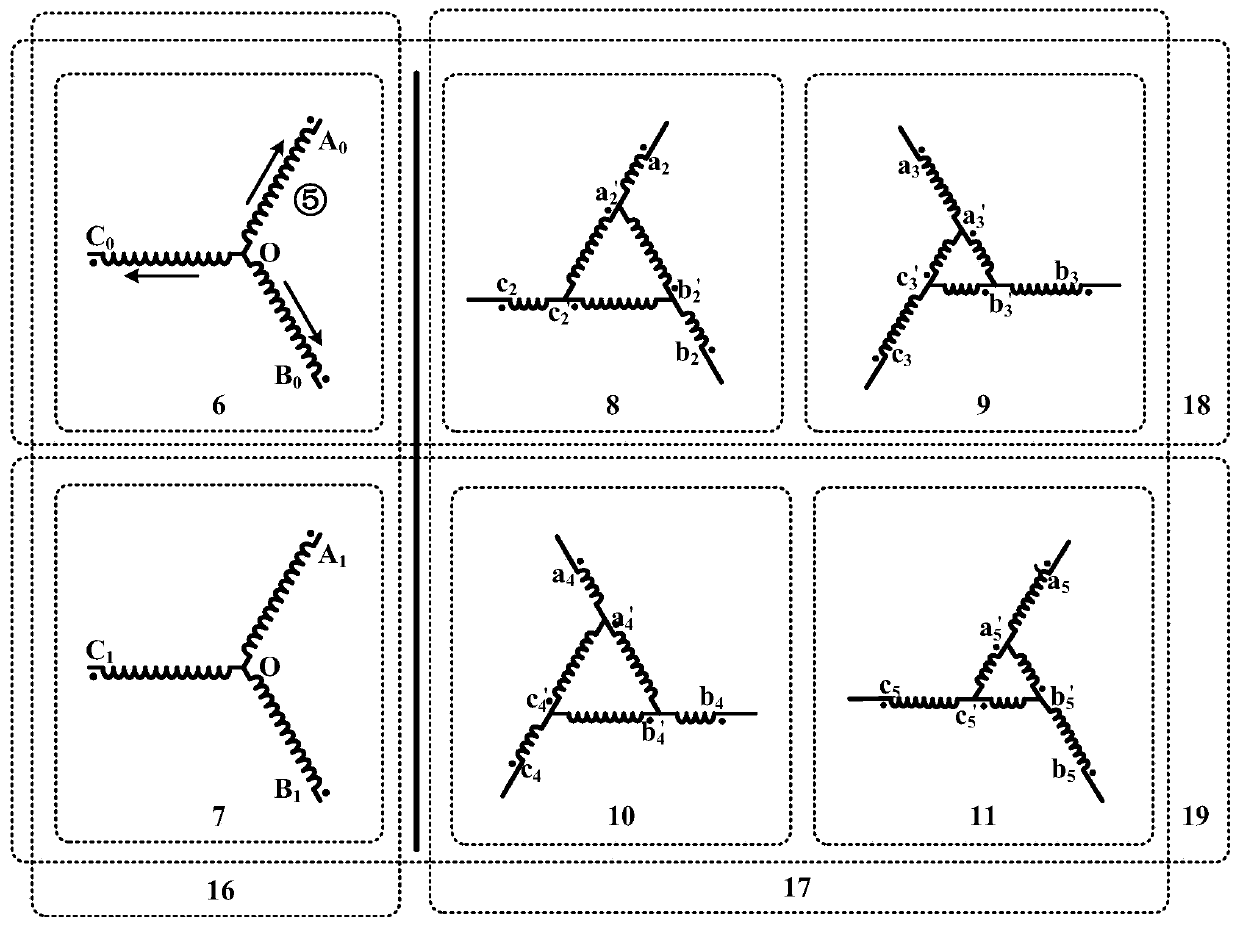

Magnetically integrated 24-pulse traction power supply system for electric propulsion

InactiveCN110460249AImprove performanceReduce volumeAc-dc conversion without reversalConversion without intermediate conversion to dcPower qualityTraction power supply

The invention discloses a magnetically integrated 24-pulse rectifier traction power supply system for electric propulsion, which comprises a 24-pulse magnetically integrated rectifier transformer adopting staggered winding arrangement and four three-phase bridge diode rectifiers. The four three-phase output windings of the rectifier transformer are respectively connected with the three-phase inputends of the four bridge diode rectifiers. At the same time, the head ends of the input three-phase windings of the upper and lower bridges of the 24-pulse magnetically integrated rectifier transformer adopting staggered winding arrangement are connected in parallel in turn to be used as the three-phase input end of the magnetically integrated 24-pulse rectifier traction power supply system, and the output ends of the four bridge diode rectifiers run in parallel and provide a stable DC voltage for an electric propulsion system as the DC output end of the magnetically integrated 24-pulse rectifier traction power supply system. The power quality of the network side and the DC side of the rectifier traction power supply system can be improved, the volume and weight of the power supply systemcan be significantly reduced, and the complexity of the connection process can be reduced.

Owner:HUNAN UNIV

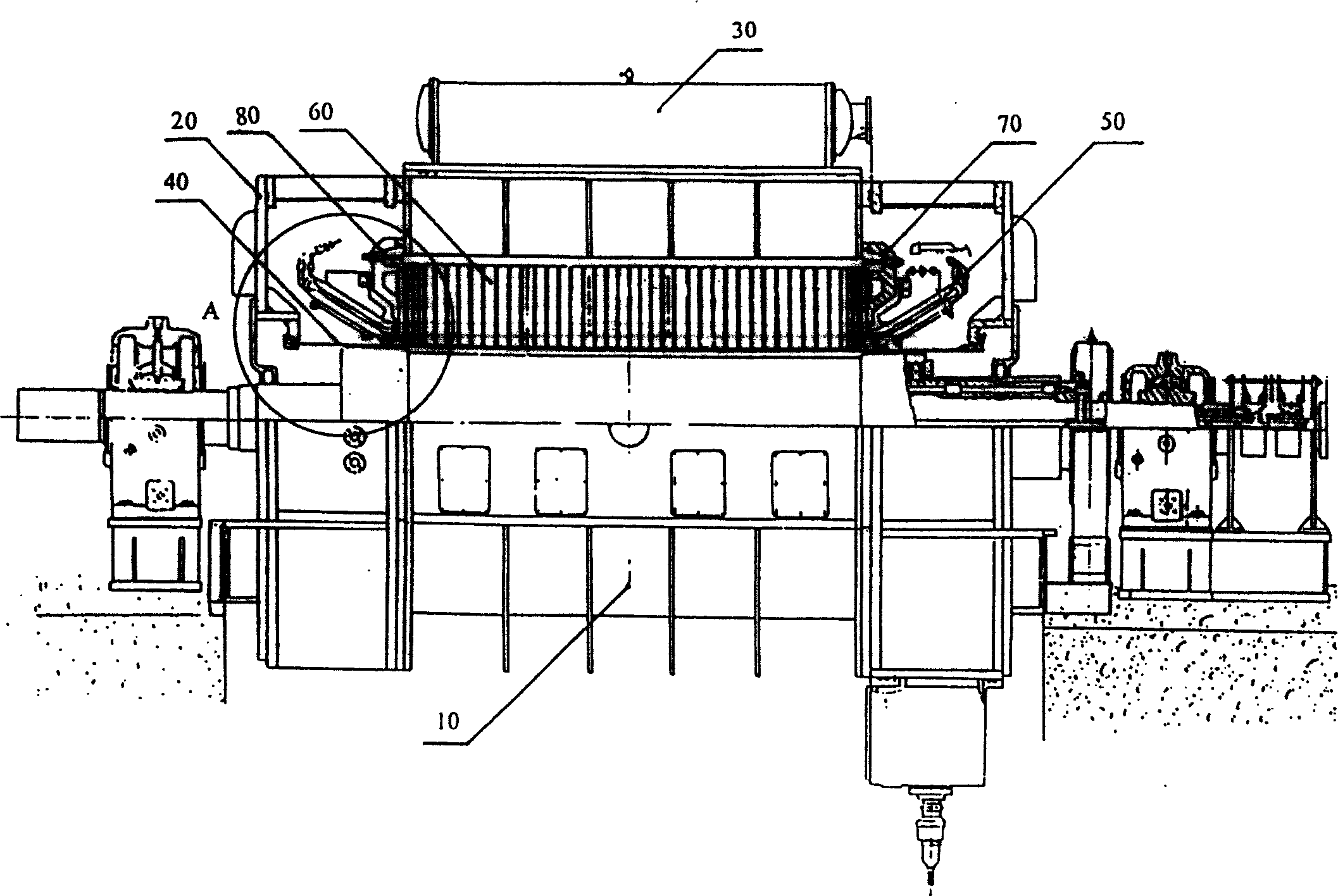

Full immersed type self circular loop of evaporative cooling stator of steam turbine generator

InactiveCN1191668CUnimpeded flowAdequate infiltrationCooling/ventillation arrangementHydrogenNuclear engineering

The cooling circulation loop includes the cooling circulation sub-loop in the slot part of the stator core, the sub-loop between the sections of the iron core and the sub-loop between the pressing rings at the end parts of the stator core and the tooth pressure plates. The liquid cooling medium with high insulation and low boiling point of good physical and chemical properties is injected into the cavity of the stator. Each sub-loop is connected to the cavity of the stator. The cooling liquid absorbs the heat so as to be boiled and gasified, flowing in the circulation loop freely getting earth part of the stator cooled. The said cooling circulation loop possesses the advantages of the water, hydrogen and air-cooling and prevents the insulatiom damage and explosion caused by the leakage of water and hdyrogen.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

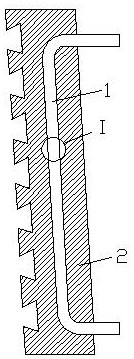

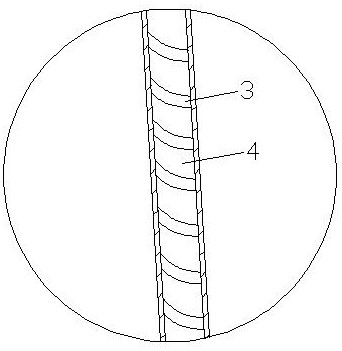

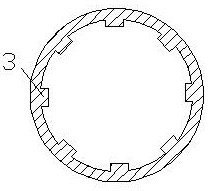

Efficient heat exchange cooling wall for blast furnace and cooling method of efficient heat exchange cooling wall

PendingCN112322816AEvenly heatedSolve local overheating problemsCooling devicesThermodynamicsWater flow

The invention relates to an efficient heat exchange cooling wall for a blast furnace and a cooling method of the efficient heat exchange cooling wall. The efficient heat exchange cooling wall for theblast furnace comprises a cooling wall body and a heat exchange water pipe, multiple spiral bosses are arranged on the inner wall of the heat exchange water pipe, and a spiral groove is formed betweenevery two adjacent spiral bosses. The spiral bosses are arranged on the inner wall of the heat exchange water pipe to form the spiral grooves, and therefore cooling water flows in the axial directionand flows in the circumferential direction of the heat exchange water pipe at the same time, the heat exchange water pipe is heated evenly, then the portions, on the two sides of the heat exchange water pipe, of the cooling wall are heated evenly, and the problem of local overheating caused by single-side heating of the cooling walls is solved.

Owner:LAIWU TIANMING METALLURGICAL EQUIP

Transformer capable of controlling magnetic flux leakage

ActiveCN106373762AAvoid local overheatingSolve local overheating problemsUnwanted magnetic/electric effect reduction/preventionUpper jointFuel tank

The invention discloses a transformer capable of controlling magnetic flux leakage. The transformer comprises lung lobe type shields which are arranged in yoke cushion blocks at the upper end and the lower end of a transformer body, a copper shield which is arranged on the inner wall of a transformer oil tank, bar-type magnetic shields which are paved at the upper end and the lower end of the copper shield and are composed of at least one magnetic shielding bar respectively, and L-shaped copper plates which are arranged at the positions of tank edges of an upper joint and a lower joint to be connected with the copper shield. According to the transformer, the problems such as local overheating of metal structural members inside the transformer and local overheating of the transformer oil tank and connecting bolts of the upper joint and the lower joint can be solved effectively.

Owner:山东输变电设备有限公司 +1

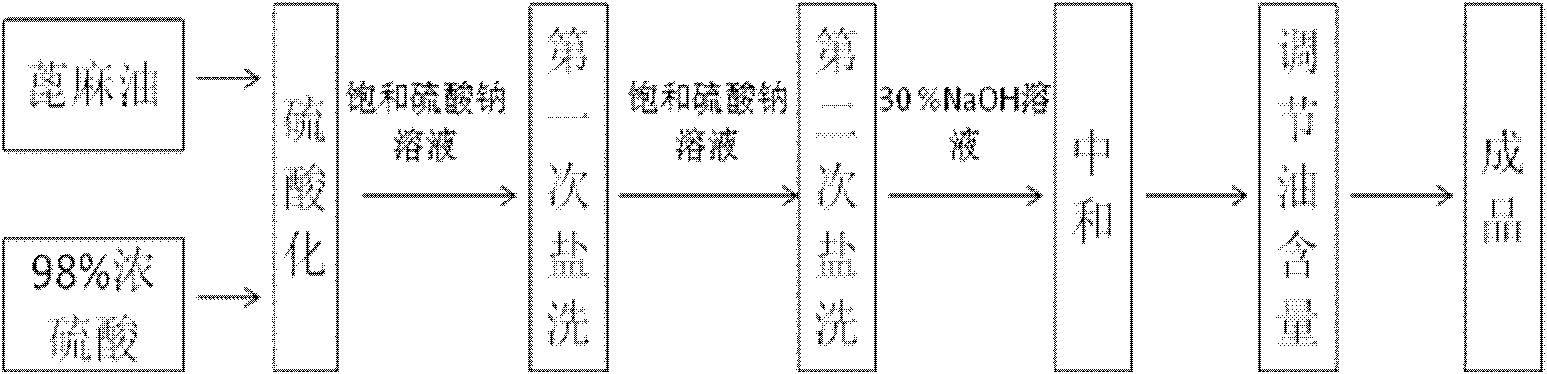

Method for preparing turkey red oil by using microstructure reactors

InactiveCN102139192AImprove securityGood mass/heat transfer propertiesTransportation and packagingMixingSmall footprintCastor oil

The invention relates to a method for preparing turkey red oil by using microstructure reactors, which comprises the steps of: taking concentrated sulfuric acid and castor oil as raw materials, sulfating in a microstructure reactor at first, then delivering the raw materials to the other microstructure reactor for salt washing, standing still, demixing, and neutralizing upper layer oil liquid with alkali liquor in the microstructure reactor to prepare the turkey red oil. The processes are all the processes featured by strong heat release or controlled by mass transfer; by adopting a micro-reaction technology provided by the invention, the method has the advantages of high safety, easiness for production operation, small floor area and the like.

Owner:NANJING TECH UNIV

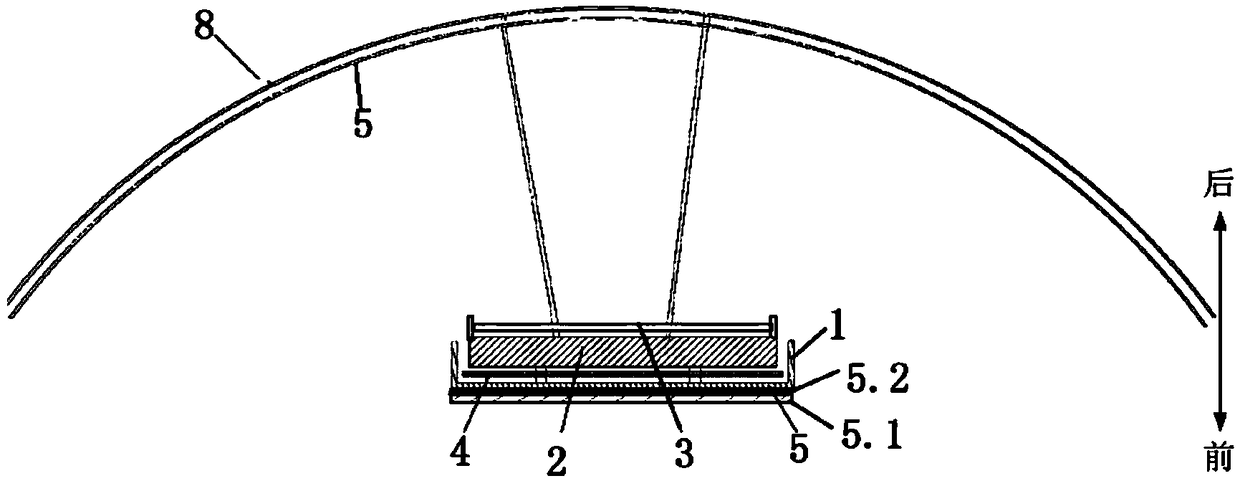

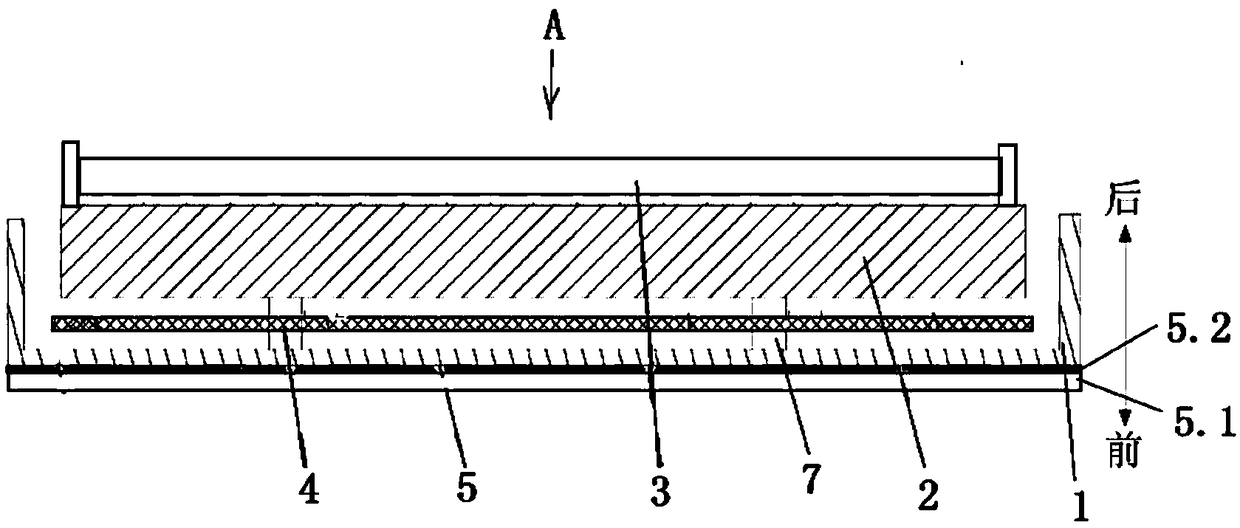

Heating disc assembly and radiation warmer

InactiveCN109413778AEliminates local overheating problemsImprove user comfortLighting and heating apparatusElectric heating systemElectric heatingInfrared

The invention discloses a heating disc assembly and a radiation warmer. The heating disc assembly comprises a shell, wherein a base is arranged at a rear side of the shell, a carbon fiber infrared quartz electric heating pipe is arranged at a rear side of the base, a heat isolation plate is arranged between a front side of the base and the shell or in front of the shell, a heat conduction radiation cooling film is attached onto a front surface of the shell and / or the heat isolation plate, an axial-flow fan is arranged between an upper end of the carbon fiber infrared quartz electric heating pipe and a lower part of an upper end cover of the shell, the heat conduction radiation cooling film mainly comprises a heat conduction radiation layer and an adhesive layer, and the adhesive layer is closely connected with the heat conduction radiation layer. The warmer comprises a reflection cover and the heating disc assembly, the heating disc assembly is arranged at a front side of the reflection cover and is fixedly arranged on the reflection cover, the carbon fiber infrared quartz heating pipe faces the reflection cover, and the heat conduction radiation cooling film is also attached ontoa surface of the reflection cover. By the heating disc assembly, the problem of local overheat of the electrical warmer is solved, and the purposes of enhancing application comfortableness of a product and enhancing the feeling of a user are achieved.

Owner:JIANGSU JIUZHOU ELECTRIC APPLIANCE CO LTD

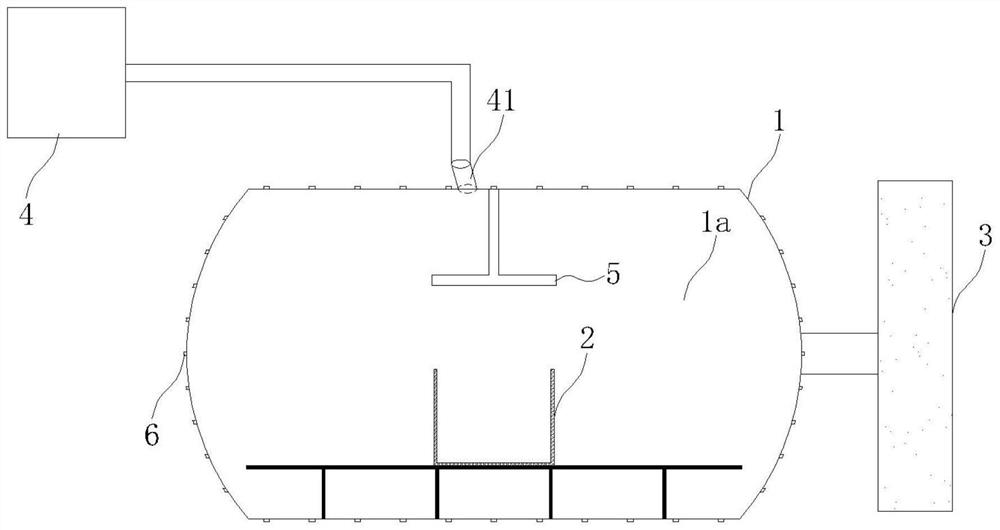

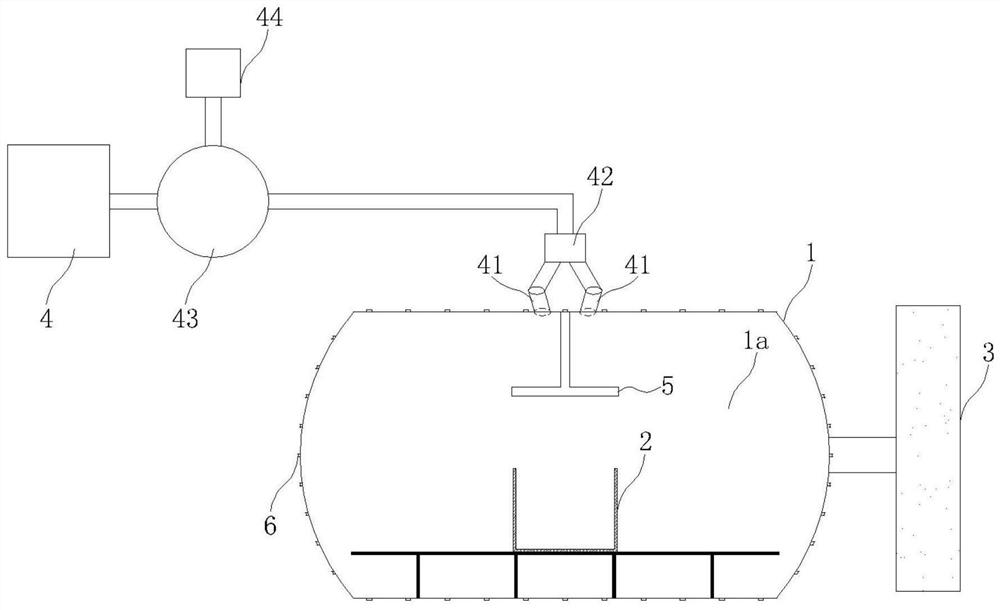

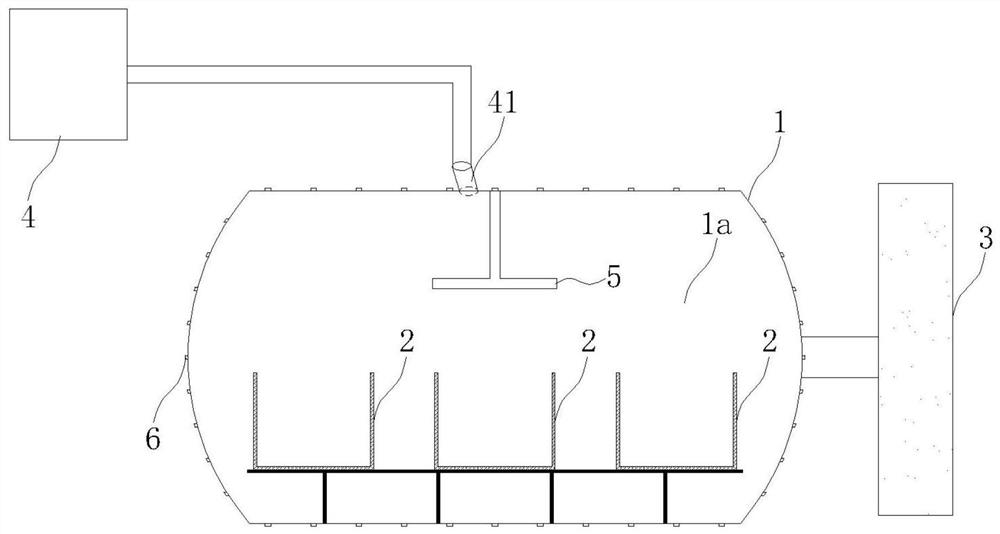

Vacuum microwave smelting device

PendingCN113483570AHeating evenlySolve local overheating problemsStirring devicesCharge treatment typeMicrowaveEngineering

The invention discloses a vacuum microwave smelting device. The vacuum microwave smelting device comprises a furnace body, a crucible, a vacuum system, a wave source, a stirring paddle and a cooling pipeline, wherein the furnace body is a horizontal furnace body with a containing cavity, and a microwave breach is formed in the furnace body; the crucible is arranged in the containing cavity, does not make direct contact with the furnace body and is used for metal smelting; the vacuum system communicates with the containing cavity and is used for vacuumizing the containing cavity; the wave source is connected with the microwave breach through a waveguide and is used for conveying microwaves to the containing cavity; the stirring paddle is arranged in the containing cavity and is used for changing electromagnetic field distribution in the containing cavity; and the cooling pipeline is arranged on the furnace body. According to the vacuum microwave smelting device, the single microwave source, large working area, high vacuum and uniform electromagnetic field space distribution statistics are realized, thus uniform heating is guaranteed, and local overheating is avoided.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS +1

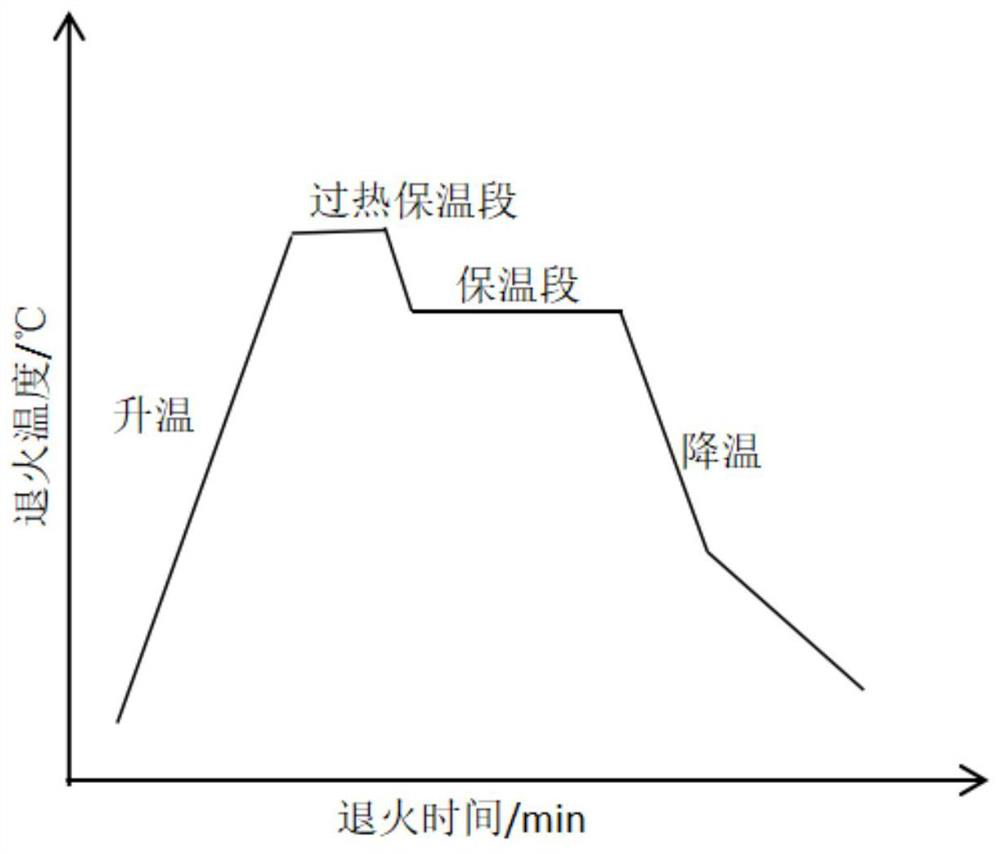

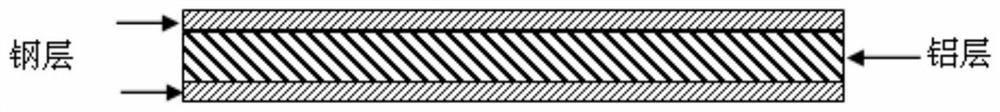

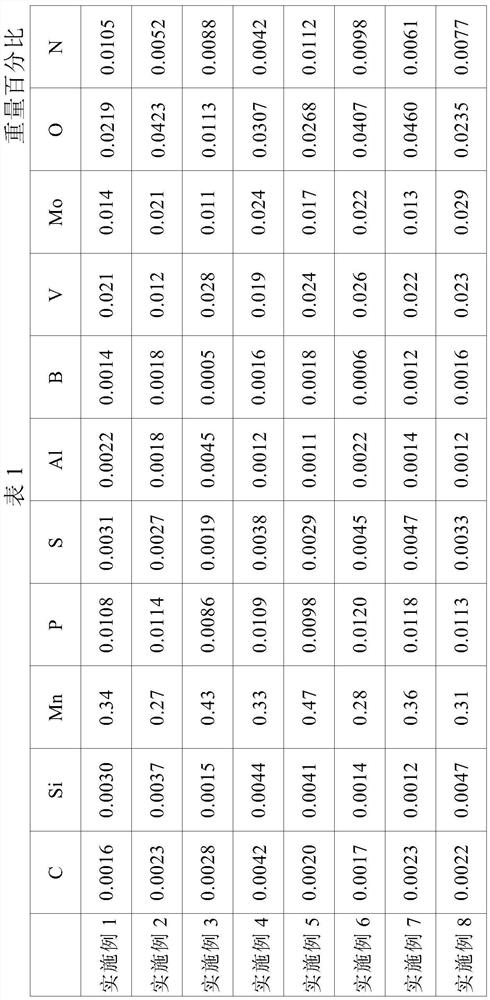

Aluminum-coated plate strip for kitchen ware and production method of aluminum-coated plate strip

ActiveCN114248508AImprove mechanical propertiesImproved interfacial bonding propertiesCooking-vessel materialsLamination ancillary operationsAluminum coatingUltimate tensile strength

The invention relates to an aluminum-coated plate strip for kitchen ware and a production method thereof, the aluminum-coated plate strip comprises at least one layer of aluminum strip and at least two layers of steel strips, the upper and lower surfaces of the aluminum strip are coated with the steel strips, and the steel strips comprise the following chemical components in percentage by weight: 0.0015-0.005% of C, 0.001-0.005% of Si, 0.25-0.50% of Mn, less than or equal to 0.012% of P, less than or equal to 0.006% of S, 0.001-0.005% of Al, 0.004-0.012% of N, 0.0005-0.002% of B, 0.01-0.05% of O, 0.01-0.03% of V, 0.01-0.03% of Mo and the balance of Fe and inevitable impurities; and meanwhile, N is greater than or equal to 1.4 B + 0.6 Al, and V-1. 93 (N-1. 4B-0.6 Al) is greater than or equal to 3.65 C. The aluminum-coated plate strip not only has the strength of steel, but also has the characteristics of good heat dissipation and portability of aluminum, and also has good aluminum coating and drawing properties, the tensile strength of the aluminum-coated plate strip is greater than or equal to 320 MPa, the elongation is greater than or equal to 28%, the strength is not obviously reduced after nitriding treatment, the nitriding treatment requirement in kitchen ware production is met, and the aluminum-coated plate strip can be used for producing and processing novel kitchen ware such as a frying pan.

Owner:BAOSHAN IRON & STEEL CO LTD

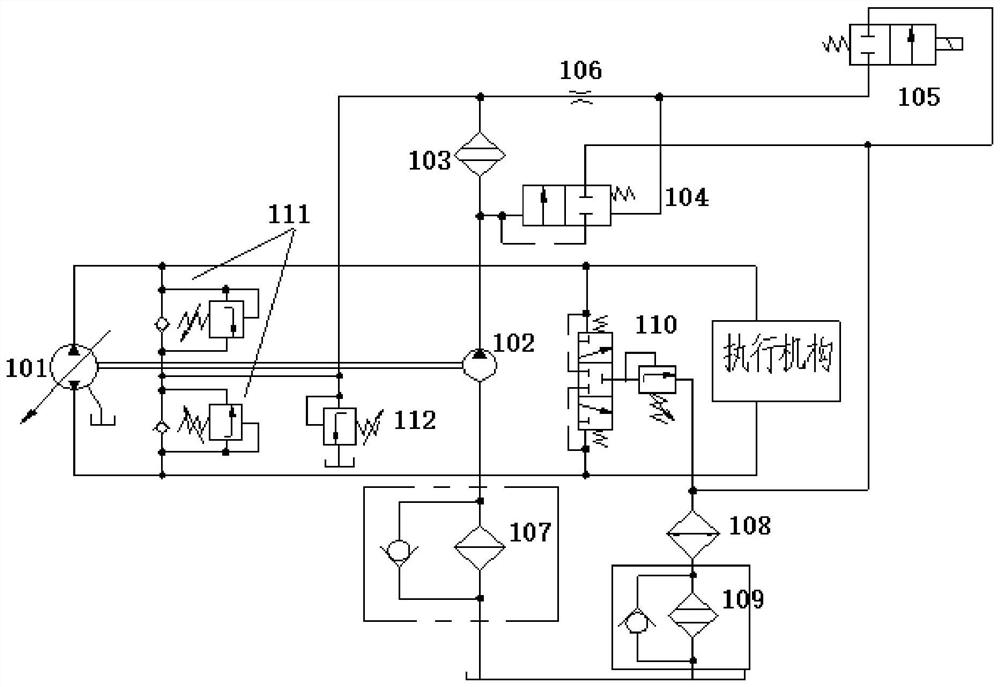

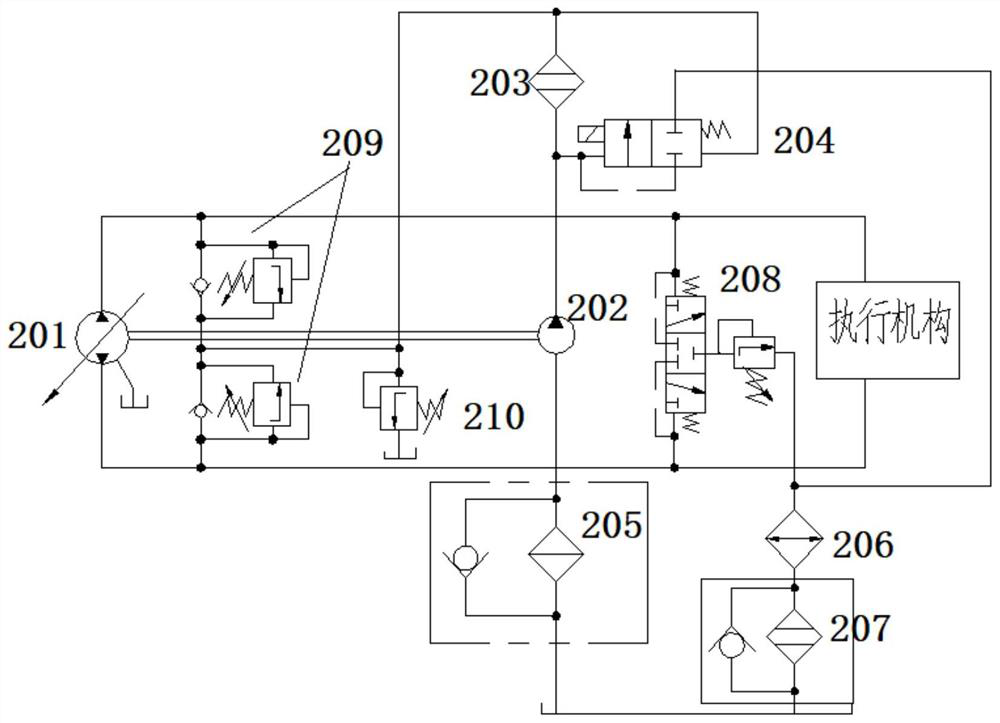

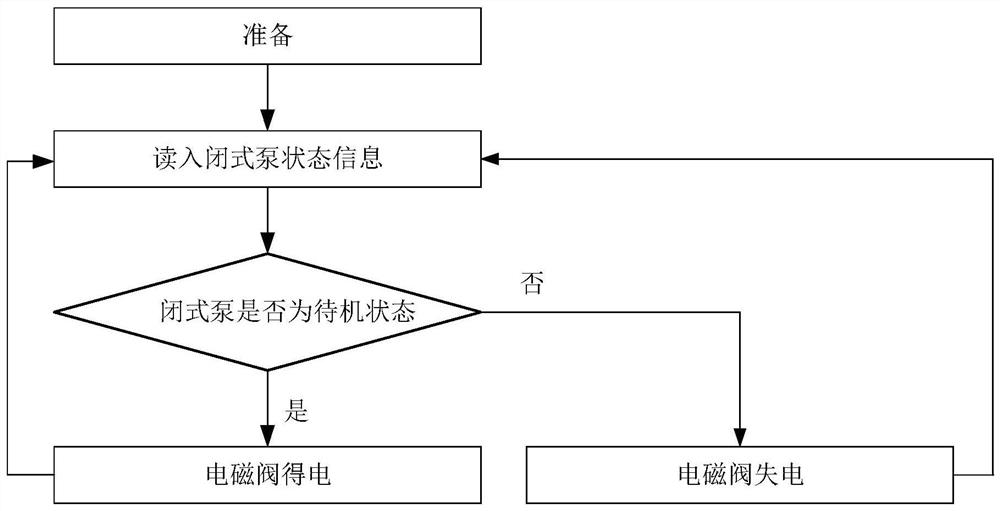

Closed hydraulic system and mechanical equipment

ActiveCN114263656ARelieve pressureReduce power lossServomotor componentsServomotorsMechanical equipmentOil intake

The invention relates to the field of engineering machinery, and discloses a closed hydraulic system and mechanical equipment, the closed hydraulic system is applied to the mechanical equipment, and the closed hydraulic system comprises a closed pump connected with an execution mechanism and used for driving the execution mechanism; the oil supplementing pump is arranged on a passage between the closed pump and the oil tank and is used for pumping oil in the oil tank to the closed pump; the filter is arranged on a passage between the oil supplementing pump and the closed pump and is used for filtering oil output from the oil supplementing pump to the closed pump; the pressure control device comprises a first control cavity and a second control cavity, the first control cavity is communicated with the oil inlet of the filter, the second control cavity is communicated with the oil outlet of the filter, the oil inlet is communicated with the oil inlet of the filter, and the oil outlet is communicated with the oil tank; an oil inlet of the electromagnetic valve communicates with the second control cavity, and an oil outlet of the electromagnetic valve communicates with the oil tank; and the throttling element is arranged on a passage between the oil outlet of the filter and the oil inlet of the electromagnetic valve. The problem of local overheating is solved.

Owner:ZOOMLION HEAVY IND CO LTD

A method for hydrodesulfurization of inferior gasoline

ActiveCN103805261BReduce coking factorEfficient use ofTreatment with hydrotreatment processesNaphthaFluidized bed

Owner:CHINA PETROLEUM & CHEM CORP +1

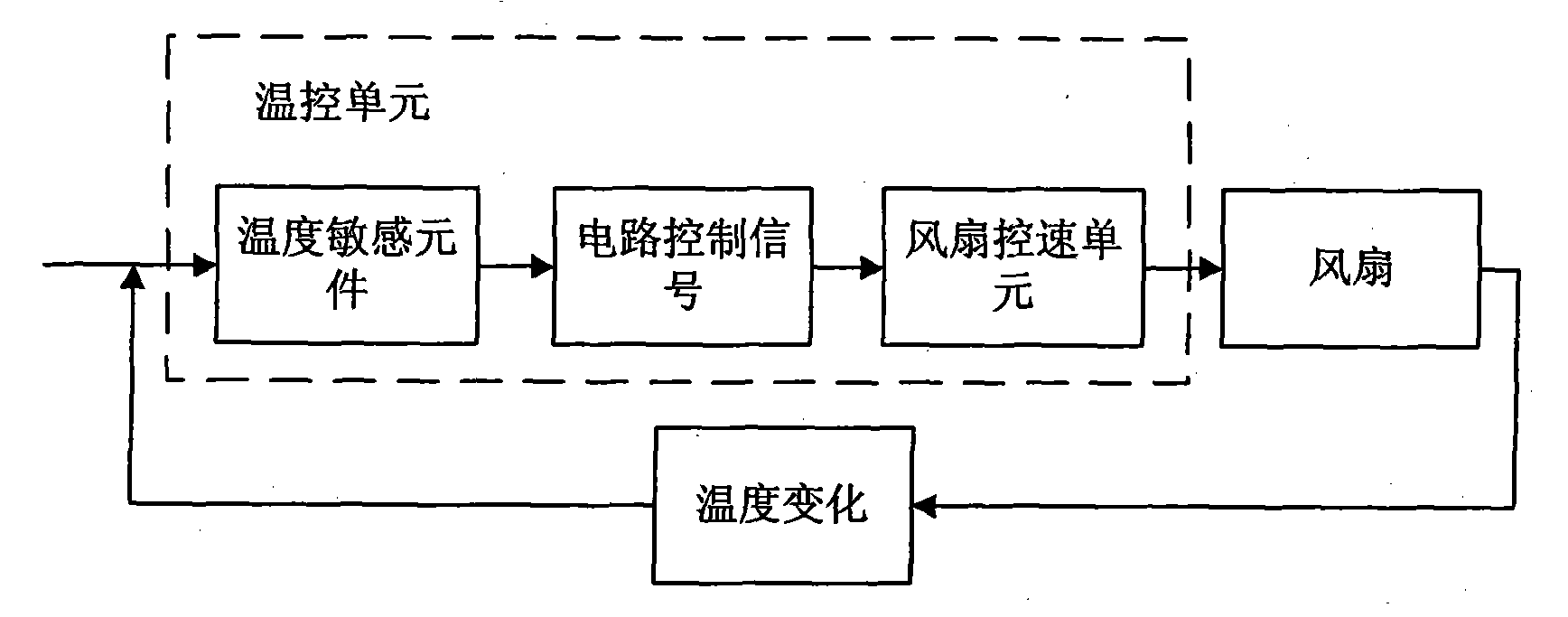

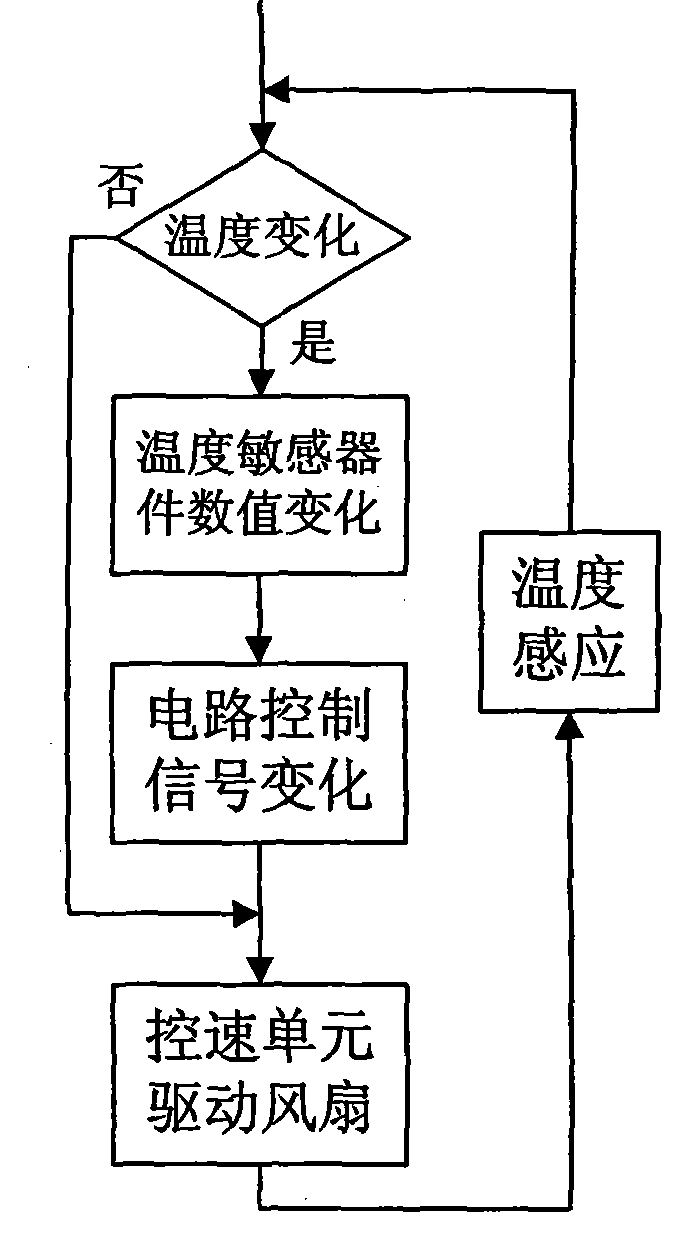

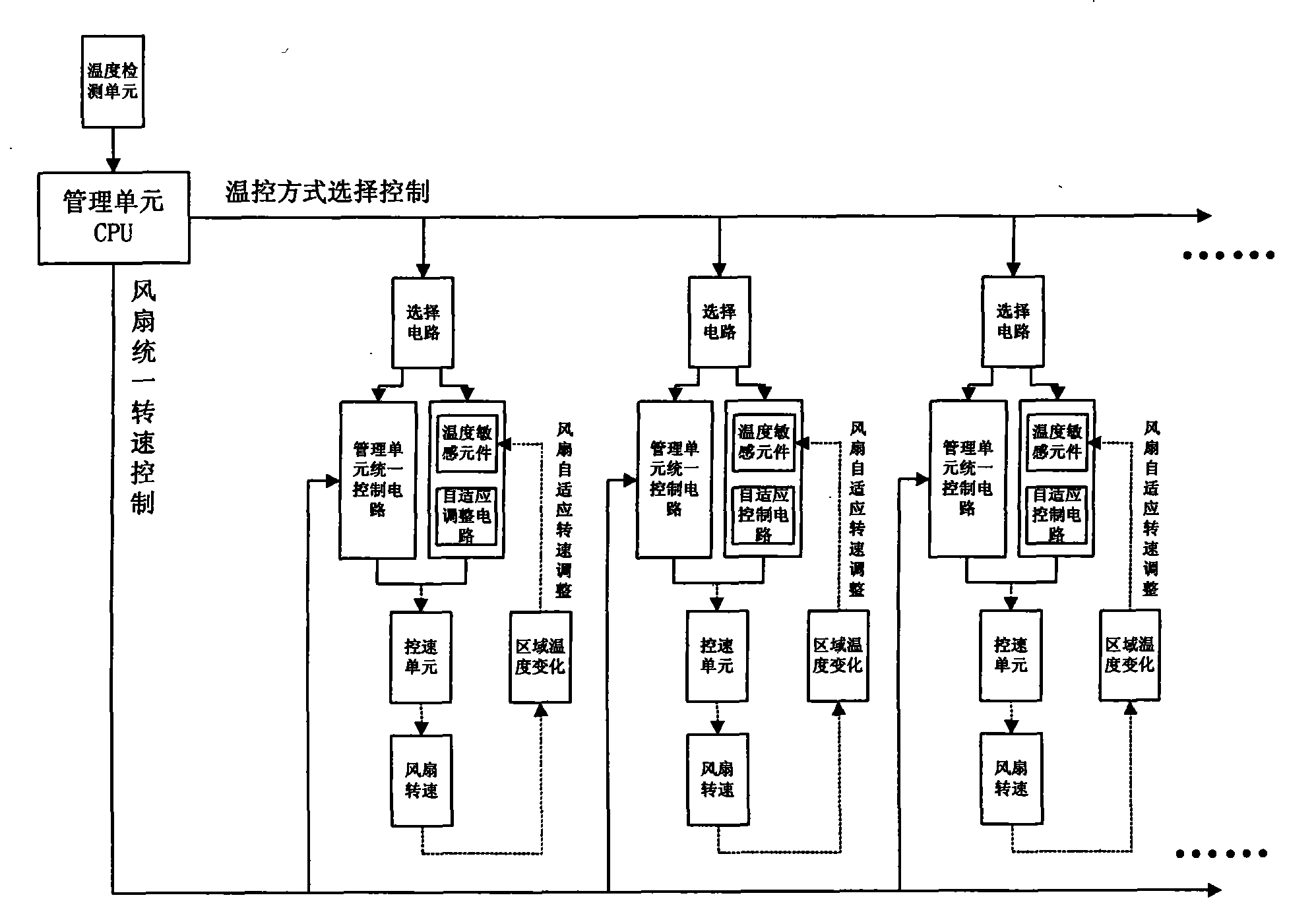

Machine frame equipment temperature control system and temperature control method

ActiveCN101334677BUniform temperatureExtended service lifeTemperature control with auxillary non-electric powerPump controlTemperature controlEquipment temperature

The invention discloses a frame equipment temperature control system and a temperature control method. The system comprises a plurality of fans which are respectively arranged in the frame equipment and a plurality of temperature control units which are arranged adjacent to the fans in a one-to-one correspondence way and used for detecting the ambient temperature of the fans and controlling the rotation speed of the corresponding fan according to the temperature change. As the system and the method of the invention are added with the regional temperature control function, the local over-heat problem possibly caused by single temperature detection can be effectively avoided, and the temperature control system has the capacity of uniform adjustment and regional self-adjustment, furthermore,the energy resource is saved, the noise is lowered and the service life of the fan is prolonged.

Owner:ZTE CORP

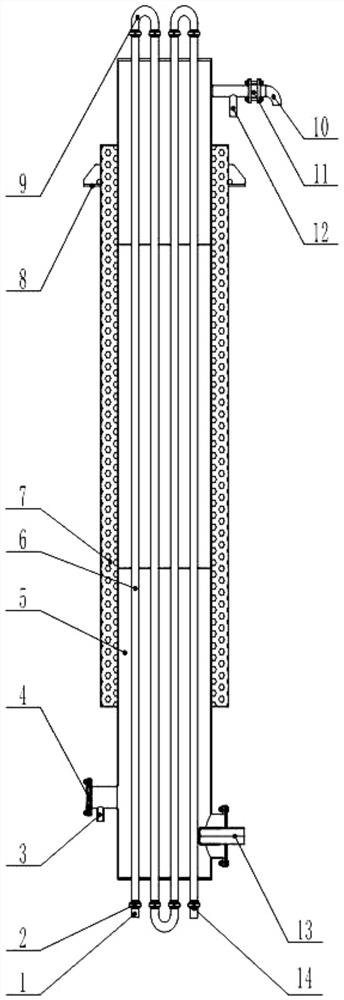

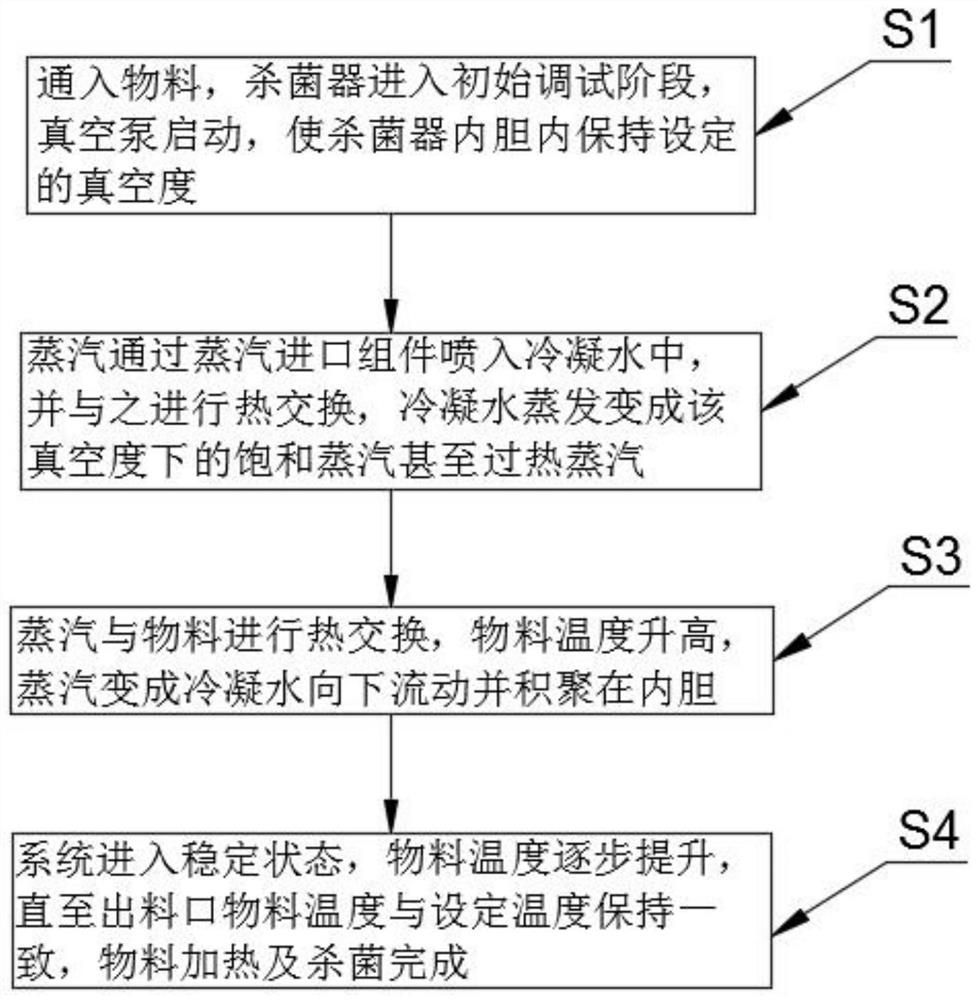

Vacuum tube type steam sterilizer and sterilization method thereof

PendingCN113209323AAvoid Gel Pad Failure ProblemsSolve local overheating problemsLavatory sanitoryHeatEngineeringMechanical engineering

The invention relates to the technical field of sterilization equipment, in particular to a vacuum tube type steam sterilizer and a sterilization method thereof. The vacuum tube type steam sterilizer comprises a sterilizer body, the sterilizer body is fixedly arranged on a rack, a platform or a floor through a support, a rock wool heat preservation layer is arranged in the sterilizer body, the outermost side of the sterilizer body is wrapped with 304 stainless steel, the sterilizer body is provided with an inner container, the inner container is higher than the upper end of the 304 stainless steel and lower than the lower end of the 304 stainless steel, cover plates are arranged at the upper end and the lower end of the inner container, holes are formed in the cover plates, and material pipes penetrate through the cover plates; a pressure-bearing loose joint and a feed port are welded at the starting end of each material pipe, and a pressure-bearing loose joint and a discharge port are welded at the tail end of each material pipe; and the pressure-bearing loose joint is welded with a 180-degree elbow, so that the material pipes communicate up and down in an S shape, and the sterilizer is also provided with an exhaust hole, a water outlet and a vacuumizing opening. According to the vacuum tube type steam sterilizer, low-temperature vacuum steam sterilization of thick materials is realized, the problems of rubber mat failure of a plate type sterilizer and local overheating of a tubular sterilizer are avoided, and the continuous working time is long.

Owner:秦皇岛燕大源达机电科技股份有限公司

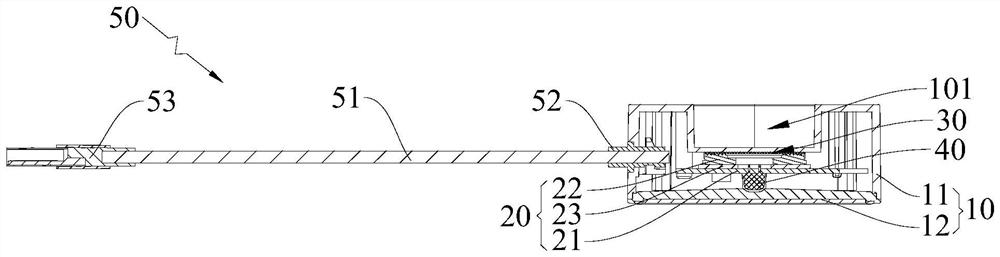

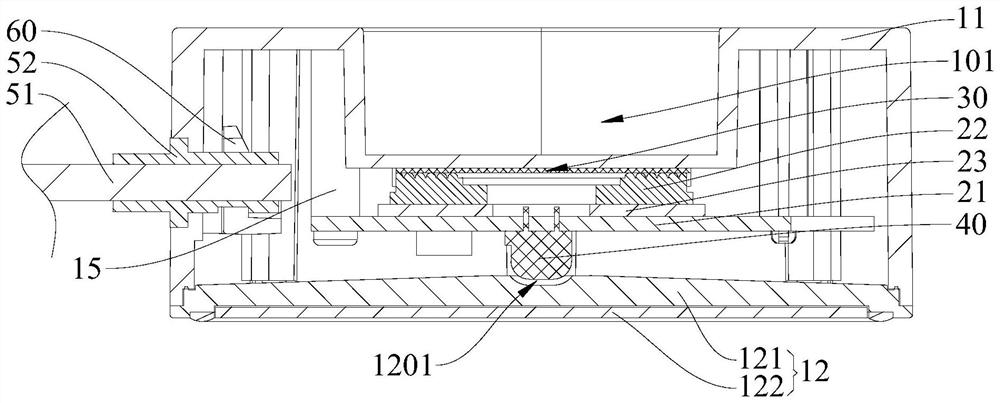

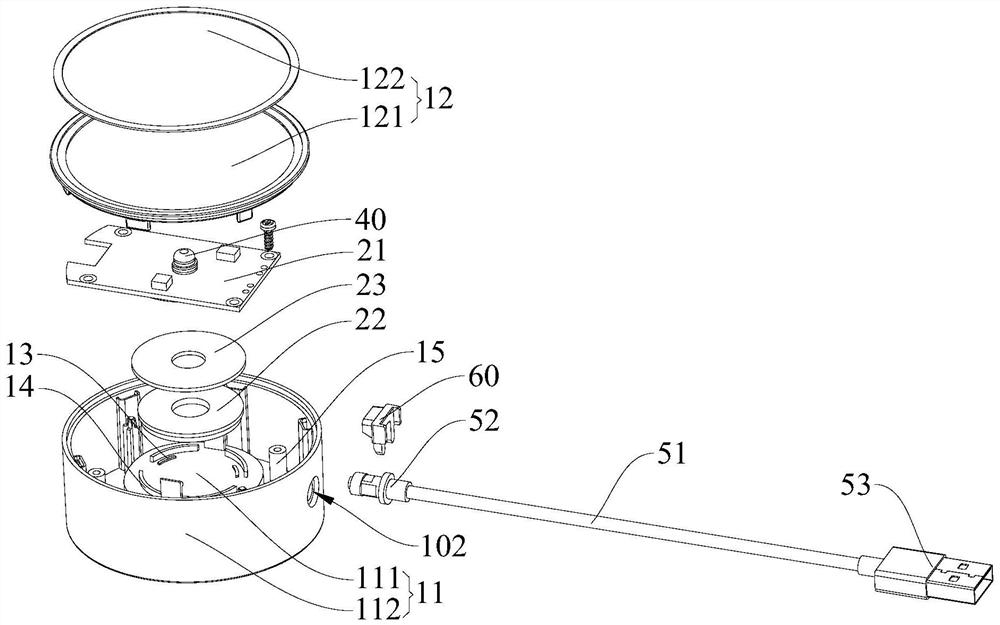

Charging device and tooth set

PendingCN114583782ASolve the problem of local overheatingSolve local overheating problemsBatteries circuit arrangementsElectric powerLight guideMechanical engineering

The invention is suitable for the technical field of daily necessities, and provides a charging device and a tooth set, the tooth set comprises the charging device and an electric toothbrush, and the charging device comprises a base, a charging assembly and an indicator lamp; the base comprises a shell and a light guide assembly arranged at one end of the shell. The charging assembly is arranged in the shell, and one side, back to the light guide assembly, of the charging assembly and the inner wall of the shell are spaced to form a spacing gap; the indicating lamp is arranged on one side of the charging assembly back to the spacing gap, and one end of the indicating lamp back to the charging assembly right faces the light guide assembly. Through the arrangement, heat generated by the charging assembly during charging is not directly conducted to the position, close to the charging assembly, of the shell, but is slowly dissipated under the heat insulation effect of the spacing gap, so that the heat is dissipated to all positions of the shell, and the problem that local overheating is generated during charging of the charging device can be effectively solved; therefore, both the charging device and the electric toothbrush have better use performance.

Owner:SHENZHEN SOOCAS TECH CO LTD

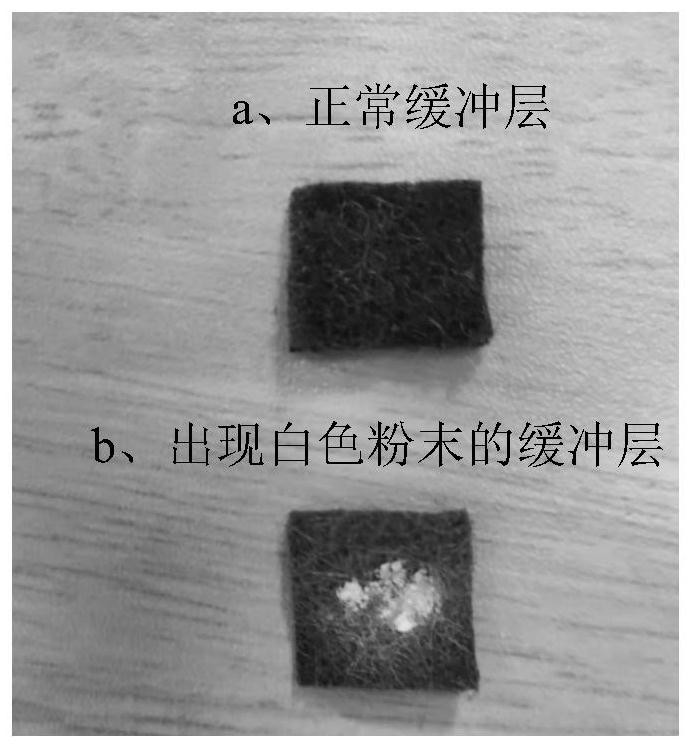

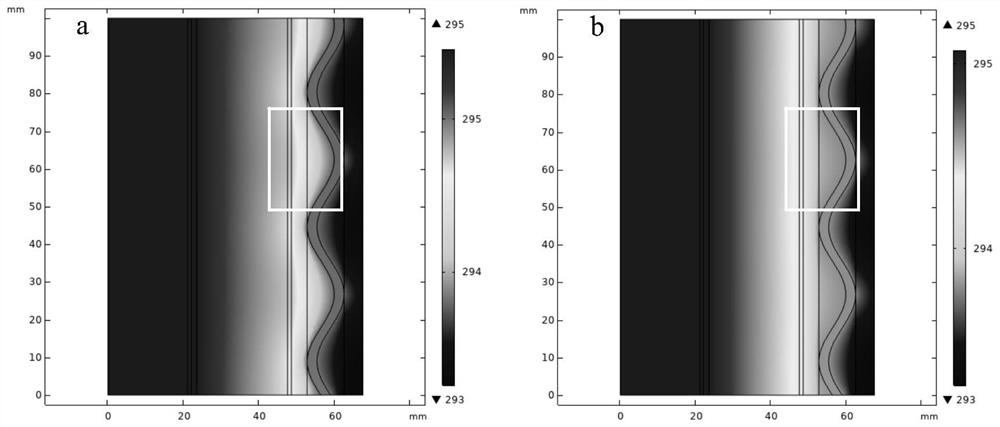

Novel cable and method for relieving ablation of cable buffer layer

PendingCN114883061ASolve local overheating problemsImprove conductivityLiquid conductorsClimate change adaptationEngineeringCross-linked polyethylene

The invention relates to a novel cable and a method for relieving ablation of a cable buffer layer. According to the method, conductive liquid is filled between the aluminum sheath and the insulation shielding layer. The problem of ablation of the buffer layer can be effectively solved, and the service life of the high-voltage crosslinked polyethylene cable is prolonged.

Owner:XIAMEN ELECTRIC POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com