A pre-lubrication device for starting an engine

An engine start-up and pre-lubrication technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of unfavorable user acceptance and use, scattered parts distribution, increased dry friction time, etc., to facilitate standardized production, flow Unobstructed, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

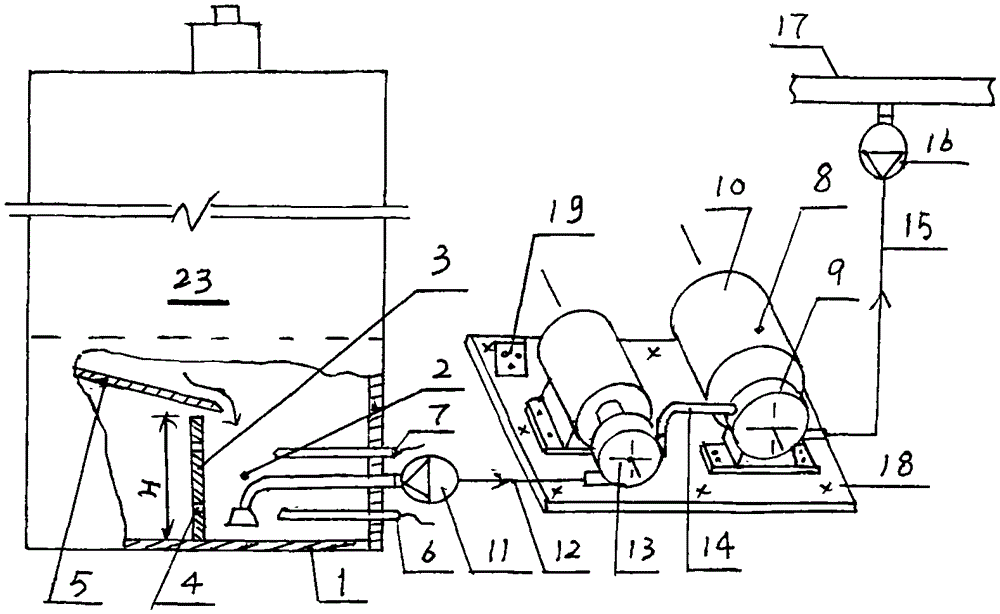

[0011] Further detailed explanation in conjunction with accompanying drawing; Among the figure: 23-engine, the main oil channel of 17-engine 23;

[0012] Such as Figure 1~2 As shown, the oil pan 1 also has a hot oil area tank 2 surrounded by a coaming plate 3 with a through hole 4, the coaming plate 3 is fixed on the inner wall of the oil pan 1, and the oil pan 1 is also equipped with a The upper opening of the hot oil zone groove 2 corresponds to the oil return guide plate 5, and the electric heater is installed in the hot oil zone groove 2.

[0013] The volume of the tank 2 in the hot oil area is about 1 / 4 to 1 / 3 of the volume of the oil pan 1, and the height H of the coaming plate 3 should be slightly higher than the normal oil level of the oil stored in the oil pan 1. The function of the oil return guide plate 5 is to make the lubricated engine oil mainly collect into the groove 2 of the hot oil zone, so that the heat is concentrated during the pre-lubrication process, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com