Patents

Literature

41results about How to "Unimpeded flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

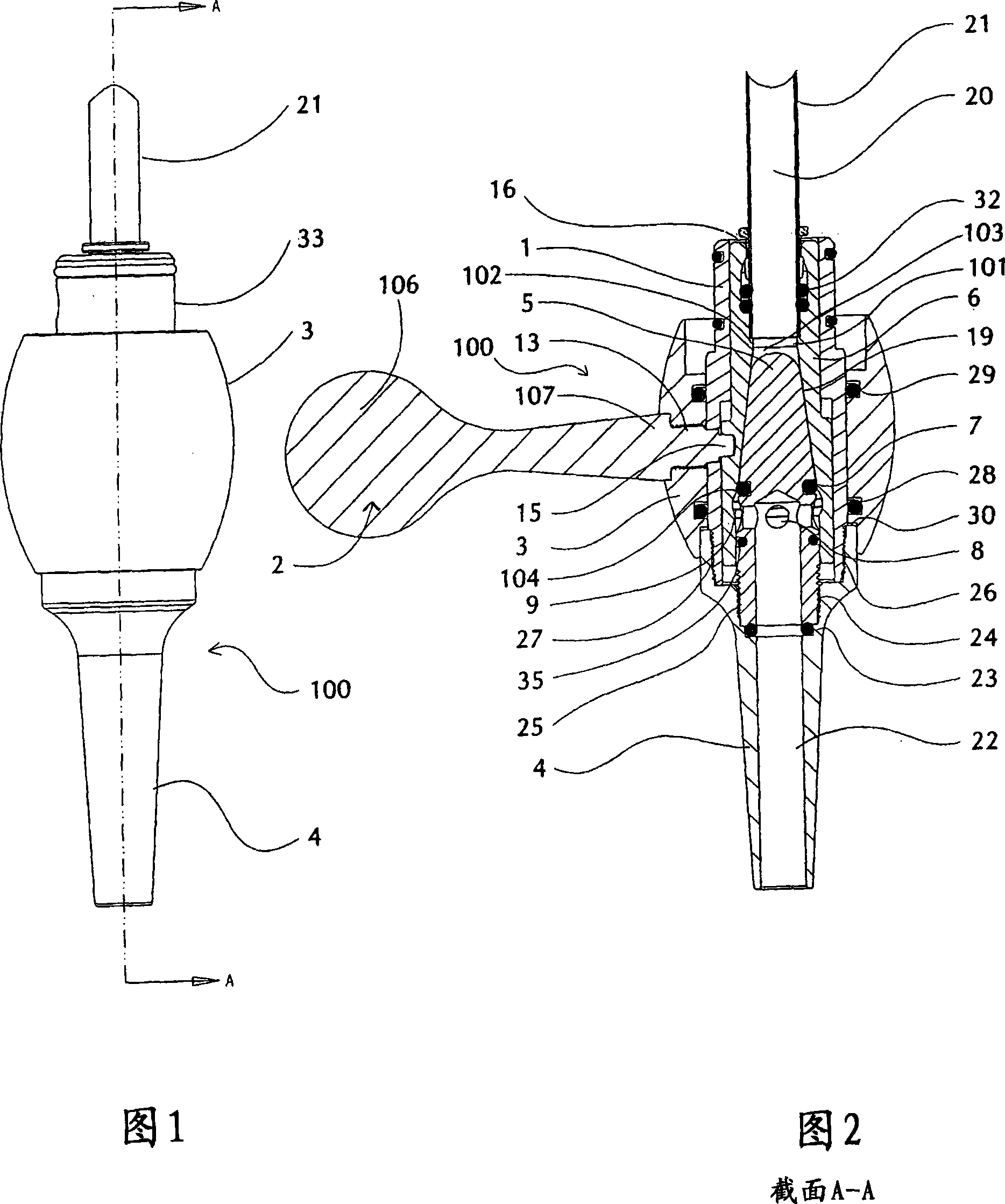

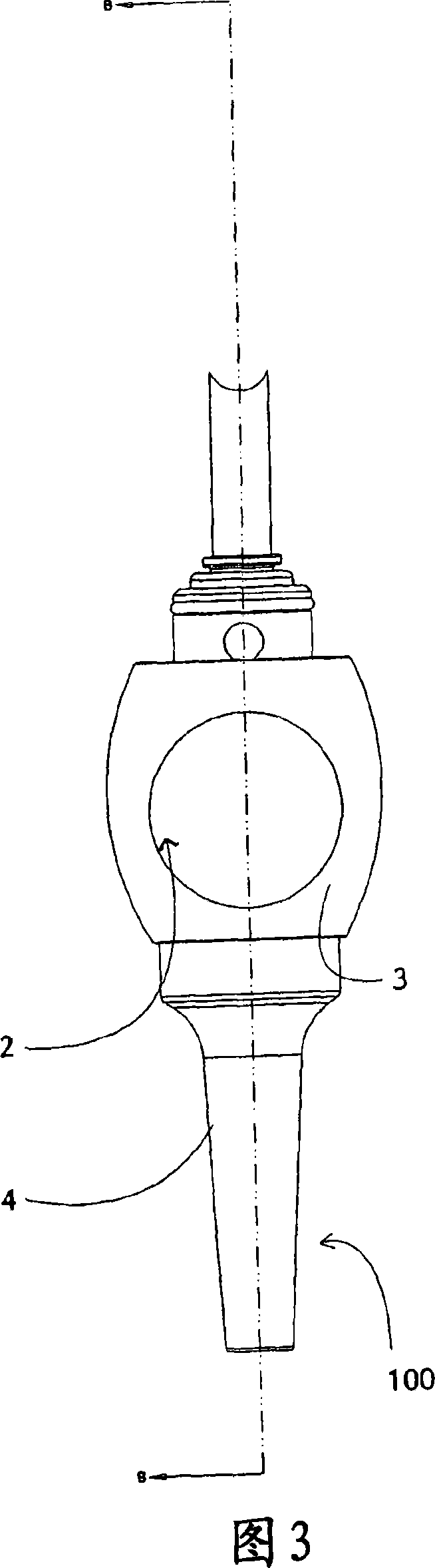

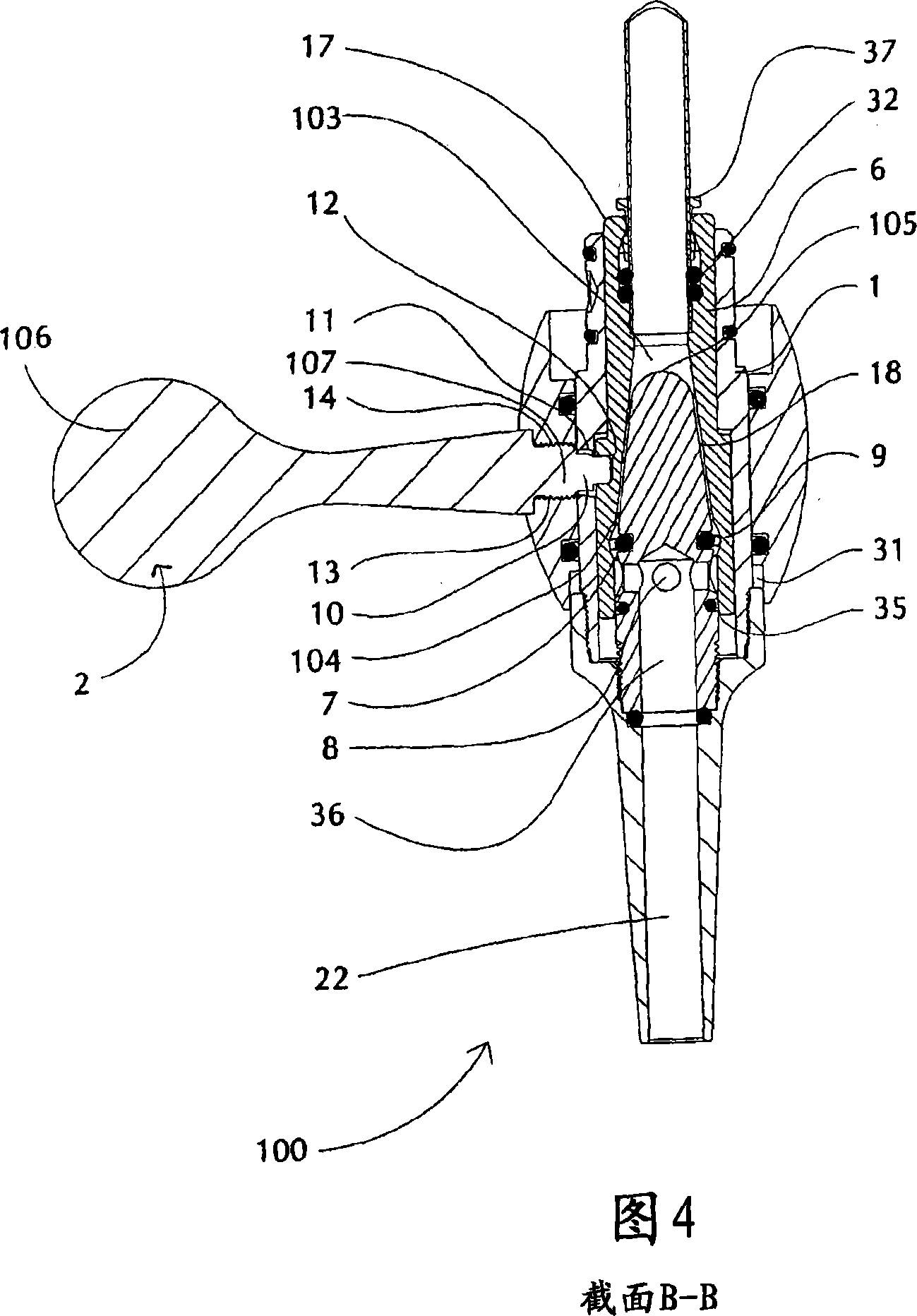

Beverage dispensing valve

InactiveCN101049901AUnimpeded flowUniform and stable flow rateLiquid flow controllersLiquid dispensingEngineeringMechanical engineering

A beverage dispense valve comprising (i) a valve body; (ii) a female taper member inside the valve body the internal diameter increasing in a downstream direction away from the beverage inlet port; (iii) a male taper member, the external diameter of the taper portion increasing in a downstream direction so as to be at least partially complementary to the female taper member, and having a hollow outlet portion downstream of the taper portion, one taper member being slidable relative to the other forming a flow regulator; (iv) one or more apertures penetrating through the male taper member to allow beverage to pass into the interior of the outlet portion, (v) a valve closure arrangement for sealing flow between the beverage inlet port and the beverage outlet port; and (vi) an actuating mechanism outside the valve body to operate both the flow regulator and the valve closure arrangement. The beverage dispense valve described allows simultaneous control of the flow rate of beverage through the valve in unison with the opening and closing of the valve.

Owner:SCOTSMAN BEVERAGE SYST

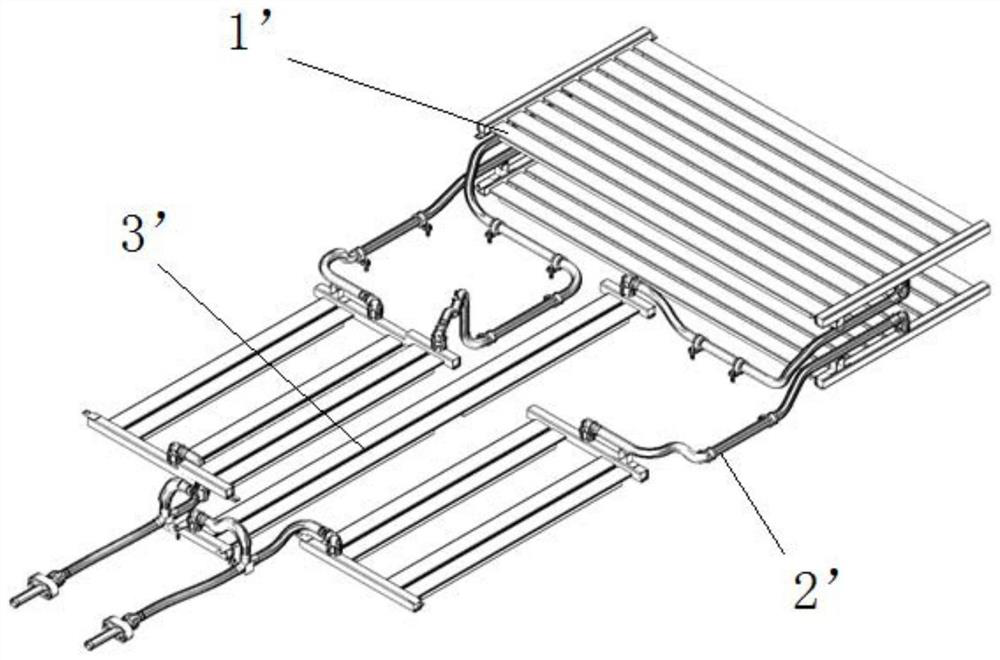

Spiral or helical counterflow heat exchanger

ActiveCN104995473AAvoid corrosionEasy maintenanceStationary tubular conduit assembliesCoatingsEngineeringHigh heat

Counterflow heat exchanger consisting of two adjoining chambers, in which a fluid at a high temperature flows in one chamber in one direction, and in which a fluid at a low temperature flows in the opposite direction in the other chamber, characterised in that both chambers are separated by a separating plate of flat monolithic double-sided enamelled steel annealed at temperatures above 500°C, and which together form a spiral or helical heat exchanger.

Owner:POLYVISION NV

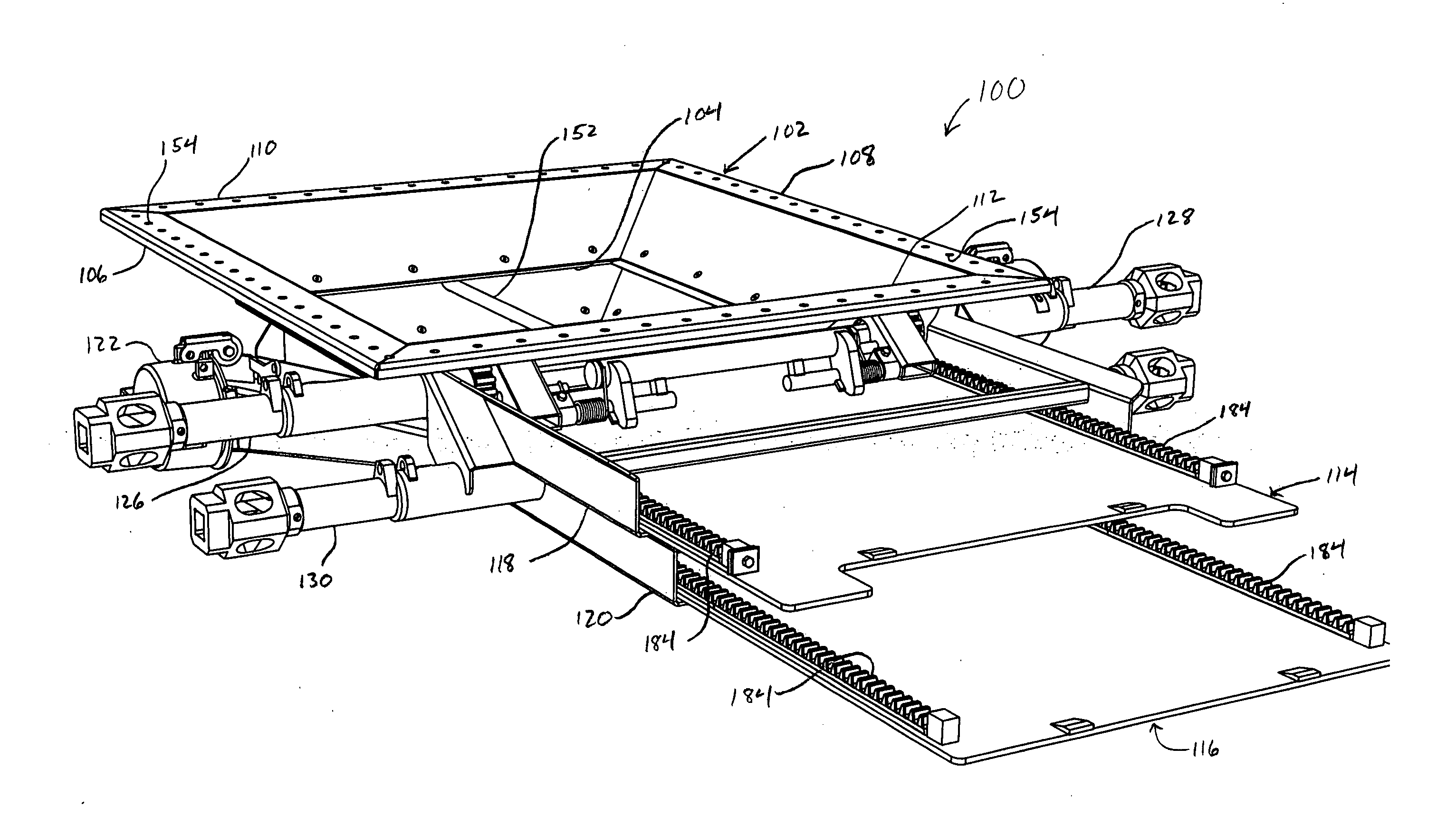

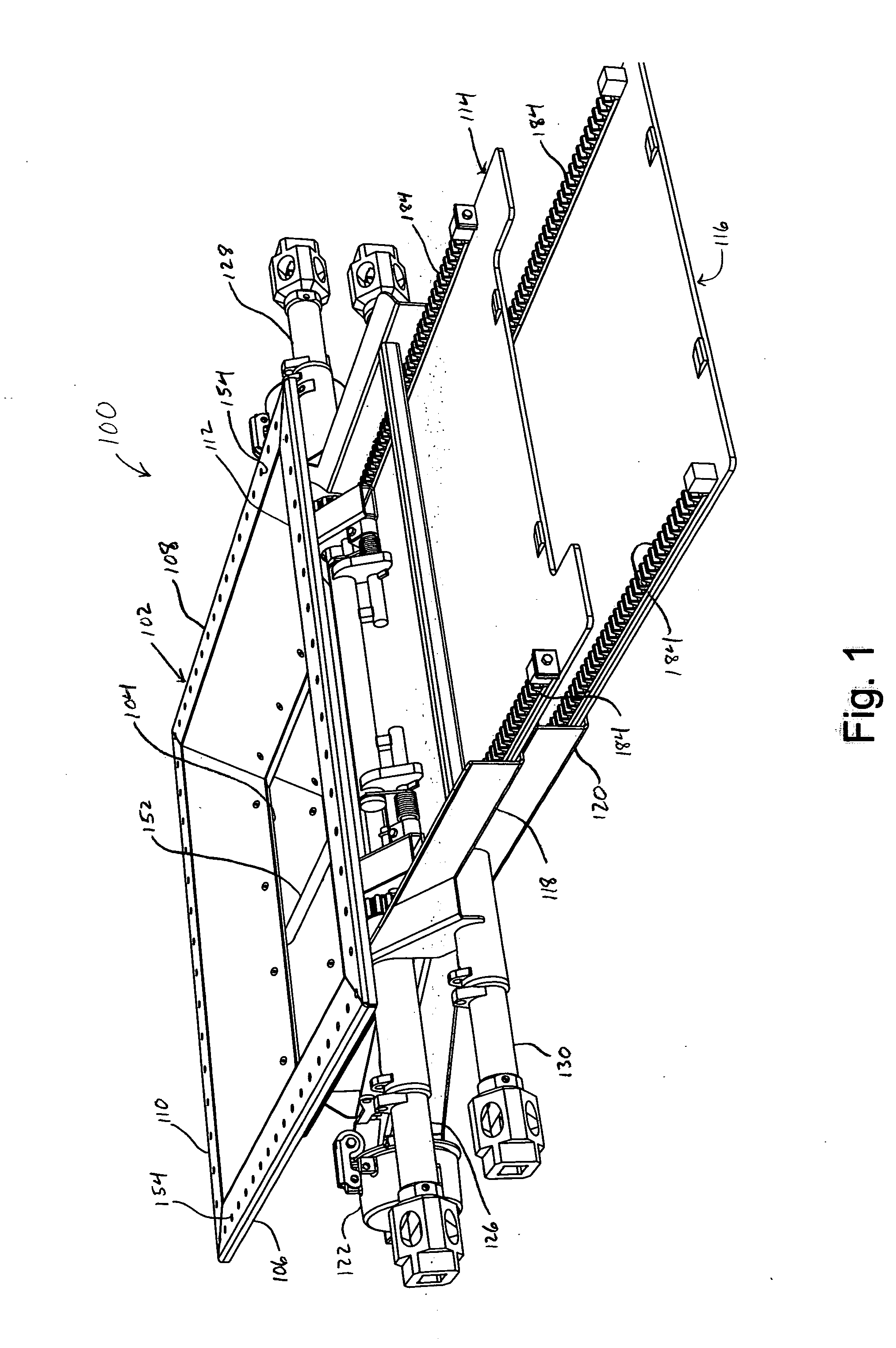

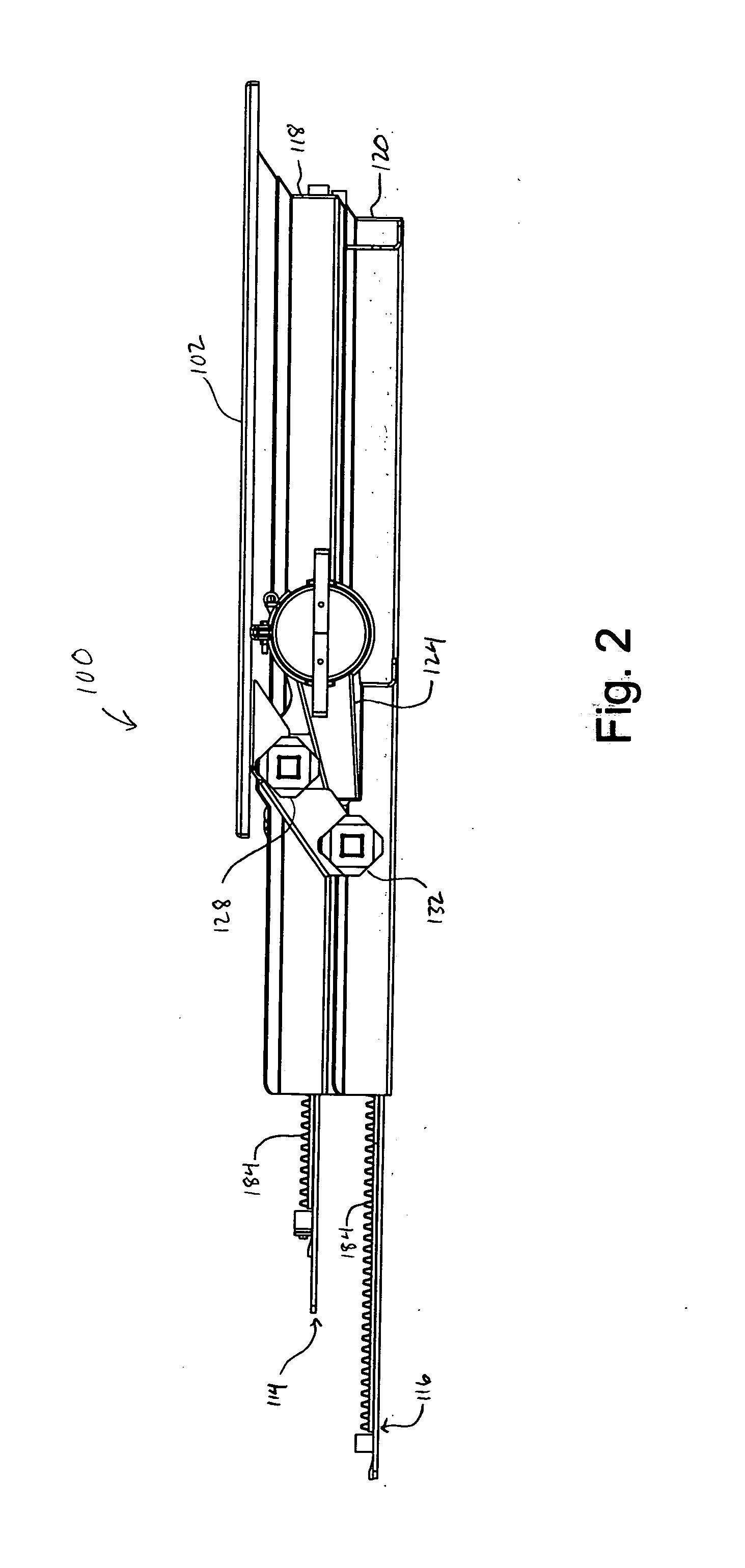

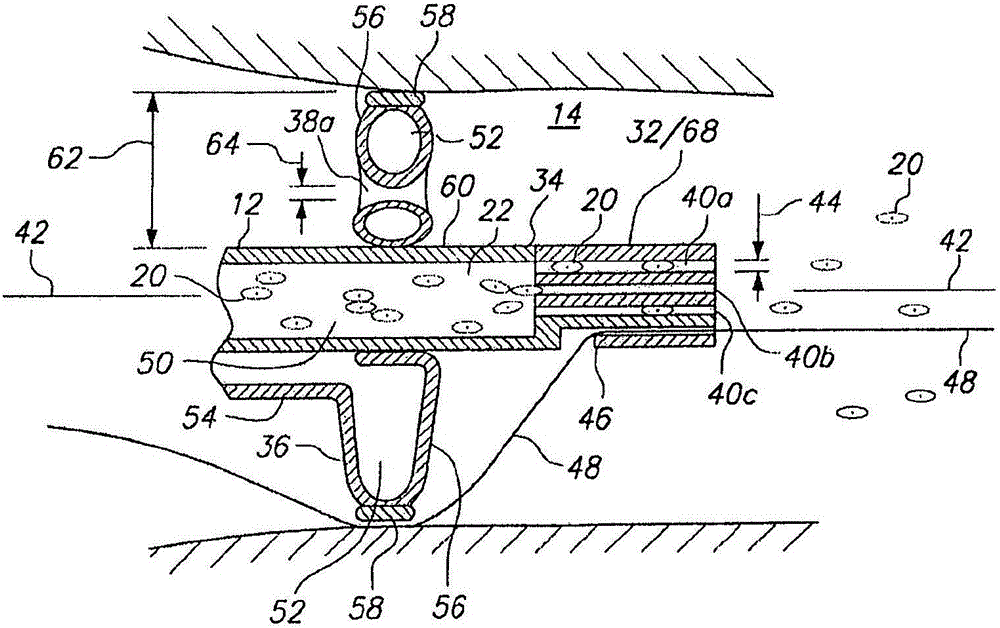

Railway hopper car discharge gate

A railroad hopper car discharge gate is assembled from unitary stacked frames that provide unimpeded flow of lading during discharge. A low-wear glide system minimizes friction between the gate panels and other components of the apparatus, and an improved sealing system protects lading from contaminants such as rain, dust and insect infestation and provides enhanced vacuum sealing for greater efficiency during vacuum discharge.

Owner:AERO TRANSPORTATION PRODS

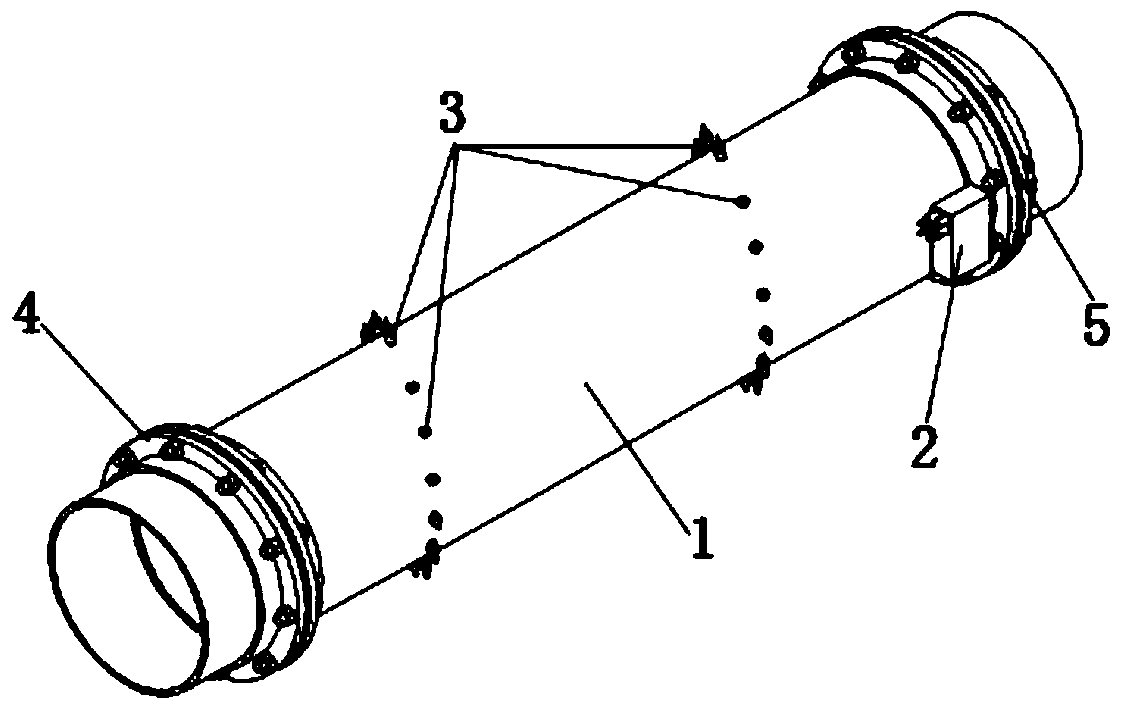

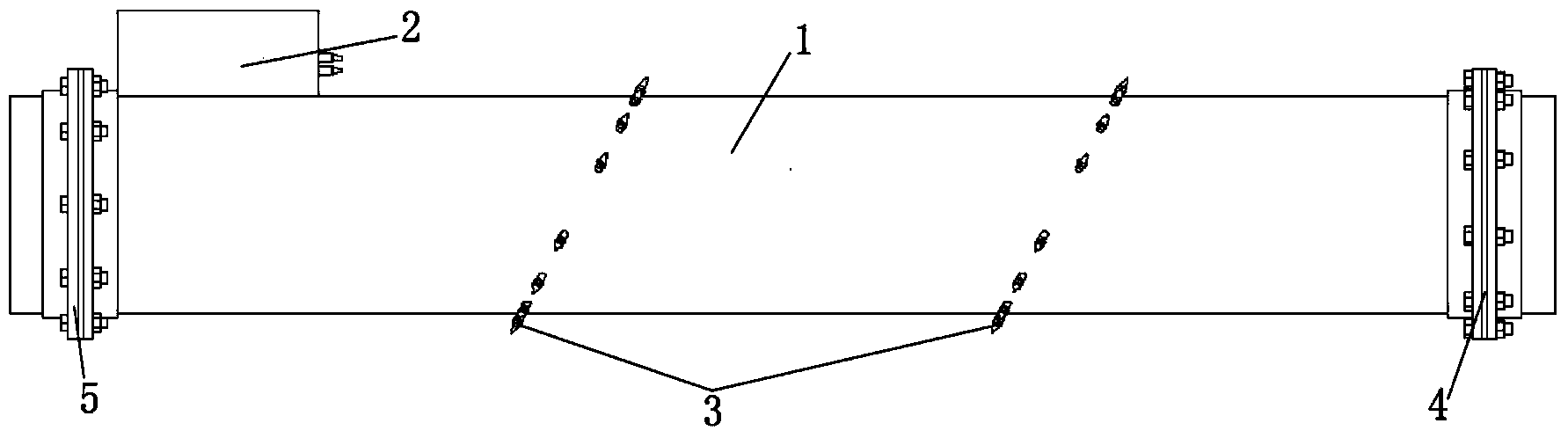

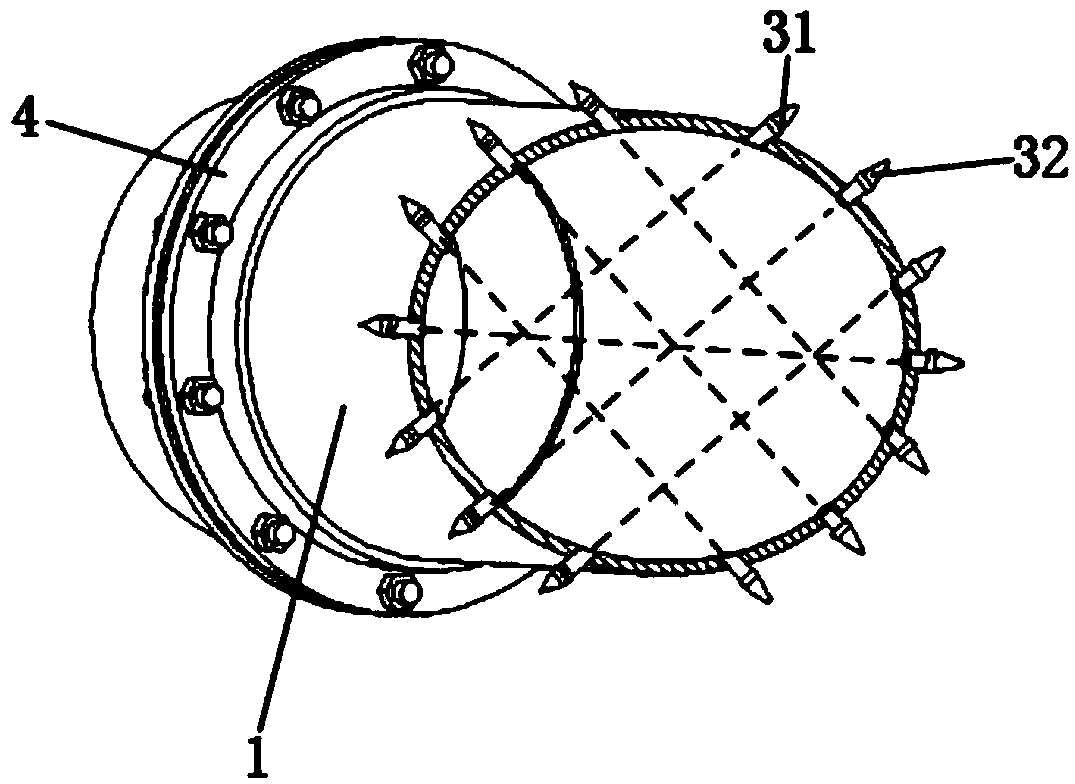

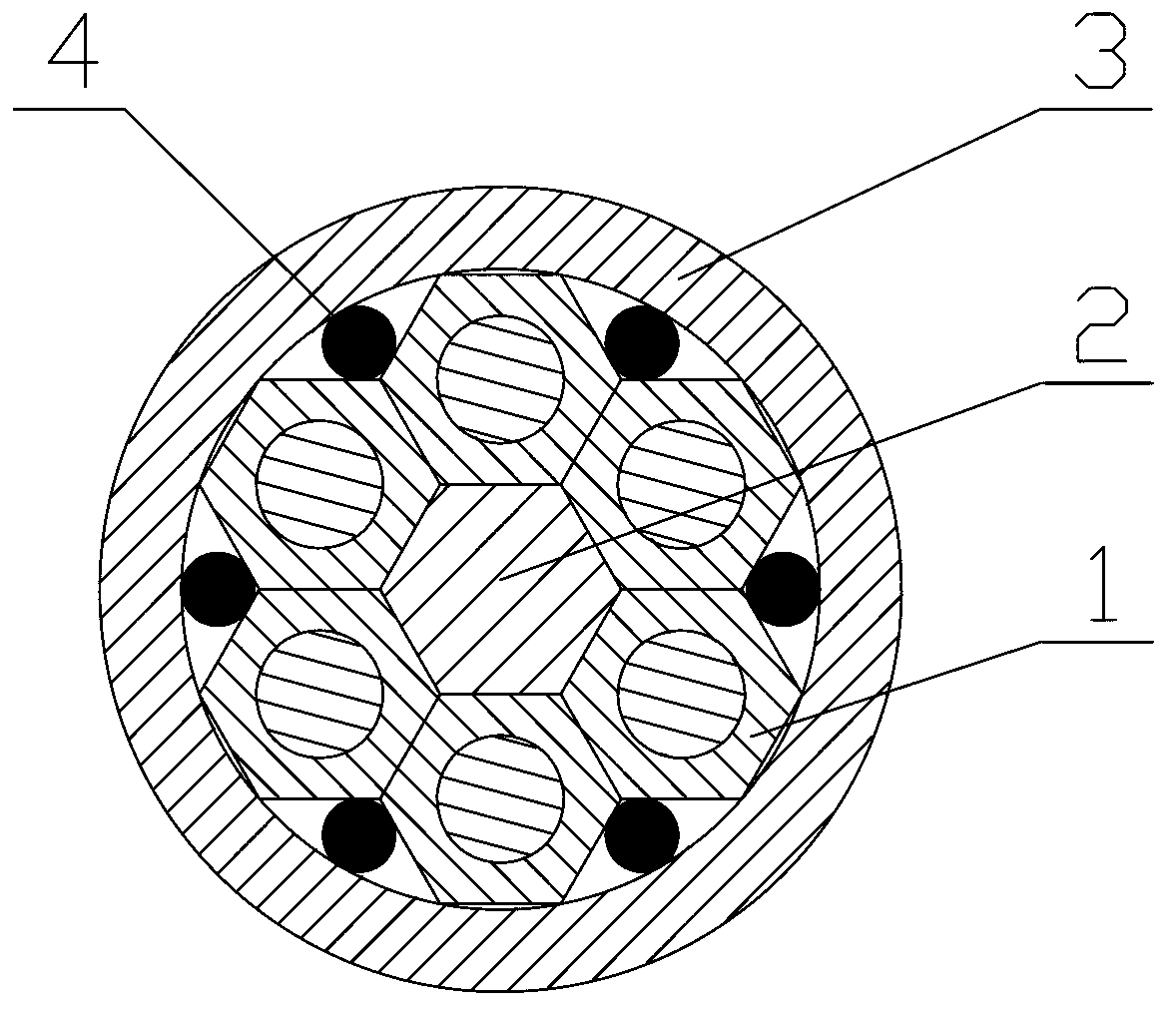

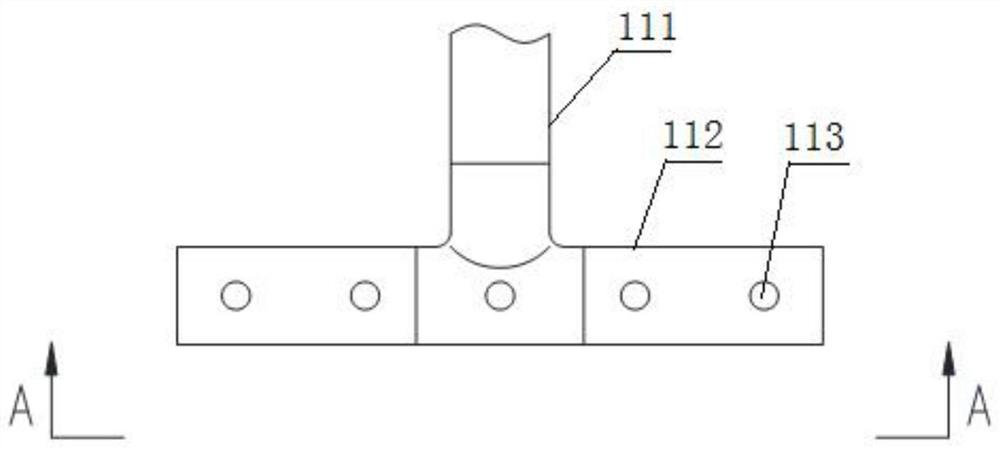

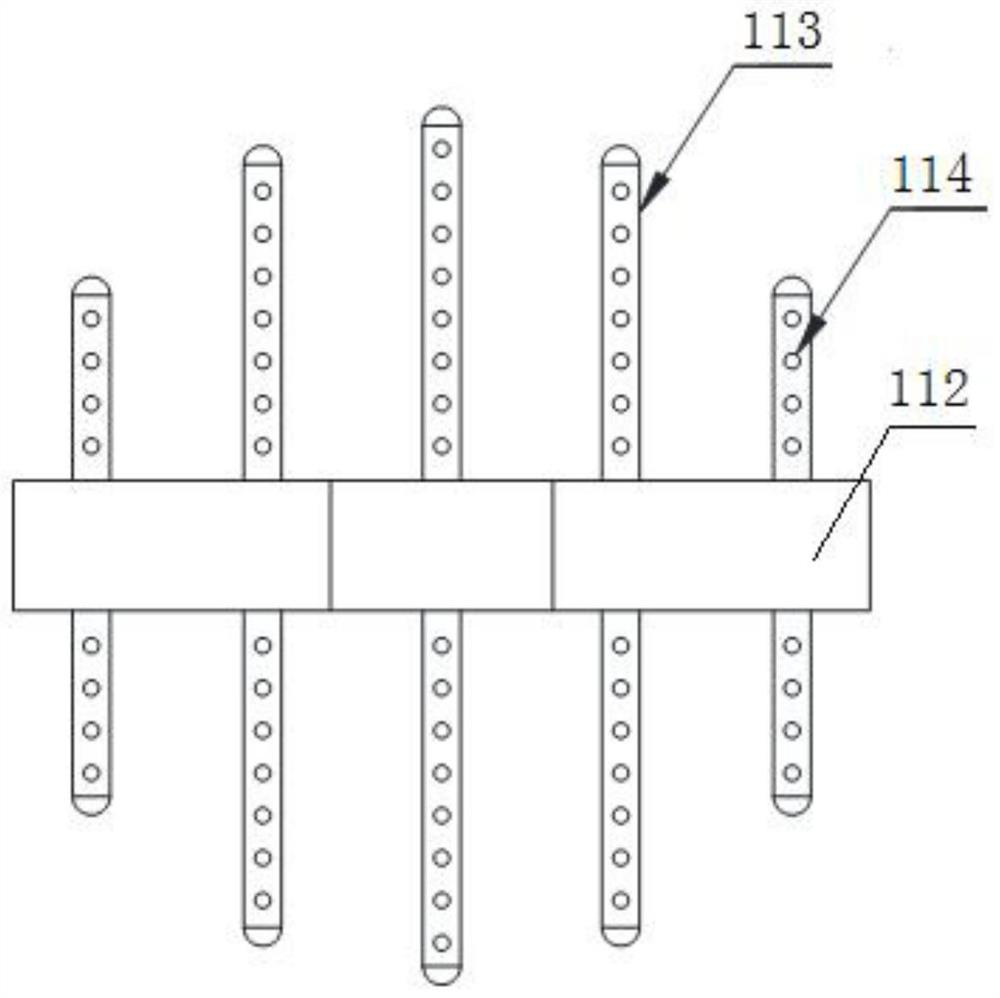

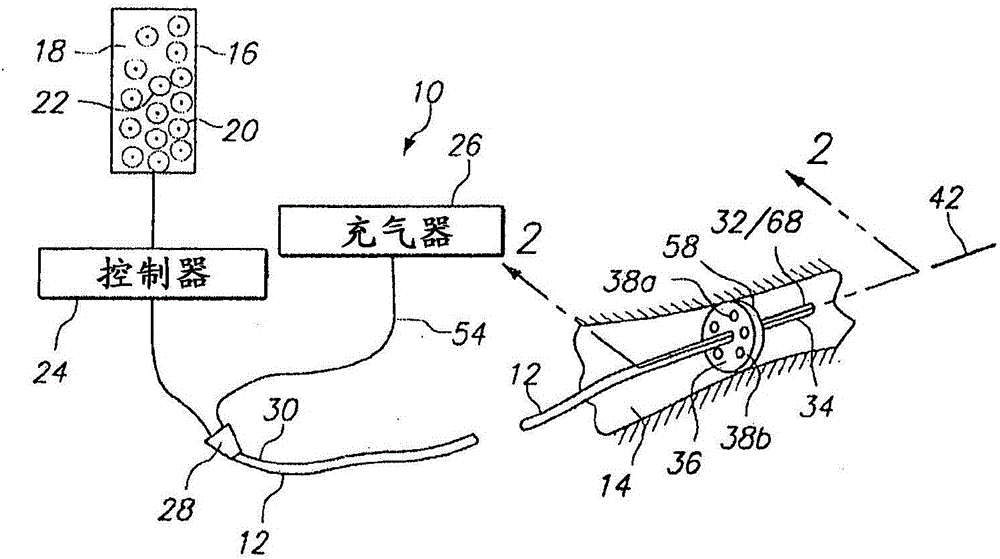

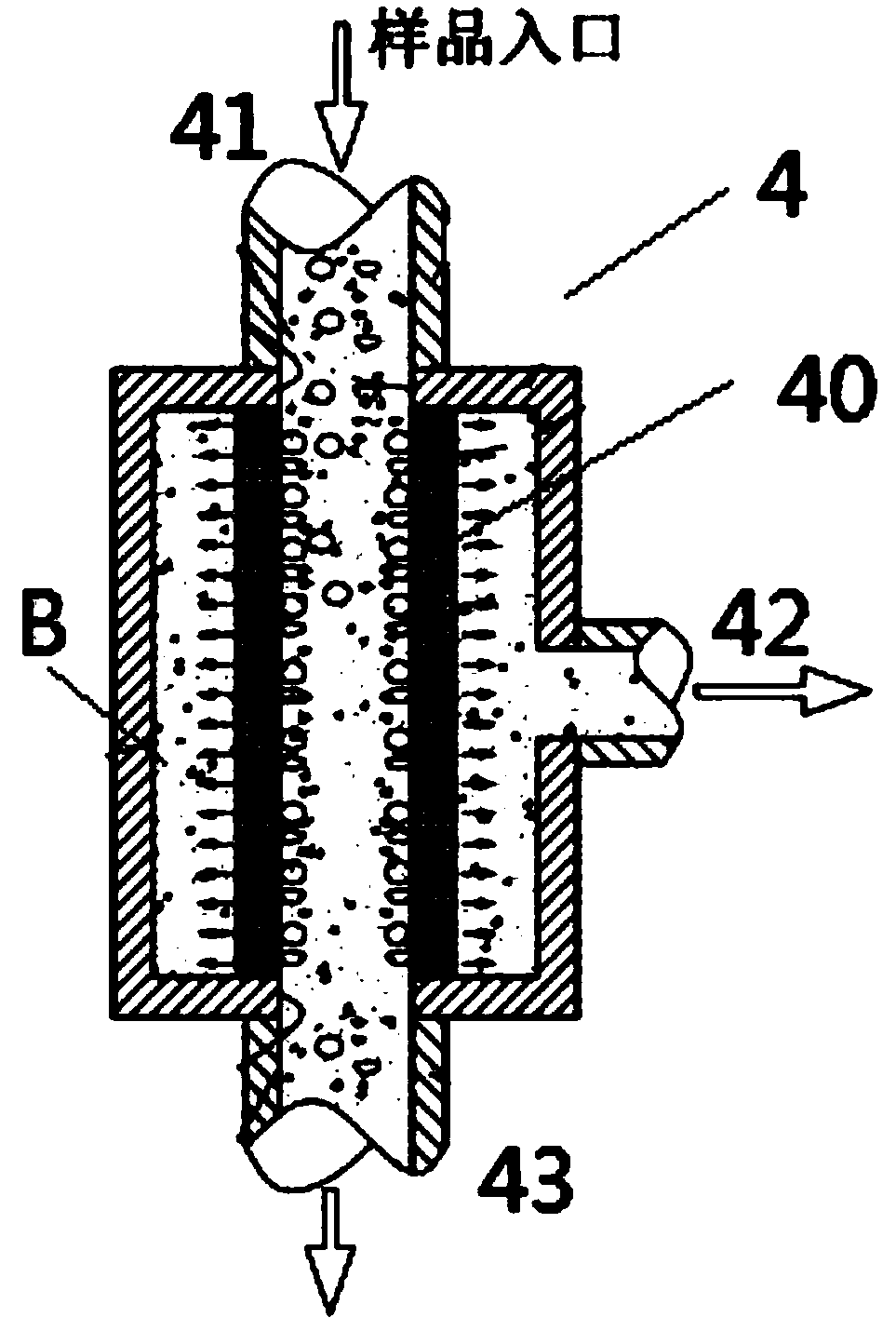

Sensor and gas/solid two-phase flow concentration detection device and method

InactiveCN104316597ARealize continuous measurementQuick responseAnalysing fluids using sonic/ultrasonic/infrasonic wavesInformation processingControl signal

The invention discloses a sensor and a gas / solid two-phase flow concentration detection device and method. The sensor comprises a measurement pipe and a plurality of ultrasonic measurement assemblies; at least two detection cross sections are arranged on the measurement pipe in the axial direction, the multiple ultrasonic measurement assemblies are arranged on the detection cross sections, and each ultrasonic measurement assembly comprises at least one transmitting device and at least one receiving device. The gas / solid two-phase flow concentration detection device comprises an information processing device and the sensor; the information processing device comprises a signal analysis module used for receiving and analyzing signals transmitted by the sensor, an information fusion module used for calculating the information obtained after analysis, an output module used for outputting the signals, a control module used for controlling signal transmission between the modules and a power module used for supplying power to control movement. By means of the sensor and the gas / solid two-phase flow concentration detection device and method, the technical problems of discontinuous measurement, high radioactivity, poor adaptability and flowing hinders can be solved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

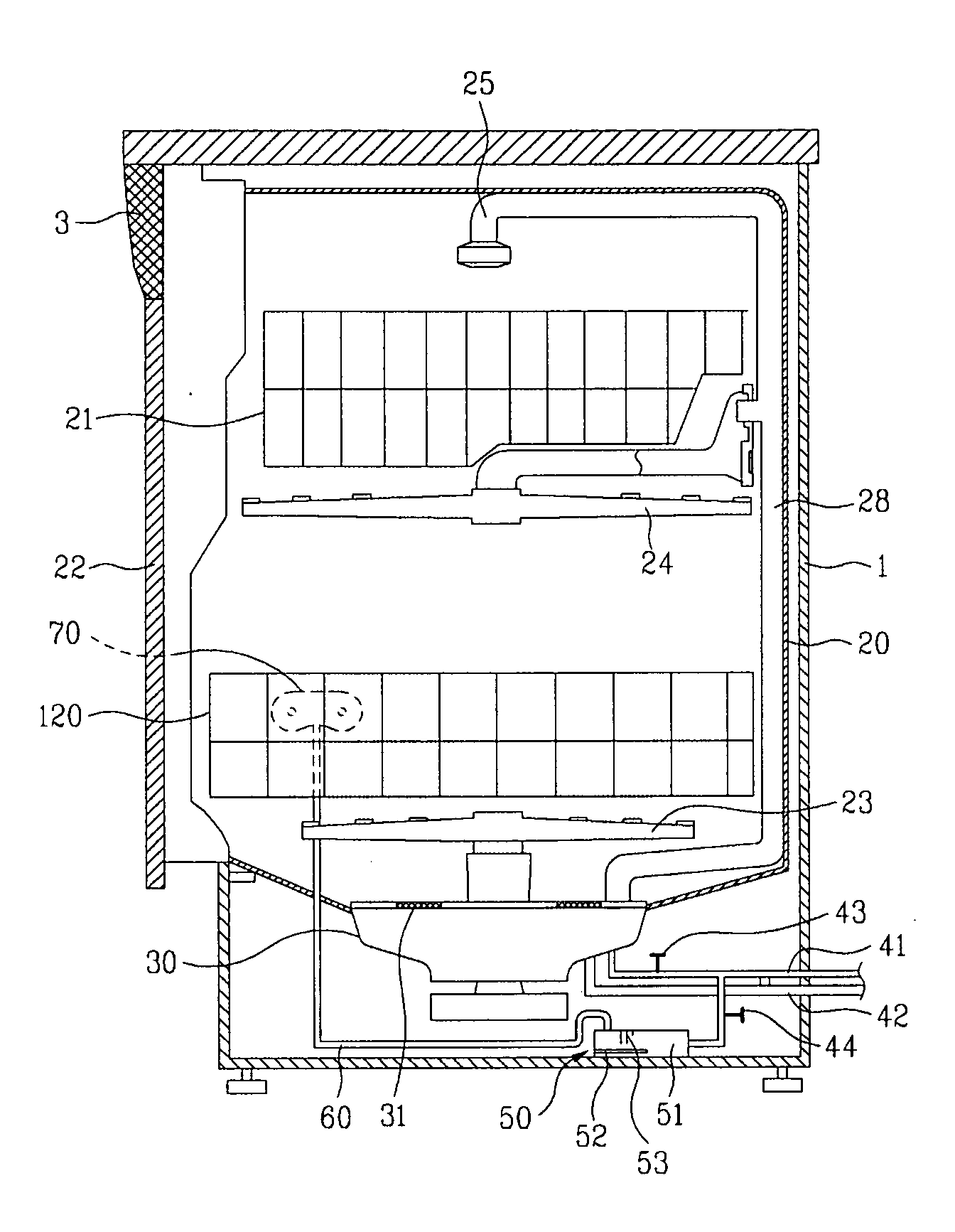

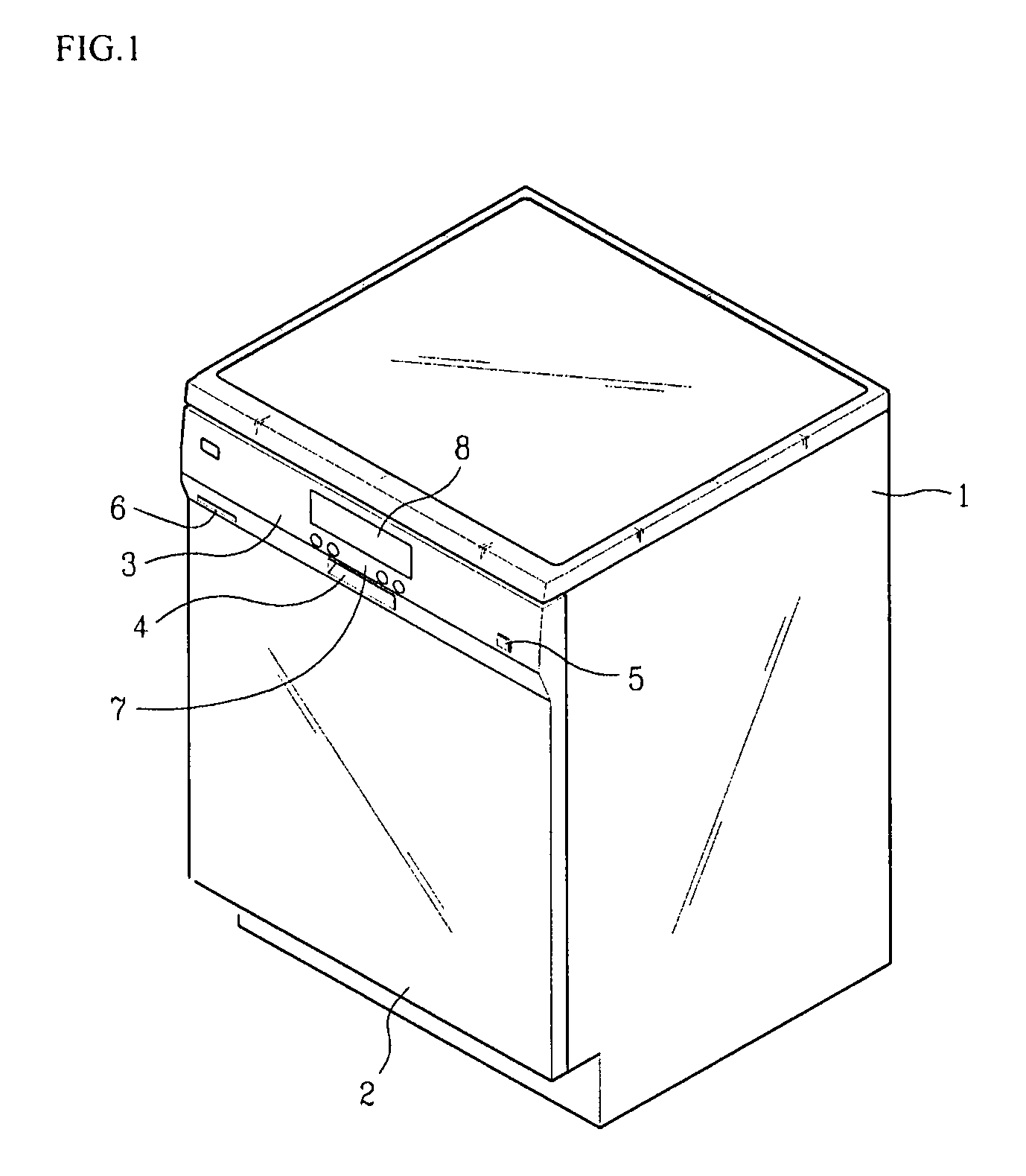

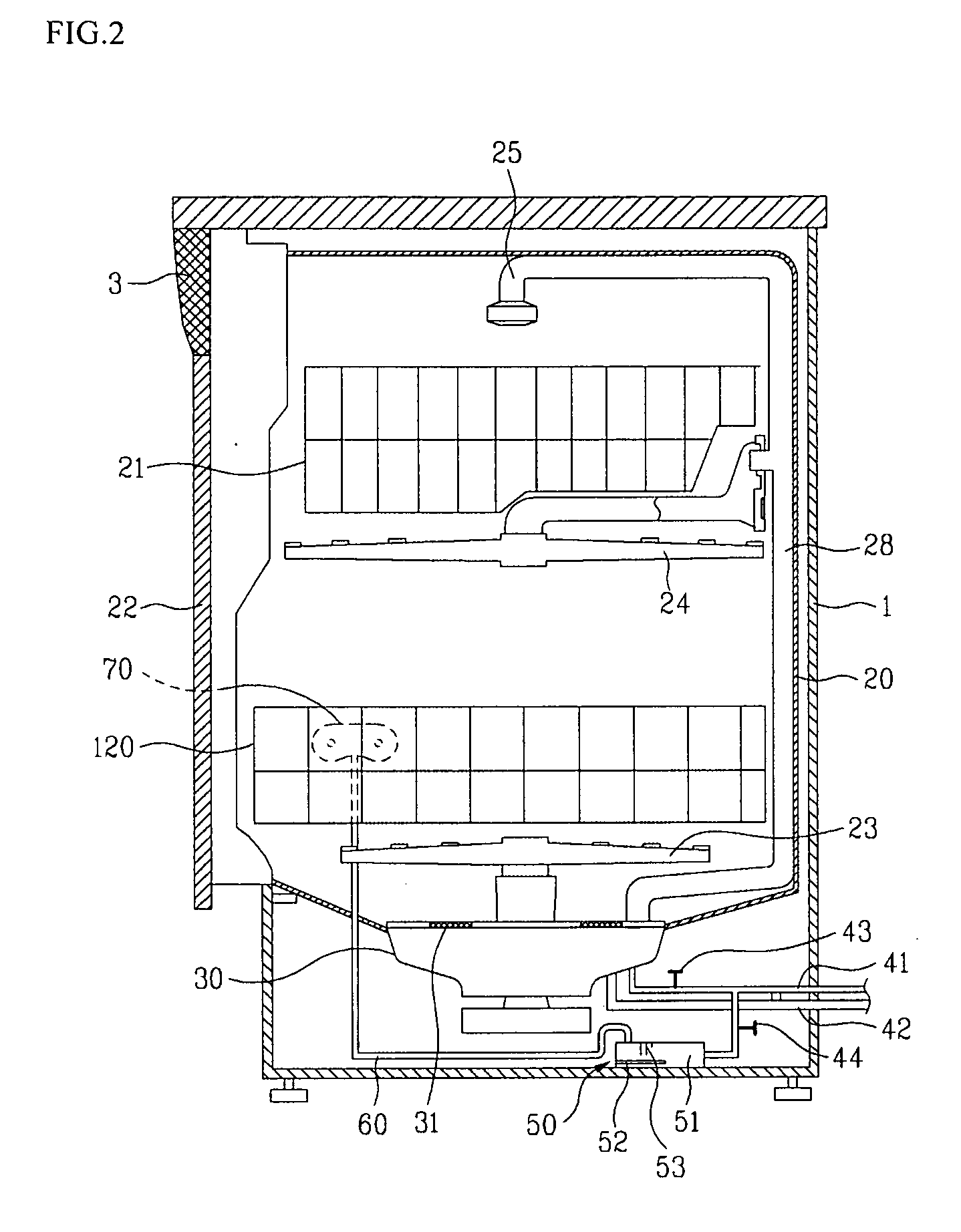

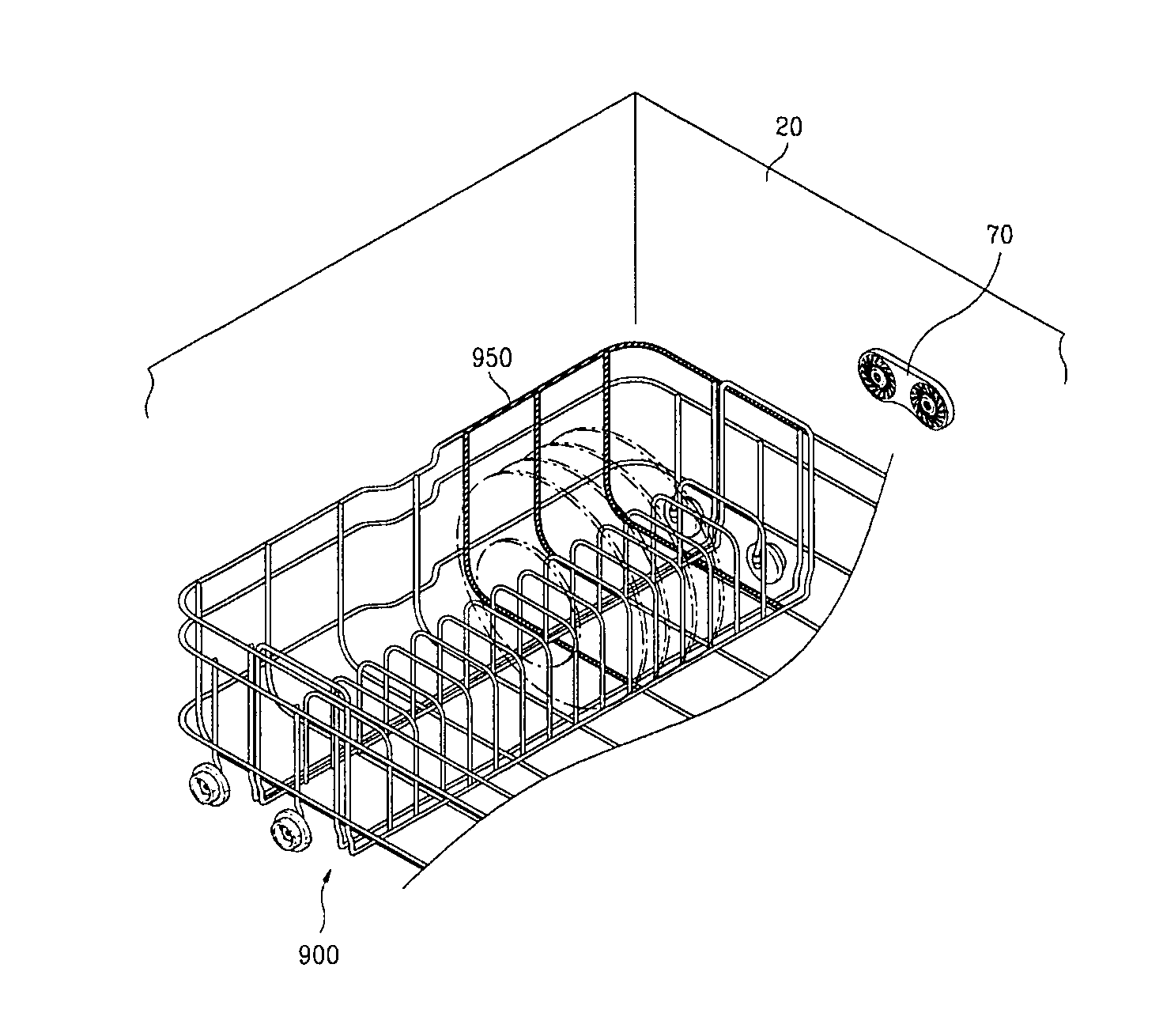

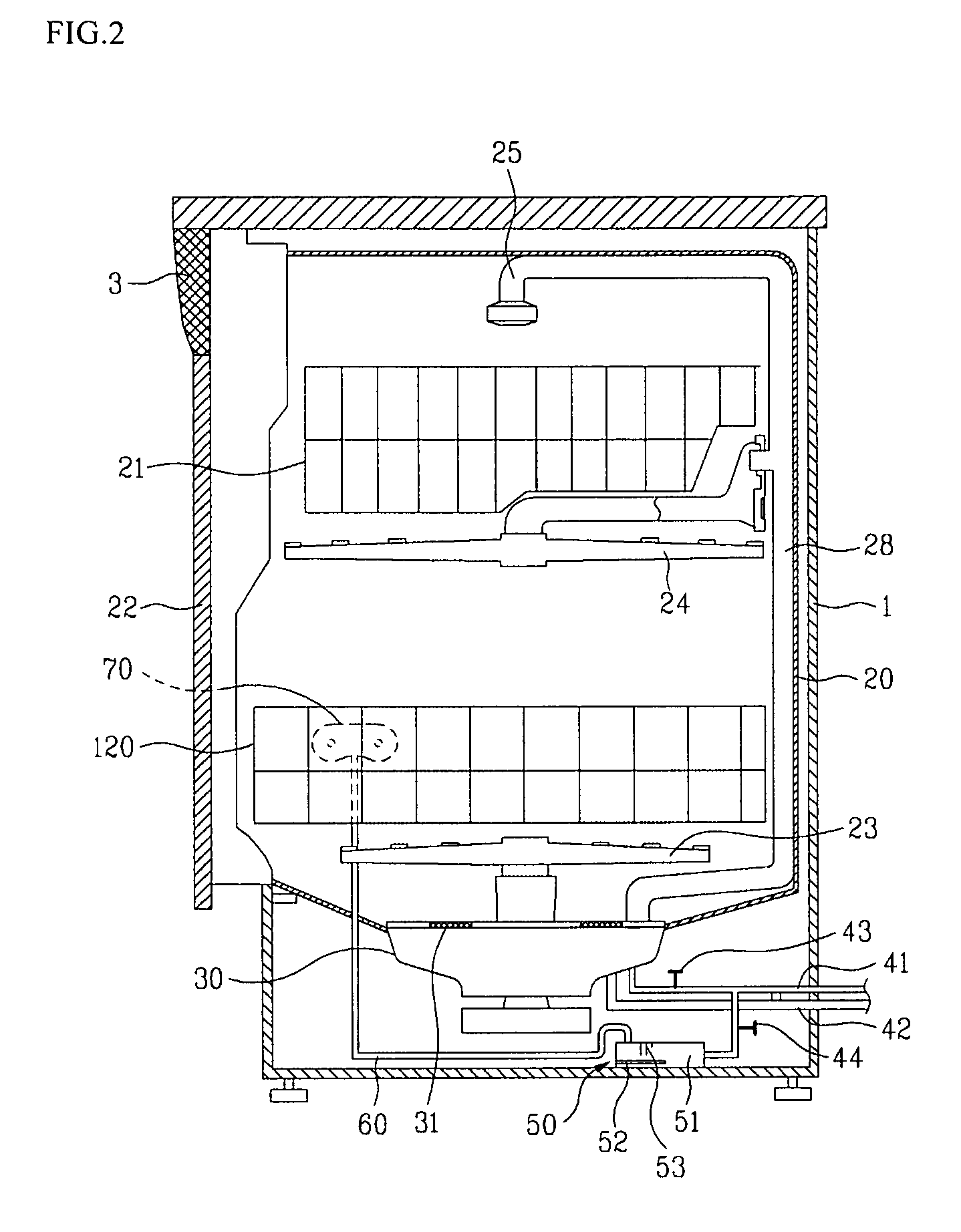

Steam dish washing machine with effective positioning and orientation of items to be washed

ActiveUS20090007941A1Maximize the effectEffective positioningTableware washing/rinsing machine detailsCleaning using liquidsPulp and paper industryHigh intensity

Dish washing machine that includes a steam generator, which supplies steam during a washing operation, to aid in the washing of dishes and other items in the dish washing machine. The dish washing machine further including one or more dish washing racks that effectively orient the dishes, and other items to be washed, in such a way so as to avoid inhibiting the steam from being evenly distributed around each of the dishes and other items to be washed. The dish washing machine also including a steam zone indicator to aid in effectively positioning the dishes and other items to be washed by visually distinguishing the region or zone within the dish washing machine that corresponds with high-intensity steam.

Owner:LG ELECTRONICS INC

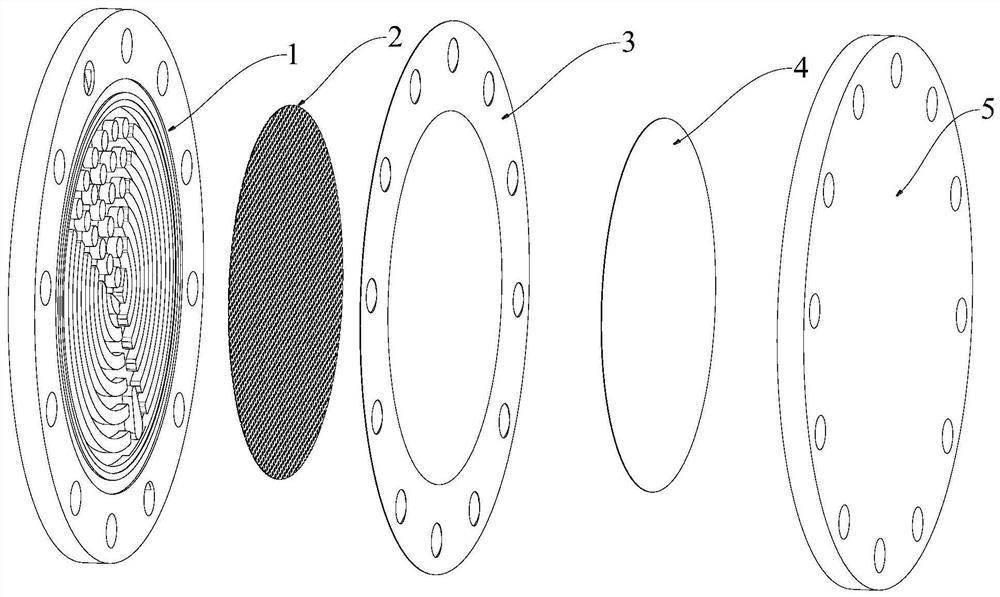

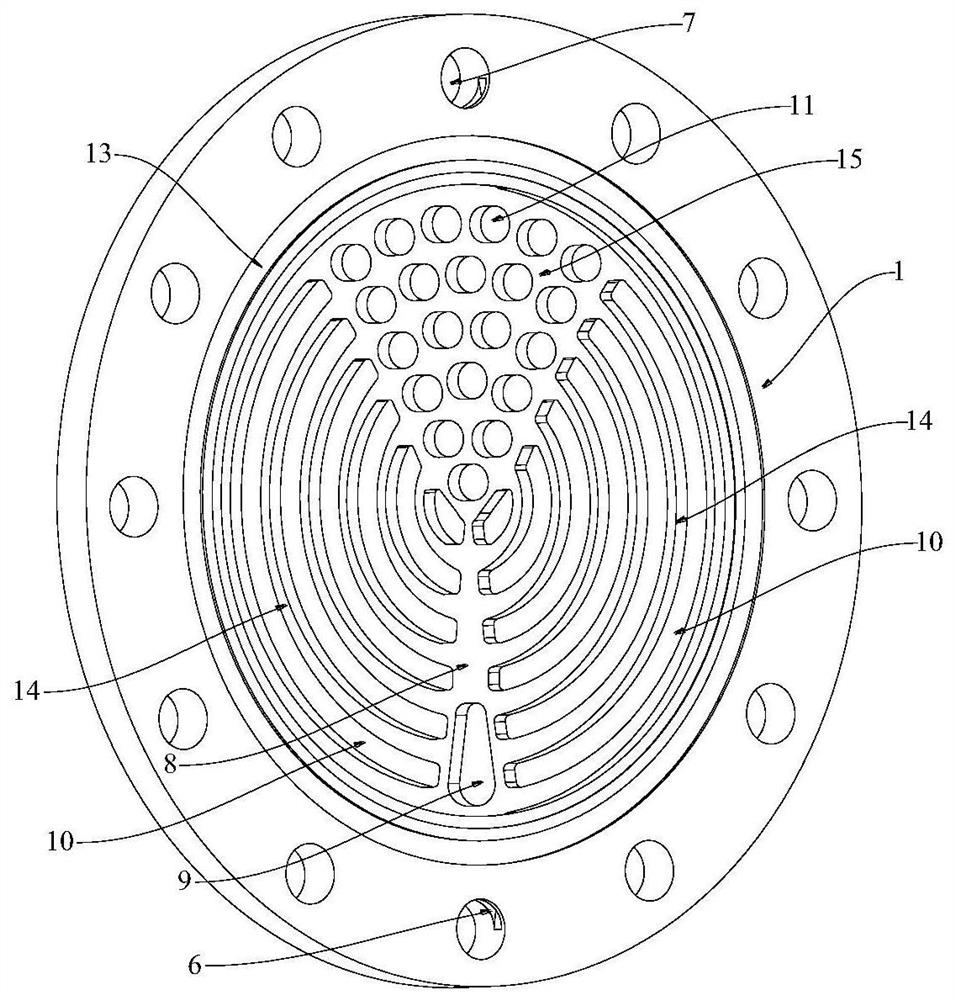

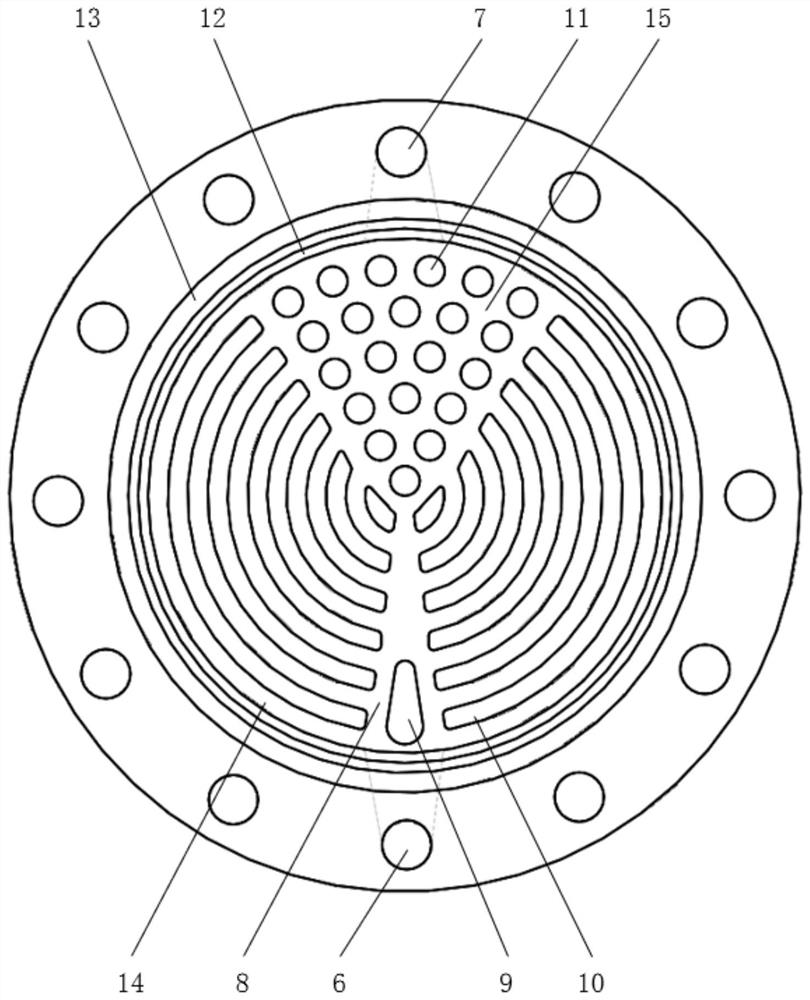

Proton exchange membrane water electrolyser structure and anode plate

The invention discloses a proton exchange membrane water electrolyser structure and an anode plate. The proton exchange membrane water electrolyser structure comprises the anode plate, an anode diffusion layer, a CCM membrane electrode, a cathode diffusion layer and a cathode plate. The anode plate comprises a fluid distribution area, an arc flow channel reaction area and a dotted flow field reaction area; and an anode plate fluid distribution area is an arc-shaped stepped flow field area which is gradually reduced from two sides to the circle center, an ellipse-like distribution structure is arranged in the middle of the area, the part, close to a water inlet, of the anode plate is an arc-shaped flow channel reaction area, and a flow field tail end area is a dot-shaped flow field reaction area. According to the invention, uniform diffusion of reaction water in each flow channel after entering a flow field is ensured by arranging the ellipse-like distribution structure in a fluid distribution area; the flow resistance of reaction water is reduced through an arc-shaped flow channel of the arc-shaped flow field, and the transmission efficiency of the reaction water is improved; and through the dot-matrix type structure of the dot-shaped flow field, formation of bubble plugs is reduced, the mass transfer capacity of reaction water is enhanced, and then the performance of the electrolytic cell is improved.

Owner:WUHAN UNIV OF TECH

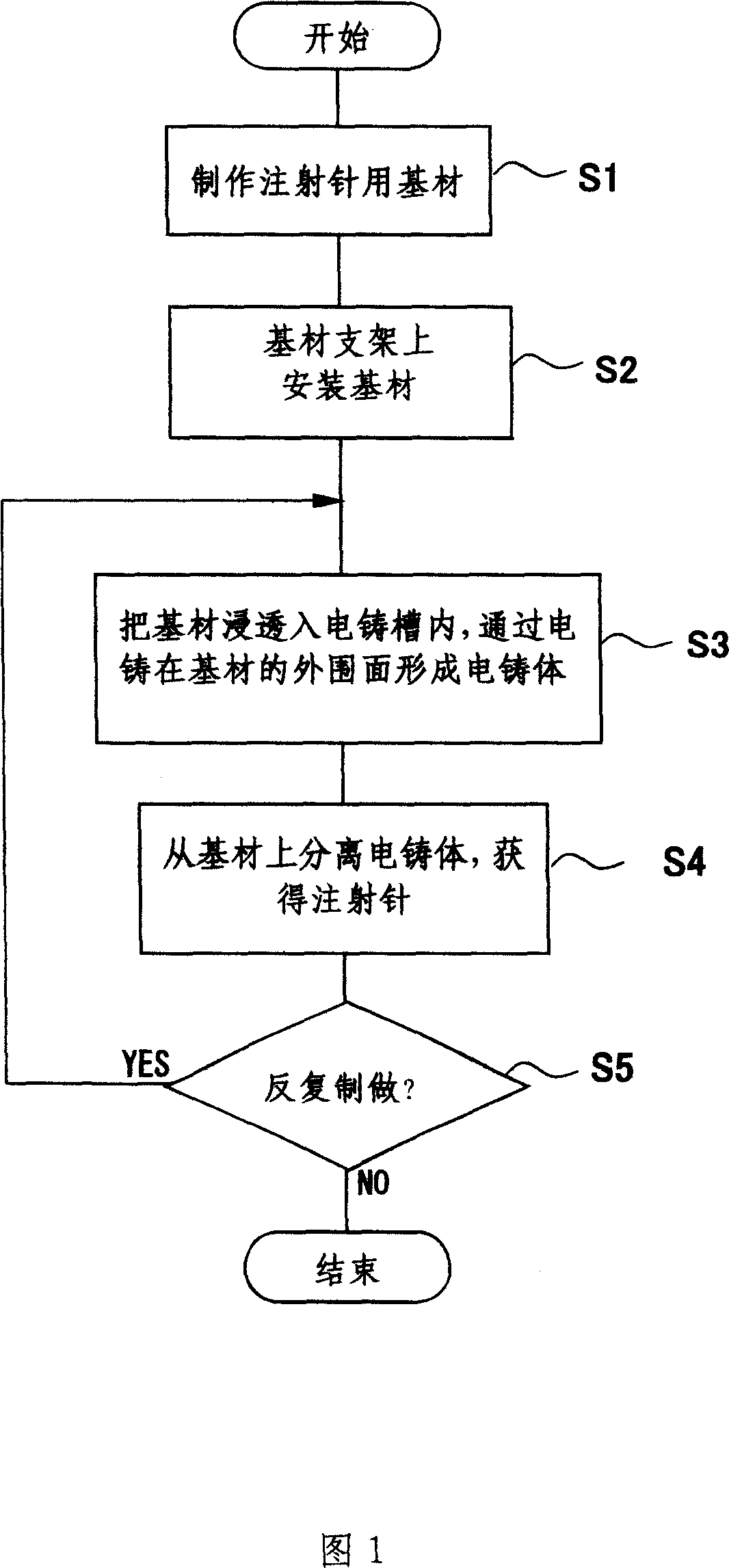

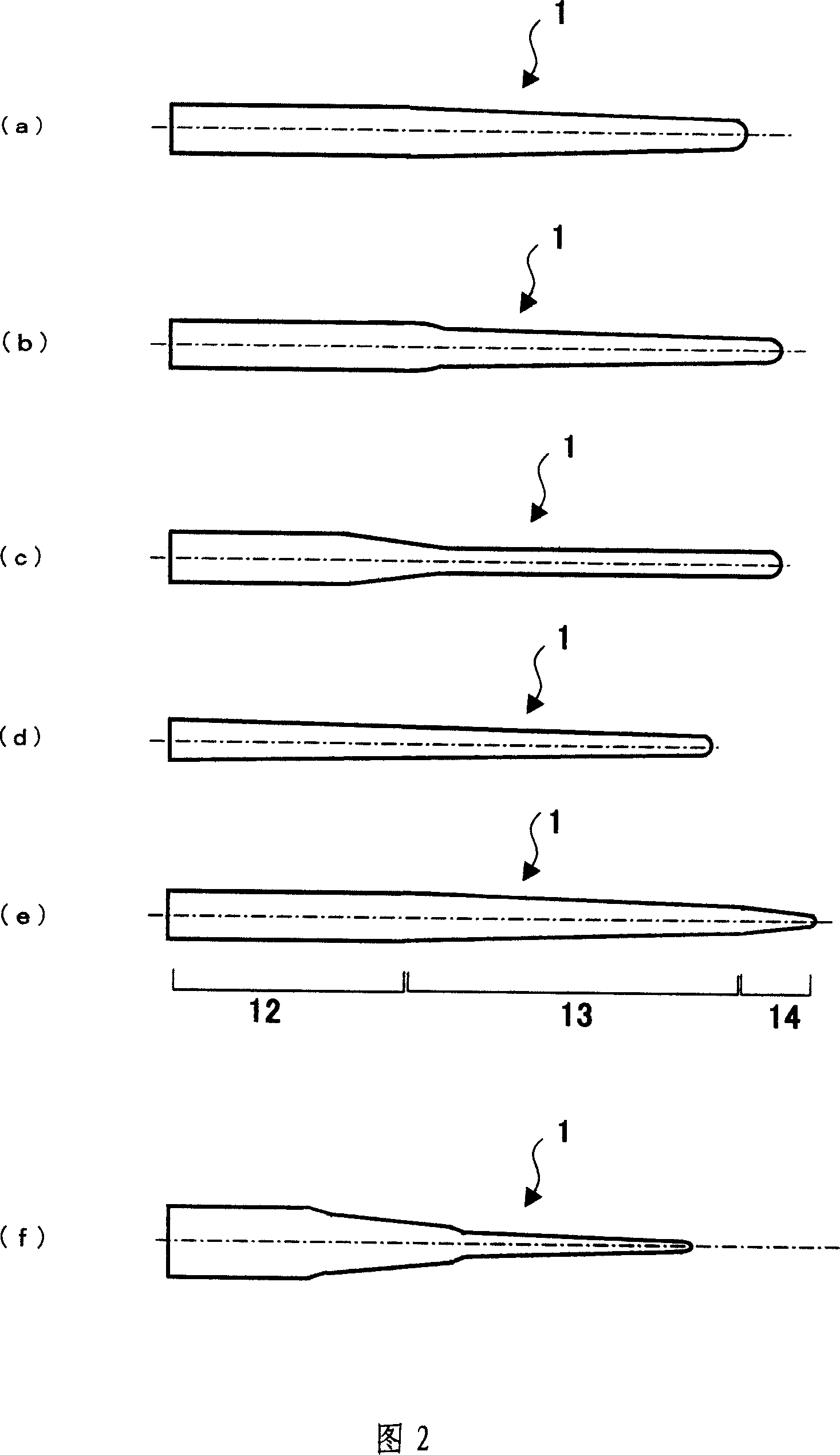

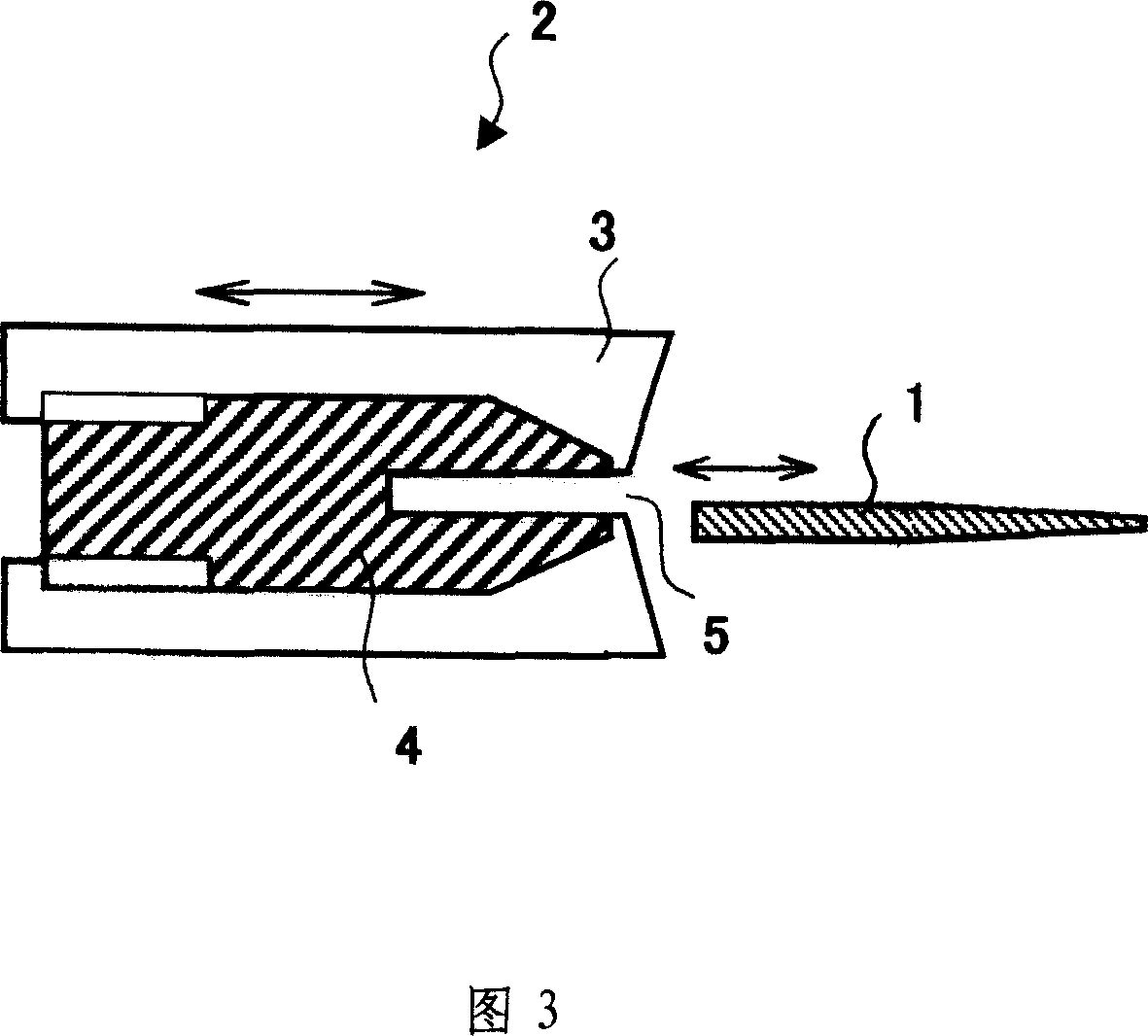

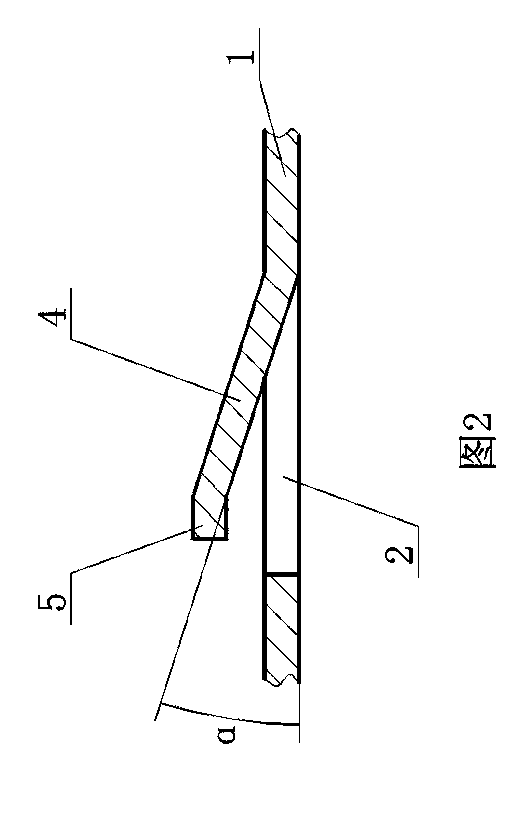

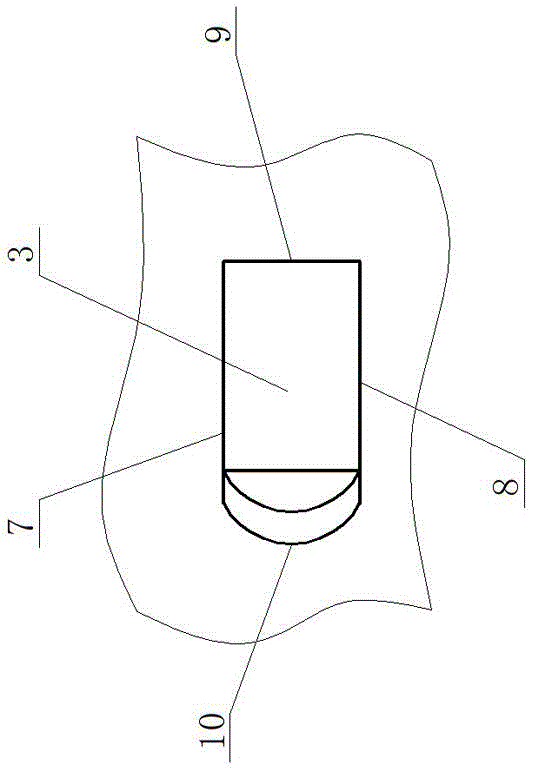

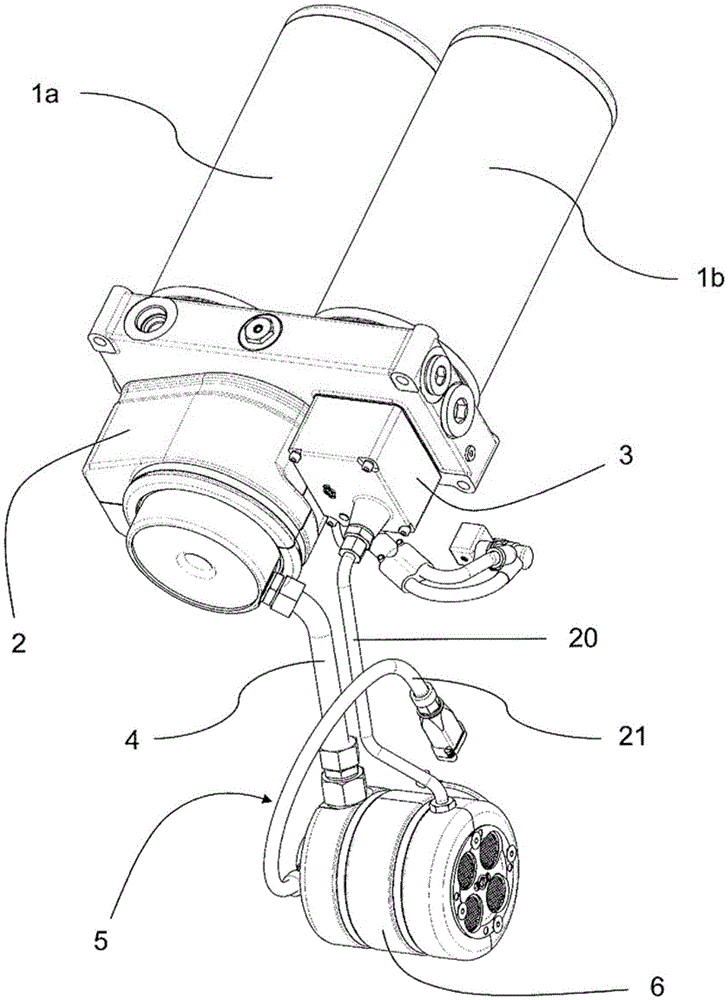

Method of manufacturing injection needle and injection needle

InactiveCN101045173ASpeed up the flowSimple manufacturing processMedical devicesInfusion needlesEngineeringMetal

The invention relates to the manufacture of injection needle, which is aimed to simply obtain an injection needle which dispenses with jointing treatment when a cylindrical shape with a small diameter is made, and enables the smooth flow of a liquid to be ensured without polishing treatment of an inner wall surface. Firstly, a master for the injection needle is made (S1); secondly, a master retaining holder is fitted with the master for the injection needle (S2); subsequently, an electroformed metal adheres to the master for the injection needle by electroforming treatment (S3); and finally, the master for the injection needle is pulled up from an electroforming tank along with the master retaining holder, so that an electroformed body as an injection needle body can be released from the master for the injection needle (S4). In the manufactured injection needle, an outside diameter of a leading end for a puncture is set on the order of 0.12 mm; and a tapered part, the outside and inside diameters of which are reduced toward the leading end, is arranged between a proximal end part and the distal end part for the puncture. The invention simplifies the manufacture of injection needle, and enables the smooth flow of a liquid in the injection needle, further, greatly reduces the pain in puncture.

Owner:日本插芯株式会社

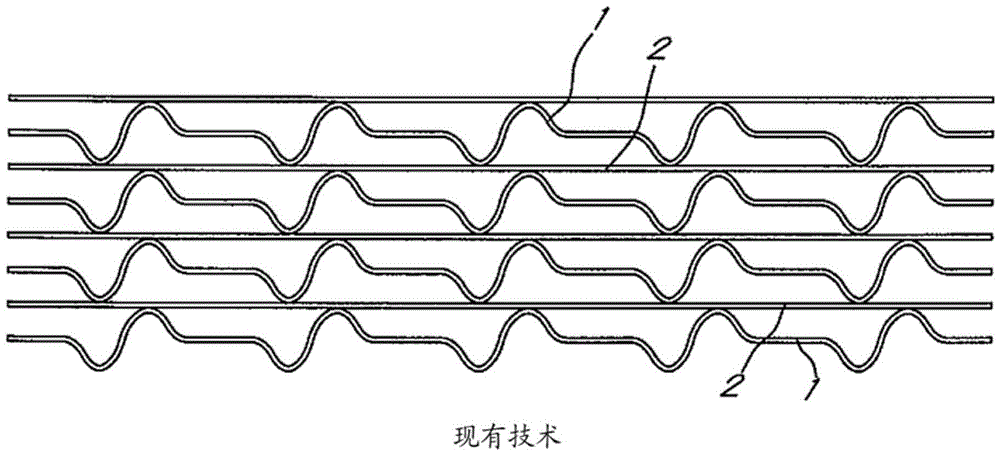

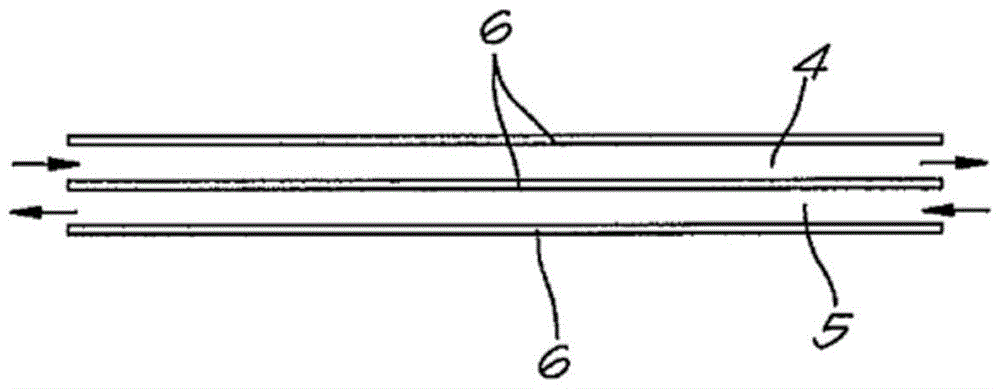

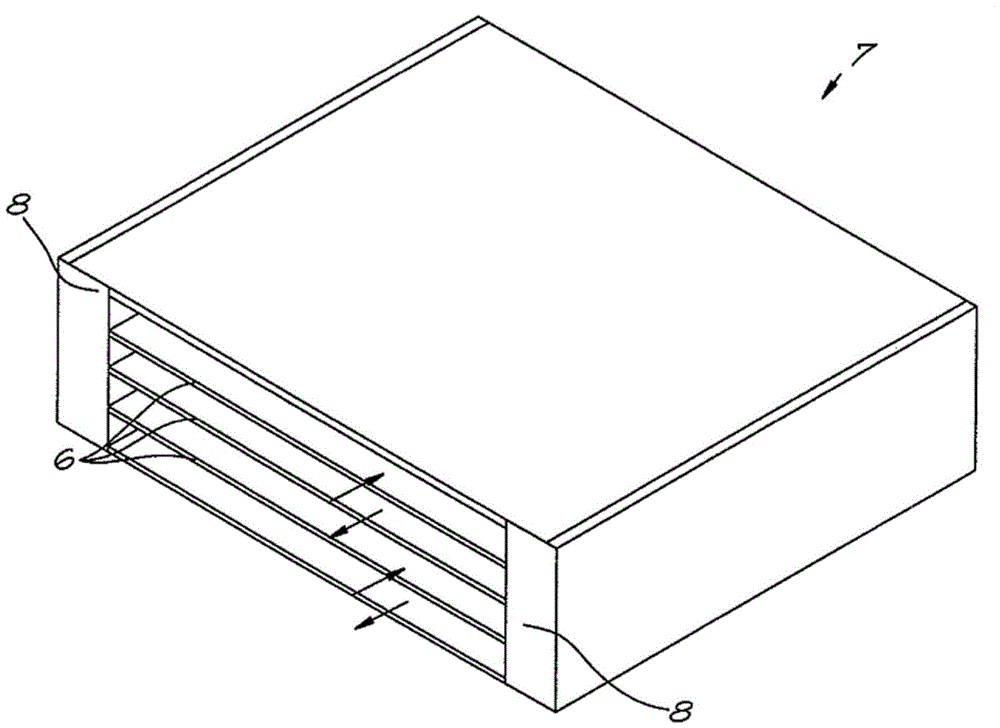

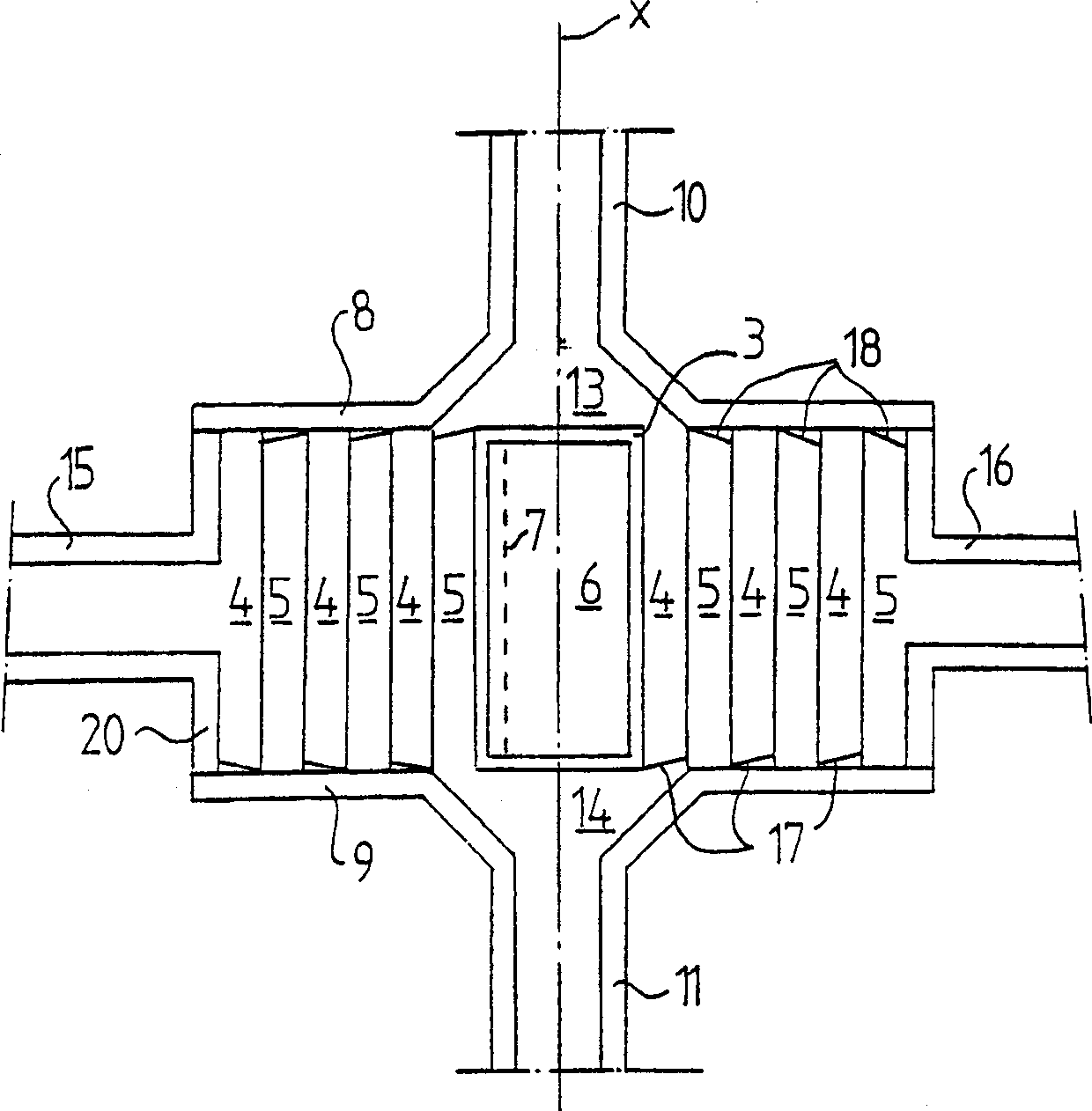

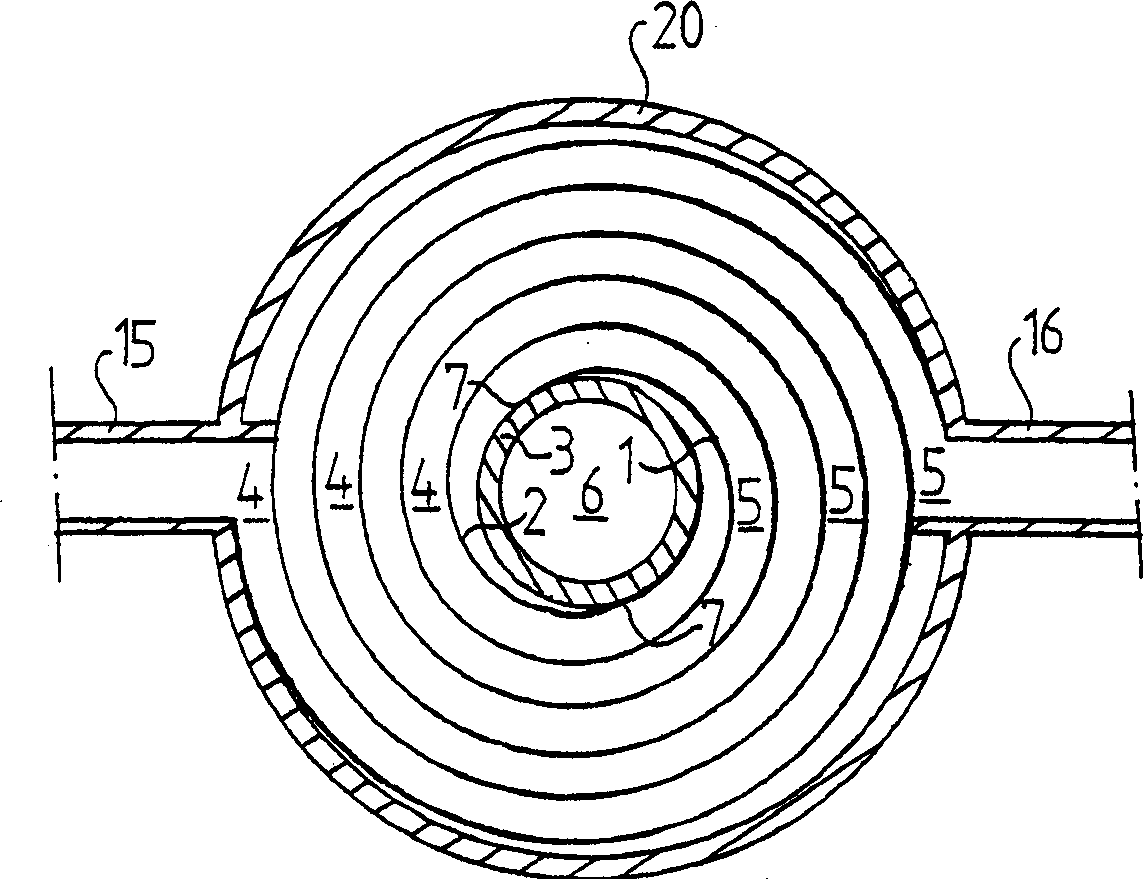

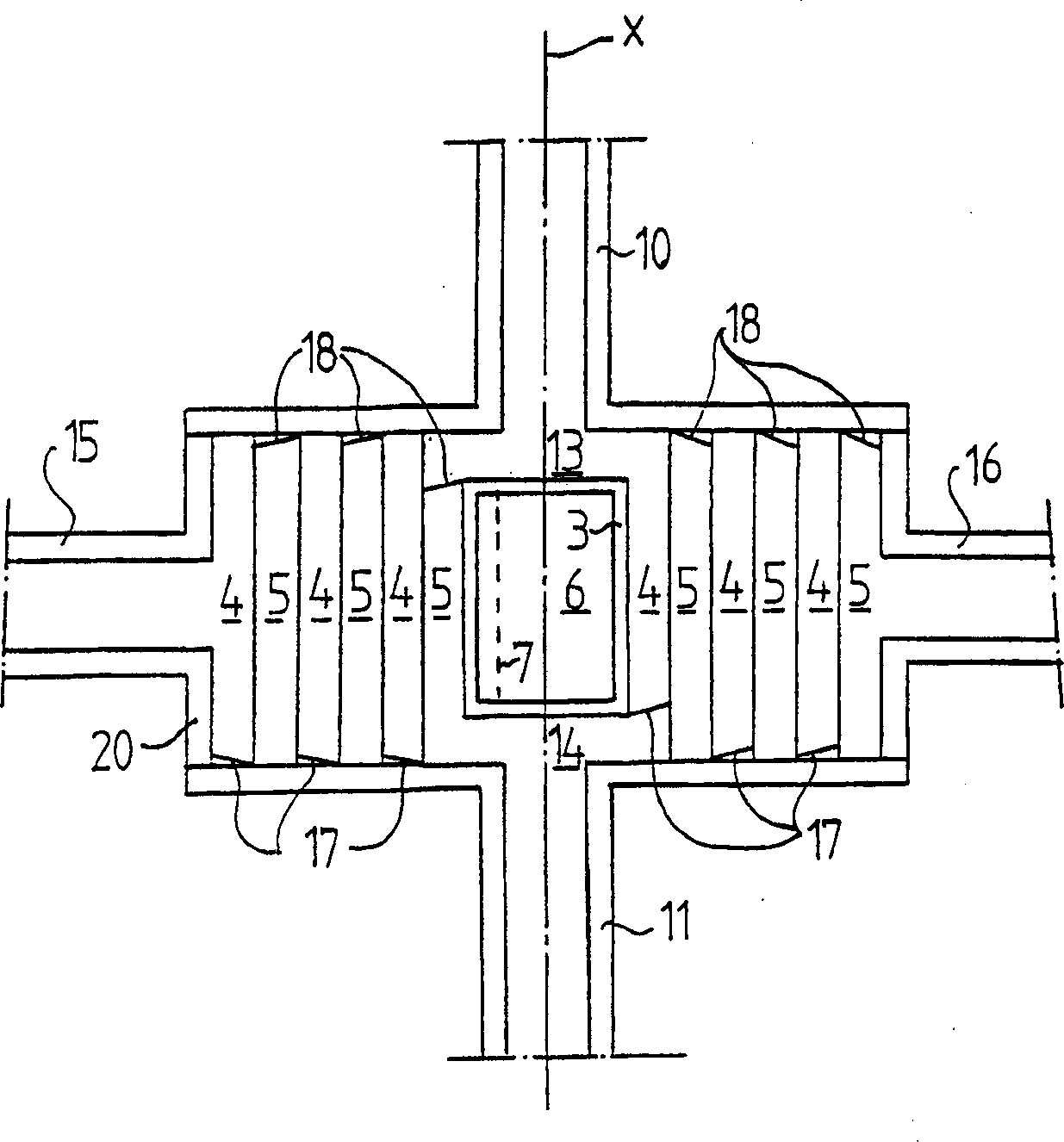

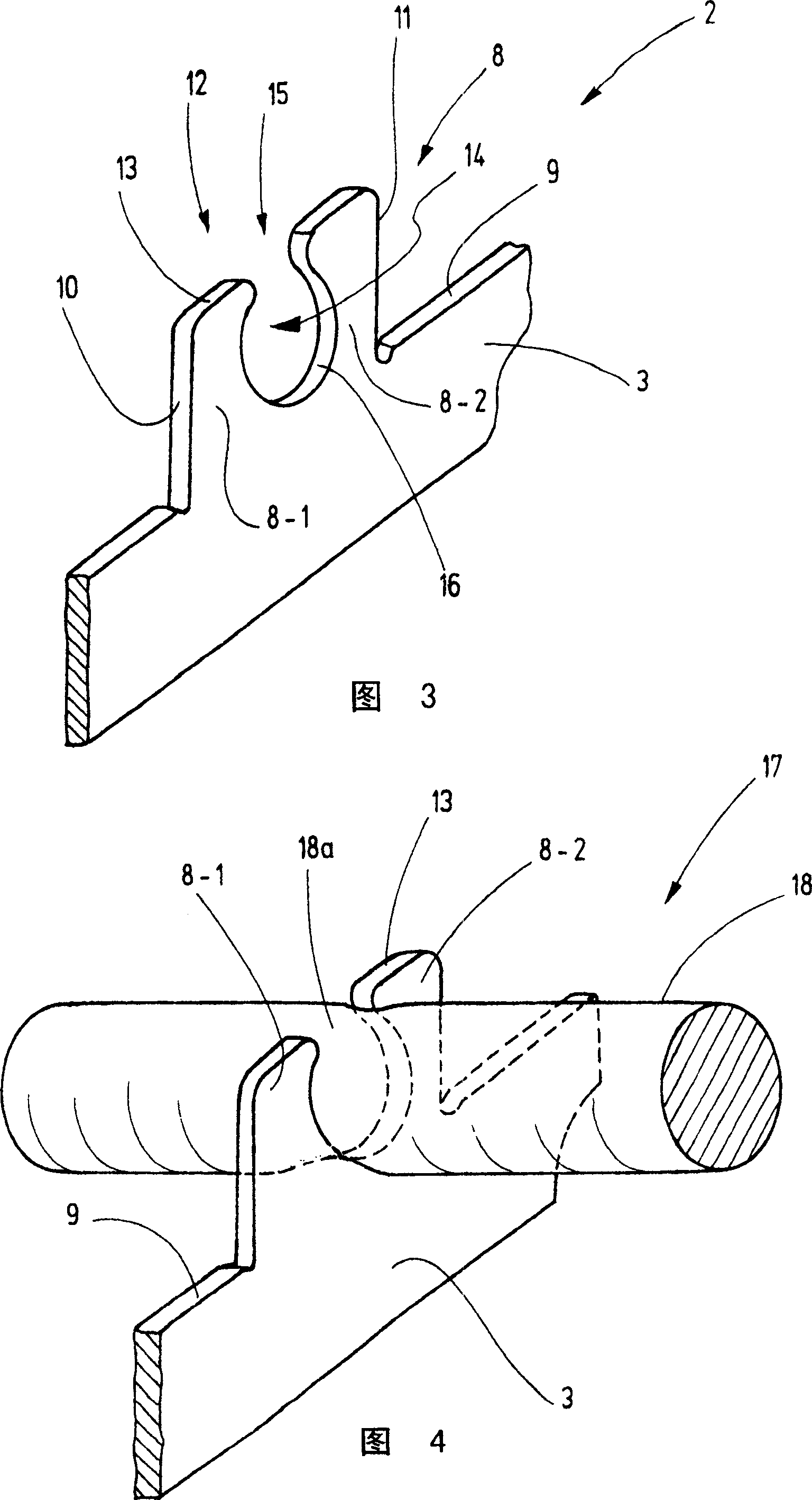

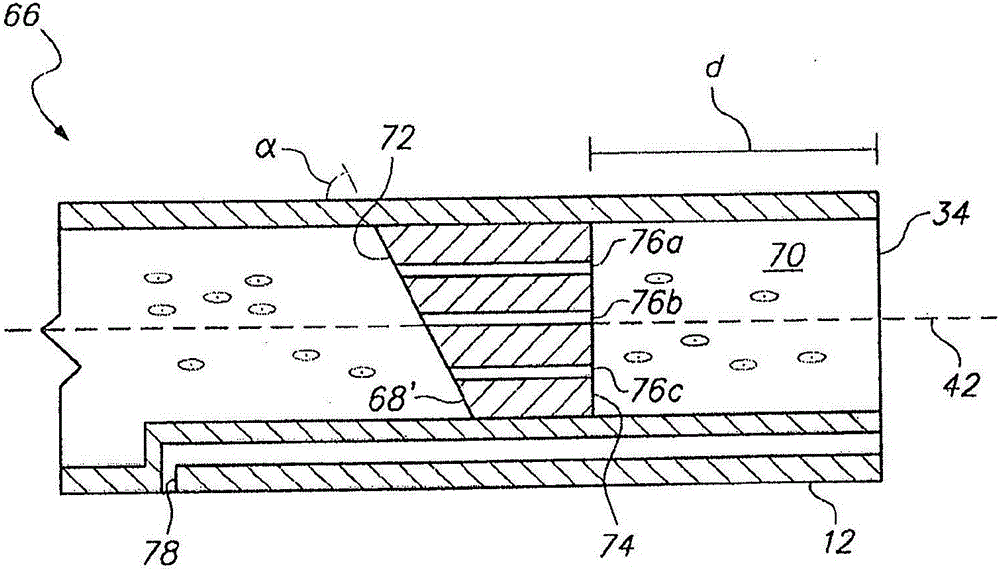

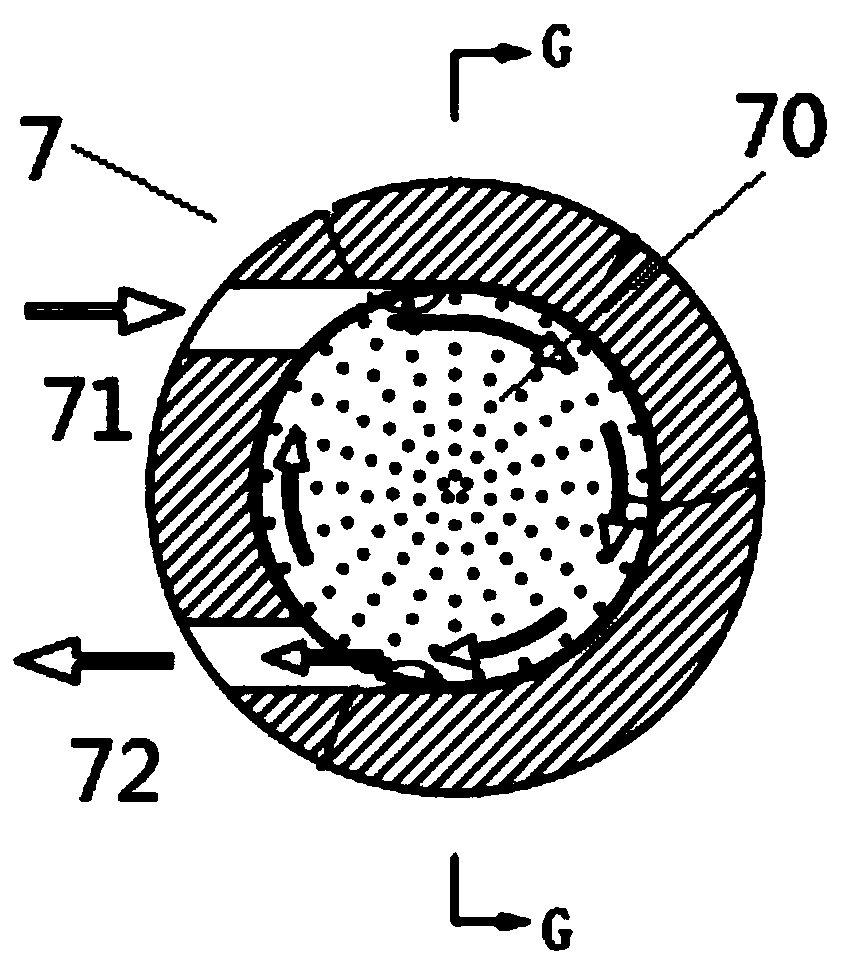

A spiral heat exchanger

InactiveCN1375051ARoughly unimpeded flowUnimpeded flowStationary plate conduit assembliesMechanical engineeringMechanics

The invention relates to a spiral heat exchanger including at least two spiral sheets (1, 2) extending along a respective spiral-shaped path about a common center axis (x) and forming at least two spiral-shaped, substantially parallel flow channels (4, 5). Each flow channel (4, 5) permits a heat exchange fluid to flow in a substantially tangential direction with respect to the center axis (x). Each flow channel includes a radially outer orifice, which forms an outlet or an inlet of the respective flow channel and which is located at a radially outer part of the respective flow channel and a radially inner orifice, which enables communication between the respective flow channel and a respective inlet / outlet chamber (13, 14). The center axis (x) extends through the inlet / outlet chamber of the radially inner orifice. The spiral heat exchanger includes a center body (3) extending around the center axis (x) and being closed with respect to the flow channels (4, 5).

Owner:ALFA LAVAL CORP AB

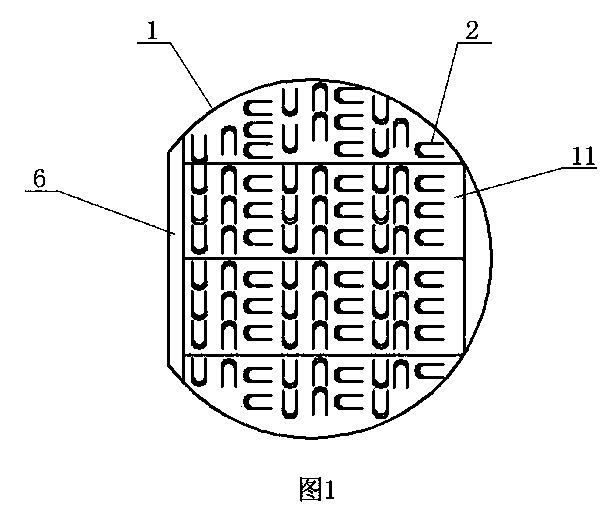

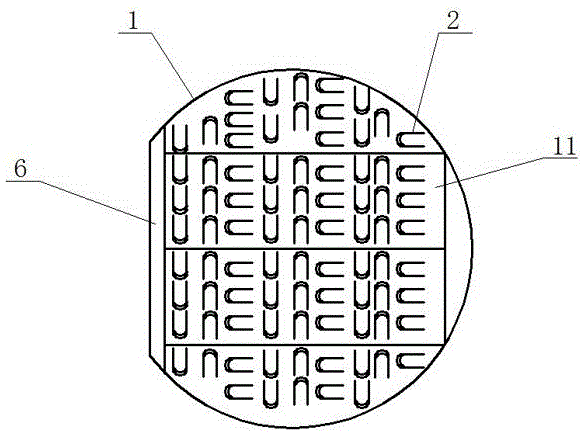

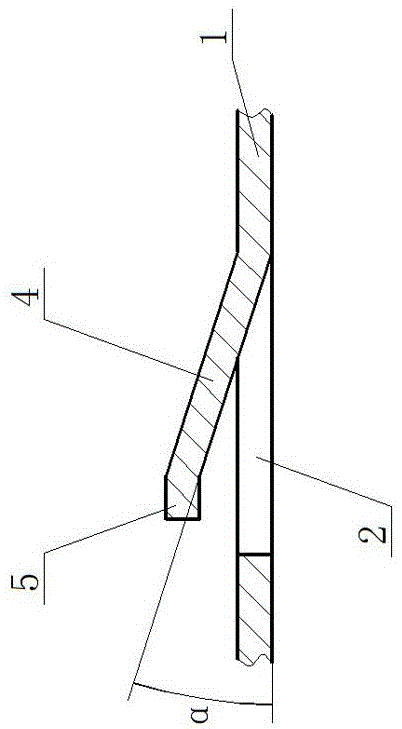

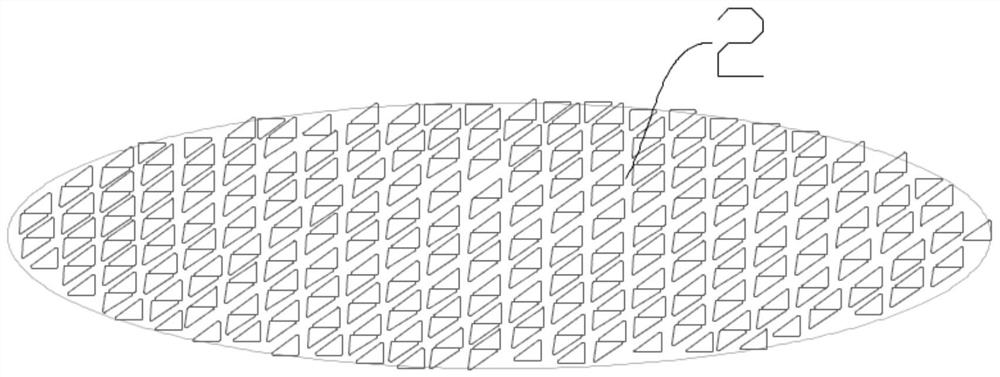

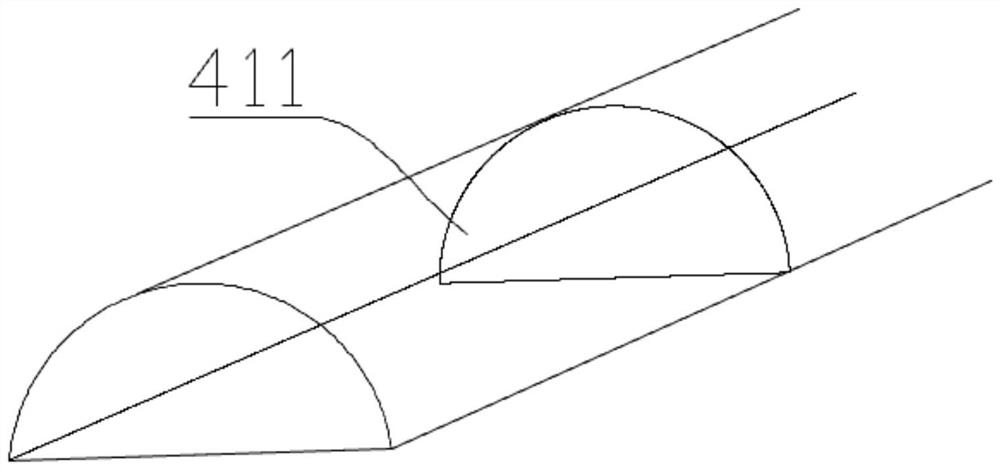

Inclined hole tray for distillation

ActiveCN103816692AImprove contact efficiencyShorten the timeDistillation separationGas phaseDistillation

The invention provides an inclined hole tray for distillation. The inclined hole tray comprises a liquid holding plate, wherein an overflow weir is arranged on the liquid holding plate; a plurality of tongue holes are formed in the liquid holding plate; a tongue plate is respectively arranged on one side of each tongue hole; the tongue plate on one side of each tongue hole comprises an inclined tongue plate and a horizontal tongue plate; one end of each inclined tongue plate is connected with the liquid holding plate; the other side of each inclined tongue plate is connected with each horizontal tongue plate; each horizontal tongue plate is in parallel with the liquid holding plate; the included angle alpha of each inclined tongue plate and the liquid holding plate is 15 to 30 degrees; the tongue holes are formed in the liquid holding plate in rows, each row is in parallel with the length direction of the overflow weir respectively; the row number of the tongue holes in the liquid holding plate is an integral multiple of 3. The inclined hole tray can effectively improve the contact efficiency of gas phase and liquid phase, reduces the time when the gas phase and the liquid phase are balanced, and enables the airflow resistance to keep in a relatively lower level.

Owner:JIGANG INT ENG & TECH CO LTD

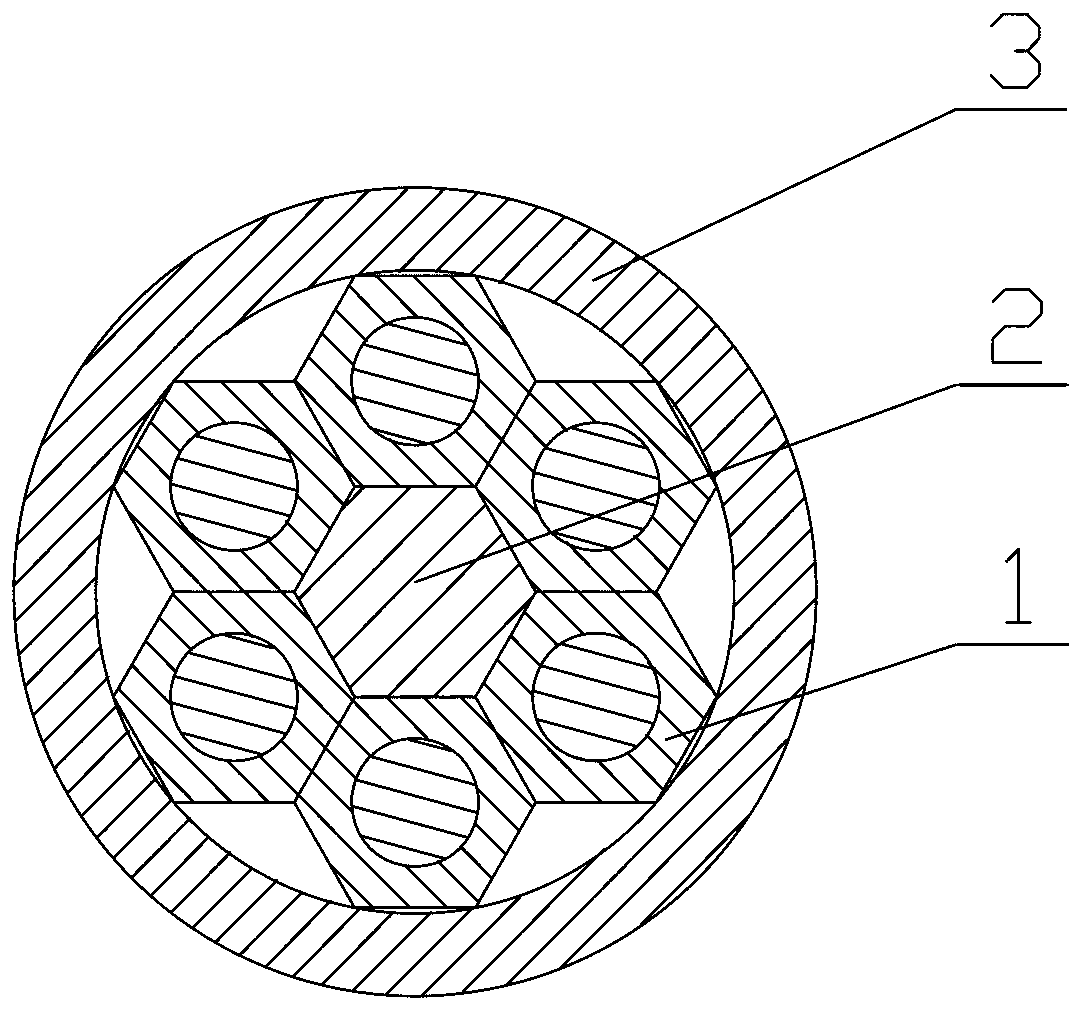

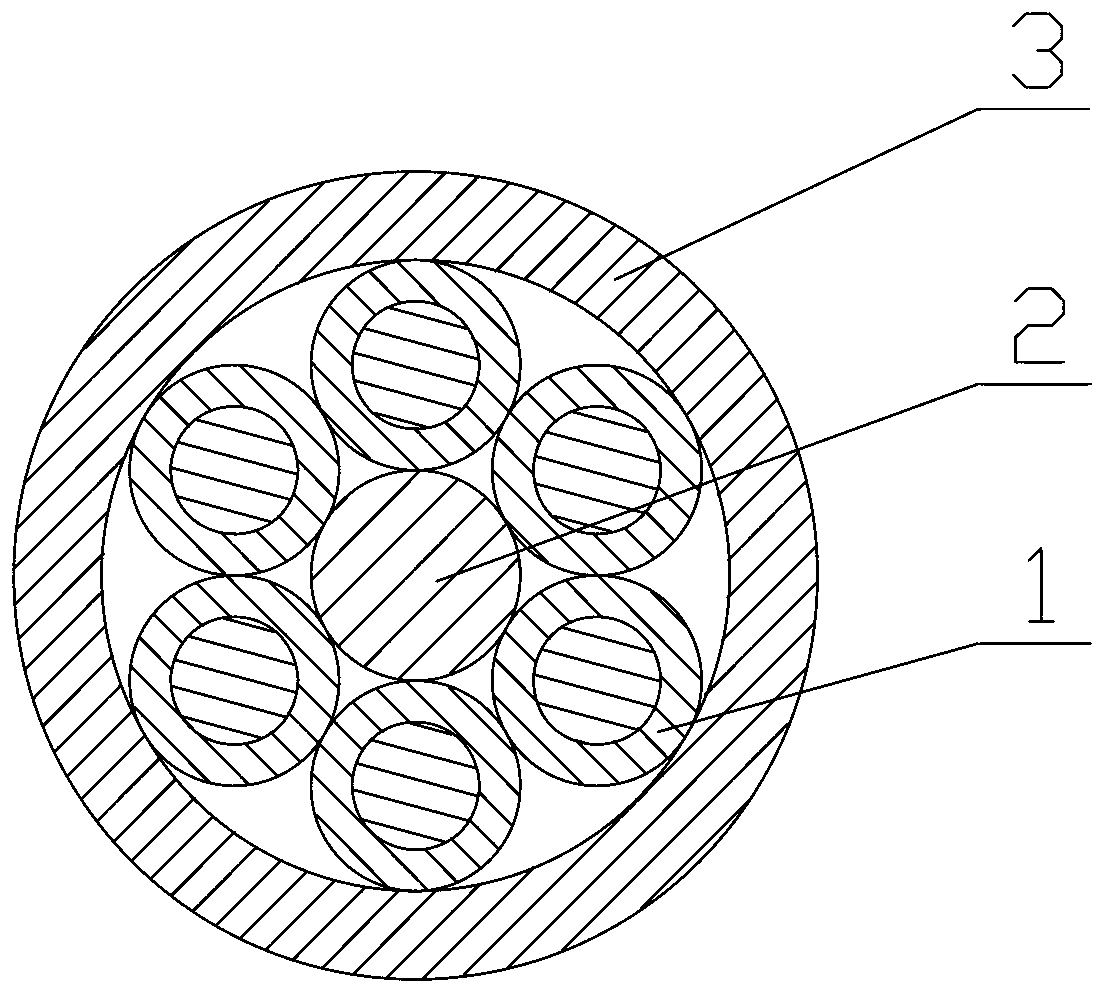

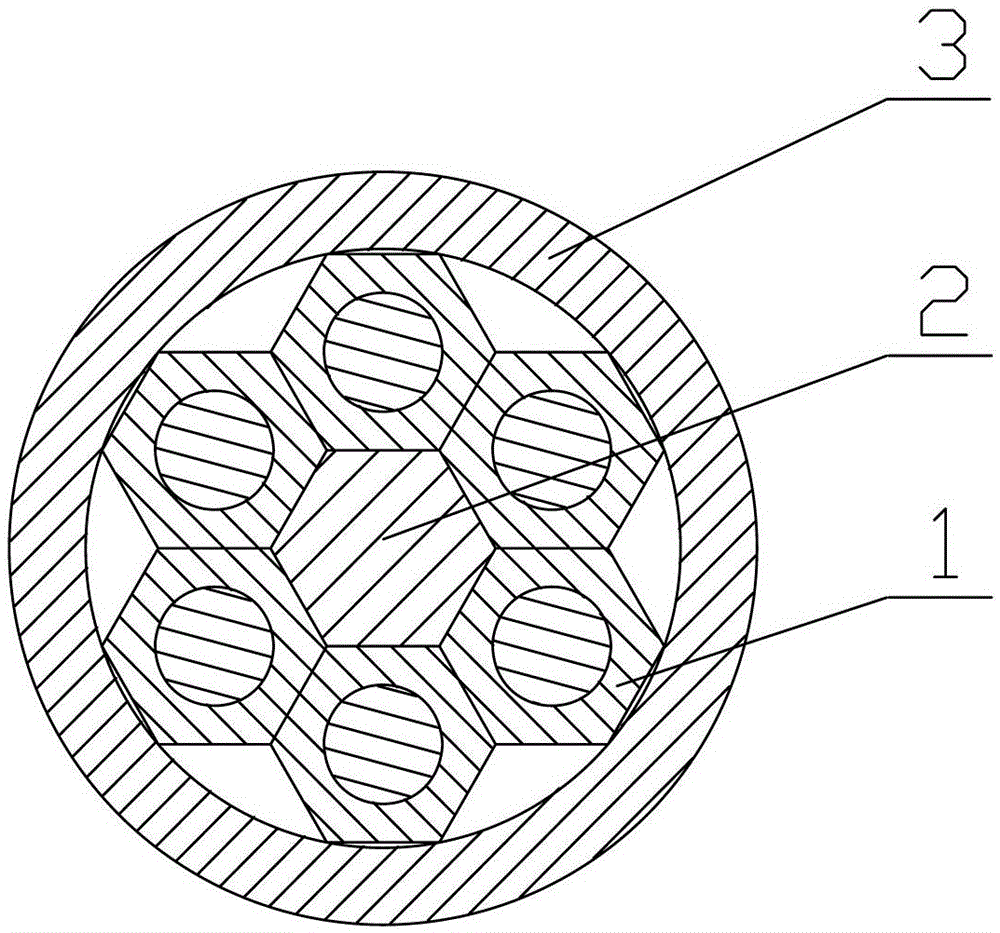

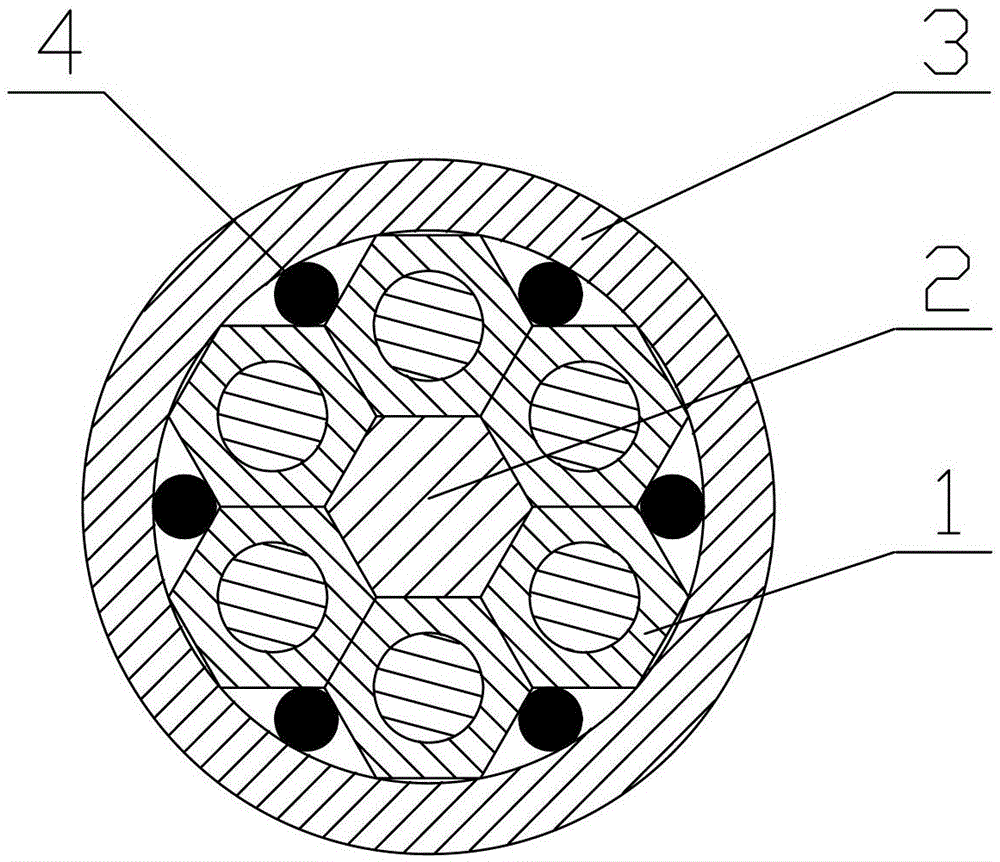

High-strength MgB2 wire manufacturing method

ActiveCN103310914APlasticGuaranteed plasticityCable/conductor manufacturePhase formationArgon atmosphere

The invention discloses a high-strength MgB2 wire manufacturing method. The method includes: 1, manufacturing primary composite wires; 2 assembling secondary composite tubes; 3, drawing the secondary composite tubes for three times at 20%-25% pass processing rate, and then drawing at 10%-15% pass processing rate to obtain wires with required dimensions; 4, performing phase-formation heat treatment on the wires under the protection of argon atmosphere to obtain high-strength MgB2 wires with strength between 220MPa-280MPa. According to the method, CuAg alloy bars are used as reinforcement cores, manufactured multi-core super-conducting wires are transformed evenly, and inner parts are combined tightly, so that the manufactured multi-core super-conducting wires have good plasticity. According to the method, flow of powder in the drawing process is smooth. The method is particularly suitable for processing of MgB two-kilometer long wires and can meet requirements for practical application of super-conducting magnets, especially super-conducting nuclear magnetic resonance spectrometer and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Steam dish washing machine with effective positioning and orientation of items to be washed

ActiveUS7909046B2Maximize the effectEffective positioningTableware washing/rinsing machine detailsCleaning using liquidsPulp and paper industryHigh intensity

Dish washing machine that includes a steam generator, which supplies steam during a washing operation, to aid in the washing of dishes and other items in the dish washing machine. The dish washing machine further including one or more dish washing racks that effectively orient the dishes, and other items to be washed, in such a way so as to avoid inhibiting the steam from being evenly distributed around each of the dishes and other items to be washed. The dish washing machine also including a steam zone indicator to aid in effectively positioning the dishes and other items to be washed by visually distinguishing the region or zone within the dish washing machine that corresponds with high-intensity steam.

Owner:LG ELECTRONICS INC

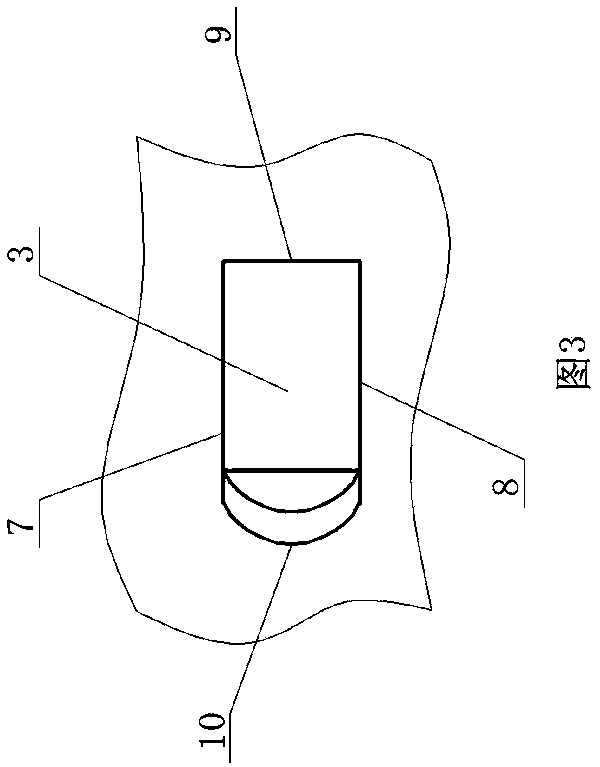

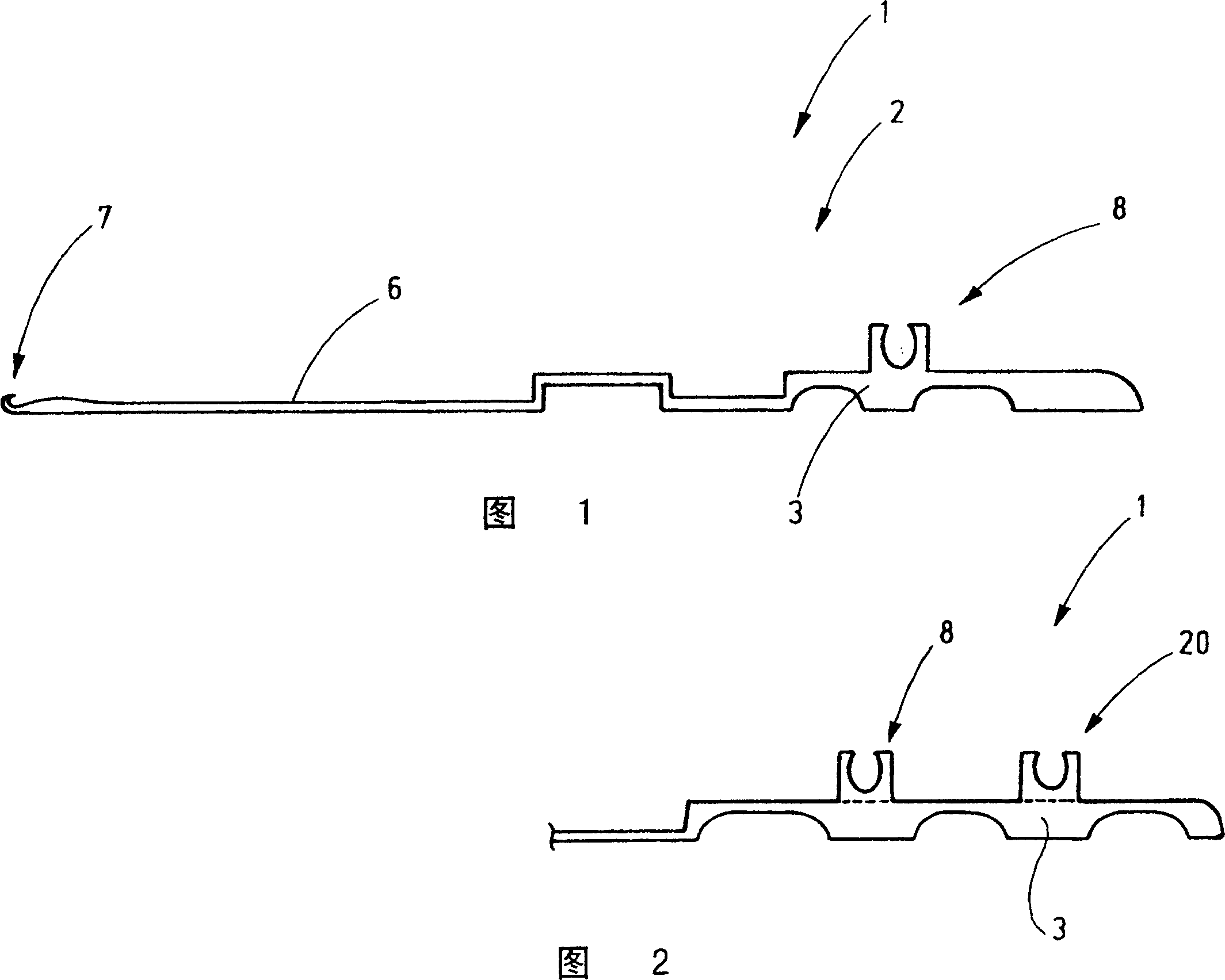

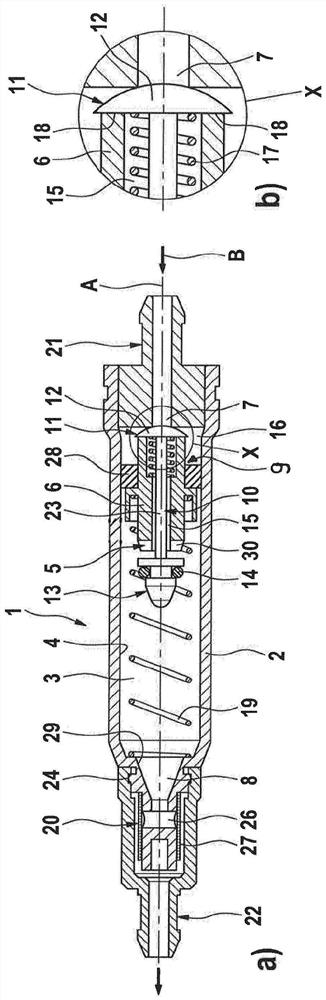

System component for a knitting system, and handling process

ActiveCN101012596AEasy accessUnimpeded flowWeft knittingWarp knittingUnit operationBiomedical engineering

A system component ( 1 ), such as, for example a knitting machine needle ( 2 ), intended for a loop-forming machine has in its foot ( 8 ) at least one cutout ( 14 ) that is set up to accommodate a section of a holder ( 17 ). This holder can be clipped into the cutout in order to hold several such system components in a pre-specified sequence and at a lateral distance and in alignment with respect to each other. The systems components, which are thus temporarily connected to each other, can be handled as a unit and, in this manner, can be removed from the bed ( 5 ), can be treated, for example be cleaned, and can be replaced in the same sequence and alignment in the bed ( 5 ).

Owner:GROZ BECKERT KG

Full immersed type self circular loop of evaporative cooling stator of steam turbine generator

InactiveCN1191668CUnimpeded flowAdequate infiltrationCooling/ventillation arrangementHydrogenNuclear engineering

The cooling circulation loop includes the cooling circulation sub-loop in the slot part of the stator core, the sub-loop between the sections of the iron core and the sub-loop between the pressing rings at the end parts of the stator core and the tooth pressure plates. The liquid cooling medium with high insulation and low boiling point of good physical and chemical properties is injected into the cavity of the stator. Each sub-loop is connected to the cavity of the stator. The cooling liquid absorbs the heat so as to be boiled and gasified, flowing in the circulation loop freely getting earth part of the stator cooled. The said cooling circulation loop possesses the advantages of the water, hydrogen and air-cooling and prevents the insulatiom damage and explosion caused by the leakage of water and hdyrogen.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

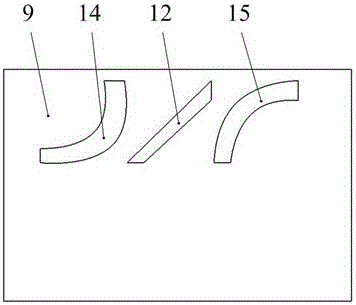

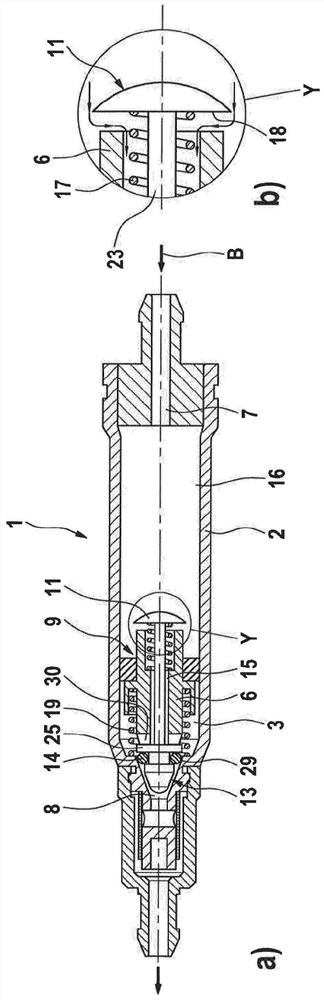

Plunger type oil spraying pump achieving variable oil supply under multiple working conditions

InactiveCN105697206AEffective travel is convenient and precisely controlledImproved Linear RegulationMachines/enginesFuel injecting pumpsLow speedDrive shaft

The invention provides a plunger type oil spraying pump achieving variable oil supply under multiple working conditions. The plunger type oil spraying pump mainly comprises a plunger and barrel assembly, an oil adjusting device composed of a rack, a gear and a rotating shaft, a driving selecting device composed of a driving frame, a top plate and a top plate stirring rod, an auxiliary driving device composed of a guide plate, a wheel frame and a wheel, and a double-speed-cam driving device composed of a driving shaft, a low-speed cam and a high-speed cam. The plunger type oil spraying pump achieving variable oil supply under the multiple working conditions is characterized in that variable oil supply under the multiple working conditions is achieved through three kinds of chutes, the high-speed cam and the low-speed cam. Multi-working condition adjustment on the effective stroke of a plunger is achieved through the three kinds of chutes in the side face of the plunger, in other words, fine adjustment and buffered oil spraying are achieved through the double-curve type chute, convenient linear adjustment and accurate control are achieved through the linear chute, and rapid emergency adjustment is achieved through the fast-opened chute. Positioning of the three kinds of chutes is achieved through a magnetic block at the position of a notch of the gear and a magnetic strip on a plunger sleeve. The oil pumping frequency is adjusted through the high-speed cam and the low-speed cam on the driving shaft, and variable oil supplying under the multiple working conditions is achieved.

Owner:UNIV OF JINAN

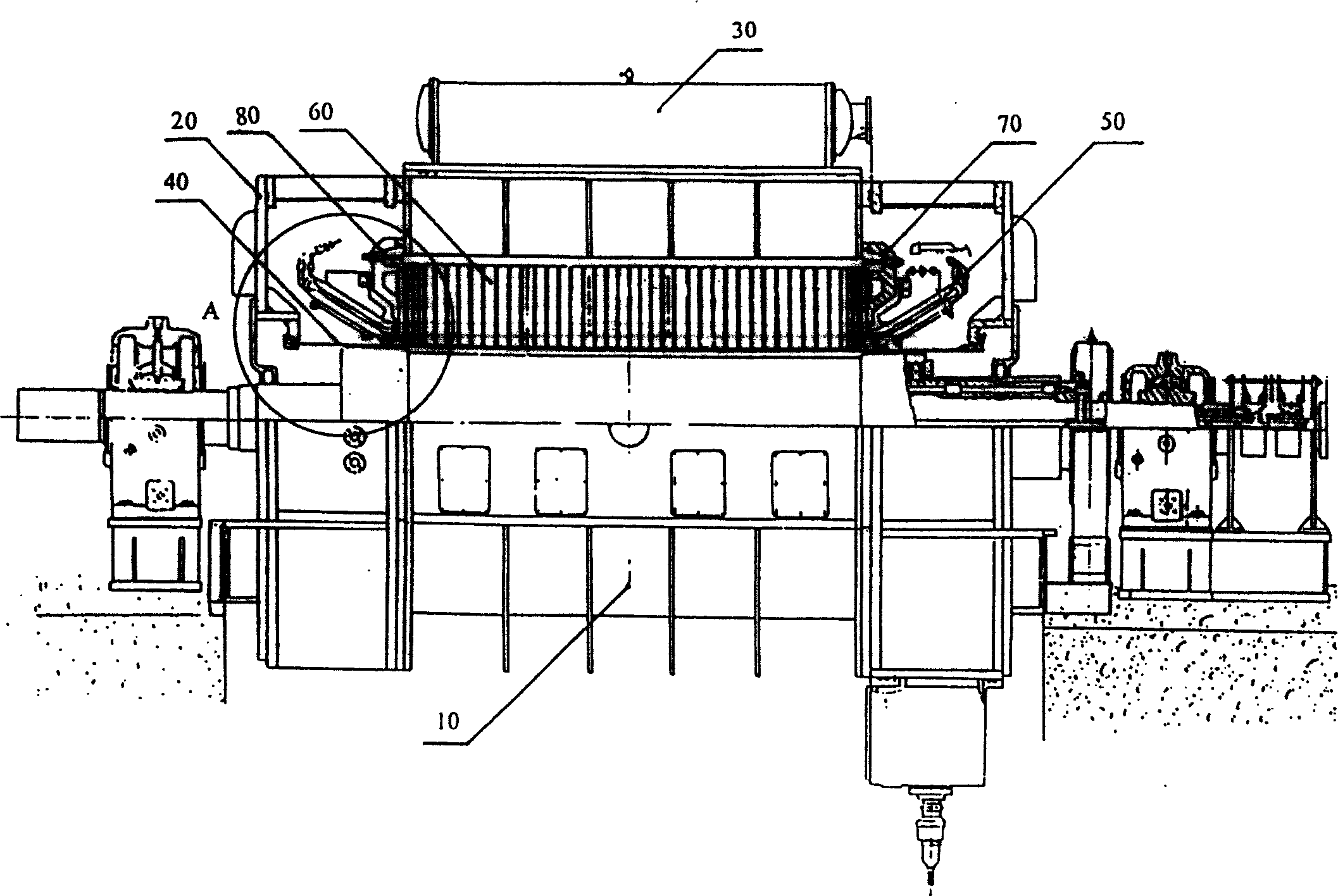

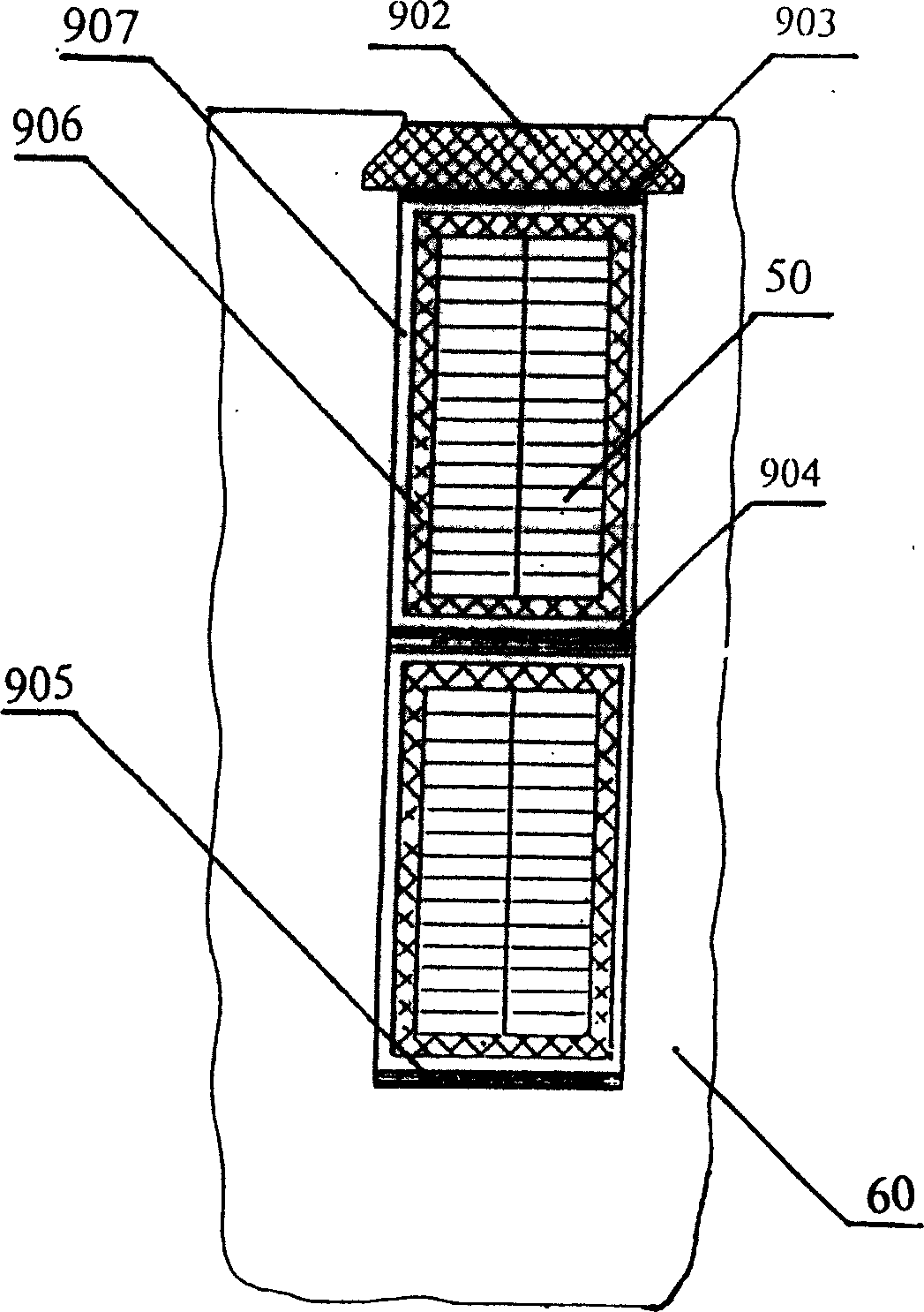

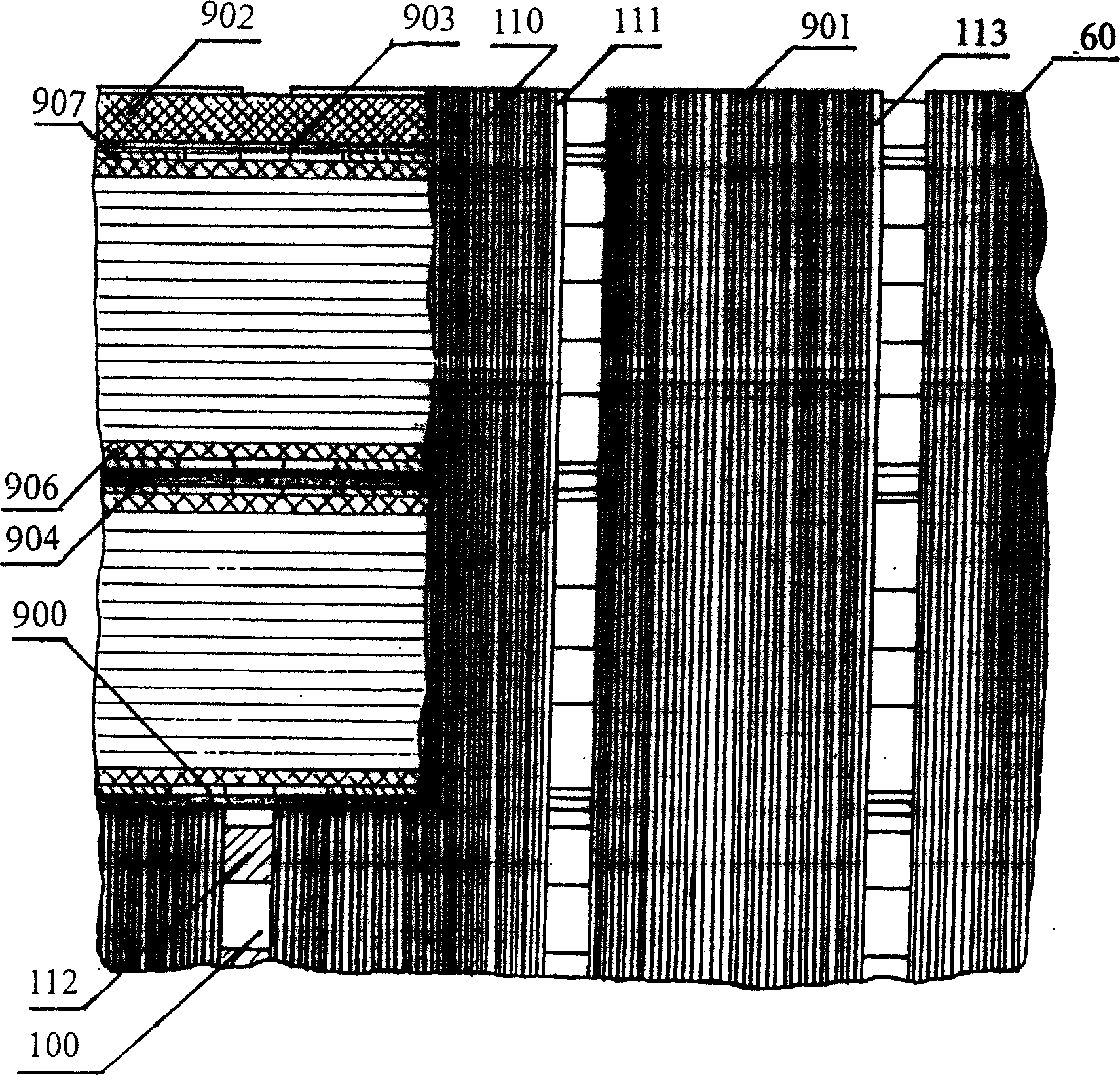

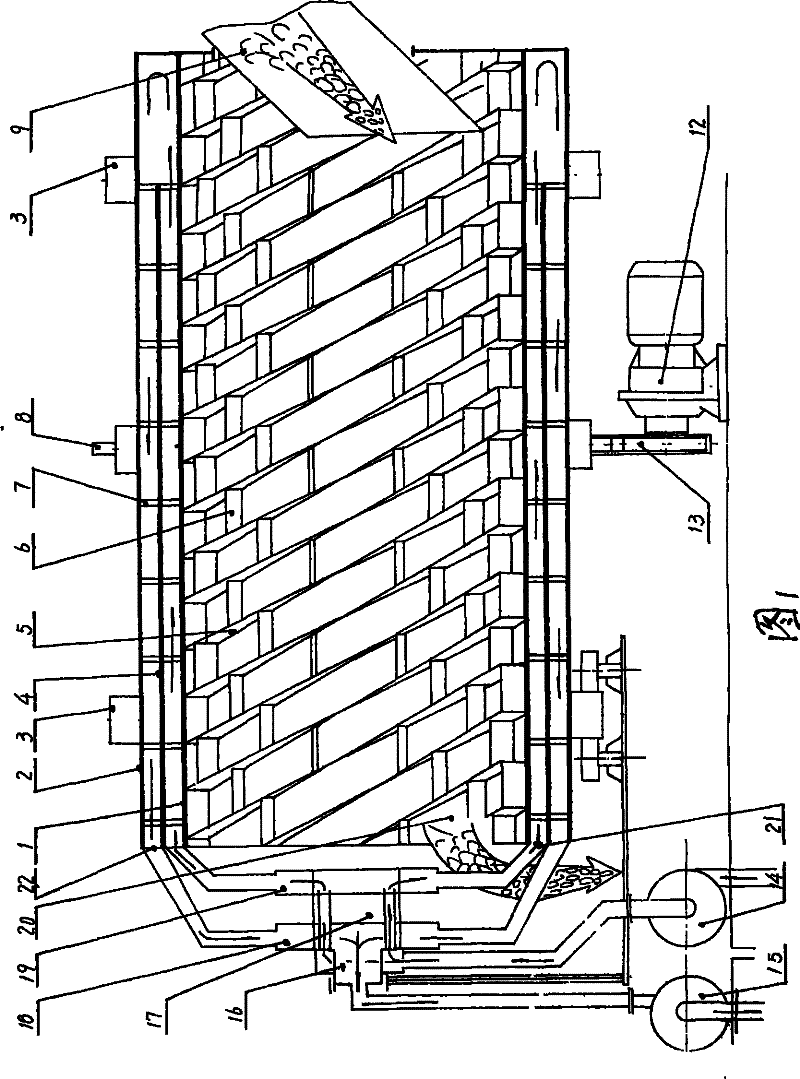

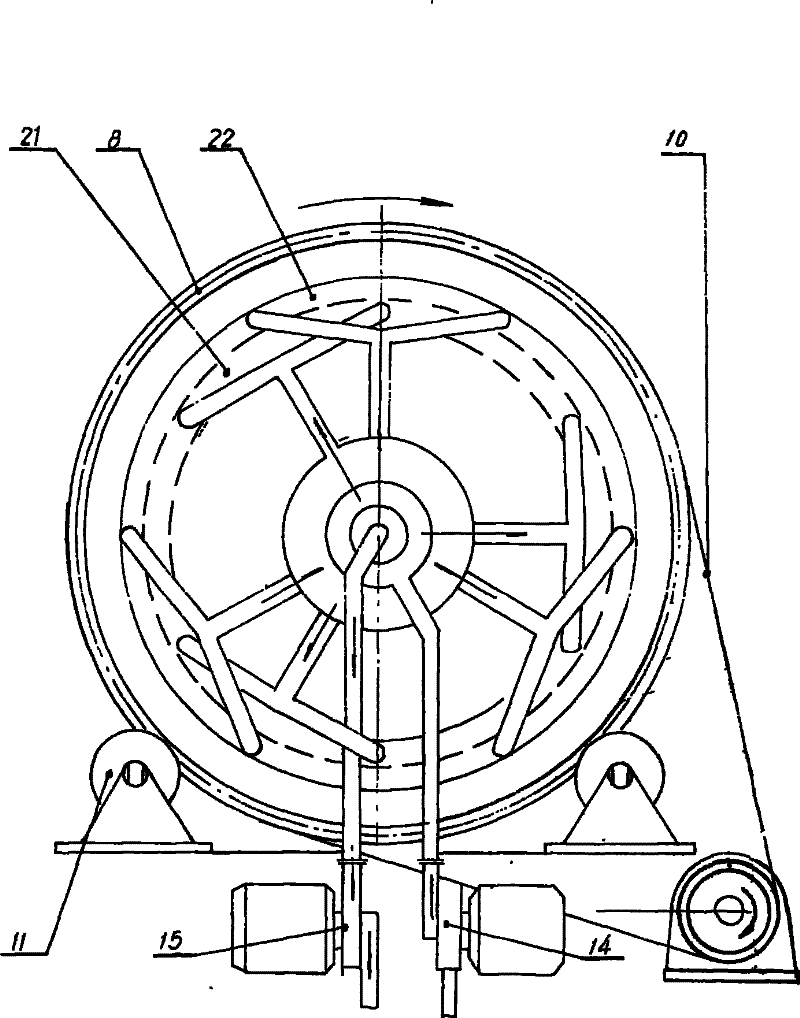

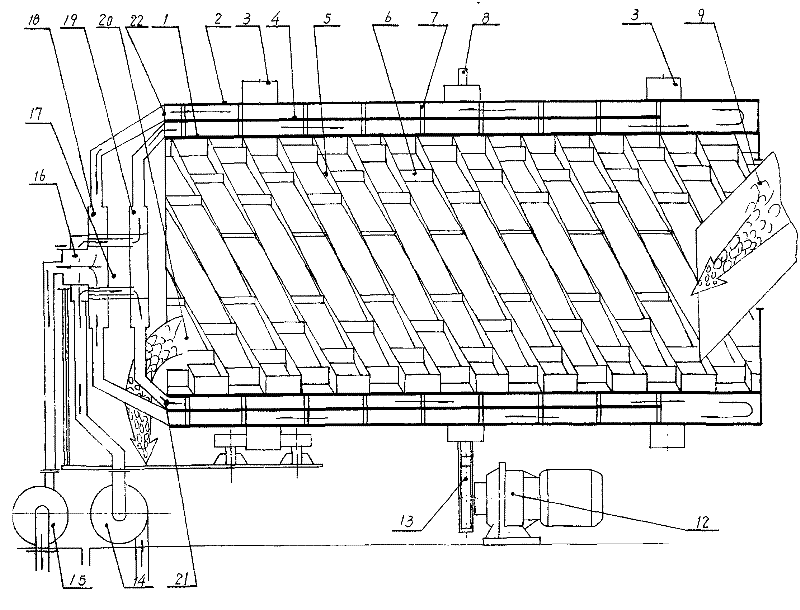

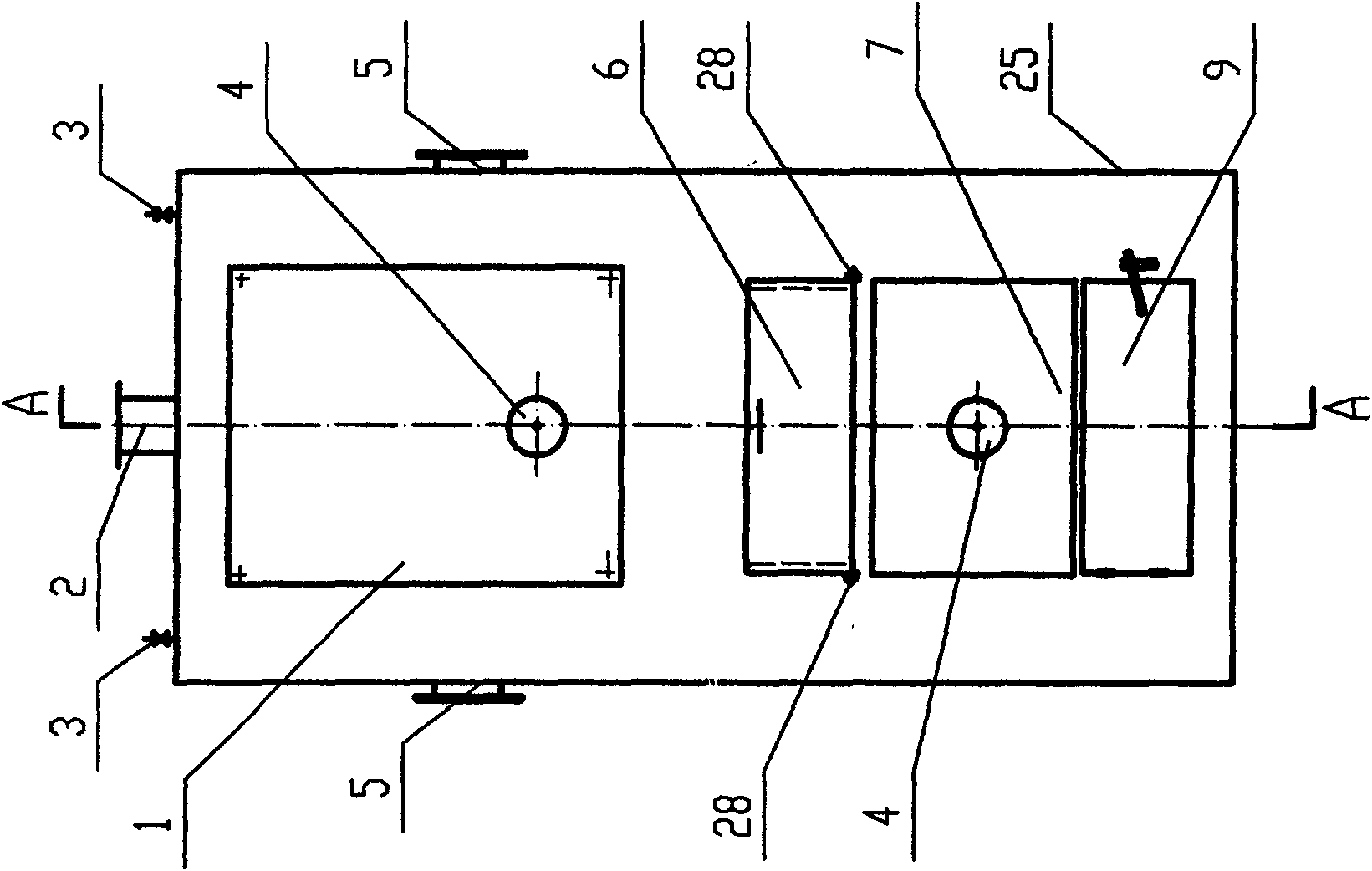

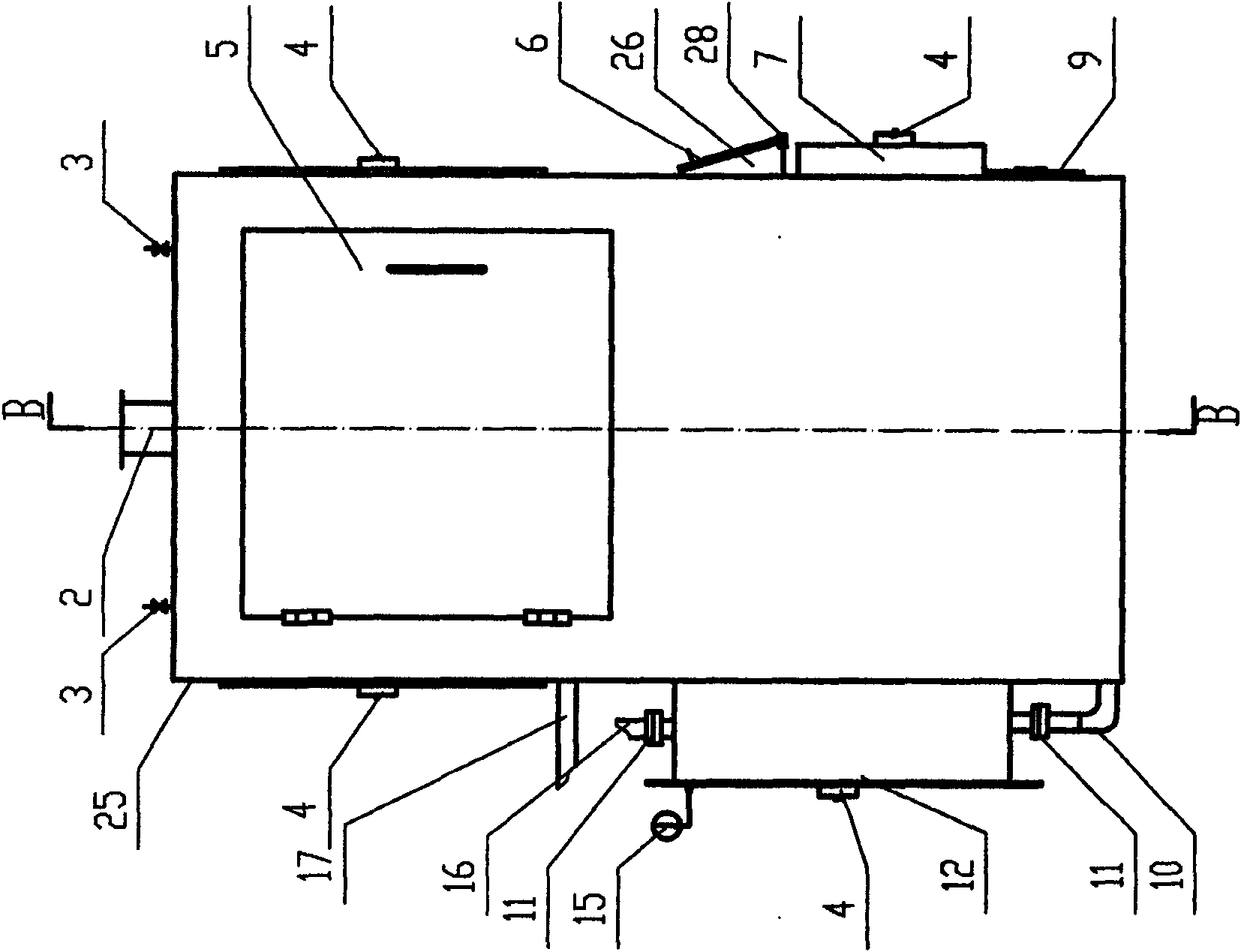

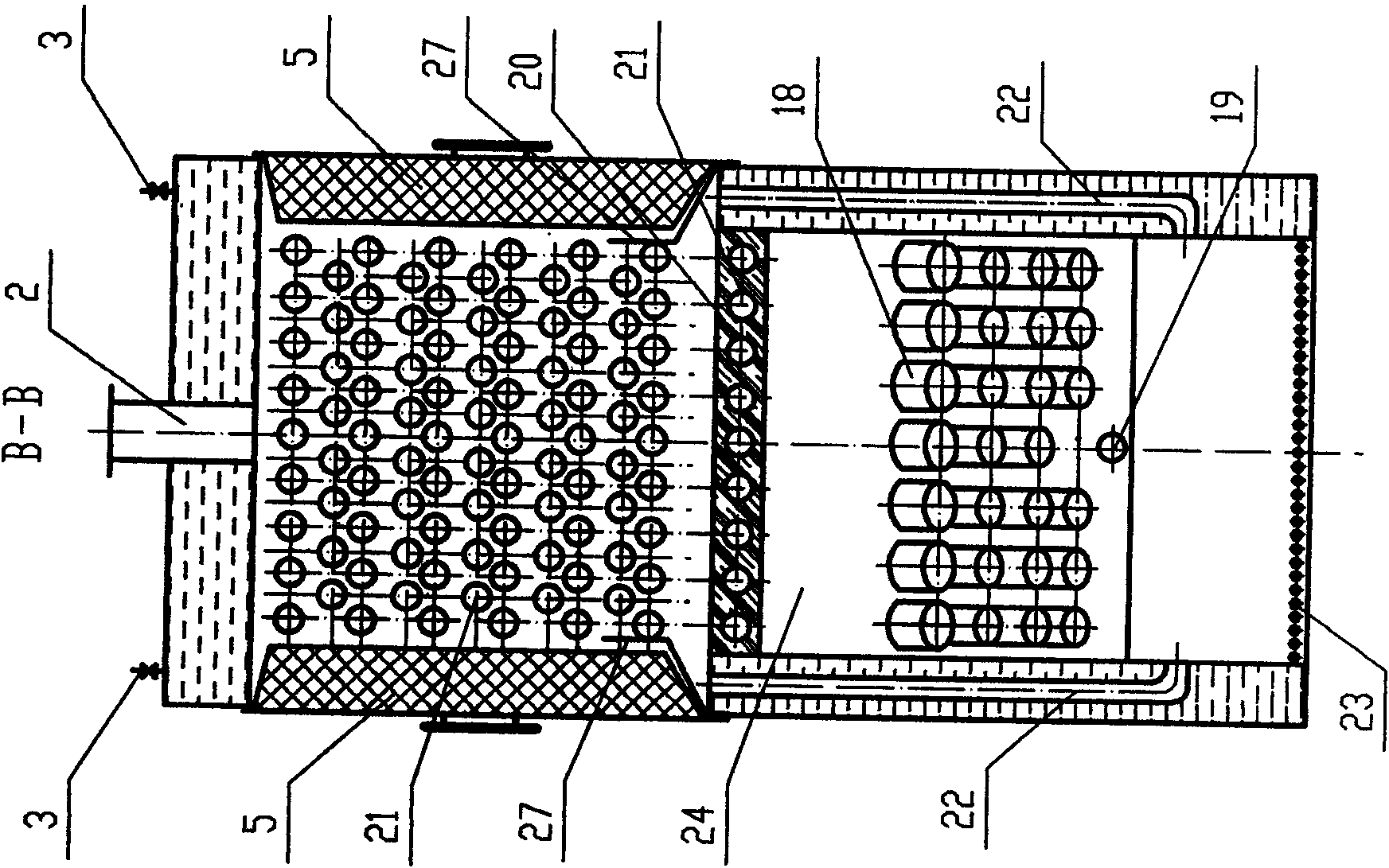

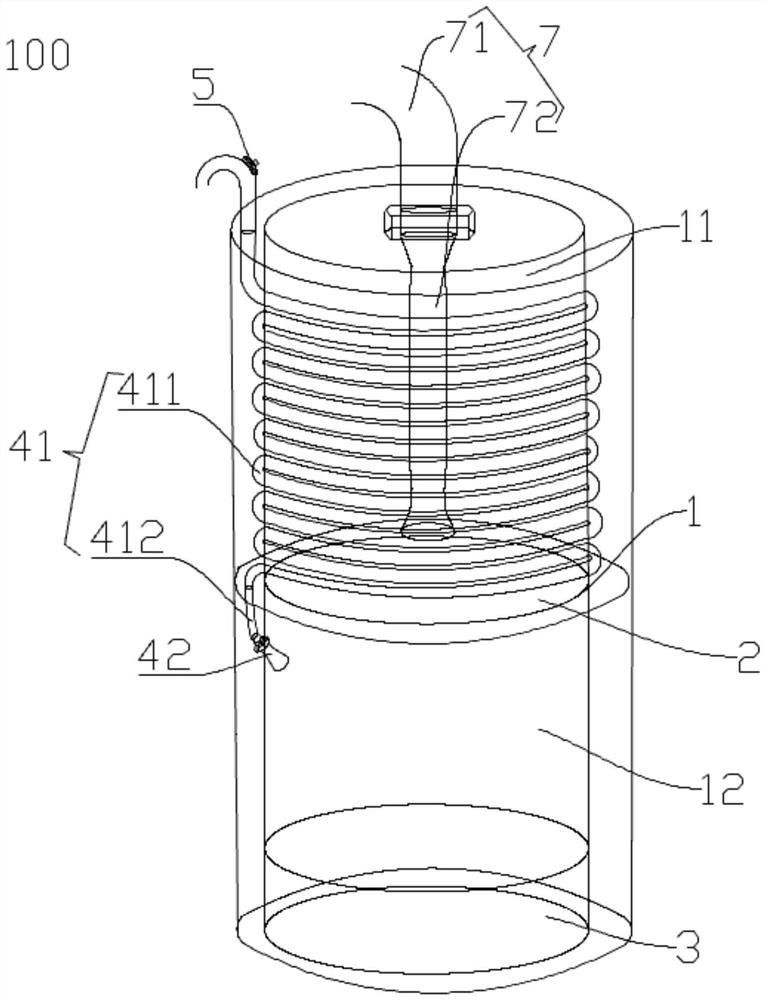

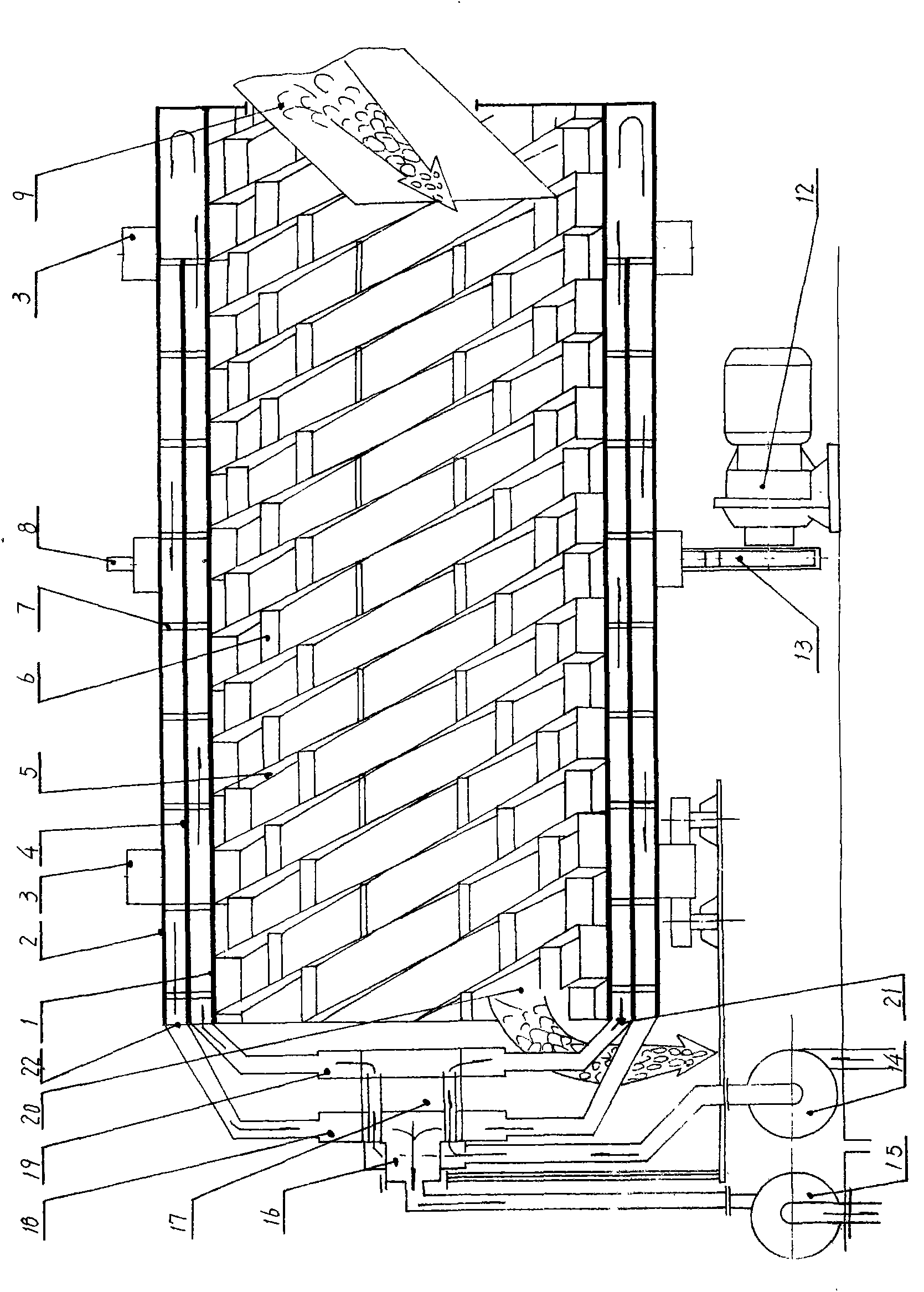

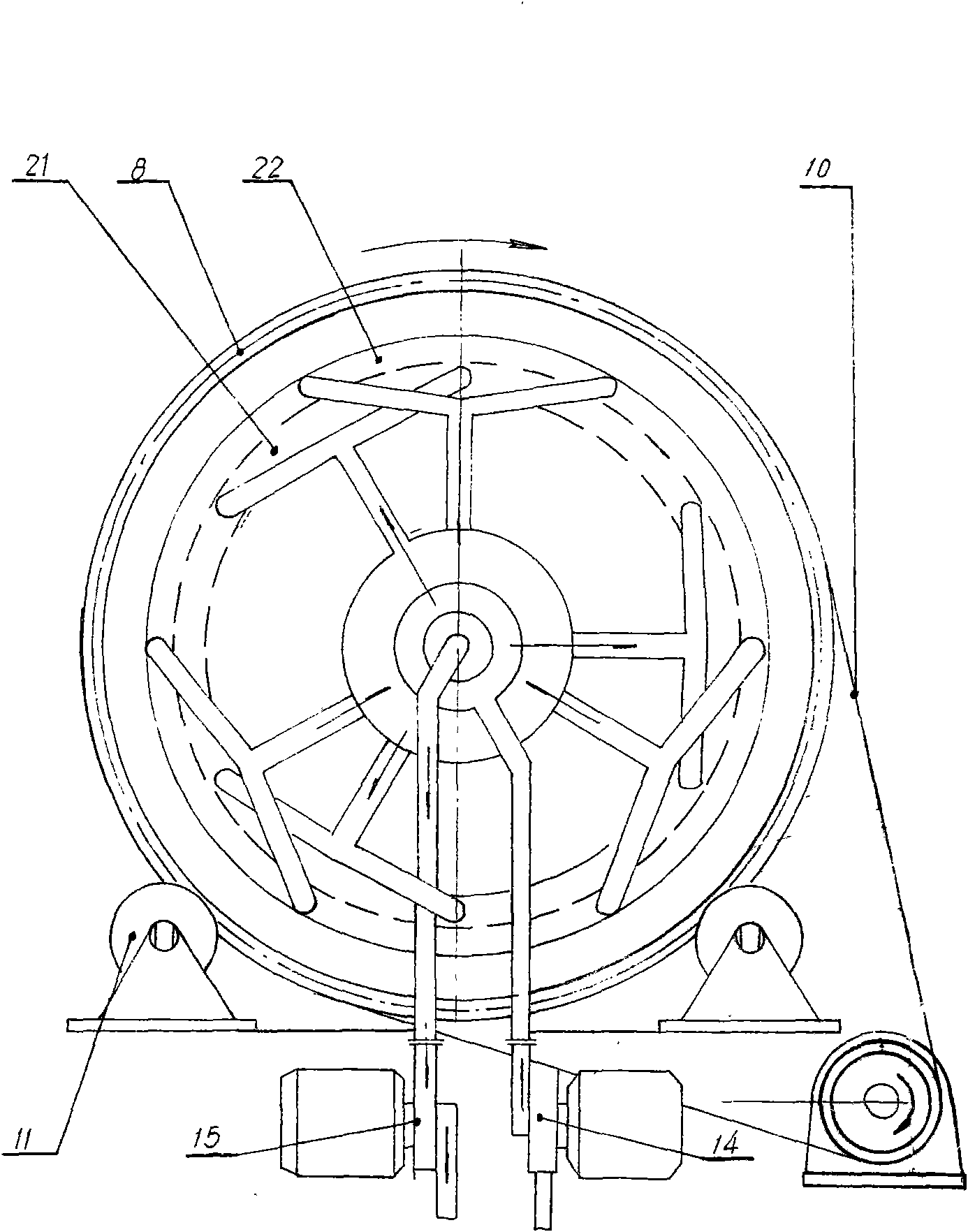

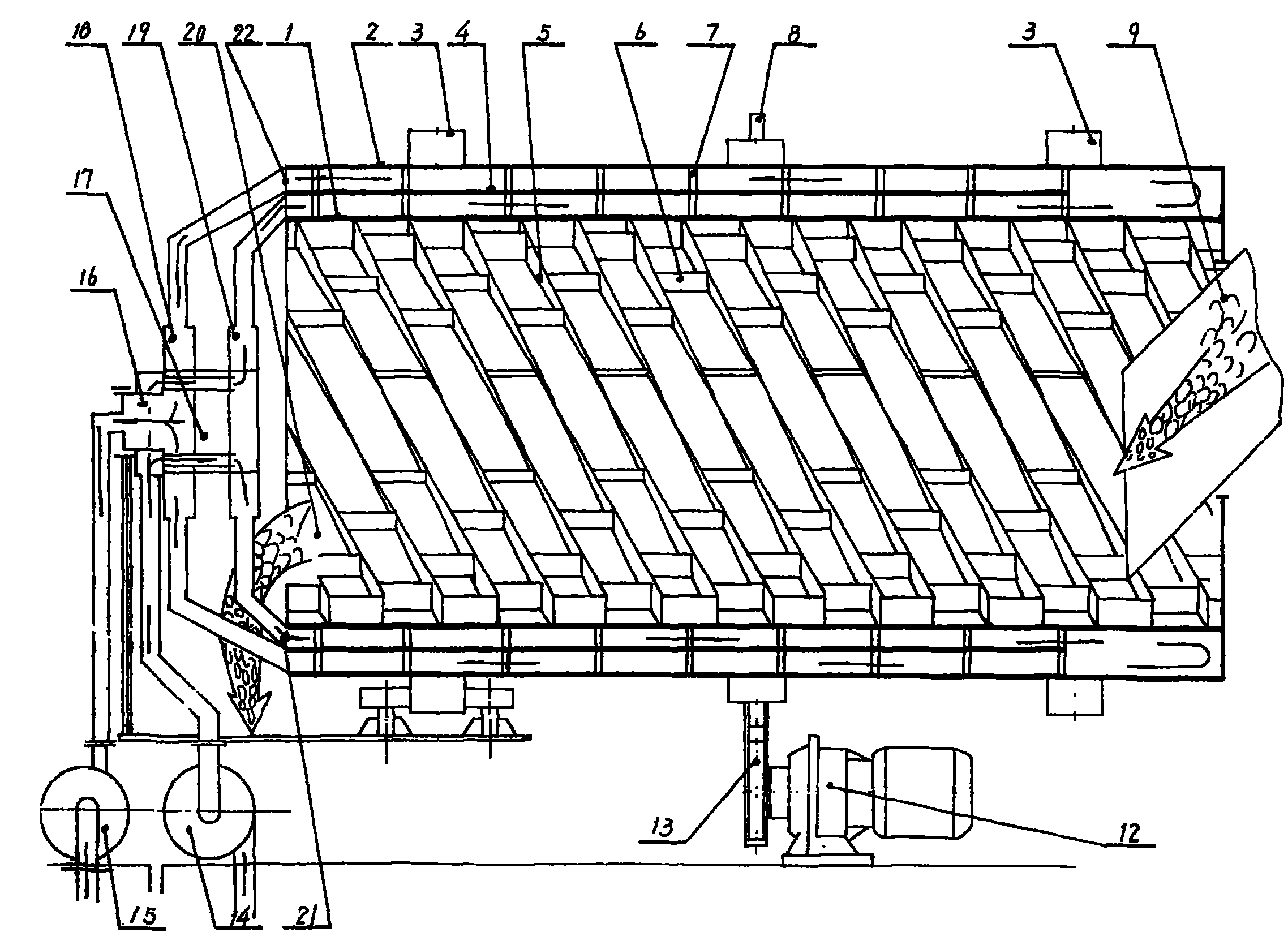

Slag cooler

ActiveCN101876446BBig spaceUnimpeded flowFluidized bed combustionApparatus for fluidised bed combustionPower stationSlag

The invention relates to a slag cooler for cooling slag of a circulating fluidized bed boiler of a power plant, mainly designed to solve the problems of poor cooling effect and easy burnout of the traditional slag cooler. The slag cooler comprises an inner cylinder wall, an outer cylinder wall, a cooling water interlayer, a slag guide sheet, a slag inlet, a slag outlet end, a track, a track supporting wheel, a large sprocket, a water inlet pump and a water pumping pump, wherein a partition wall is arranged between the inner cylinder wall and the outer cylinder wall, a small support upright column is respectively arranged between the partition wall and the inner cylinder wall as well as between the partition wall and the outer cylinder wall, an inner sealing head and an outer sealing head are also arranged between the partition wall and the inner cylinder wall as well as between the partition wall and the outer cylinder wall, a pipeline is arranged on the water inlet pump and is connected with an inner ring of a water separator, the inner ring is provided with a water outlet and is connected with an outer ring in a sliding and sealing mode, a water outlet pipe is arranged on the outer ring and is connected with the inner sealing head, a pipeline is arranged on the water pumping pump and is connected with an inner ring of a water collector, a water inlet is arranged on the innerring of the water collector, the external of the inner ring of the water collector is connected with the outer ring of the water collector in the sliding and sealing mode, and a water inlet pipe is arranged on the outer ring and is connected with the outer sealing head. The invention has the advantages of good cooling effect and long service life.

Owner:LIAONING BEIFANG ELECTRIC MACHINERY COMPLETE EQUIP

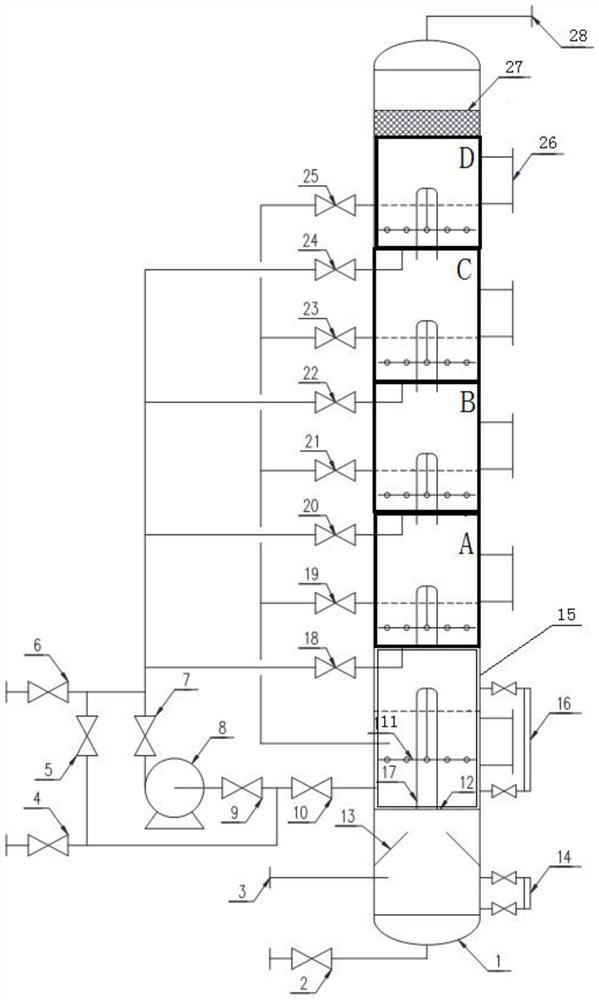

Sulfur-containing gas emptying and desulfurizing device

PendingCN111921341AImprove desulfurization effectUnimpeded flowDispersed particle separationThermodynamicsOil field

The invention is applicable to the technical field of chemical equipment, and provides a sulfur-containing gas emptying and desulfurizing device, which comprises a separator for removing liquid dropsentrained in emptying gas, a storage device for containing a desulfurizing agent and a plurality of desulfurizing areas for desulfurizing the emptying gas, which are sequentially arranged from bottomto top, and gas distributors are arranged in the storage device and the desulfurizing areas. Therefore, hydrogen sulfide in the emptying gas can be fully absorbed, the desulfurization effect of the emptying gas is improved, and the quality of the surrounding environment of an oil field is improved; the whole device is of a skid-mounted structure, the equipment manufacturing cost is low, emptying gas flows smoothly in the device, the safety is high, the desulfurizing agent is recycled, and the production cost is reduced.

Owner:BEIJING SHIDA ORIENTAL ENG DESIGN

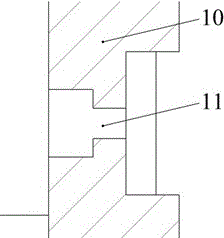

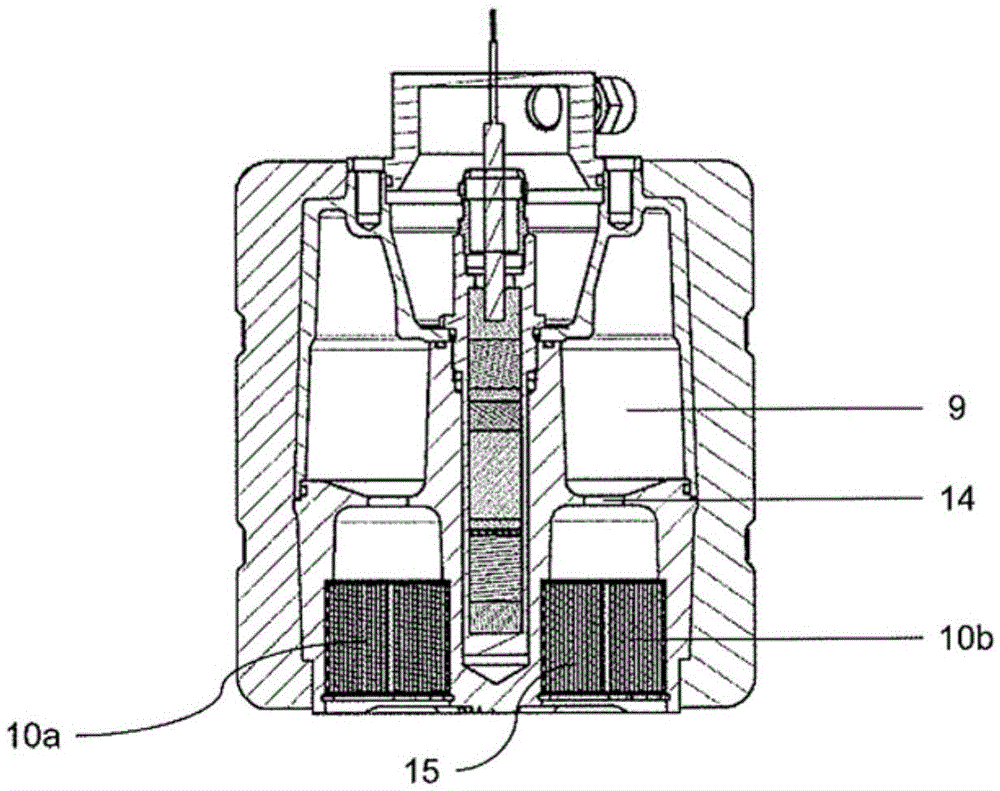

Device for the volume-controlled portioning of cleaning fluid

ActiveCN112351840AEasy to driveReliable driveSpraying apparatusVolume meteringThermodynamicsMechanical engineering

The invention relates to a device (1) for the volume-controlled portioning of cleaning fluid, comprising a housing (2) and a piston unit (9) slidingly arranged in the housing (2), which displaces a cleaning fluid out of a chamber (3) into an out-flow channel (8). In order to provide an improved generic device, which permits an exact portioning at a reduced temperature dependency and in a quick-as-possible cleaning sequence, according to the invention, the piston unit (9) comprises a piston body (6) and at least one valve unit (5) which is arranged on the piston body (6) and guarantees a filling of the chamber (3) with the cleaning fluid in the return movement of the piston unit (9).

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

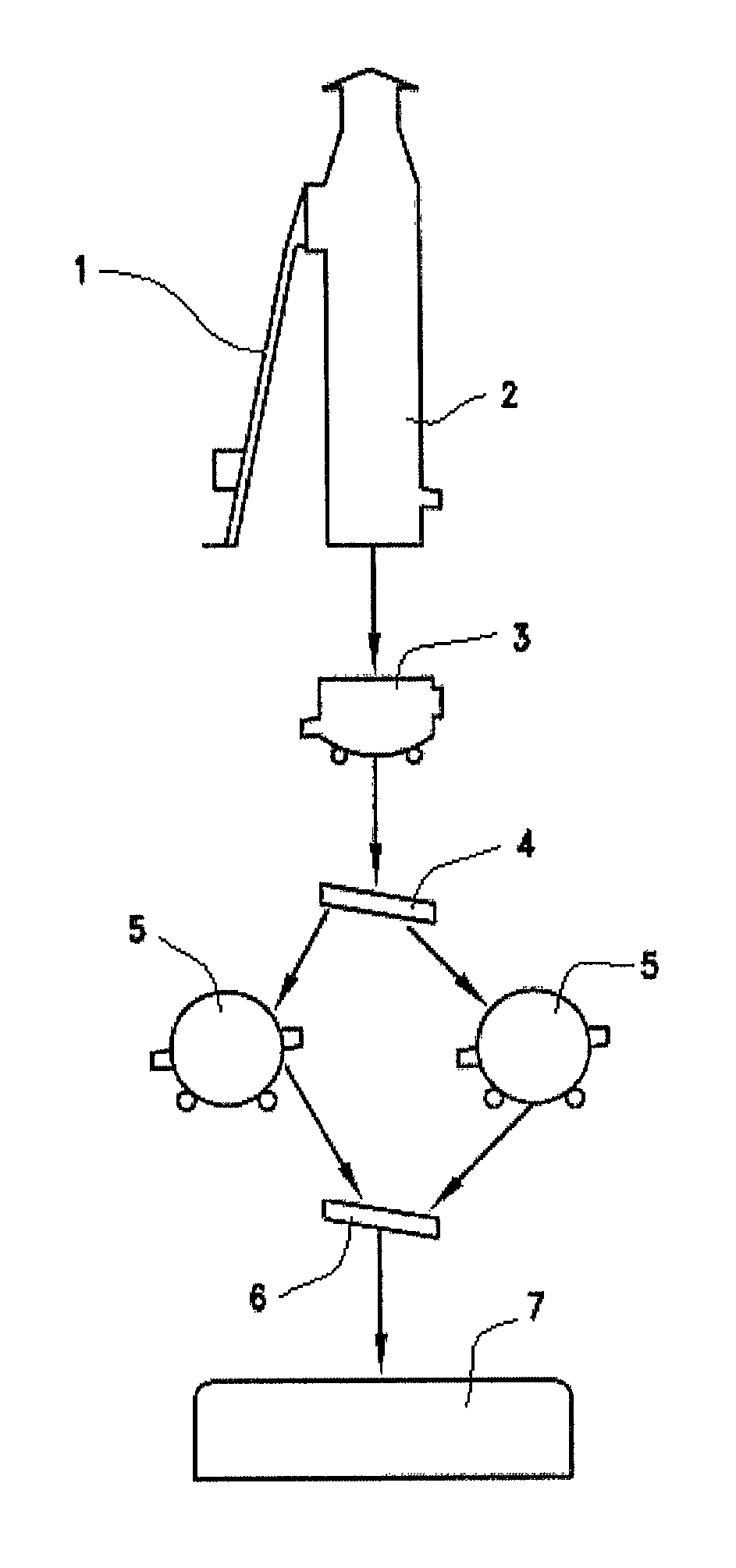

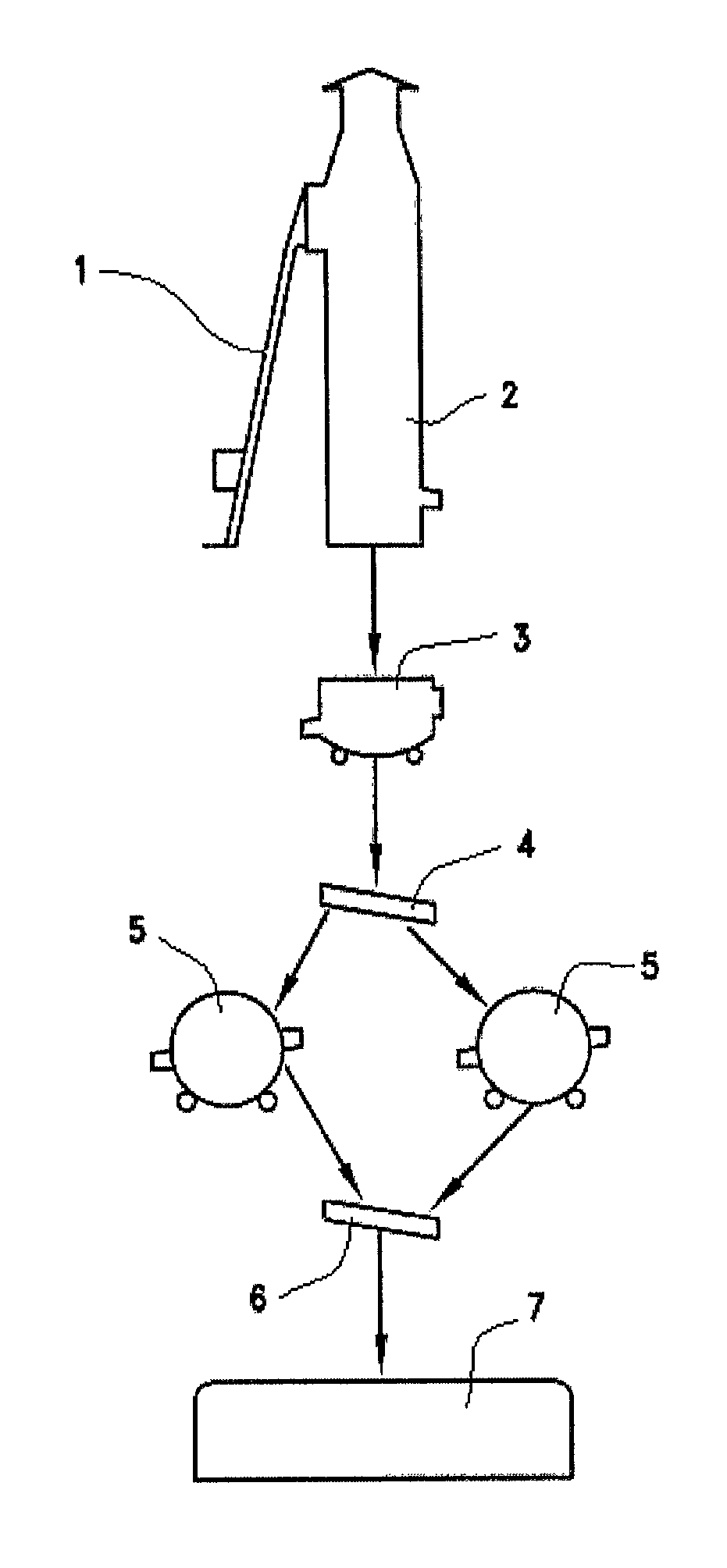

Combined furnace system for fire refining red impure copper

InactiveUS9464845B2Easy to removeImprove production efficiencyCharge manipulationFurnace typesSlagCopper

A combined furnace system for fire refining red impure copper, comprising in order: a shaft furnace (2) for smelting red impure copper raw material into red impure copper liquid; a red impure copper liquid groove (4); at least one rotary furnace (5) for refining and producing refined copper liquid by means of oxidation reduction; a refined copper liquid groove (6). The combined furnace system is characterized in that the system comprises a tilting furnace (3) between the shaft furnace (2) and the red impure copper liquid groove (4) for removing slag from red impure copper liquid having slag. The invention thereby provides a combined furnace system that easily removes slag, has a smooth, unobstructed red impure copper liquid groove, and smelts and refines with stable production efficiency.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

Ingredient distributing element

InactiveCN101501460BPermanent connectionUnimpeded flowClosuresVolume measurement and fluid deliveryAdditive ingredientMechanical engineering

Owner:METTLER TOLEDO INC

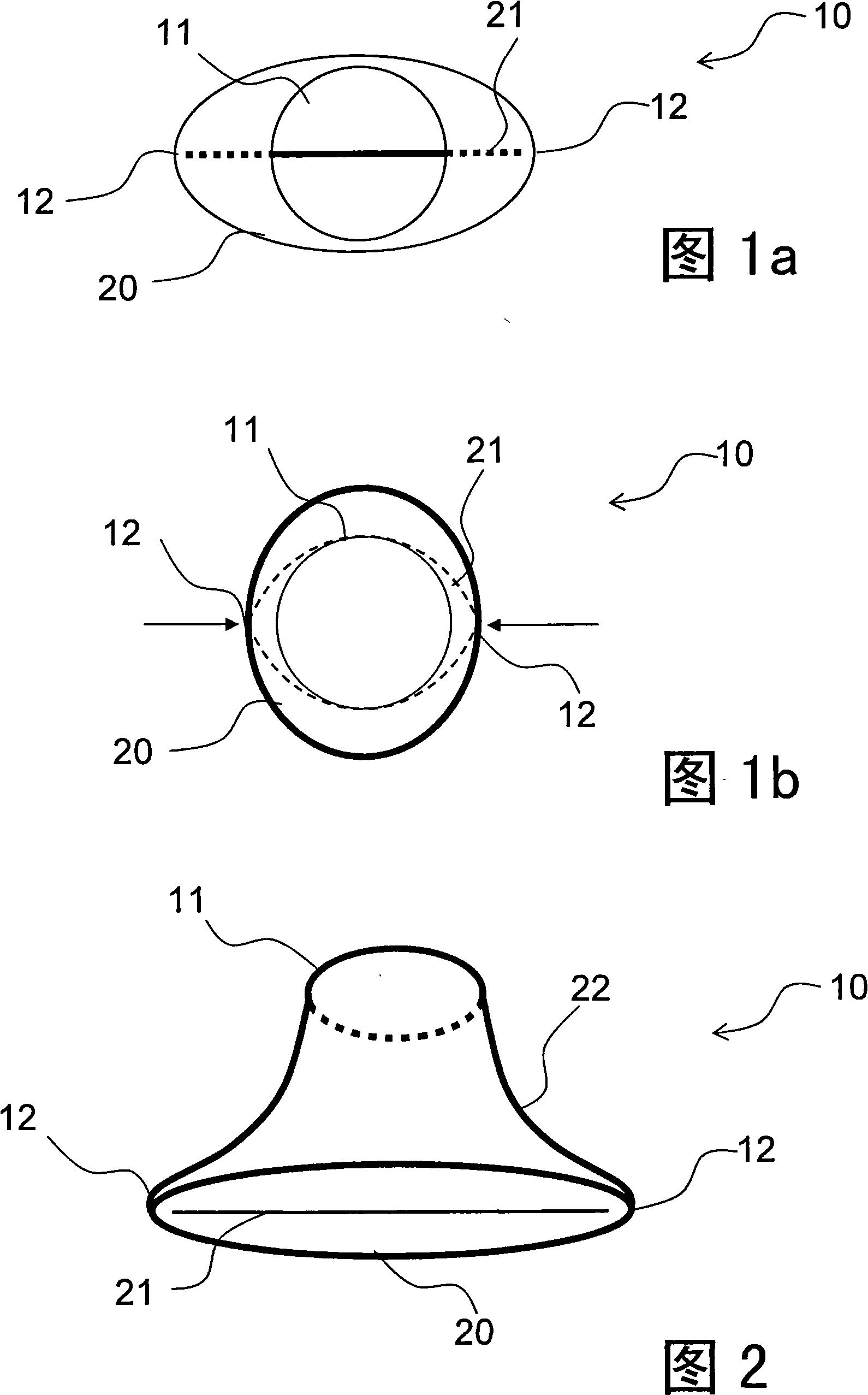

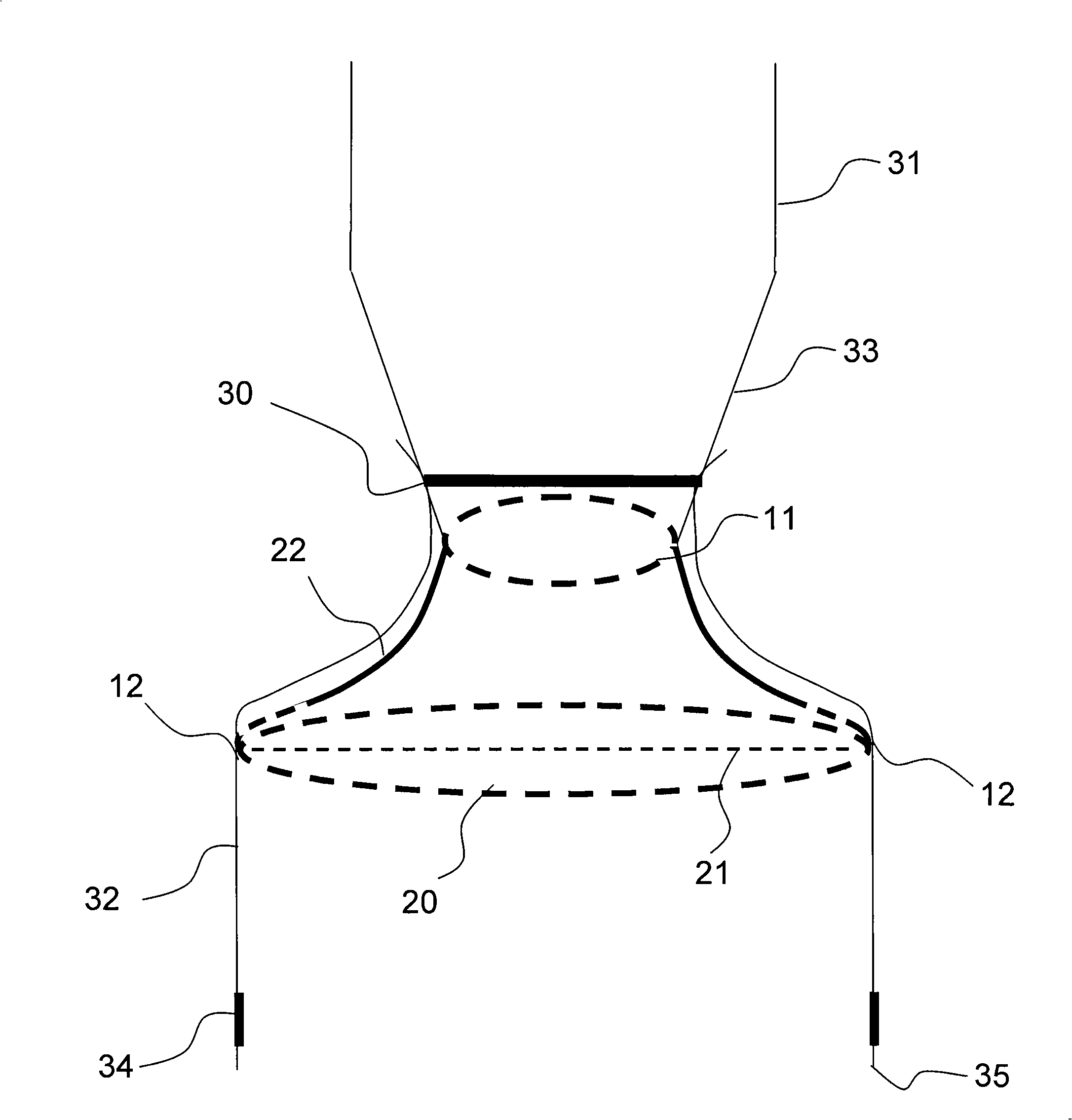

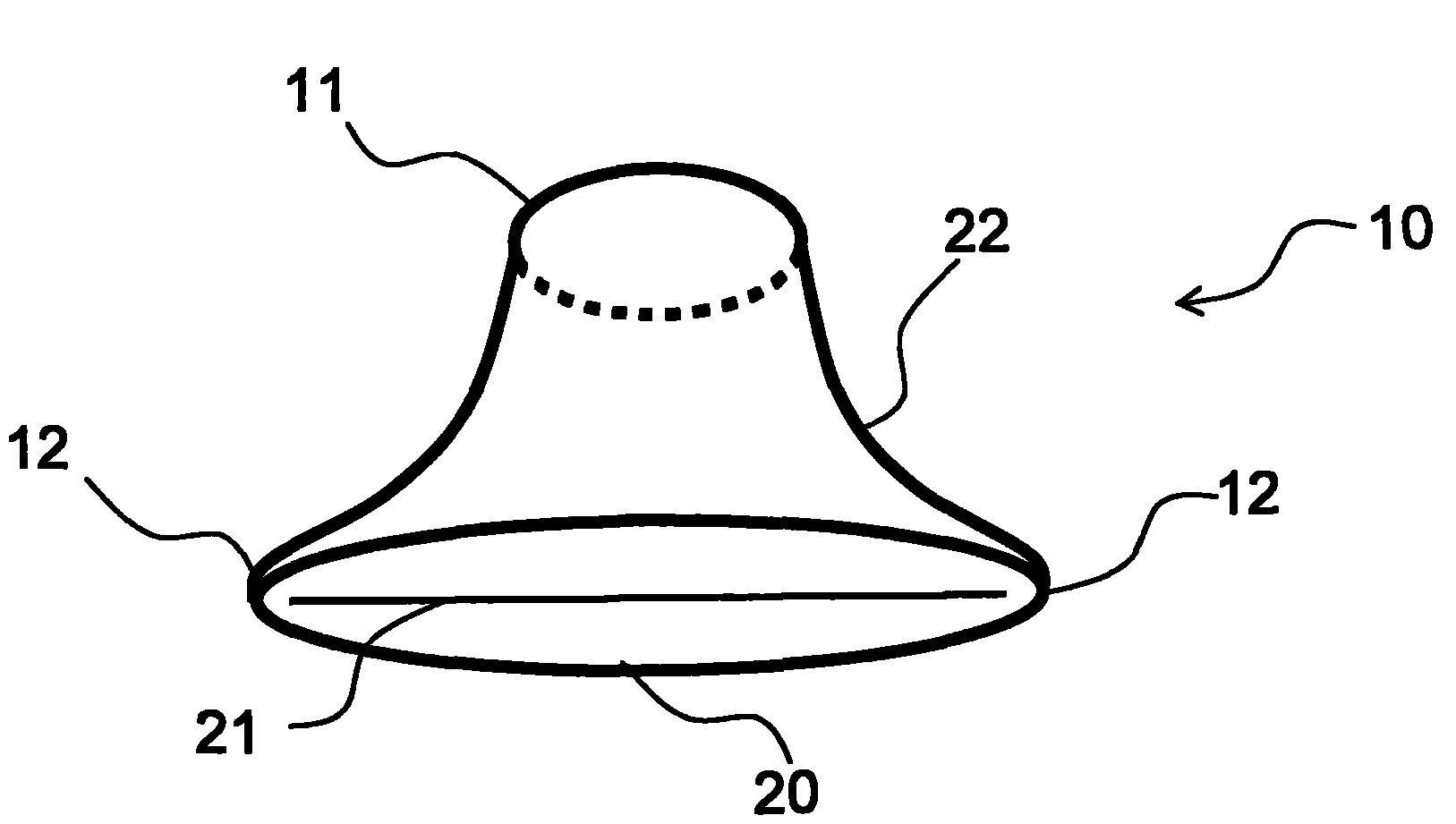

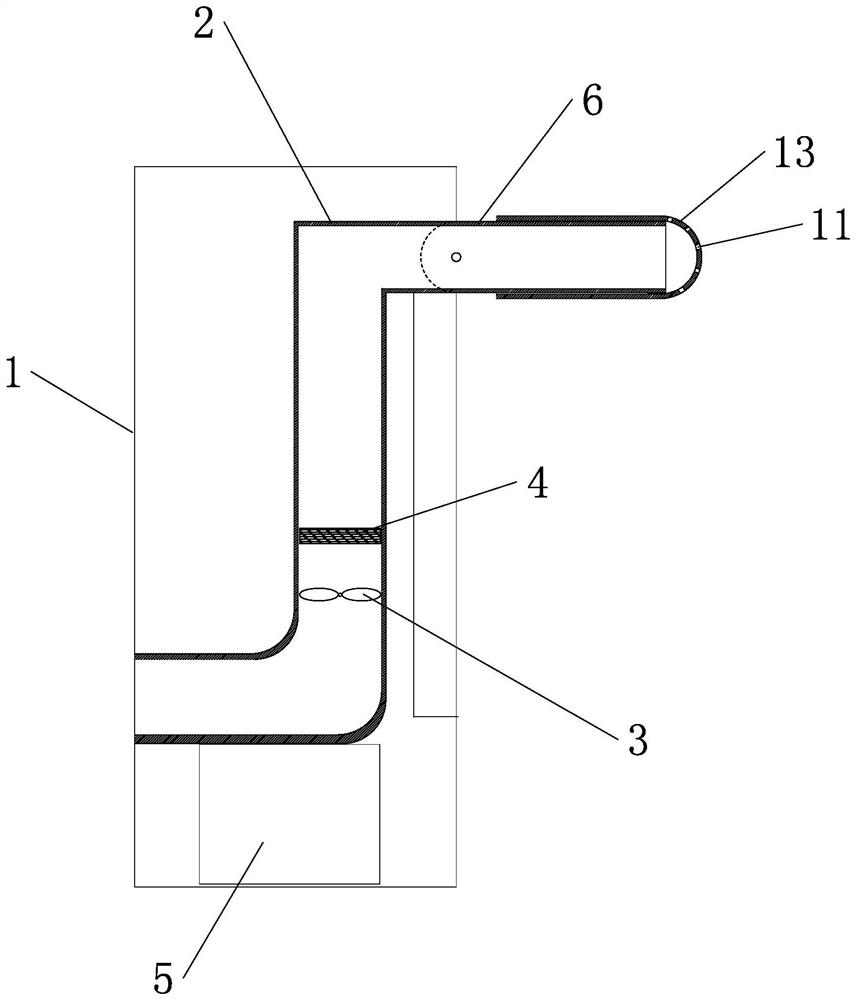

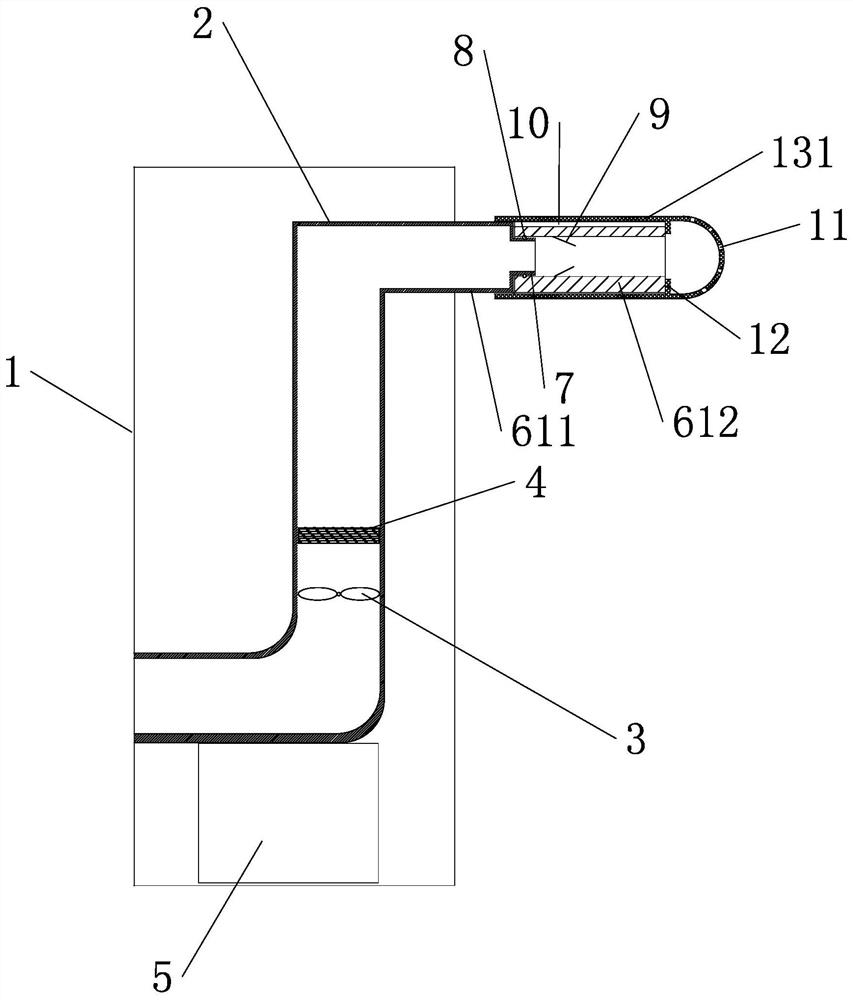

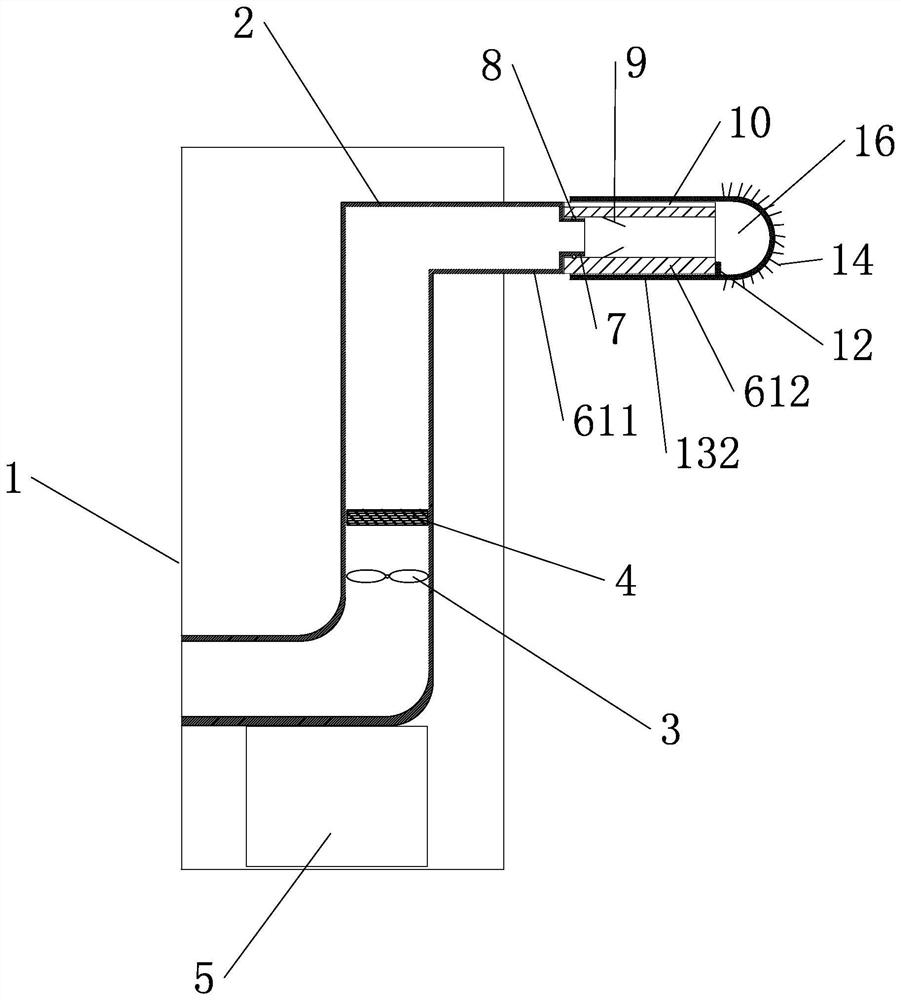

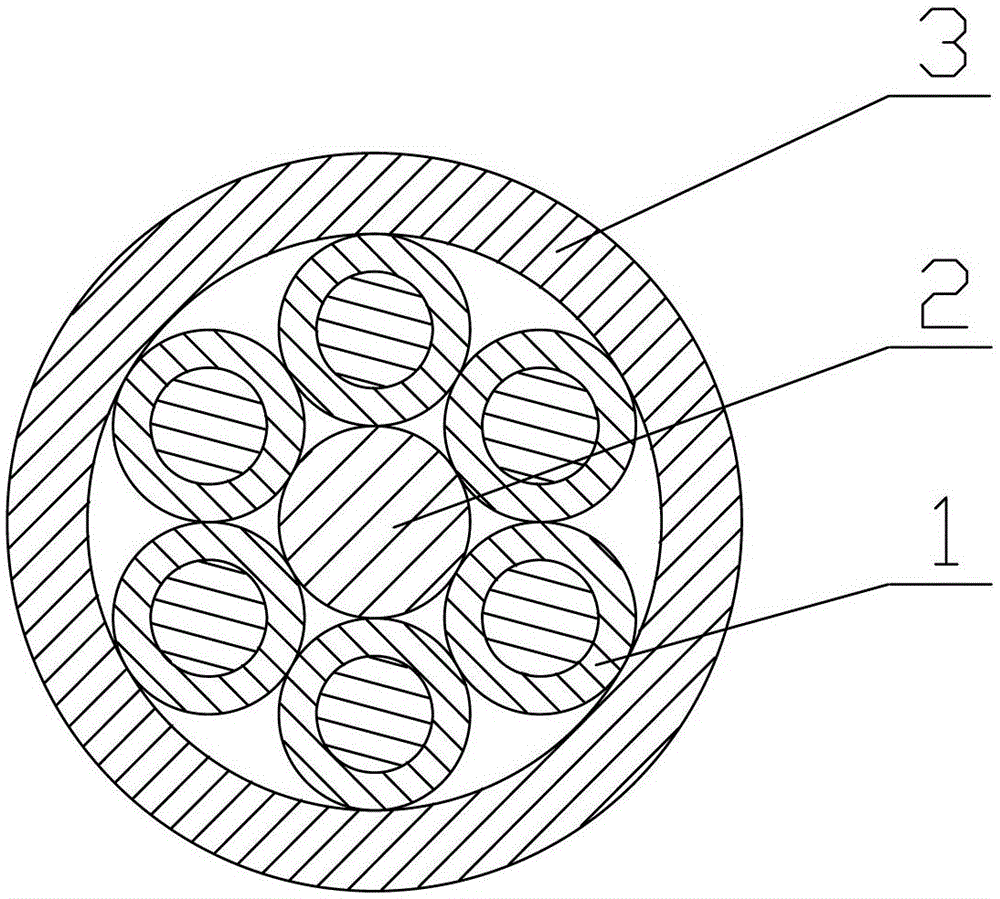

Infusion catheter tip for biologics with reinforced external balloon valve

ActiveCN106029154AUnimpeded flowPrevent flocculationBalloon catheterMedical devicesInfusion catheterVALVE PORT

A system for moving particles suspended in a first fluid, and for infusing them into the stream of a second fluid, includes a catheter with a multi-lumen distal separator. The separator is formed with a plurality of parallel lumens, wherein each lumen has a predetermined diameter to reduce particle flocculation. An inflatable balloon, affixed to the outside of the catheter, can be provided to regulate flow of the second fluid and thereby facilitate entry of the particles into the stream of the second fluid. A reinforcing member is employed to strengthen the catheter wall under the inflatable balloon. With this arrangement, the catheter does not kink or collapse due to the pressure exerted on the catheter wall when the balloon is inflated. In one embodiment, the reinforcing member includes an annular shaped ring. In another embodiment, the separator is positioned under the balloon and acts as the reinforcing member.

Owner:COOK REGENTEC

A kind of inclined-hole tray for distillation

ActiveCN103816692BImprove contact efficiencyShorten the timeDistillation separationGas phaseDistillation

The invention provides an inclined hole tray for distillation. The inclined hole tray comprises a liquid holding plate, wherein an overflow weir is arranged on the liquid holding plate; a plurality of tongue holes are formed in the liquid holding plate; a tongue plate is respectively arranged on one side of each tongue hole; the tongue plate on one side of each tongue hole comprises an inclined tongue plate and a horizontal tongue plate; one end of each inclined tongue plate is connected with the liquid holding plate; the other side of each inclined tongue plate is connected with each horizontal tongue plate; each horizontal tongue plate is in parallel with the liquid holding plate; the included angle alpha of each inclined tongue plate and the liquid holding plate is 15 to 30 degrees; the tongue holes are formed in the liquid holding plate in rows, each row is in parallel with the length direction of the overflow weir respectively; the row number of the tongue holes in the liquid holding plate is an integral multiple of 3. The inclined hole tray can effectively improve the contact efficiency of gas phase and liquid phase, reduces the time when the gas phase and the liquid phase are balanced, and enables the airflow resistance to keep in a relatively lower level.

Owner:JIGANG INT ENG & TECH CO LTD

Fire coal water heater

The invention relates to a fire coal water heater which is characterized in that a front sealed water tank and a rear sealed water tank are respectively arranged at the front side and the rear side below the middle part of an interlayer water tank body. Two water tanks are communicated via a plurality of fire bar tubes; one end of an overflow tube arranged below the fire bar tubes is communicated with the front water tank, and the other end thereof passes through the rear water tank to be communicated with the bottom of the interlayer water tank via a water conduit; the rear water tank is provided with a discharging tube; and the discharging tube and the water conduit are respectively provided with a binding head; the whole body composed of the rear water tank, the front water tank and a plurality of fire bar tubes can move out of or be matched into the furnace body; a hearth top is in the horizontal state; the hearth top is internally provided with a plurality of heat-absorbing tubes; the interlayer water tank on the upper half part of the rear side of the box body is the heat-absorbing box three surfaces of which are sealed and the top of which is opened; and a water inlet is arranged above a water-stop sheet behind the box body. The fire coal water heater has the advantages of saving energy to causing heat efficiency to reach 96%, having strong adaptability to be used by fire coal or firewood, and being convenient for cleaning and maintenance to be worth popularizing and using.

Owner:周志洋

Ear canal drying and cleaning device

ActiveCN112998948AUnimpeded flowImprove drying effectEar treatmentDomestic applicationsEngineeringHot blast

The invention provides an ear canal drying and cleaning device, and belongs to the technical field of articles of daily use. The problem that water enters an existing ear canal is solved. The air canal drying and cleaning device comprises a machine shell, an inner air pipe, an outer air pipe and a flexible sleeve, the inner air pipe and the outer air pipe are in butt joint and communicate with each other to form an air channel used for air circulation, a fan used for generating airflow in the air channel and a heating device used for heating the airflow in the air channel are arranged in the machine shell, a battery is further arranged in the machine shell, and a charging port is further formed in the machine shell. The flexible sleeve is detachably arranged on the outer air pipe in a sleeving mode, and air holes are formed in the flexible sleeve. The ear canal drying and cleaning device has the advantages that the ear canal can be dried and cleaned by hot air, the drying effect is good, and safety, convenience and comfort are achieved.

Owner:姚仁才

A kind of preparation method of high-strength mgb2 wire rod

ActiveCN103310914BPlasticGuaranteed plasticityCable/conductor manufacturePhase formationArgon atmosphere

The invention discloses a high-strength MgB2 wire manufacturing method. The method includes: 1, manufacturing primary composite wires; 2 assembling secondary composite tubes; 3, drawing the secondary composite tubes for three times at 20%-25% pass processing rate, and then drawing at 10%-15% pass processing rate to obtain wires with required dimensions; 4, performing phase-formation heat treatment on the wires under the protection of argon atmosphere to obtain high-strength MgB2 wires with strength between 220MPa-280MPa. According to the method, CuAg alloy bars are used as reinforcement cores, manufactured multi-core super-conducting wires are transformed evenly, and inner parts are combined tightly, so that the manufactured multi-core super-conducting wires have good plasticity. According to the method, flow of powder in the drawing process is smooth. The method is particularly suitable for processing of MgB two-kilometer long wires and can meet requirements for practical application of super-conducting magnets, especially super-conducting nuclear magnetic resonance spectrometer and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Sound attenuation devices for air drying equipment for compressed air supply systems

ActiveCN103874611BPrevent freezingUnimpeded flowDispersed particle separationPipe elementsMufflerWaste management

A sound suppressor device for an air drying unit of a compressed-air supply system having a sound suppressor housing on which is arranged an inlet opening for the supply of condensate-laden compressed air to be discharged from the air drying unit and at least one outlet opening for the discharge of the condensate-laden compressed air to the outside, wherein the inlet opening issues into at least one pre-chamber of the sound suppressor housing, which pre-chamber issues into post-chambers which are connected in parallel and which are arranged around a heating rod arranged centrally in the sound suppressor housing.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

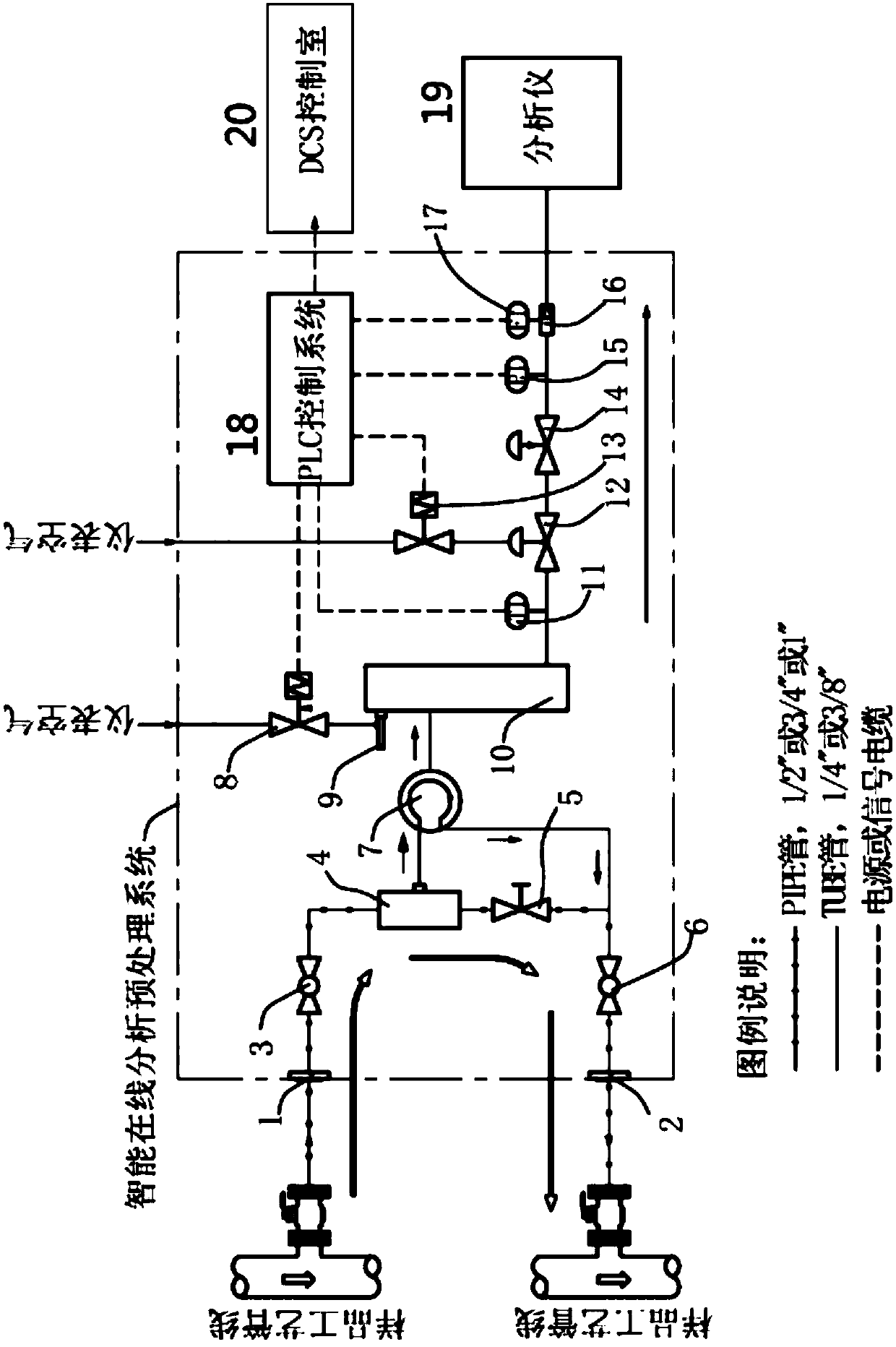

Intelligent online analysis pretreatment system

The invention discloses an intelligent online analysis pretreatment system, which comprises a sample large reflux inlet and a sample large reflux outlet, wherein a sample inlet cut-off valve and an online self-cleaning bypass filter are arranged downstream of the sample large reflux inlet; the online self-cleaning bypass filter comprises a first inlet, a first outlet and a bypass outlet; an onlinerotary centrifugal filter is arranged downstream of the bypass outlet; an air cooler is arranged downstream of the online rotary centrifugal filter; and the intelligent online analysis pretreatment system further comprises a PLC control system. The intelligent online analysis pretreatment system has the following advantages: a large reflux structure is adopted, sample flow is unimpeded, samplingis rapid and timely, the automatic filter cleaning function can be realized, maintenance is free, real-time collection and intelligent control of temperature, pressure and flow parameters of online analyzed samples can be preformed, and the intelligent degree is high.

Owner:天华化工机械及自动化研究设计院有限公司苏州研究所

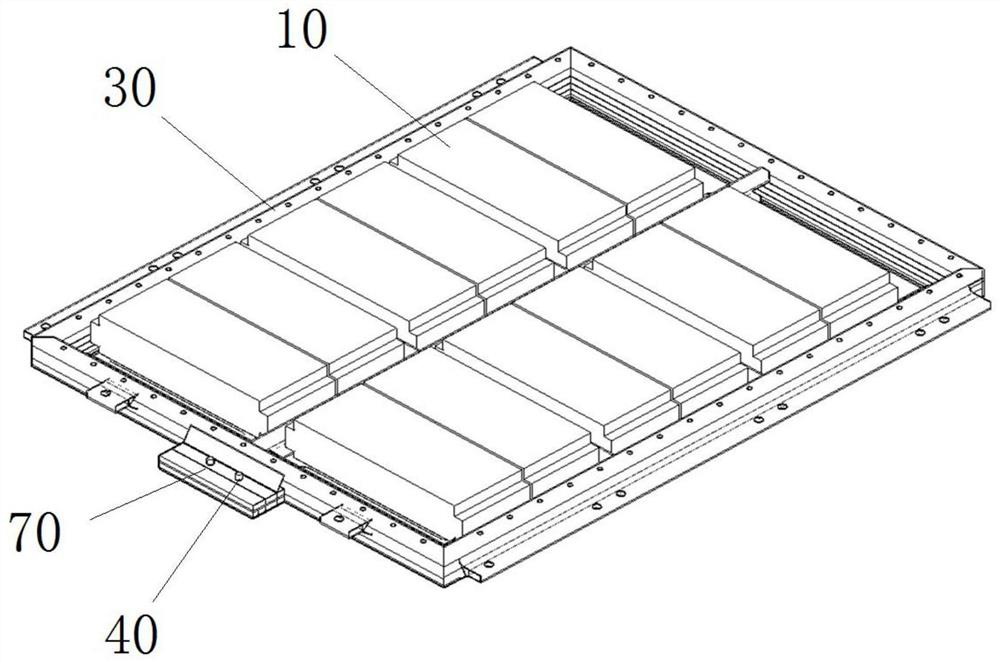

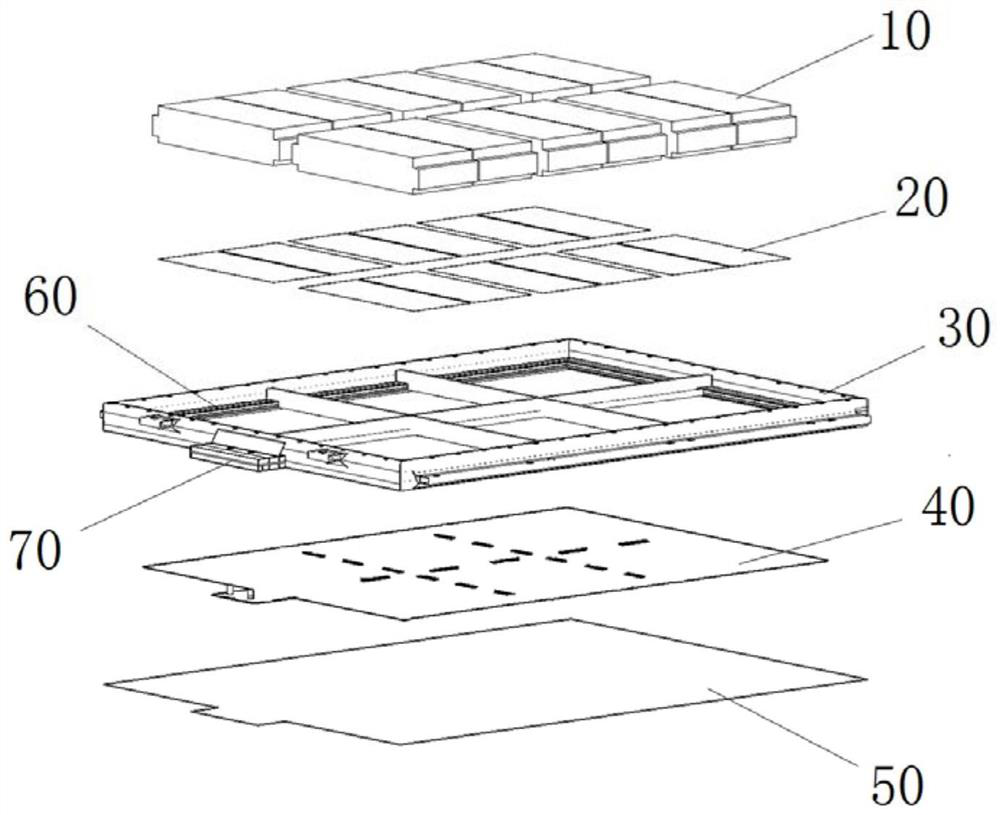

Cases for power batteries, power battery packs

ActiveCN111525213BEasy to manufactureLow costSecondary cellsCell component detailsPower batteryCoolant flow

The invention provides a casing and a power battery pack for a power battery. The casing includes a support frame and a heat conduction plate. The support frame includes a plurality of side plates, and the heat conduction plate is installed on the support frame. Enclose and form a cavity for accommodating the power battery module with the heat conducting plate; The concave part cooperates to form a cooling liquid flow channel, wherein the upper heat conducting plate and / or the lower heat conducting plate are provided with a liquid inlet for allowing the cooling liquid to flow into the flow channel and a liquid outlet for allowing the cooling liquid to flow out of the flow channel. The invention adopts the liquid cooling plate to cool the battery modules, does not need to arrange pipelines for connection, and has the advantages of high integration degree and large space utilization rate.

Owner:DONGFENG MOTOR CO LTD

Wastewater recycling device of steam heating equipment and steam heating equipment

PendingCN114754346ACompact structureSimple structureSemi-permeable membranesSteam generation heating methodsWater useThermodynamics

The invention relates to a waste water recycling device of steam heating equipment and the steam heating equipment, and the waste water recycling device of the steam heating equipment comprises a shell; the waterproof breathable film is arranged in the shell and divides the shell into a purified water cavity and a waste water cavity, and the purified water cavity is suitable for being connected with a water inlet of a water using device; the heating assembly is suitable for heating the wastewater cavity; the water inlet pipe comprises a heat exchange pipe section capable of cooling the water purification cavity and a water outlet end extending into the waste water cavity, and the water inlet pipe is suitable for being connected with a water outlet of a water using device. Therefore, the wastewater recycling device disclosed by the invention can complete operations of storing and heating the wastewater, condensing the water vapor and storing and purifying the water in one shell, is more compact in structure and small in occupied space, and can be used in steam heating equipment such as a steaming oven and the like. In addition, the water inlet pipe can cool water vapor in the water purification cavity while supplying water to the wastewater cavity, and condensation of the water vapor in the water purification cavity is accelerated.

Owner:GREE ELECTRIC APPLIANCES INC

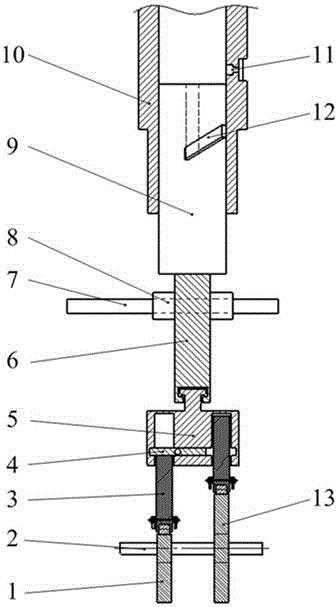

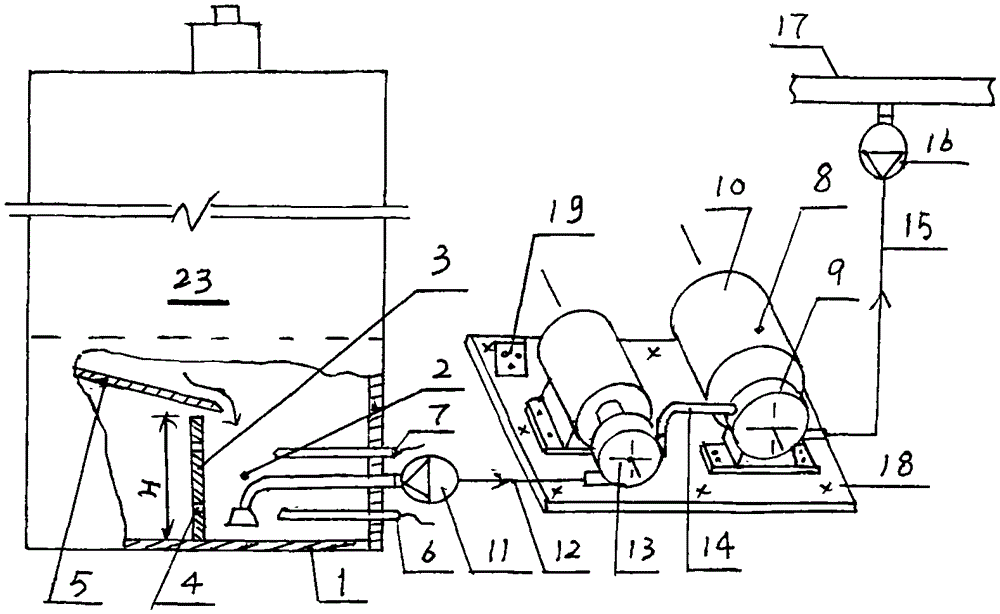

A pre-lubrication device for starting an engine

ActiveCN103993928BUnimpeded flowEasy to collectMachines/enginesLubrication temperature controlCheck valveLubrication

The invention relates to a pre-lubricating device for starting an engine and belongs to the field of auxiliary devices for automobiles. The pre-lubricating device for starting the engine solves the problem of cold start of an automobile engine and particularly solves the problem of dry friction in the low-temperature cold starting process. A hot oil area groove (2) is formed in an oil pan (1), an electric heater is installed in the oil pan (1), oil from an oil outlet of the oil pan (1) enters a main oil way (17) of an engine (23) sequentially through a first check valve (11), an oil outlet pipe (12), a pre-lubricating engine oil pump (13), a communicating pipe (14), an engine oil filter (8), an oil inlet pipe (15) and a second check valve (16), and then a pre-lubricating engine oil delivery system is formed. Meanwhile, a corresponding device is arranged, the heating device and a base plate (18) are assembled into a whole, and an electronic control panel (19) is installed on the base plate (18). The pre-lubricating device for starting the engine can guarantee pre-lubrication in the starting process of the automobile engine, dry friction is overcome, and the pre-lubricating device for starting the engine is particularly suitable for pre-lubricating in the cold starting process of the automobile engine at low temperature and starting the engine (23) and convenient to selectively use. The pre-lubricating device for starting the engine is capable of saving energy, environmentally friendly, convenient to manufacture in a standardized mode and operate, and easy to install, adjust and maintain.

Owner:BEIJING GAOXIN GREAT FILTER CO LTD

Slag cooler

ActiveCN101876446ABig spaceUnimpeded flowFluidized bed combustionApparatus for fluidised bed combustionPower stationSlag

The invention relates to a slag cooler for cooling slag of a circulating fluidized bed boiler of a power plant, mainly designed to solve the problems of poor cooling effect and easy burnout of the traditional slag cooler. The slag cooler comprises an inner cylinder wall, an outer cylinder wall, a cooling water interlayer, a slag guide sheet, a slag inlet, a slag outlet end, a track, a track supporting wheel, a large sprocket, a water inlet pump and a water pumping pump, wherein a partition wall is arranged between the inner cylinder wall and the outer cylinder wall, a small support upright column is respectively arranged between the partition wall and the inner cylinder wall as well as between the partition wall and the outer cylinder wall, an inner sealing head and an outer sealing head are also arranged between the partition wall and the inner cylinder wall as well as between the partition wall and the outer cylinder wall, a pipeline is arranged on the water inlet pump and is connected with an inner ring of a water separator, the inner ring is provided with a water outlet and is connected with an outer ring in a sliding and sealing mode, a water outlet pipe is arranged on the outer ring and is connected with the inner sealing head, a pipeline is arranged on the water pumping pump and is connected with an inner ring of a water collector, a water inlet is arranged on the inner ring of the water collector, the external of the inner ring of the water collector is connected with the outer ring of the water collector in the sliding and sealing mode, and a water inlet pipe is arranged on the outer ring and is connected with the outer sealing head. The invention has the advantages of good cooling effect and long service life.

Owner:LIAONING BEIFANG ELECTRIC MACHINERY COMPLETE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com