Cases for power batteries, power battery packs

A power battery and shell technology, applied in the field of shells and power battery packs, can solve the problems of increasing the energy density of battery packs, requiring high layout space, and many components, so as to achieve improved space utilization, strong overall stability, and The effect of high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

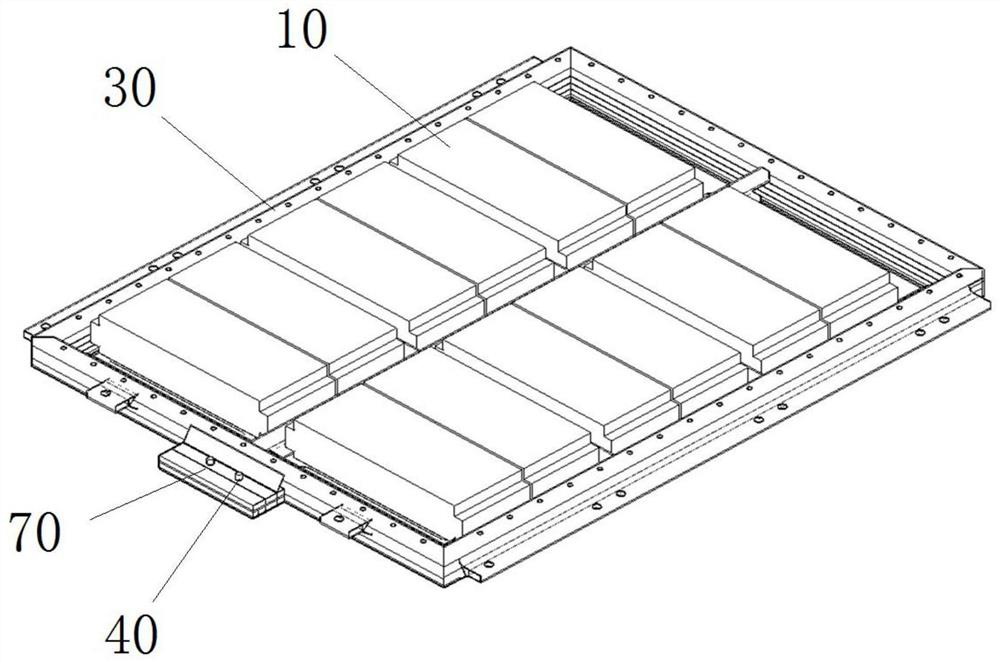

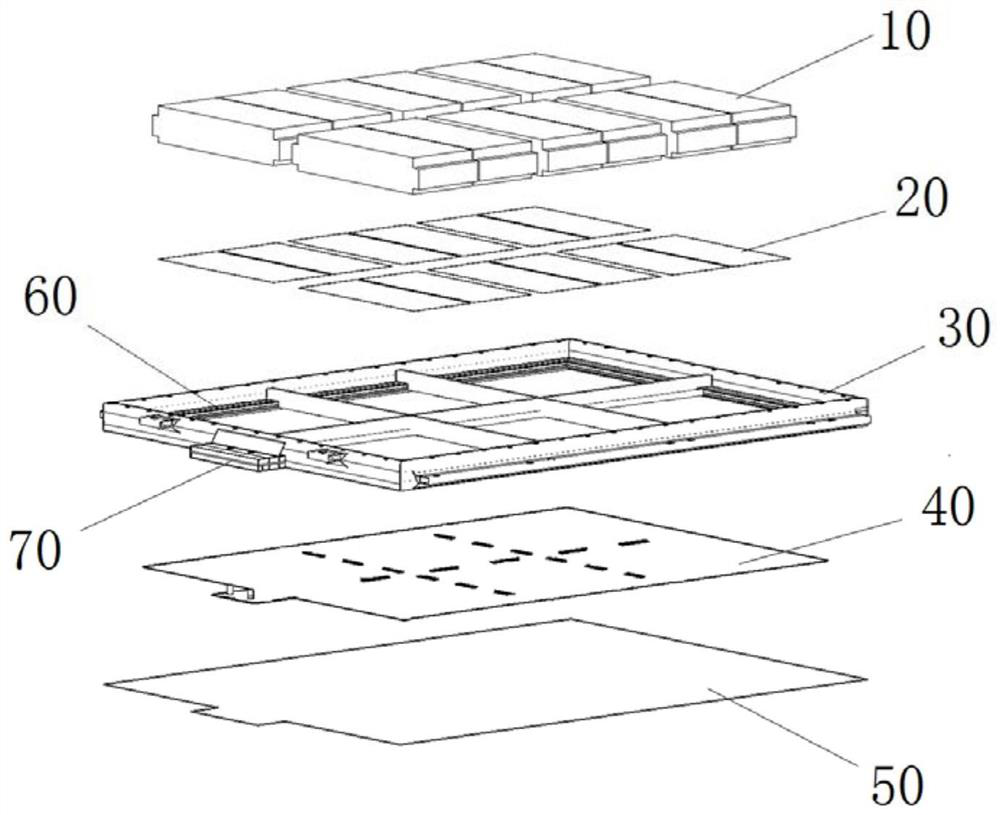

[0063] A power battery pack that can be used as a power system of an electric vehicle. The power battery pack in this example is designed in a regular square structure. In other examples, it can be in other shapes such as hexagons, such as figure 2 , 3 As shown, from top to bottom are the power battery module 10, the heat insulation layer 20, the support frame 30, the heat conduction plate 40, and the guard plate 50, wherein the support frame 30, the heat conduction plate 40, and the guard plate 50 are assembled to form a housing. A power battery module 10 is supported by the housing, and the heat insulating layer 20 is connected to the lower surface of the power battery module 10 for improving the effect of heat transfer.

[0064] The power battery module 10 in this example can adopt the existing battery structure, and the present invention aims to improve the cooling system of the power battery module 10 , and the battery structure will not be repeated here.

[0065] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com