Method of manufacturing injection needle and injection needle

A manufacturing method and technology of injection needles, which are applied in the manufacture of injection needles and the field of injection needles, can solve the problems of poor liquid flow, cumbersome manufacturing process, increased manufacturing time and cost, and achieve the effect of simplifying the manufacturing process and ensuring smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

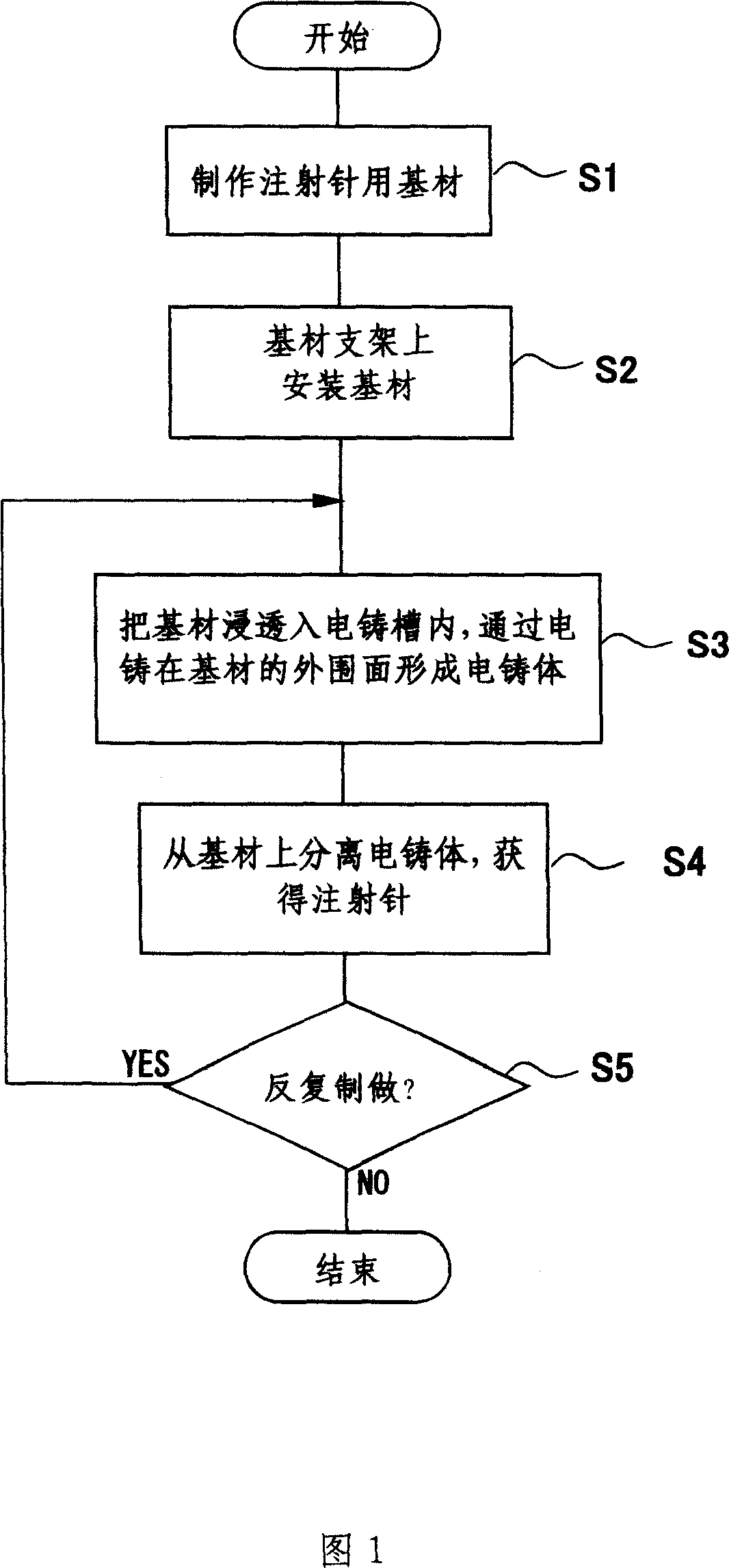

[0035] Fig. 1 shows a flowchart of the manufacturing process of the injection needle manufacturing method.

[0036] First, a base material for injection needles is produced (S1).

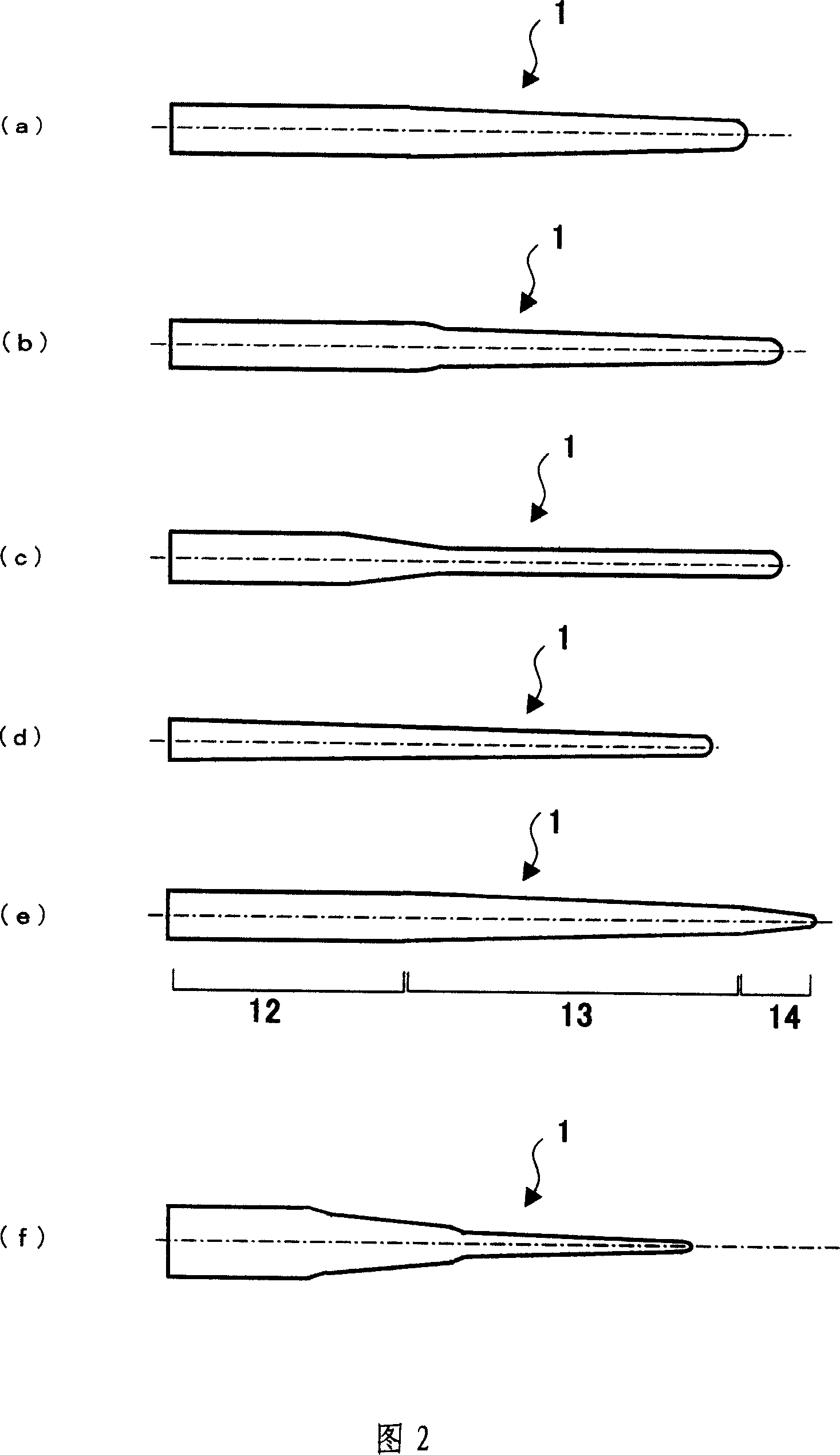

[0037] The manufacturing process of this base material is to manufacture the base material 1 for injection needles used as a molding die for the shape of the inner wall of the injection needle. The material is conductive material such as stainless steel (SUS) or non-conductive material (materials such as conductively treated plastic and nylon), and the outer surface is polished to a mirror finish. The base material 1 for injection needles in which at least a part of the outer part has a tapered shape is shown in Fig. 2 (a) to (e). Of course, it is by no means limited to this example, and it is also possible to have a rod-shaped shape without any taper. . Moreover, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com