A kind of inclined-hole tray for distillation

A technology of inclined-hole trays and tongue-holes, which is applied in the field of distillation equipment, can solve the problems of limited upward airflow guidance, difficult operation, and large airflow resistance, and achieve the effects of improving contact efficiency, low operating difficulty, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

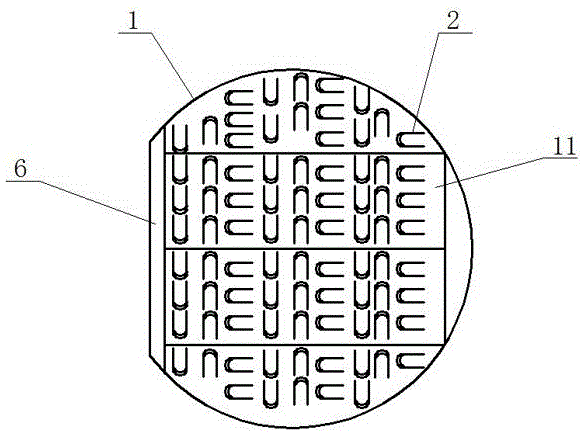

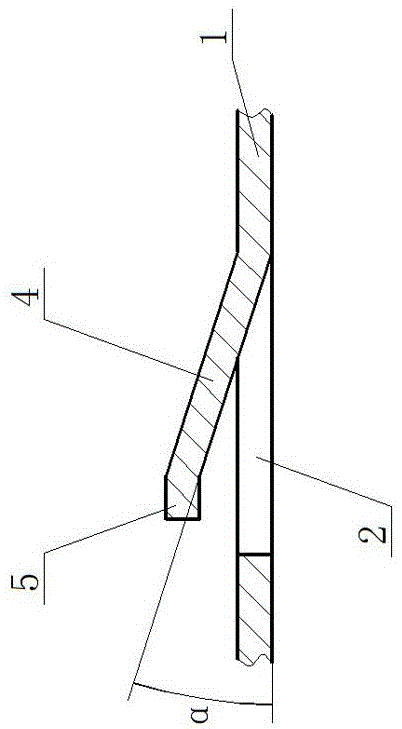

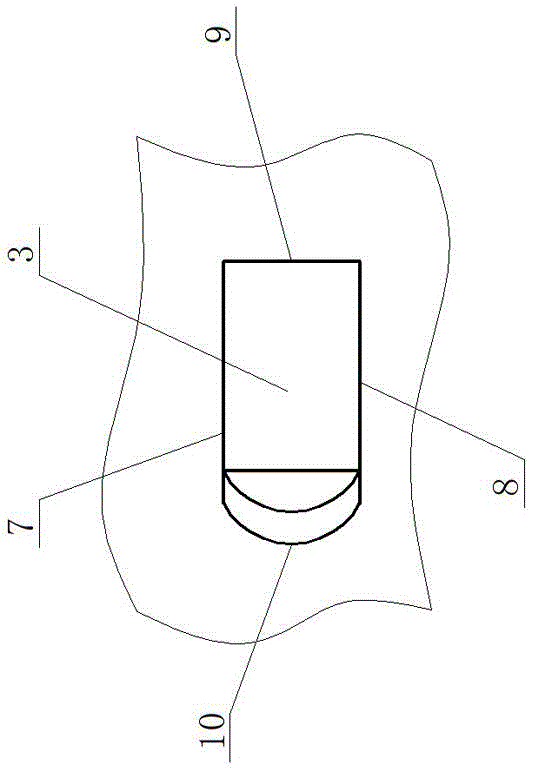

[0011] The oblique hole tray for distillation according to the present invention comprises a liquid receiving tray 1, an overflow weir 6 is arranged on the liquid receiving tray 1, and a plurality of tongue holes 2 are provided on the liquid receiving tray 1, and each tongue hole 2 has one side A tongue plate 3 is provided. The tongue plate 3 on one side of the tongue hole 2 includes an inclined tongue plate 4 and a horizontal tongue plate 5. One end of the inclined tongue plate 4 is connected to the receiving plate 1, and the other side of the inclined tongue plate 4 is connected to the horizontal tongue plate 5. , The horizontal tongue plate 5 is parallel to the receiving plate 1, the angle α between the inclined tongue plate 4 and the receiving plate 1 is 15°-30°, and each tongue hole 2 is arranged in multiple rows on the receiving plate 1. , Each row is parallel to the length of the overflow weir 6, the number of rows of tongue holes on the receiving plate is an integer mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com