Full immersed type self circular loop of evaporative cooling stator of steam turbine generator

A turbo-generator, evaporative cooling technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problem of not meeting the cooling technical requirements for the development of extra-large turbo-generator units, and the cooling requirements for large-capacity units. The problem of high electrical conductivity can achieve the effect of eliminating the water treatment system and hydrogen supply and storage equipment, low boiling point and good physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be further described in detail below in conjunction with the embodiments shown in the accompanying drawings.

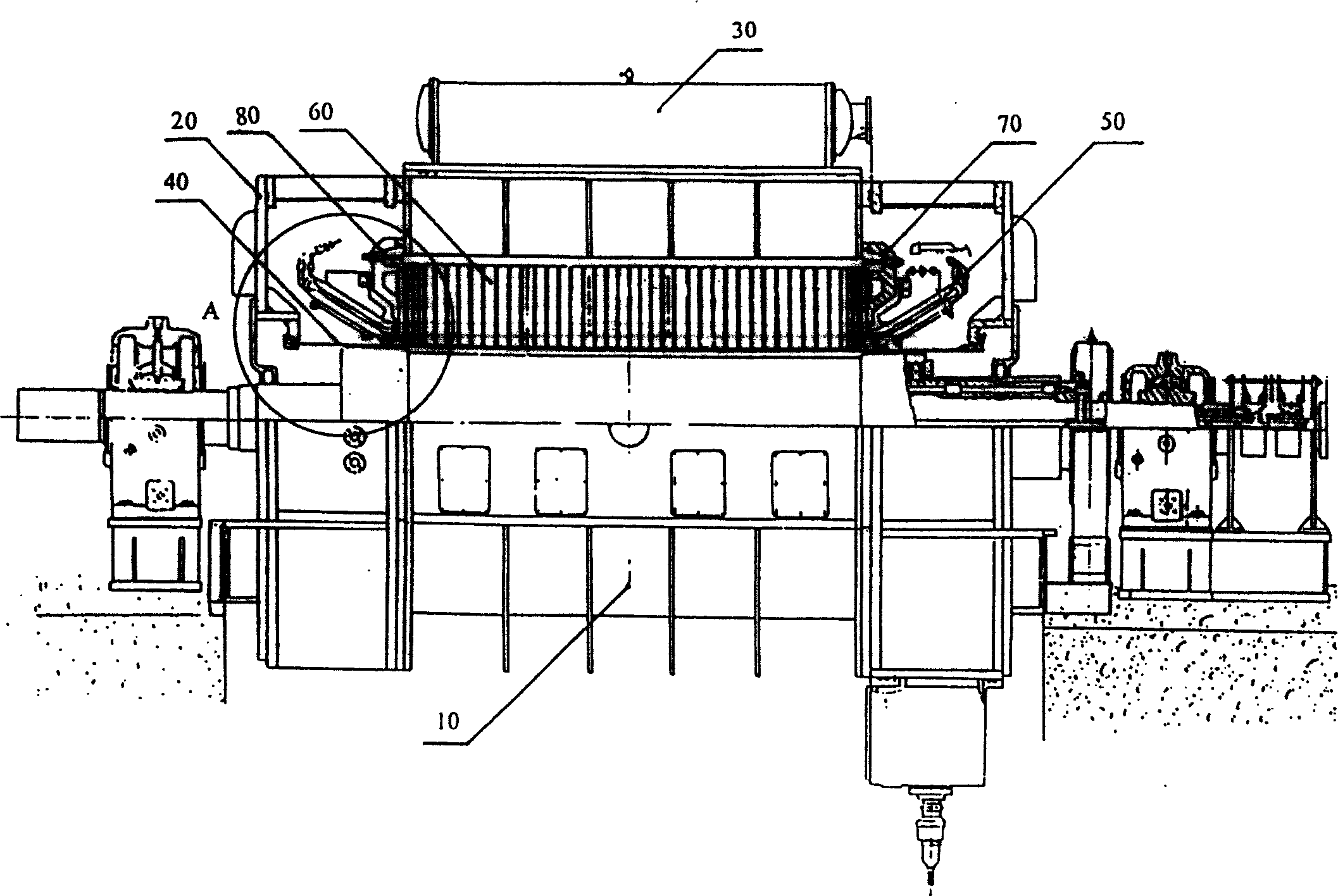

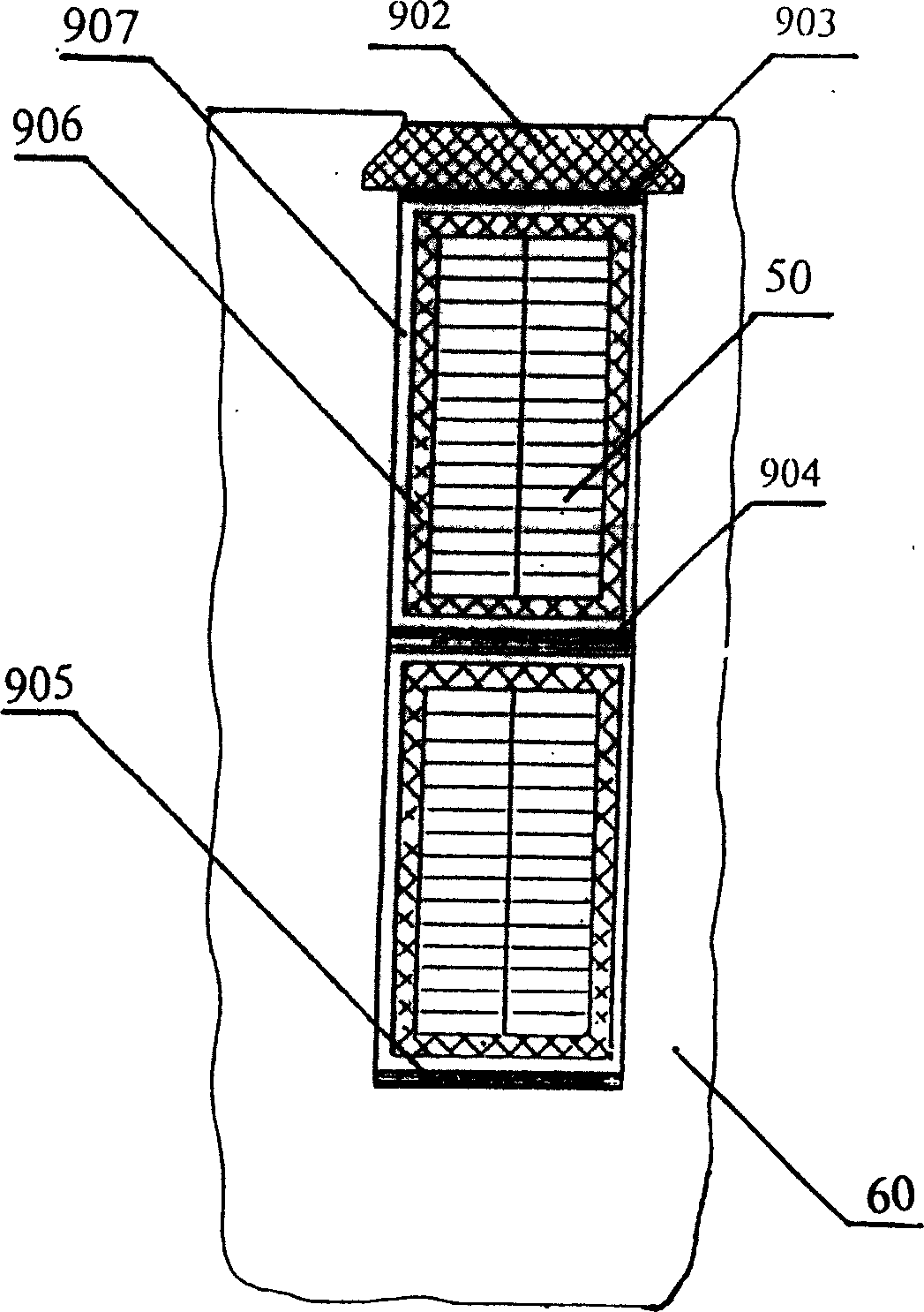

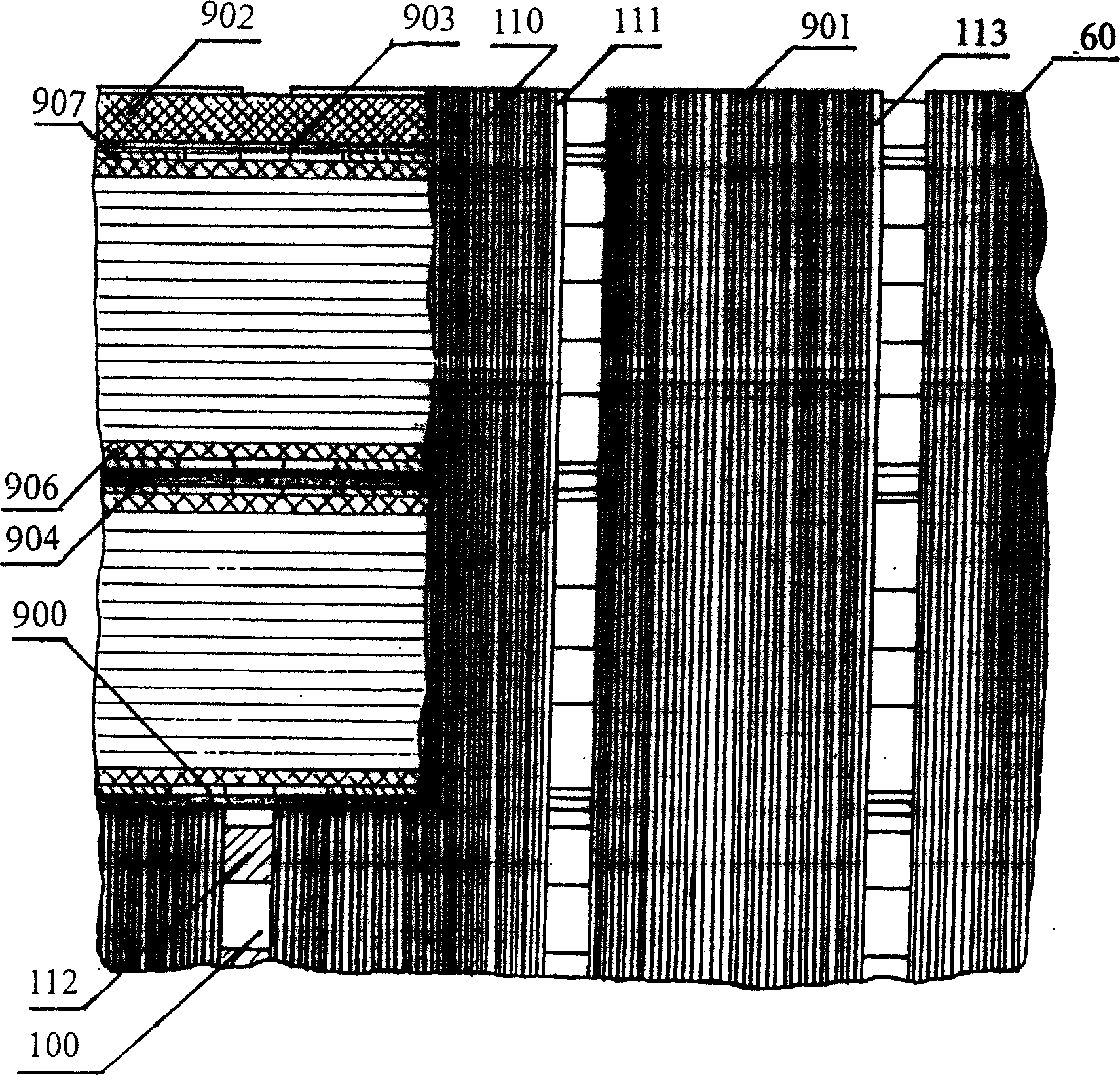

[0031] see first figure 1 . The evaporative cooling circulation circuit of the present invention comprises a stator base 10 of a turbogenerator, an end cover 20, a condenser 30 installed on the top of the base, an isolation sleeve 40 connected to the end covers at both ends of the base, and a stator winding coil 50 (it is made up of many coils), stator core 60 (it is formed by lamination of many fan-shaped iron sheets), pressure ring 70 (one at each two ends of the stator core) and tooth pressure plates 80 at both ends of the stator core. The motor stator immersion evaporative cooling cycle is divided into three parts: (1) The cooling cycle sub-circuit 900 of the stator core slot ( image 3 ), which are arranged on both sides of the fixed insulation of the straight section of the two winding coils embedded in each slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com