Sound attenuation devices for air drying equipment for compressed air supply systems

A technology of compressed air and noise reduction devices, which is applied in air treatment devices, mechanical equipment, transportation and packaging, etc. It can solve problems such as freezing of condensate, large structure, and blockage of the outlet of compressed air, achieving small structure, Good noise reduction and less space requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

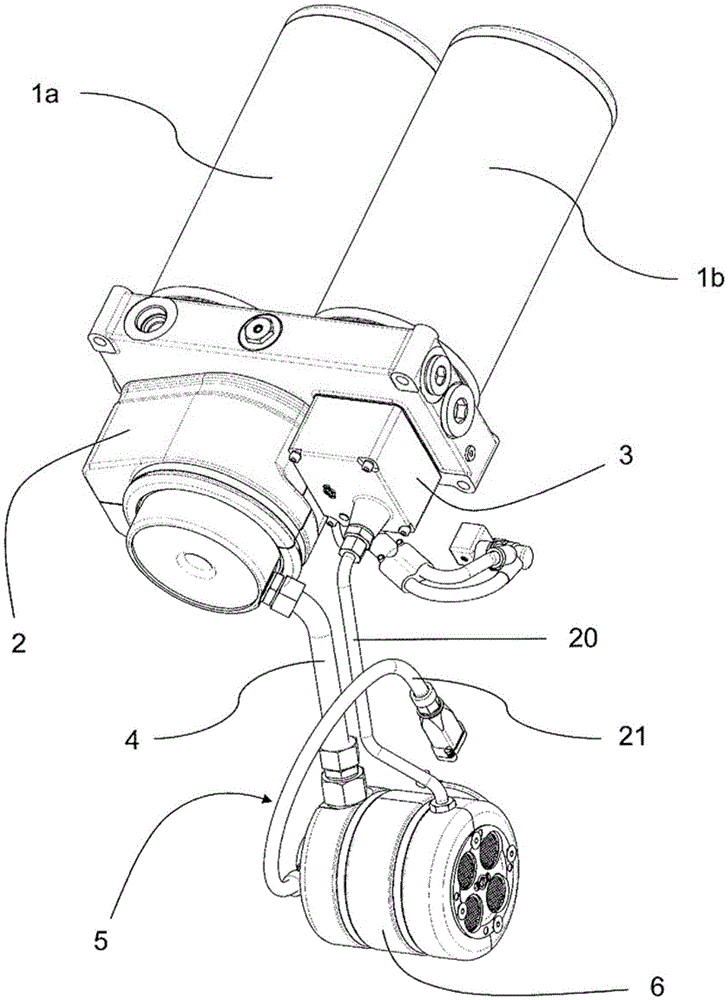

[0029] according to figure 1 , a double-chamber air drying equipment includes two drying containers 1a and 1b, these drying containers operate alternately in two states, namely a dry state and a regeneration state, to ensure the continuous flow of moist compressed air dry.

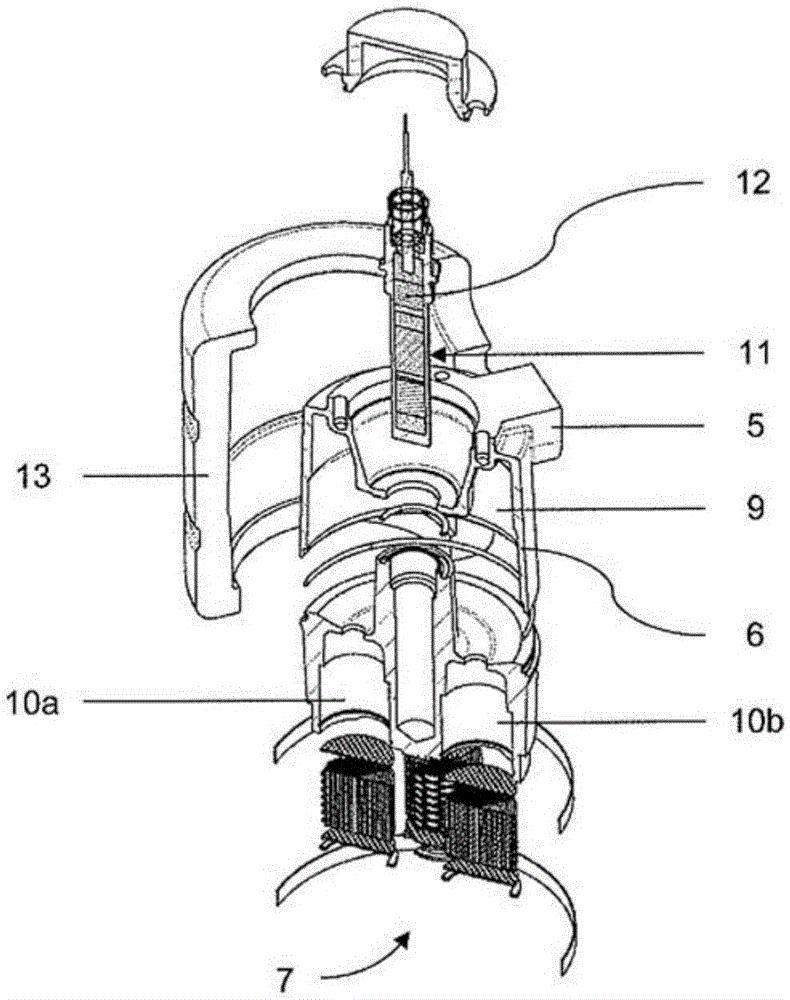

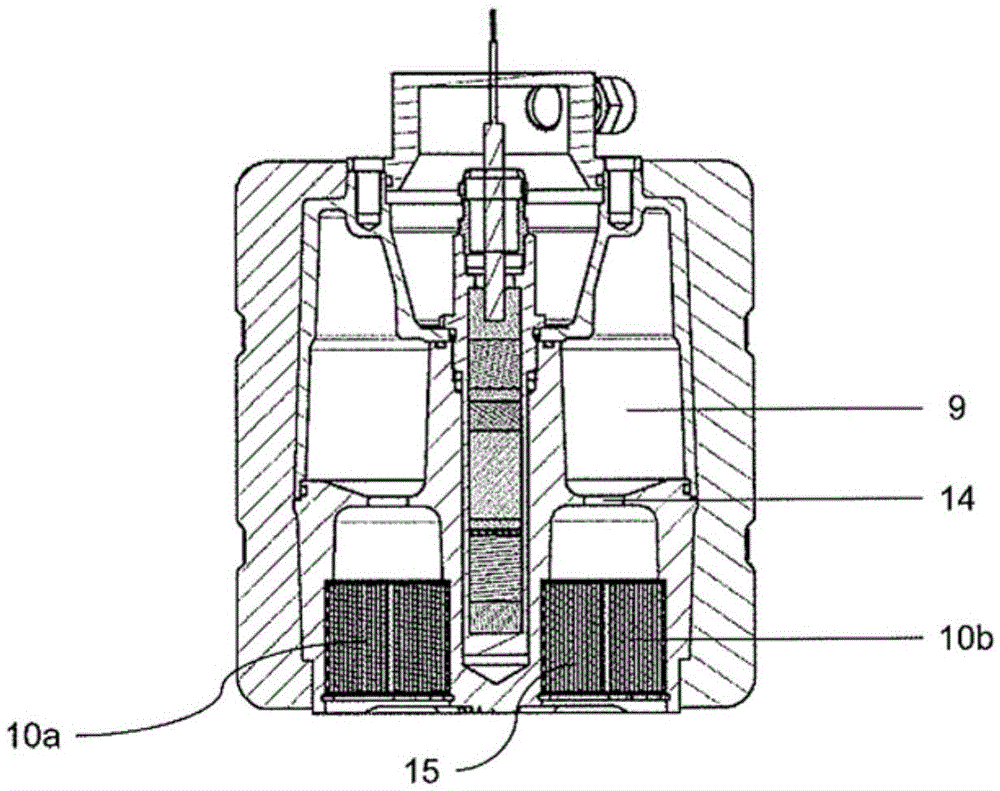

[0030] While the main air flow in one of the drying vessels 1a is being dried, the desiccant in the other drying vessel 1b is regenerated by reverse operation. These state phases are carried out via a switching valve 2 in accordance with the commands of the electronic control unit 3 . On the outlet side of the on-off valve 2 a silencer is connected via a line 4 . To this end, the line 4 engages an inlet opening 5 on the silencer housing. This inlet port 5 is used to feed in the condensate-containing compressed air to be discharged from the air drying plant. The sound attenuation device is used to dampen the outflow noise acoustically and at the same time to reliably discharge the condensate contained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com